Radial shaft seal with dust exclusion and hydrodynamic sealing feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

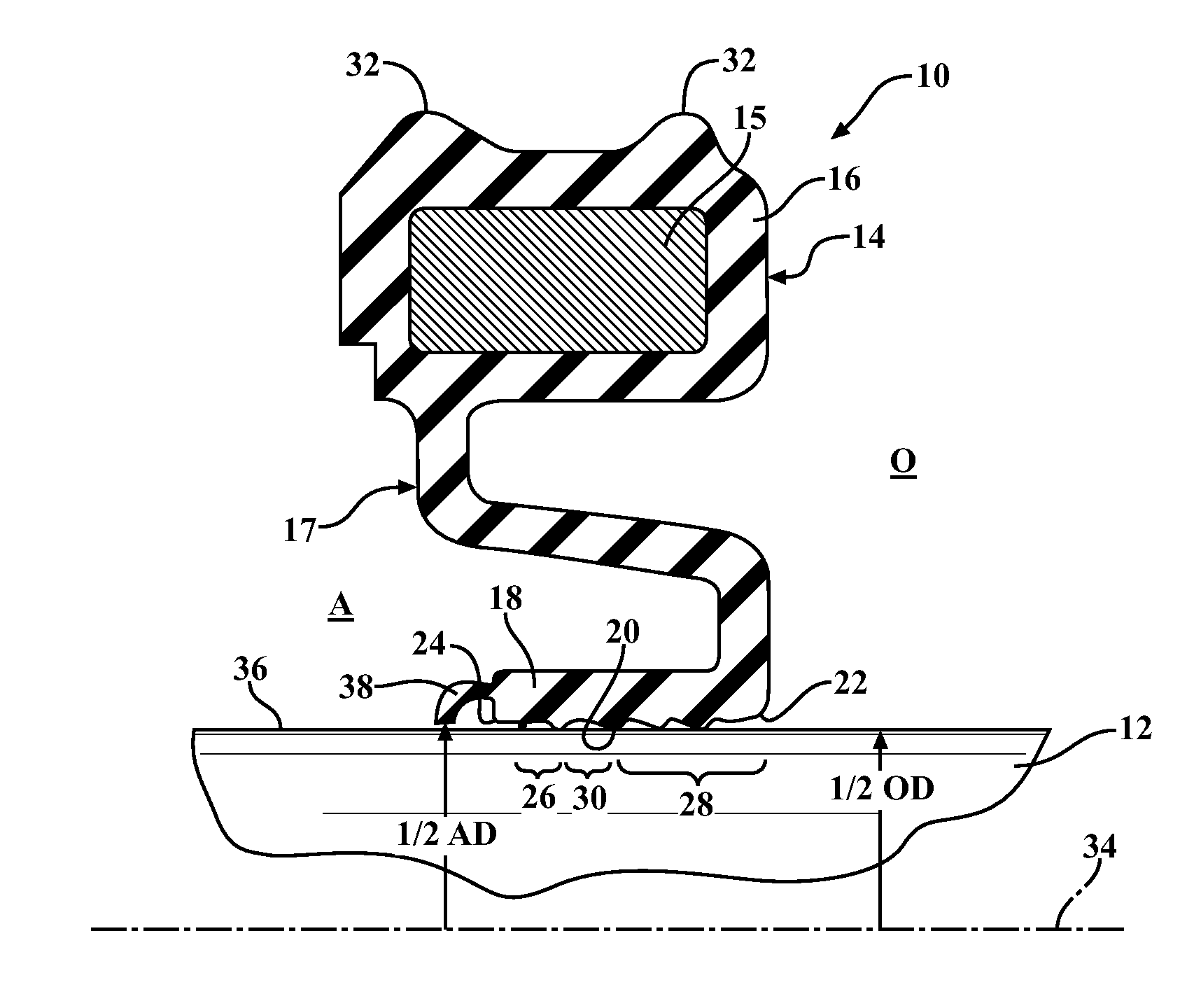

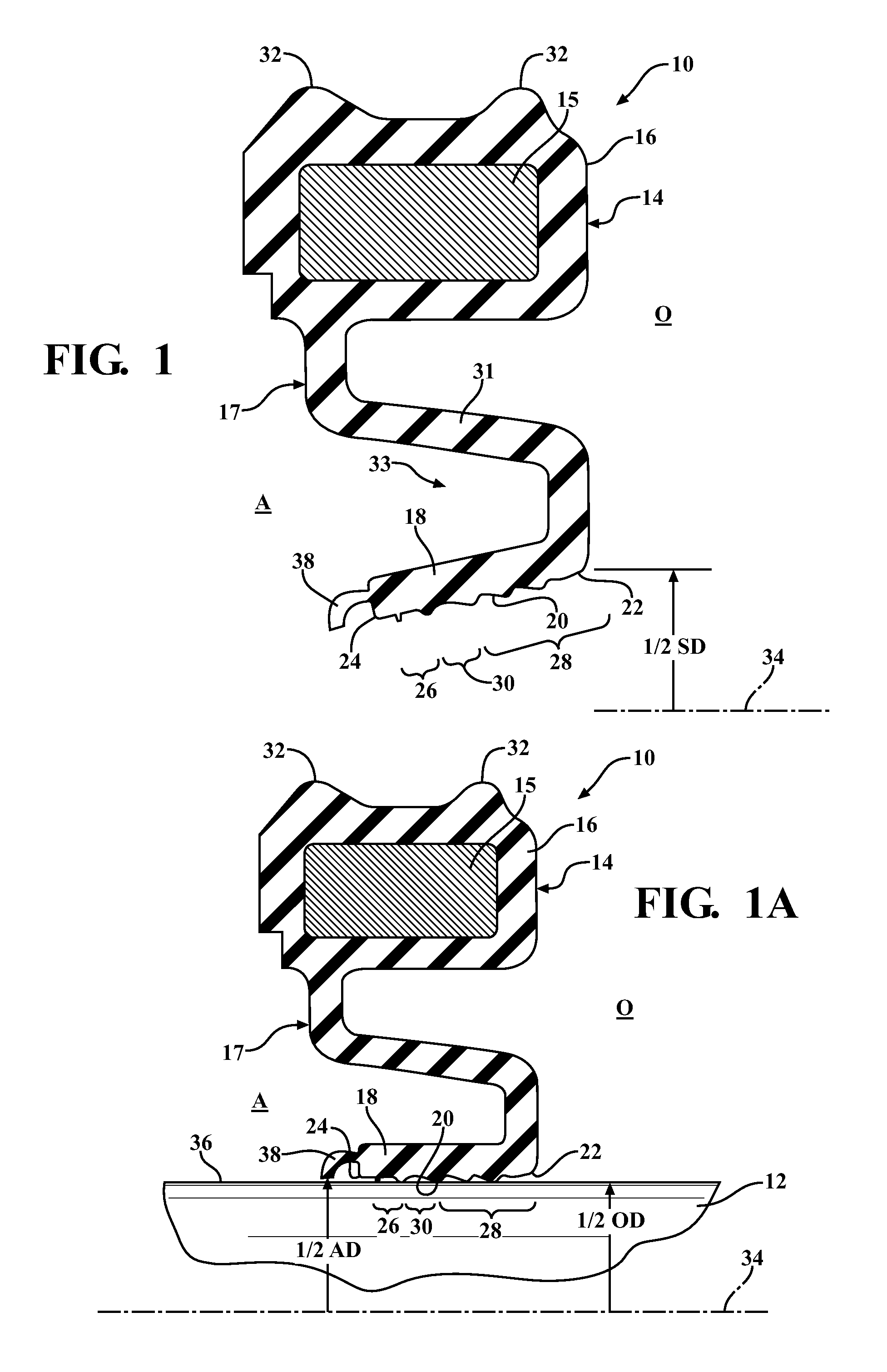

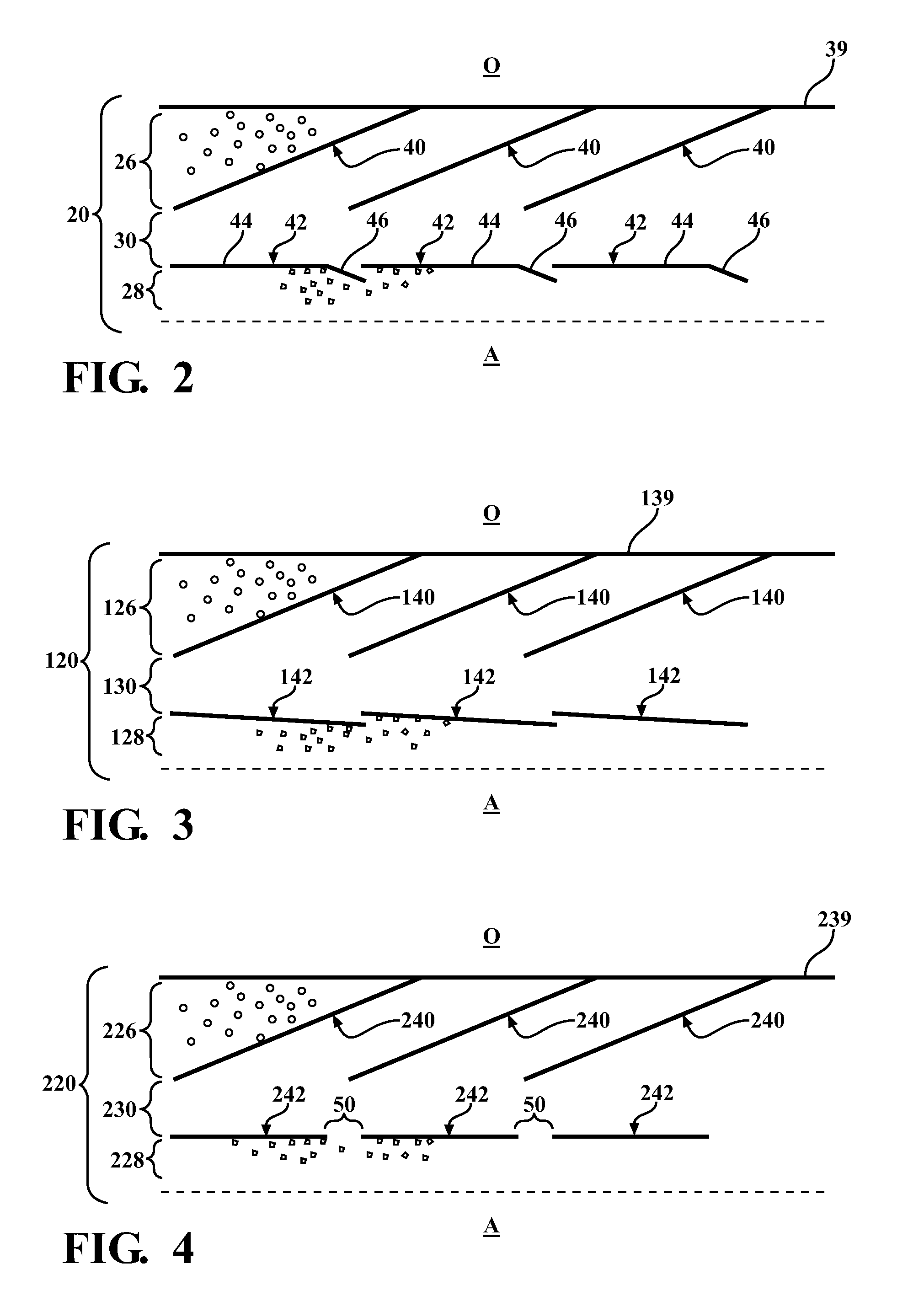

[0018]Referring in more detail to the drawings, FIGS. 1 and 1A illustrate a radial shaft seal, referred to hereafter as seal 10, constructed in accordance with one aspect of the invention, wherein the seal is suitable for use in a crankcase application, by way of example and without limitation, for sealing about a rotatable shaft 12 in a radial shaft seal assembly. The seal 10 has an oil-side O and an axially opposite air-side A, in relation to the orientation of the seal 10 when installed, with the oil-side O facing the interior of the application being sealed and the air-side A facing the outside environment of the application being sealed. The seal 10 includes a mounting portion, such as an outer case, also referred to as collar 14, provided as a metal or polymeric annulus or ring structure 15 with an elastomeric seal material 16 attached thereto. The elastomeric material 16 forms a seal body 17 and extends radially inwardly to provide a seal lip 18. The seal lip 18 has an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com