Installation of leakage barriers to enhance yield of mineral deposits in unlined solar pond systems

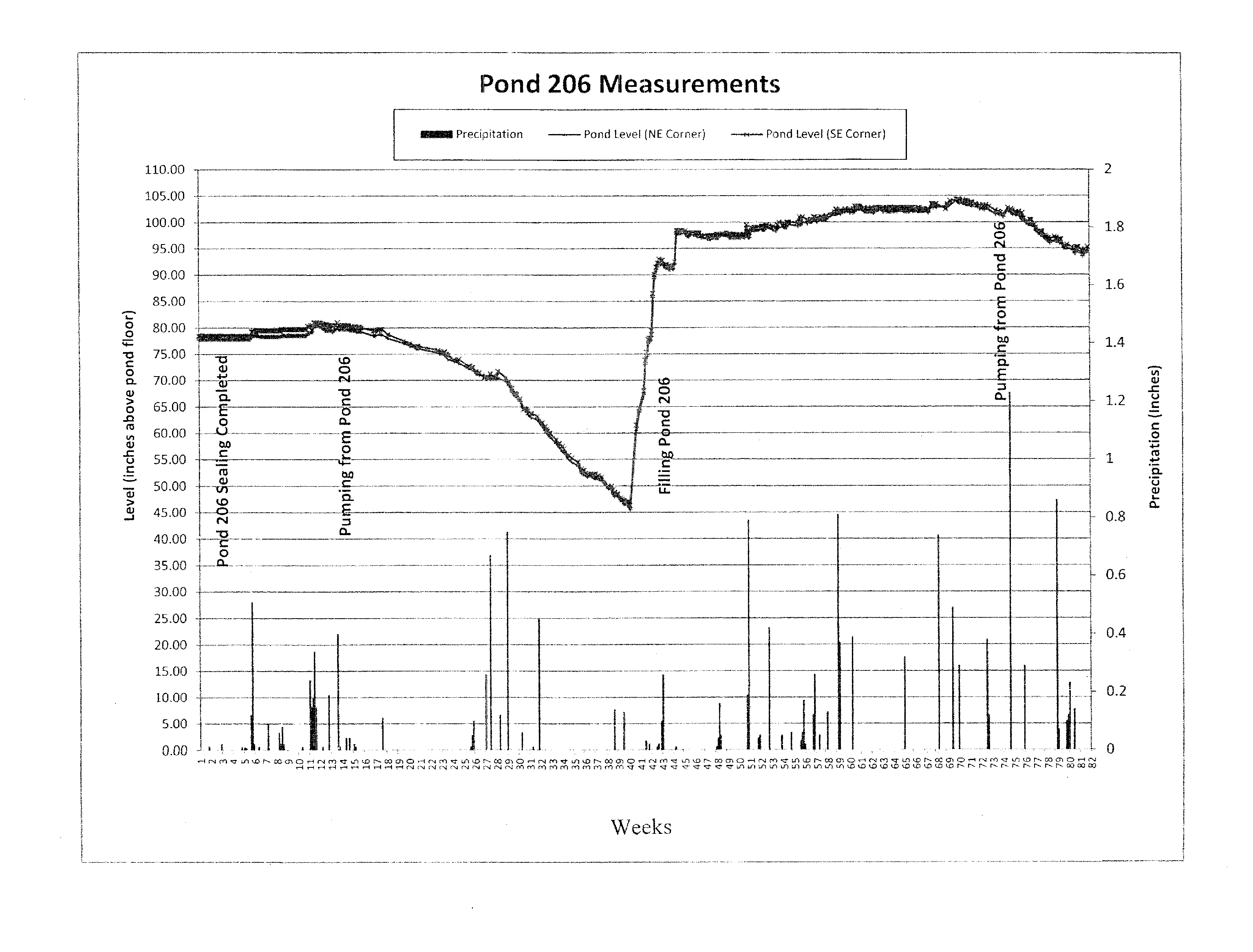

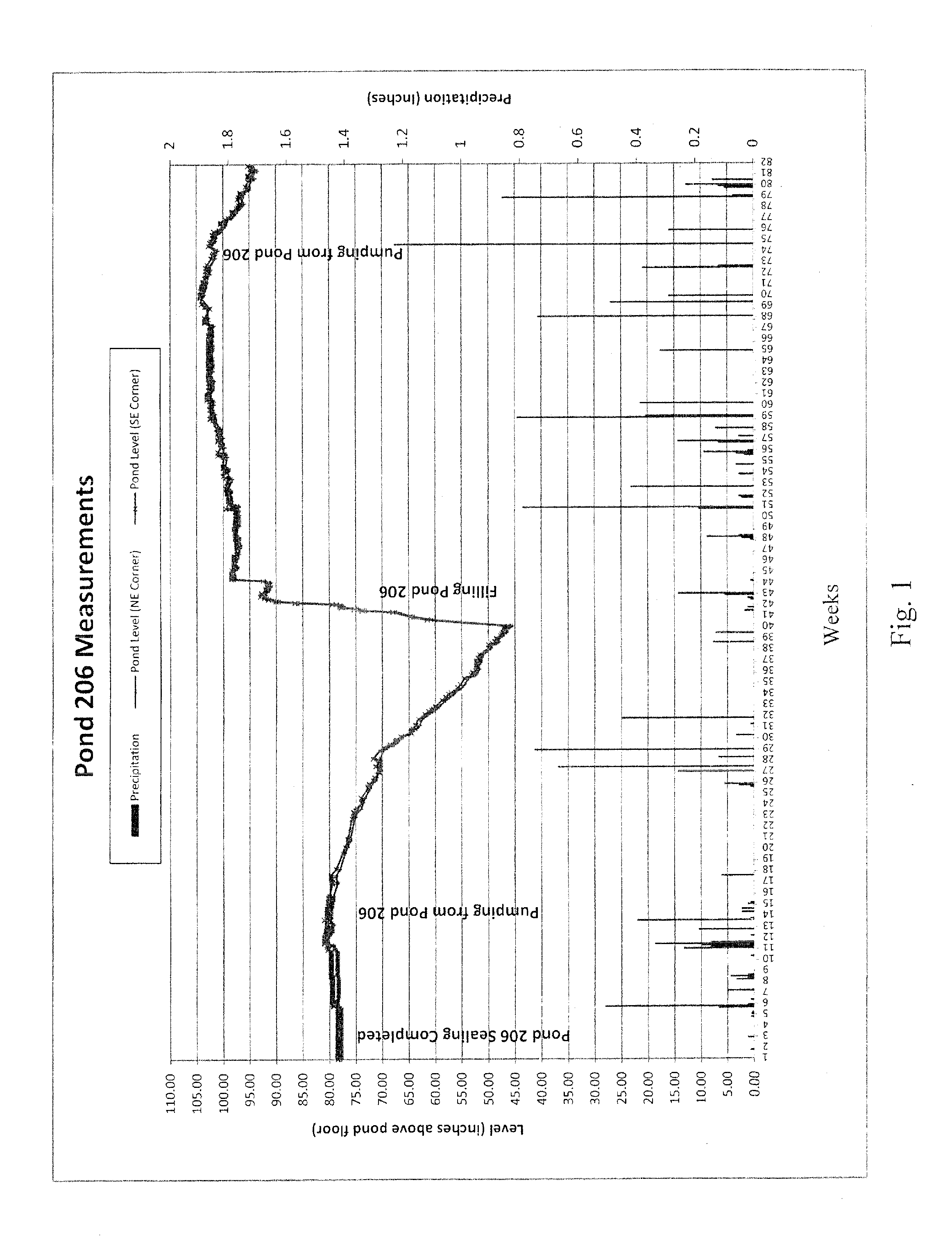

a solar pond and mineral deposit technology, applied in the field of slurry wall to seal solar ponds, can solve the problems of eroded dikes, solar ponds naturally leak brine to adjacent soils, and most unlined solar pond systems can lose as much as 70% of pumped-in brine to leakage, so as to reduce or prevent leakage from solar ponds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0030]The following examples set forth preferred methods in accordance with the invention. It is to be understood, however, that these examples are provided by way of illustration and nothing therein should be taken as a limitation upon the overall scope of the invention.

Materials and Methods

[0031]Table 1 sets forth the standards and methods utilized to test a number of the properties described herein.

TABLE 1Laboratory Standards and MethodsTestStandard or ReferenceGrainsize of soilsASTM D6913Fines ContentASTM D1140Atterberg LimitsASTM D4318Moisture ContentASTM D2216Soil Classification (USCS)ASTM D2487Water Quality (ph, Hardness, TDS)Hach Test or equalSlurry & Grout PreparationAPI 13A mod.Sample PreparationASTM D4832 mod.Slump (mini-slump method)ASTM D143 mod.Viscosity and DensityAPI RP 13B-1Filtrate, pH, and TemperatureAPI RP 13B-1Bleed and SetASTM C940 mod.Penetration ResistanceASTM D1558 mod.Unconfined Compressive Strength (UCS)ASTM D1633 / 4832 mod.Hydraulic Conductivity (permeabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com