Method for producing a blue cheese

a blue cheese and cheese technology, applied in cheese manufacture, dairy products, applications, etc., can solve the problems of unnatural openings and unctuous cheeses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

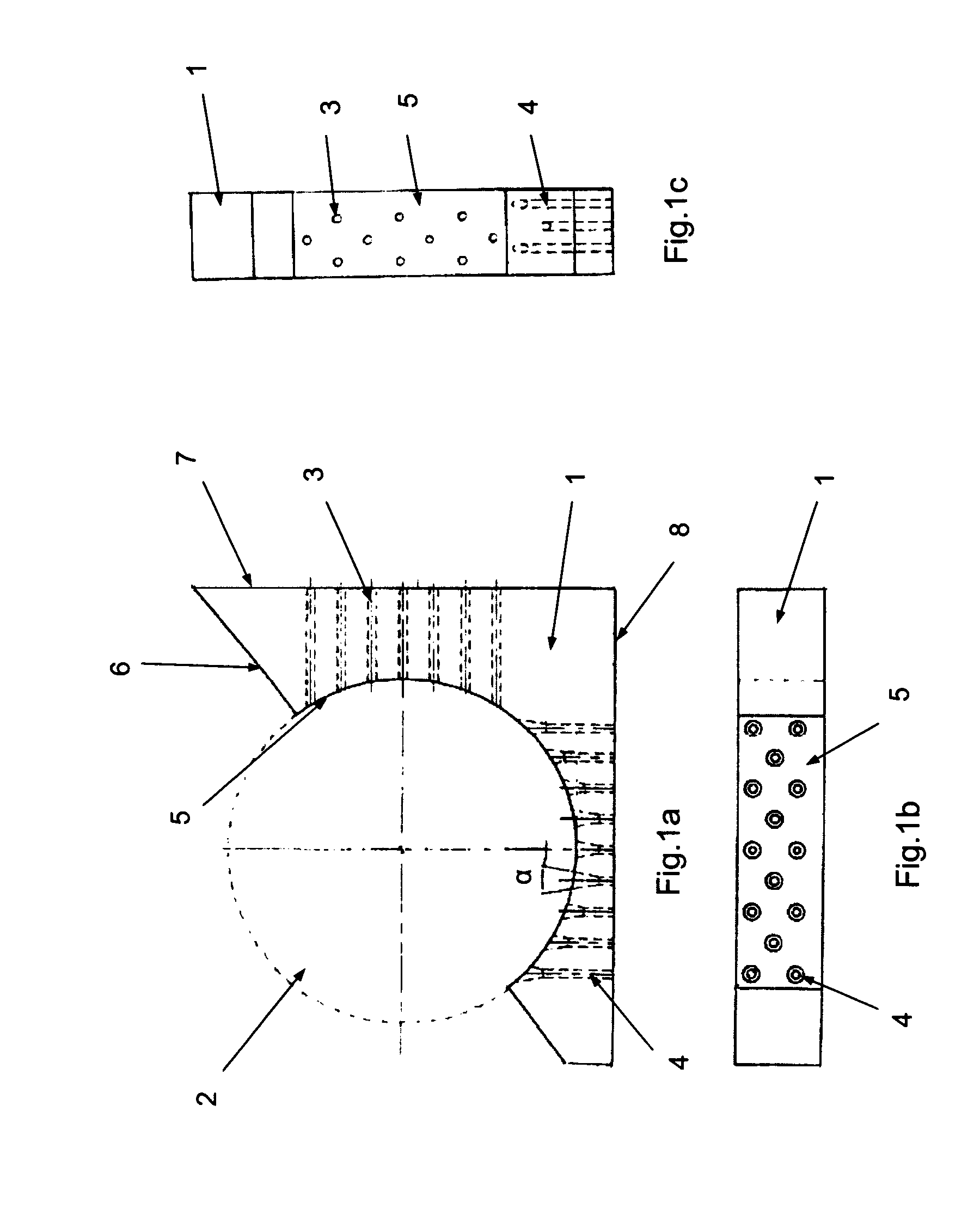

Image

Examples

examples

[0081]This example relates to the production of a blue cheese with 60% fat in the milk solids, using the process in accordance with the invention.

[0082]The raw milk was standardized into fat with twice the protein content. The protein content was 32 grams per liter; therefore, the fat was brought to 64 grams per liter by adding cream. The standardized milk was then pasteurized at 80° C. for 4 seconds, followed by cooling at 3° C. of the pasteurized milk for its intermediate storage. This milk was then heated to 40° C., introduced into a four-stage ultrafiltration device, then by ultrafiltration a concentration with a factor of 4.5 was produced to obtain a retentate (liquid pre-cheese) having the following composition: fat=288 g / l (or 64 g / l×4.5); protein=144 g / l (or 32 g / l×4.5).

[0083]This liquid pre-cheese was then cooled to 30° C. in a maturation vat, and inoculated with mesophilic ferments, while constantly monitoring the pH. When the pH reached a value of 6.30, the salt (around 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com