Motor stator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

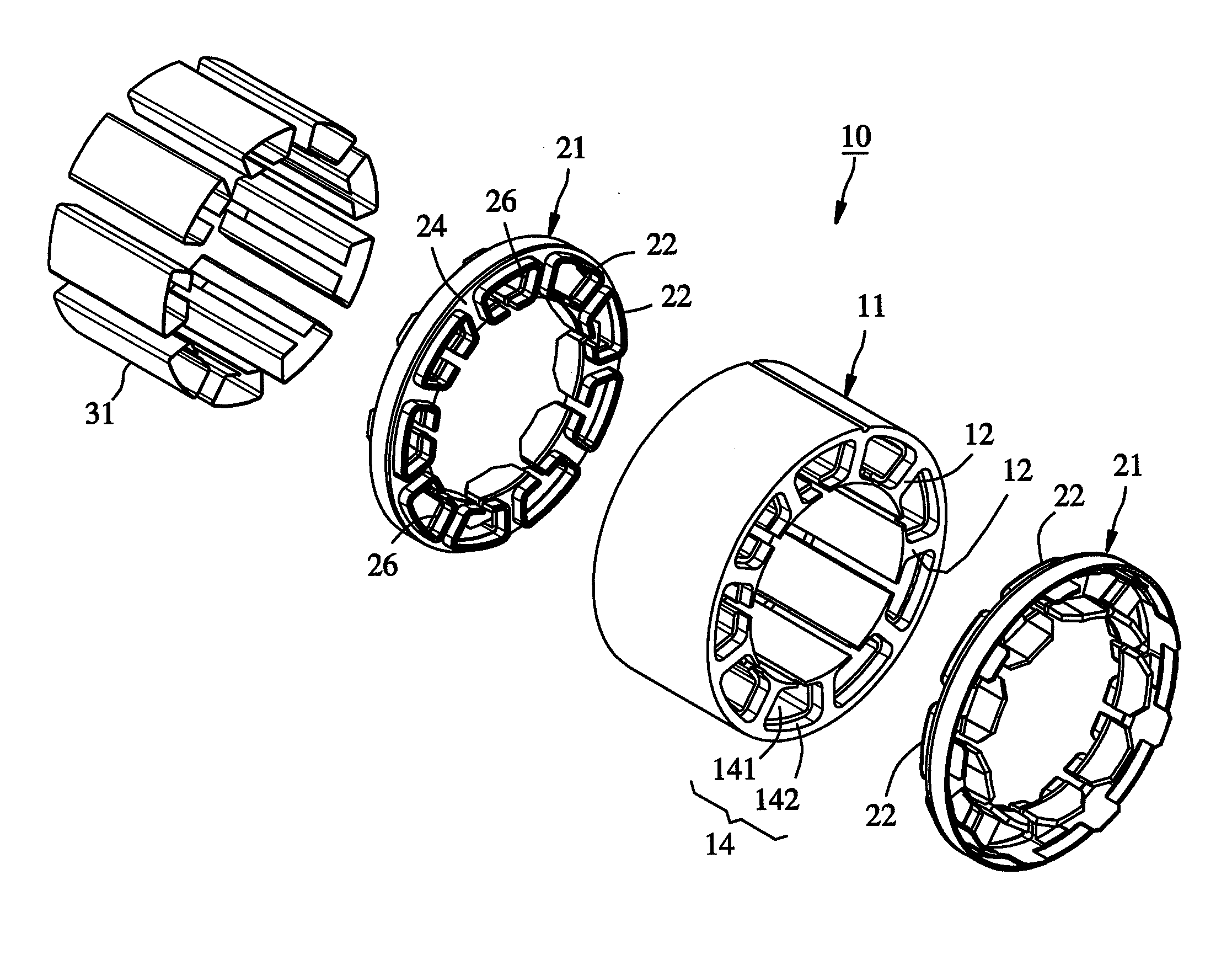

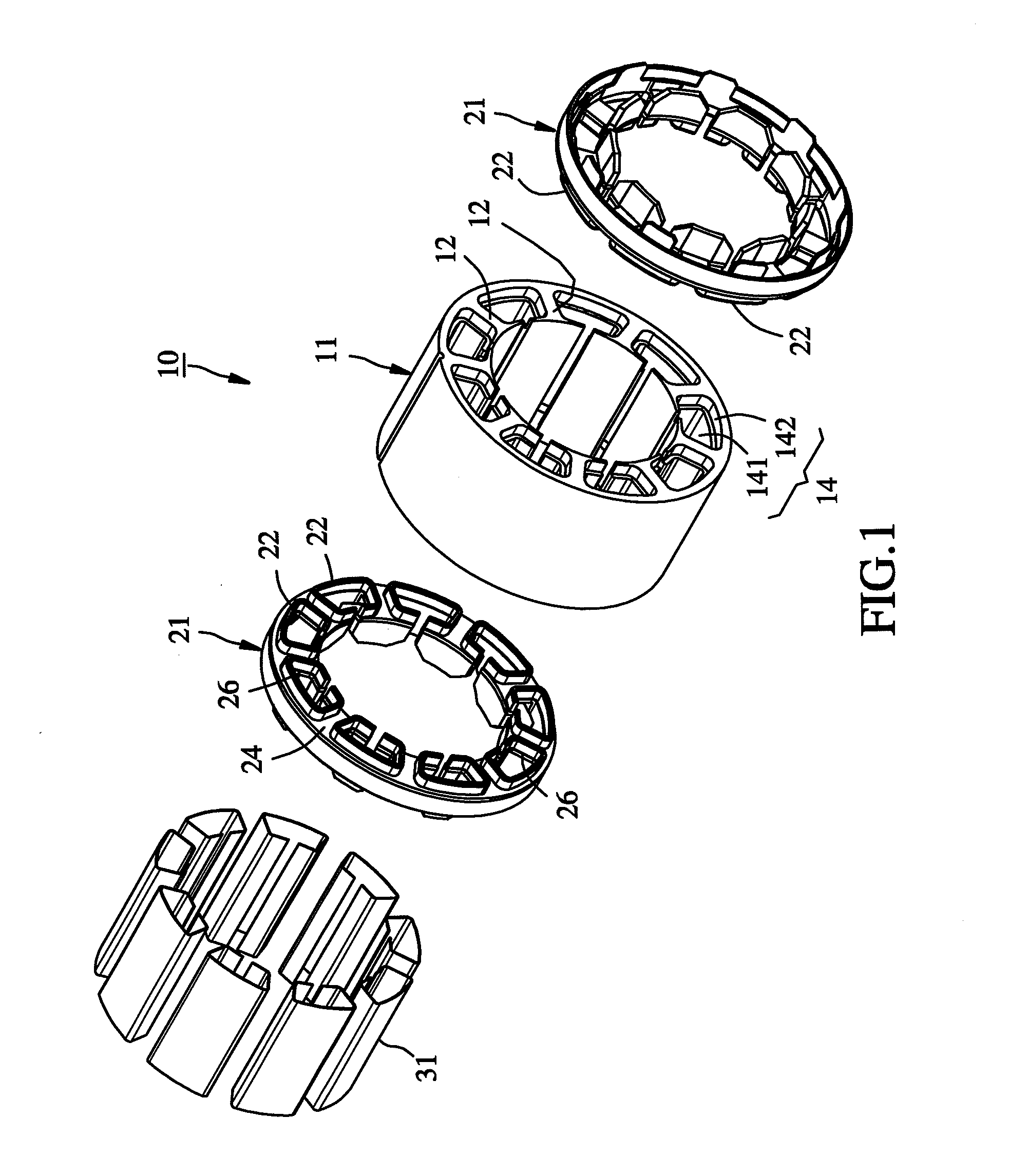

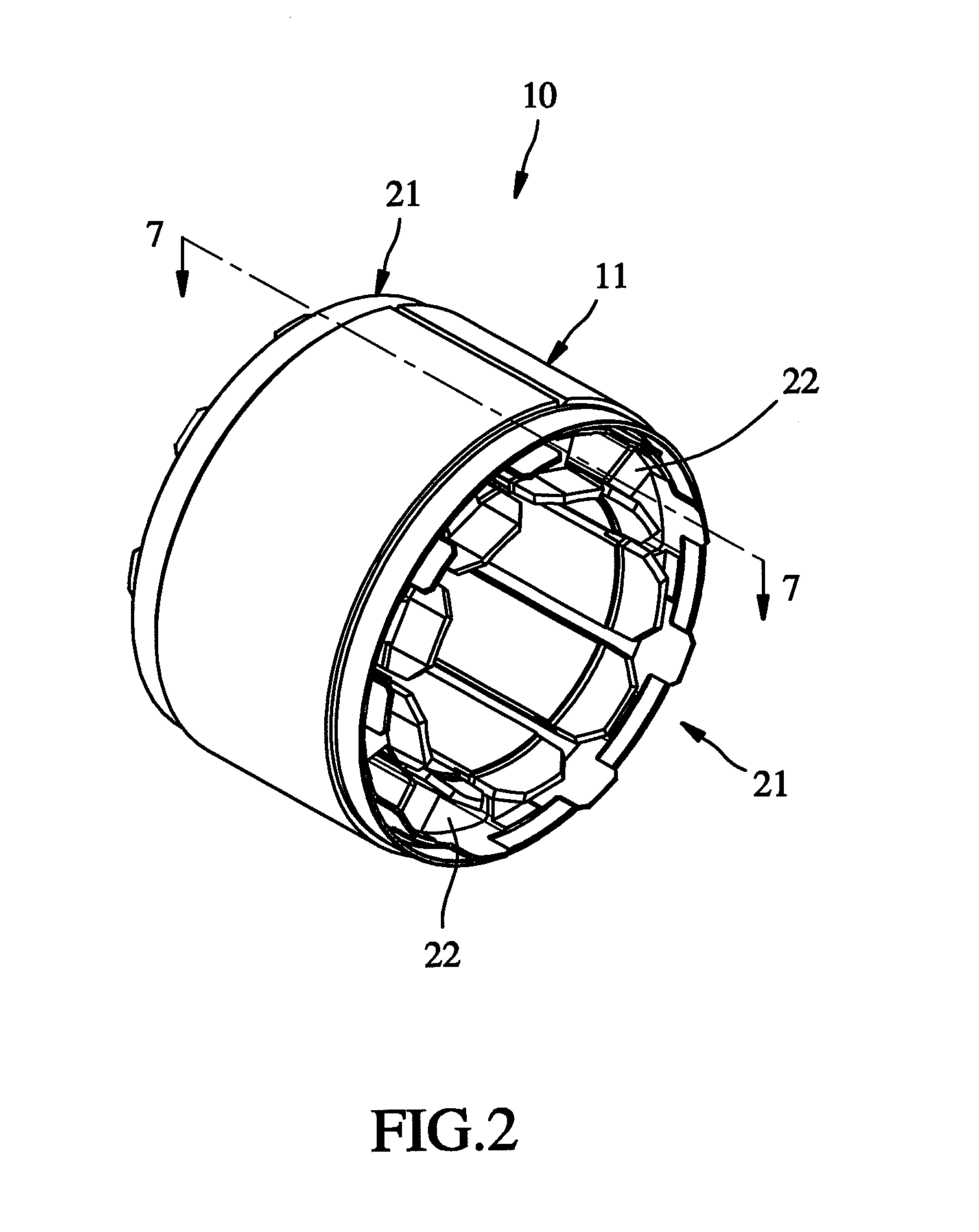

[0029]Referring to FIGS. 1 through 8, a motor stator 10 in accordance with the present invention is shown. The motor stator 10 comprises a body member 11, two wire racks 21, and a plurality of insulation sheets 31.

[0030]The body member 11 is formed of a stack of silicon steel plates. To avoid a blurred vision due to too many lines in the drawing, the body member 11 is illustrated in a block but not in a stack of silicon steel plates. The body member 11 comprises a plurality of inwardly extending polar columns 12, and a wire-winding groove 14 defined between each two adjacent polar columns 12. Further, the body member 11 defines in the axial direction thereof a middle section 111 and two opposing end sections 112 at the two ends of the middle section 111. The middle section 111 has a predetermined height. The end sections 112 have a predetermined height. The diameter of the end wire-winding groove sections 142 of the wire-winding grooves 14 corresponding to the end section portions 1...

second embodiment

[0041]Subject to the characteristic that the wall thickness of the foot tubes 51 reduces gradually in direction toward the distal end, the insulation sheets 61 can easily be inserted into the end wire-winding groove sections 442 of the wire-winding grooves 44 corresponding to the end section portions 412 of the body member 41 and respectively stopped between the stop flanges of the two wire racks. Thus, this second embodiment facilitates rapid installation.

[0042]Other structural features and effects of this second embodiment are as same as the aforesaid first embodiment, and therefore, it is not necessary to go into details.

[0043]Further, it is to be understood that, in the aforesaid two embodiments, the length of the foot tubes 22 can be shorter than the height of the end section portions 112 of the body member 11, as shown in FIG. 12. Thus, the wire racks 21 have their abutment faces 24 respectively abutted against the outer surfaces of the respective end section portions 112 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com