Lightweight, Durable Apparel and Laminates for Making the Same

a technology of durable apparel and laminates, applied in the direction of synthetic resin layered products, nuclear engineering, nuclear elements, etc., can solve the problems of bulky ensembles, high water pickup on the outer surface, and wearing an outerwear garment to protect an undergarment having a film layer, etc., to achieve the effect of sufficient durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0073]Two layer laminates were formed having an outer film surface and an inner textile surface described according to the following examples,

Membrane 1 (M1)

[0074]A moisture vapor permeable, microporous polytetrafluoroethylene (PTFE) membrane was produced that was produced from a PTFE resin made according to the teachings of U.S. Pat. No. 6,541,589, The PTFE resin comprised about 0.5 wt % polyfluorobutylethylene (PFBE) based on the total resin weight, and was processed into an expanded PTFE (ePTFE) membrane according to the teachings of U.S. Pat. No. 3,953,566. Properties for this membrane are detailed in Table 1.

Membrane 2 (M2)

[0075]A moisture vapor permeable, microporous PTFE membrane was produced from PTFE resin and processed into an expanded polytetrafluoroethylene (ePTFE) membrane according to the teachings of U.S. Pat. No. 5,814,405. Properties for this membrane are detailed in Table 1.

Membrane 3 (M3)

[0076]A moisture vapor permeable, microporous PTFE membrane was produced from...

examples 1-14

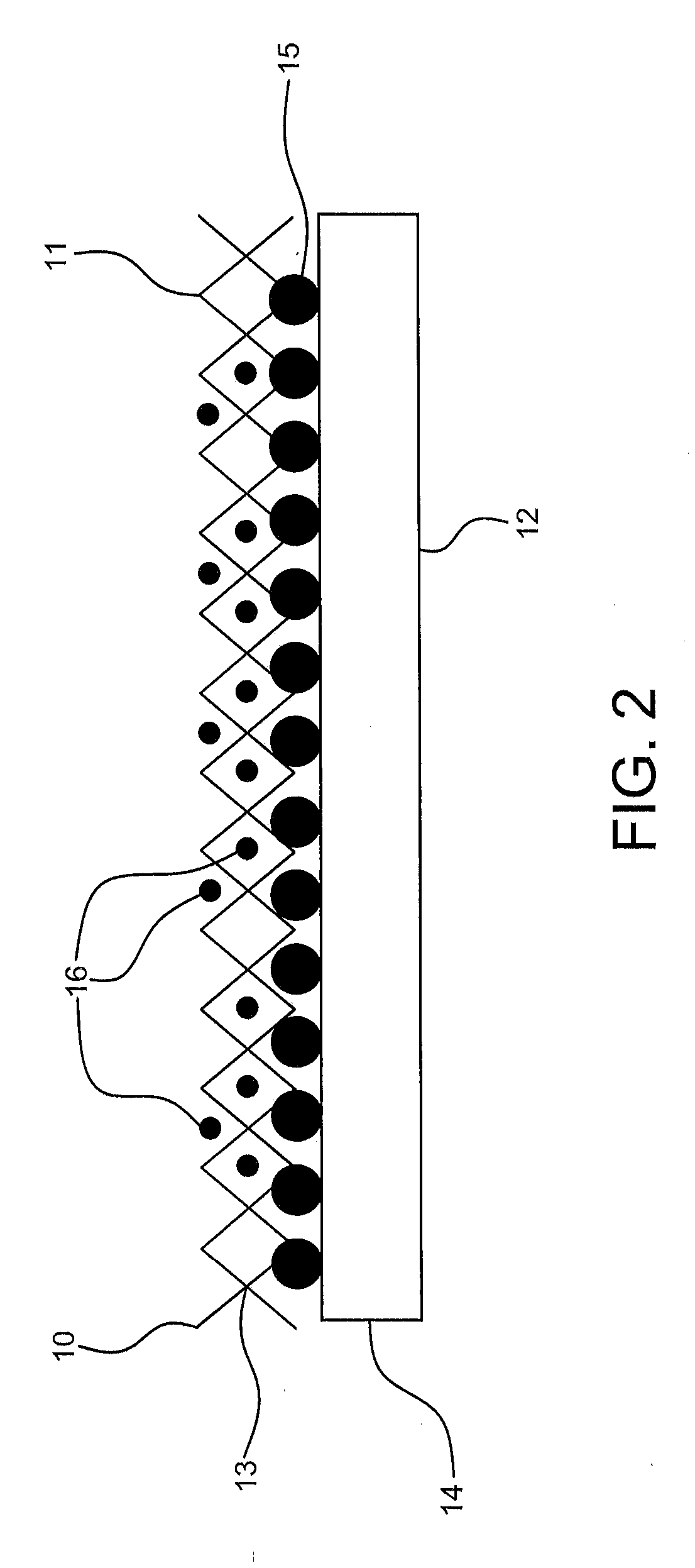

[0086]Laminates were formed comprising an outwardly facing colorized outer film surface and a textile.

