Heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

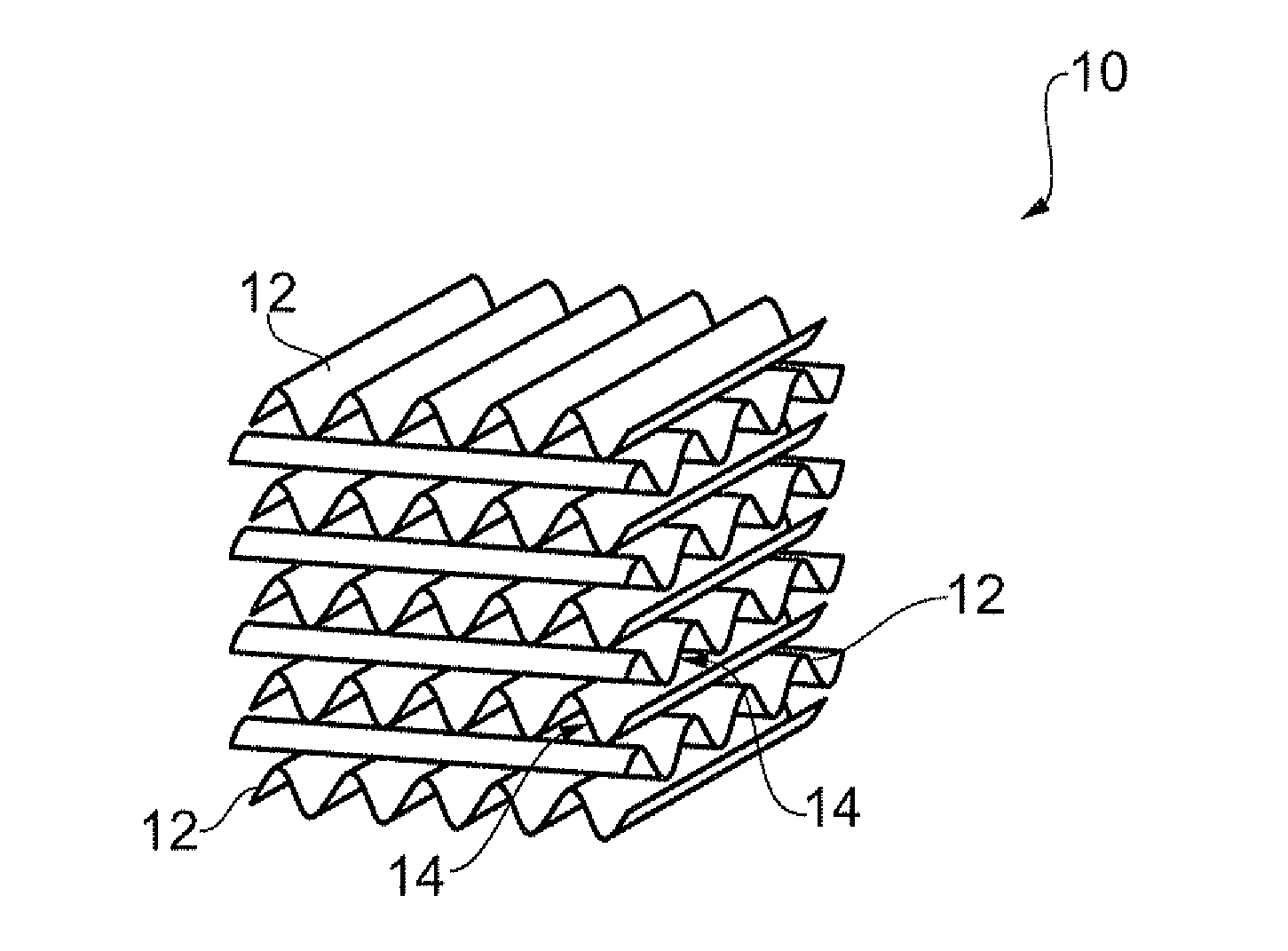

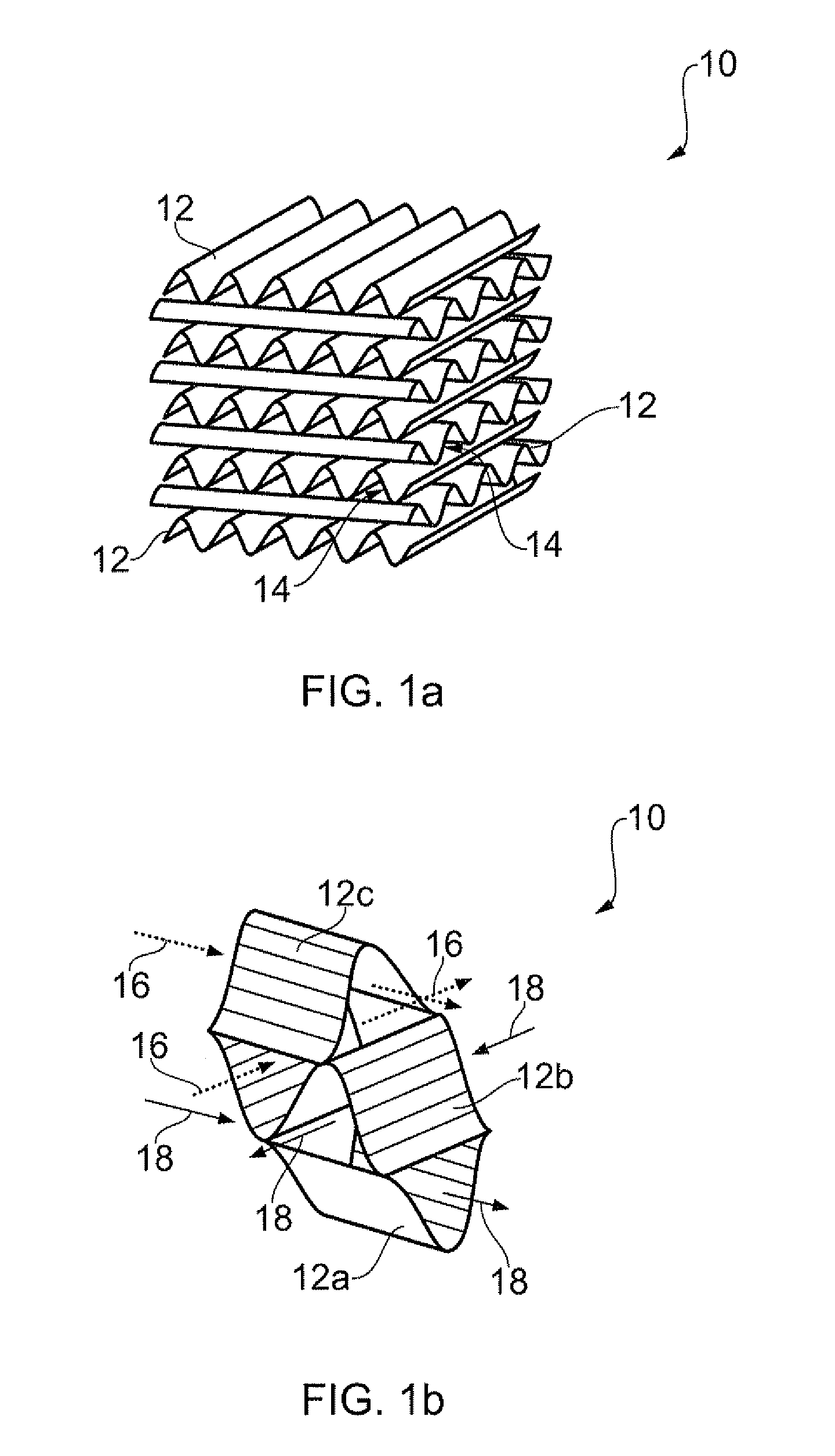

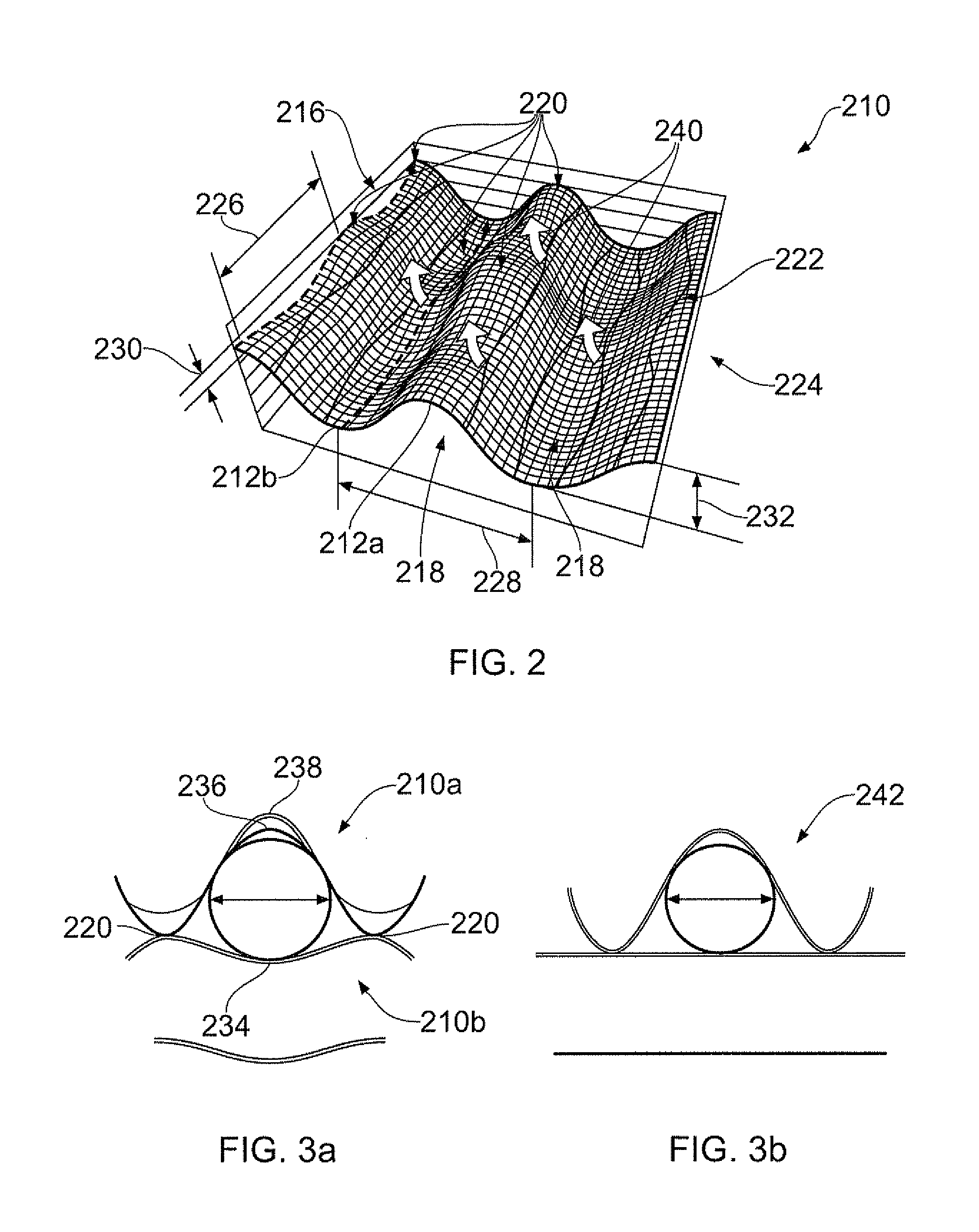

Embodiment Construction

[0036]Corrugated plate heat exchanger matrices typically have high thermal transfer coefficients and good pneumatic performance. However, conventional corrugated plate matrices have non-uniform heat transfer coefficients across the surface of each corrugated plate, with, for example, a lower heat transfer coefficient in a trough of the corrugations. This non-uniformity in heat transfer results in a non-uniform temperature distribution in the heat exchanger plates and a reduction in performance as a consequence. A typical figure for this reduction in performance can be as high as 7%, which is unnecessarily high. Further, the non-uniformity of heat transfer can lead to local thermal stresses in the heat exchanger matrix which are generally undesirable.

[0037]A further consideration of heat exchangers for aero-engines is the minimum flow cross-section area dimension through the matrix. Typically, it can be necessary for 1 mm diameter particles to be able to pass through an aero engine h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com