Fluidized bed furnace and waste treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

Outline of Embodiment

[0072]The outline of the above embodiment is as follows.

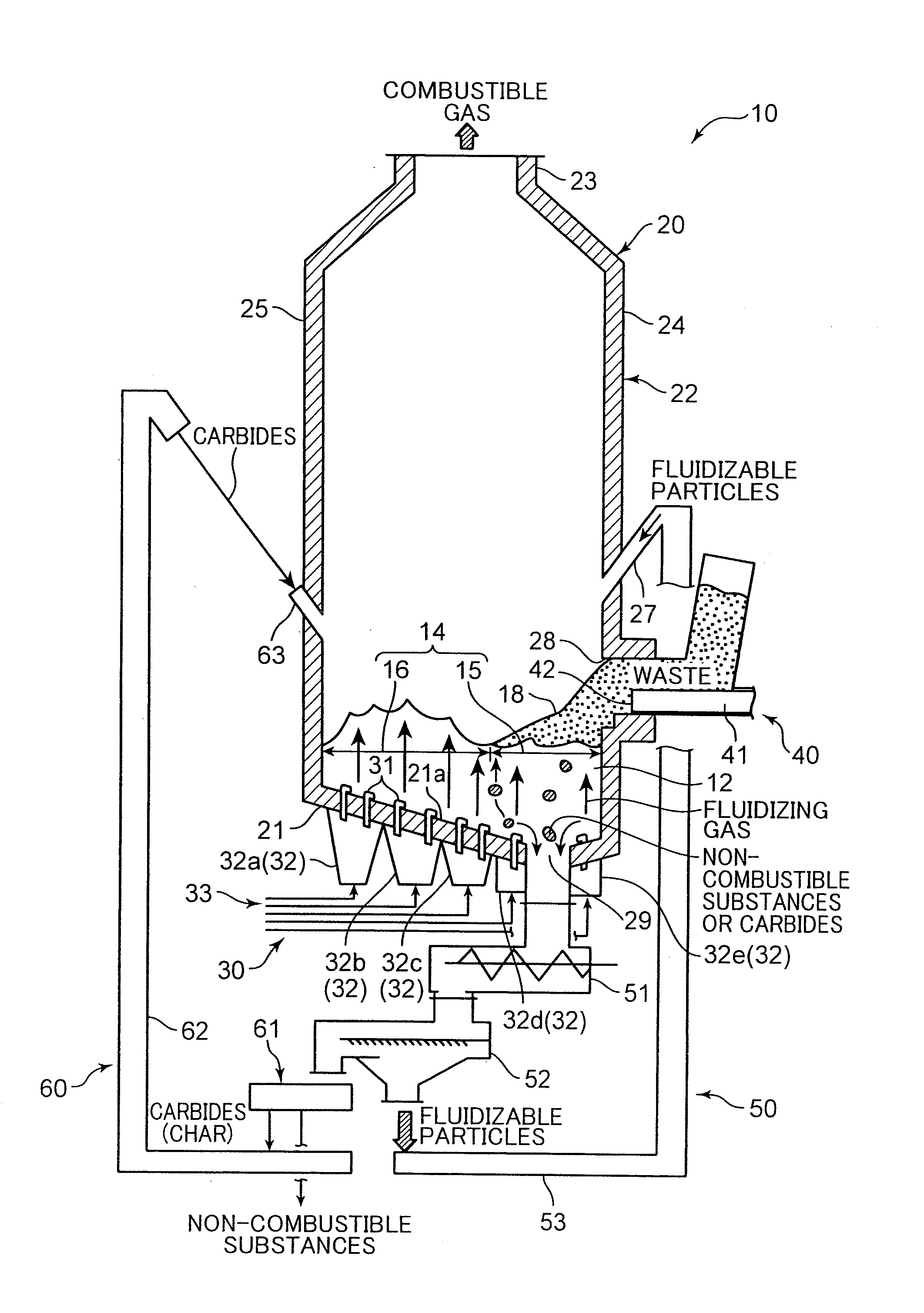

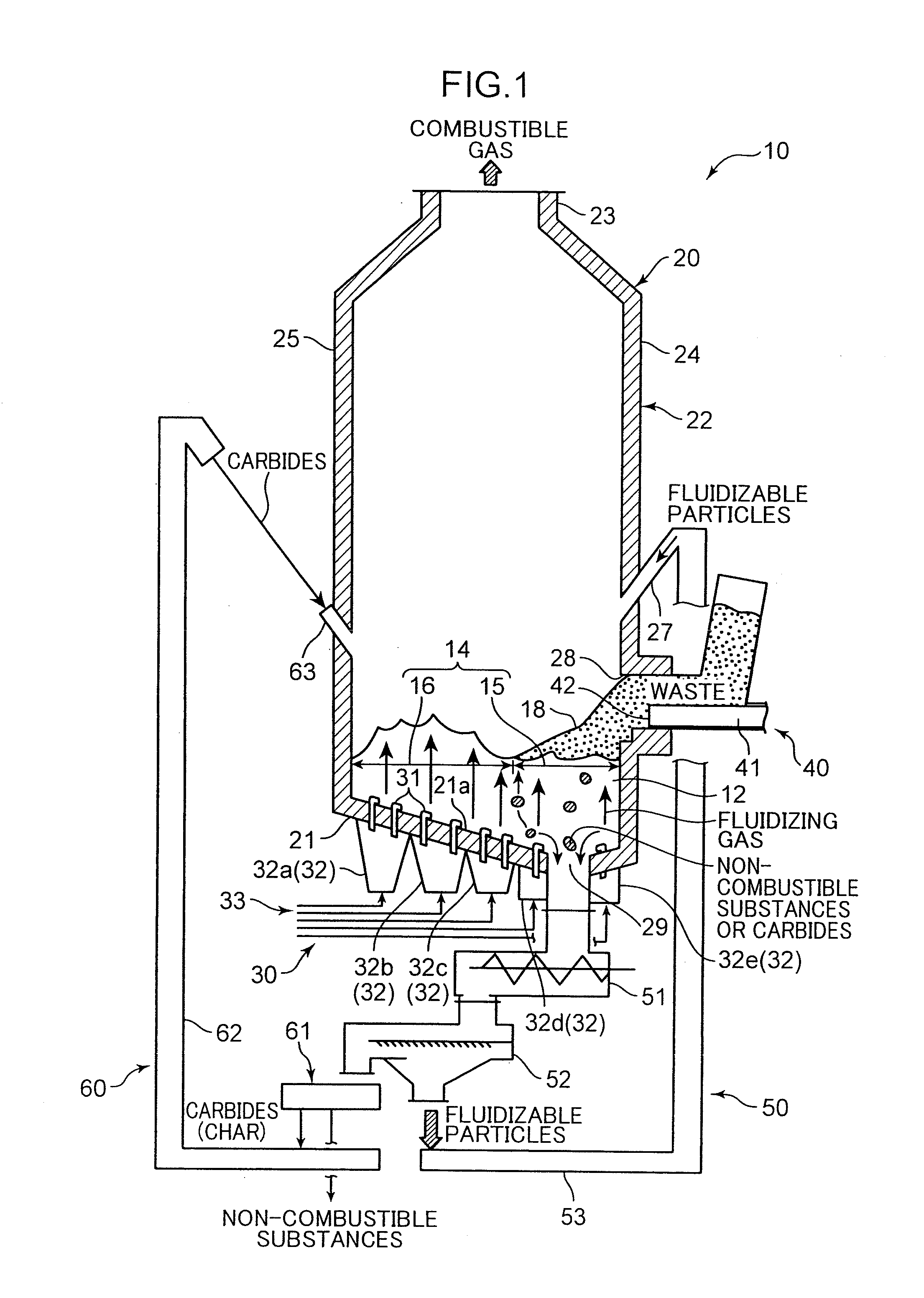

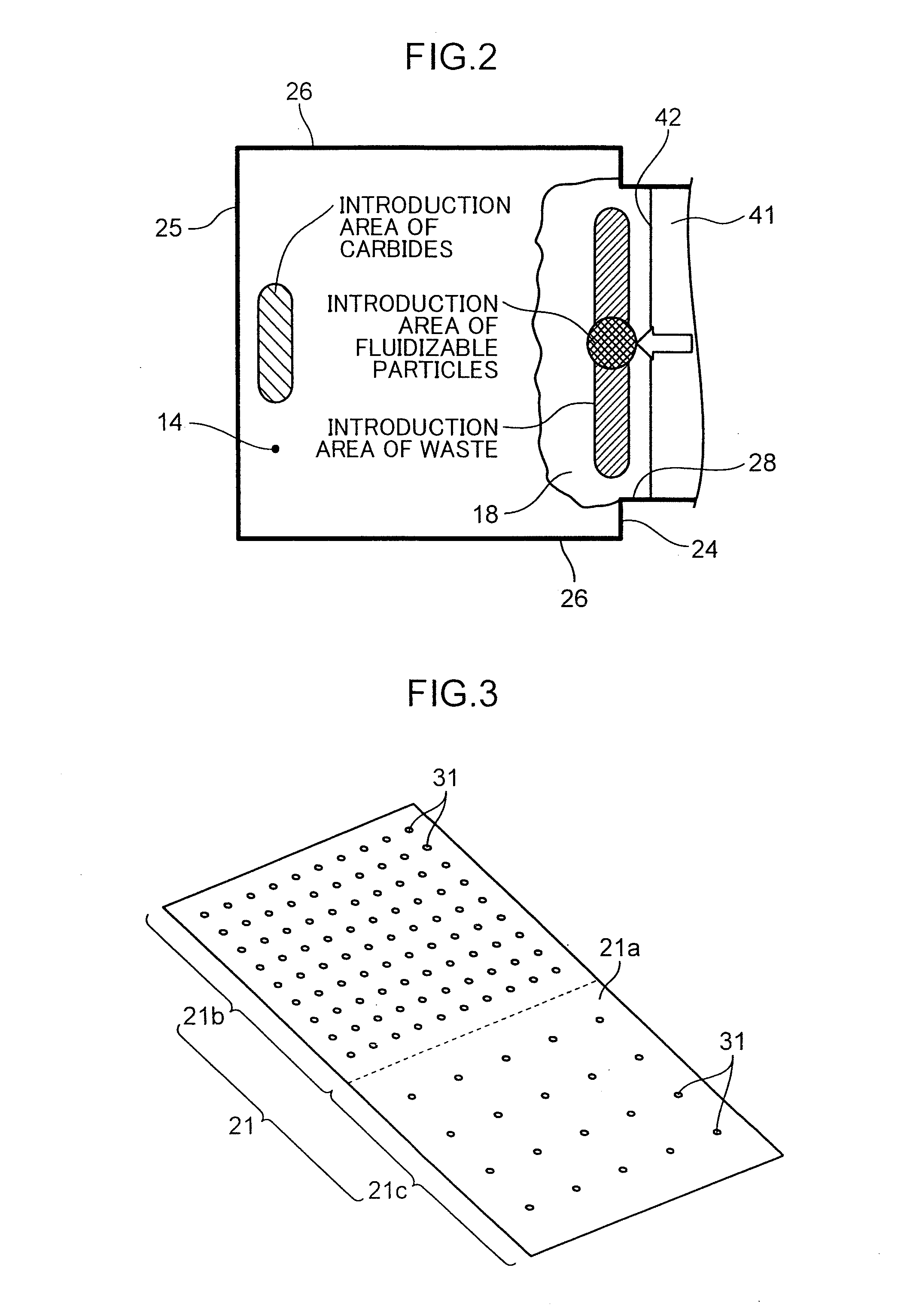

[0073]The fluidized bed furnace according to the above embodiment is designed to heat waste to extract a combustible gas from the waste. The fluidized bed furnace comprises: fluidizable particles making up a fluidized bed to heat the waste; a furnace body having a bottom wall supporting the fluidizable particles from therebelow, and a sidewall standing upwardly from the bottom wall, wherein the bottom wall has a mixture discharge port provided at a position offset from a center position of the bottom wall in a specific direction to discharge non-combustible substances in the waste and carbides produced by heating of the waste, together with a part of the fluidizable particles, and an upper surface of the bottom wall is inclined to become lower toward the mixture discharge port so as to cause the fluidizable particles to fall on the upper surface of the bottom wall toward the mixture discharge port; a gas su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com