[0087]Laminate samples for Examples 1-14 were constructed using the specific porous membrane and textile detailed in Table 2. The porous film and textile were laminated together by gravure printing a dot pattern of moisture curable polyurethane adhesive onto the membrane surface. The adhesive was prepared according to the teachings of U.S. Pat. No. 4,532,316, covering approximately 35% of the membrane surface. The adhesive-printed side of the ePTFE membrane was pressed to one side of the woven textile in a nip roll and then passed over a heated roll to form a two layer laminate. The moisture cure adhesive was allowed to cure for 48 hours.

[0088]The laminates were colorized according to the specific colorization and oleophobic coating methods in accordance to Table 2.

TABLE 2Description of Laminate Examples.ExampleNumberMembraneTextileColorizationCoating1M1T1BlueC22M2T1RedC13M1T2BlueC1...

example 15

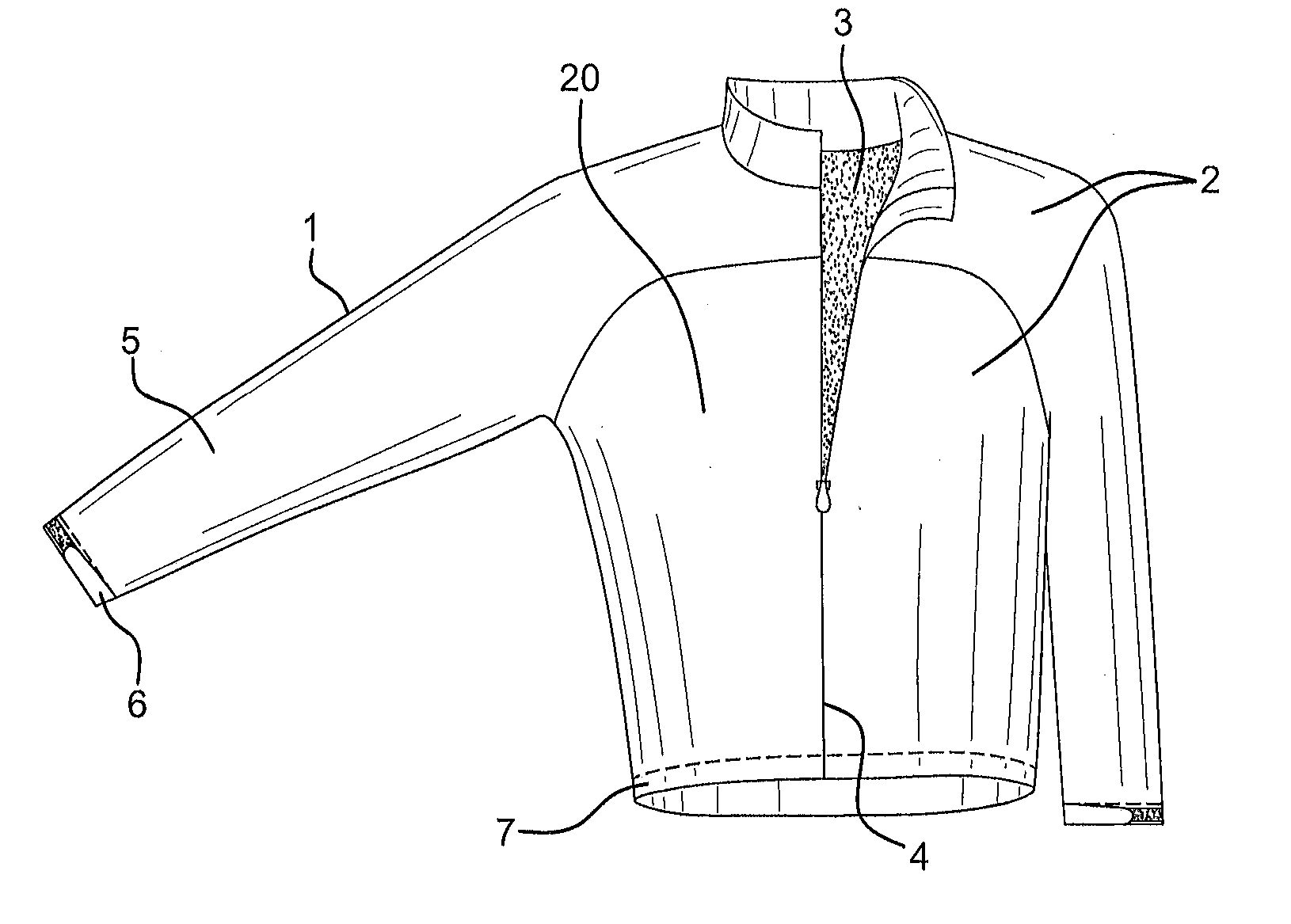

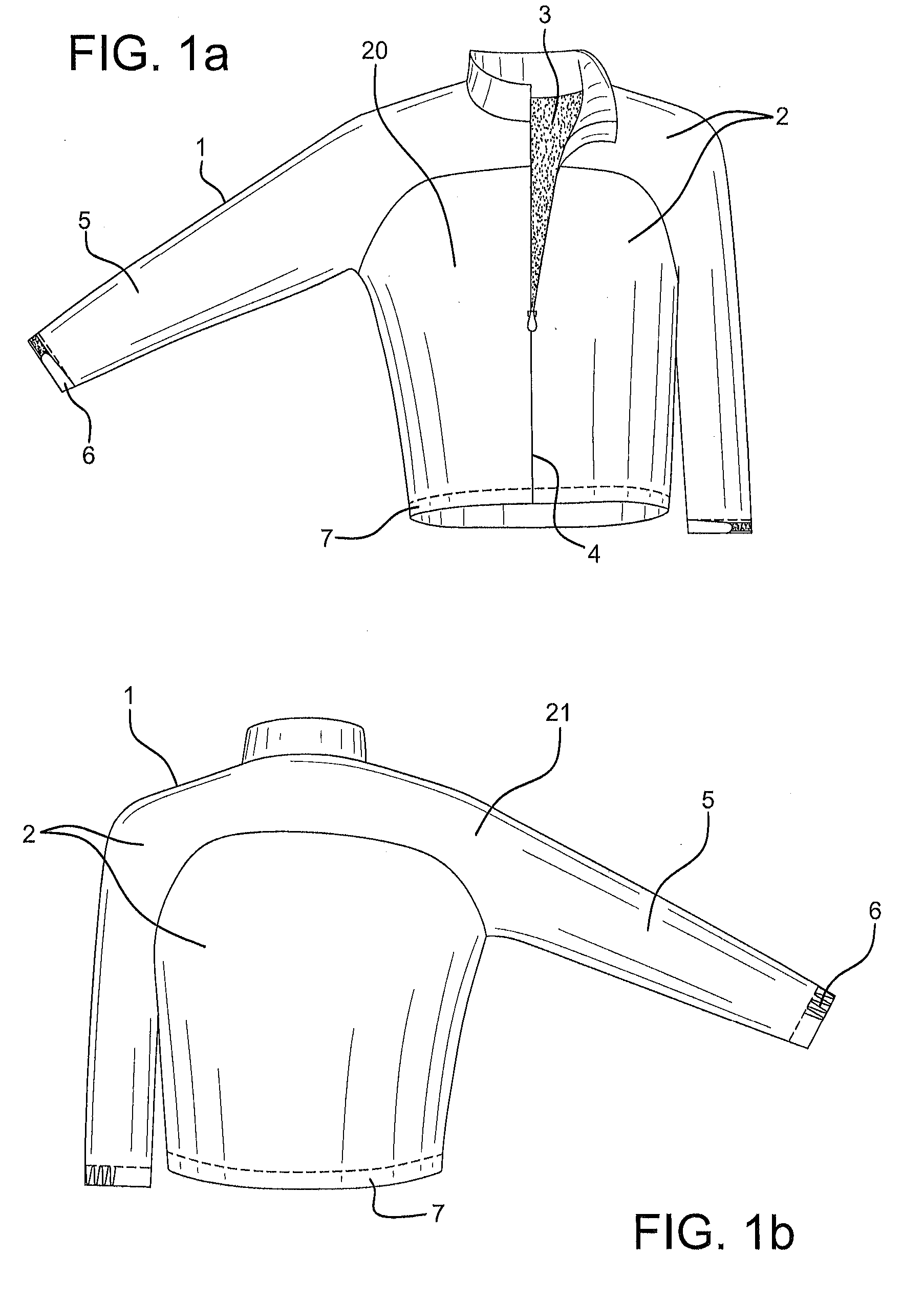

[0093]An outwear jacket having an exterior film surface was constructed using a simple garment pattern having no pockets or hood, and a full length front zipper (4), as exemplified in FIGS. 1a and 1b.

[0094]A laminate was constructed comprising an ePTFE outer film surface similar to that of Example 3 except laminated to a knit textile layer, rather than the woven textile of Example 3, by discontinuous adhesive attachments. An oleophobic coating was applied to the outer film surface. The garment sleeves were terminated with elastic cuffs having adjustable hook and loop tabs. The bottom circumferential hem was provided with an elastic draw cord in order to accommodate a range of waist sizes.

[0095]The jacket was constructed sewing the patterned laminate pieces together by orienting the outer film surface to the exterior side of the jacket using a single needle seam machine having a 65 ball point needle. The sewing machine included a knife edge which trimmed off any excess laminate so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean flow pore size | aaaaa | aaaaa |

| mean flow pore size | aaaaa | aaaaa |

| melt point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com