Portable Hydrostatic Test Pump

a portable, hydrostatic testing technology, applied in the direction of piston pumps, positive displacement liquid engines, liquid fuel engines, etc., can solve the problems of large, heavy, bulky, difficult to transport to remote areas and other areas, and the operation of conventional hydrostatic test pumps (e.g., rotary piston pumps) requires significant energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

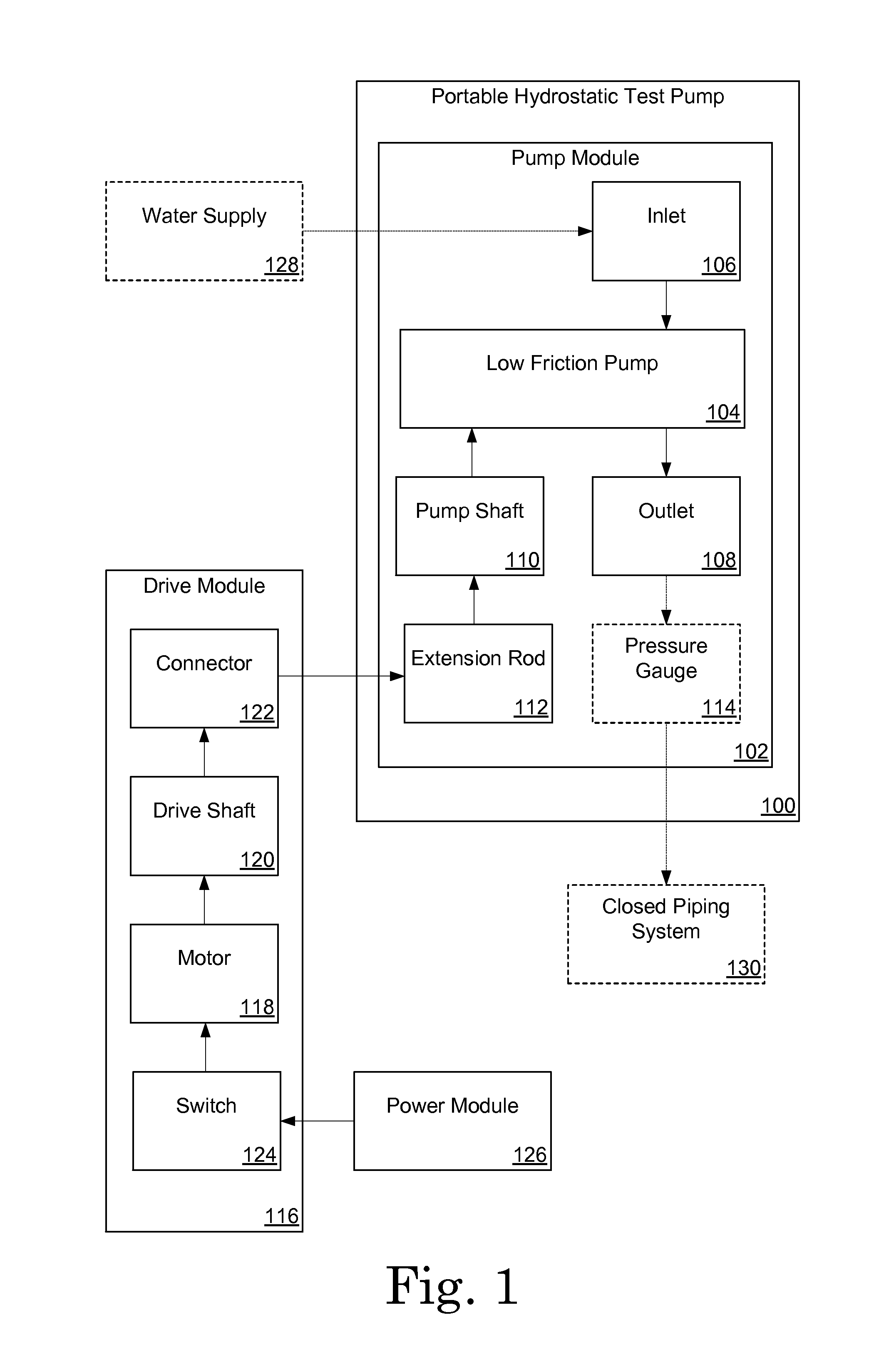

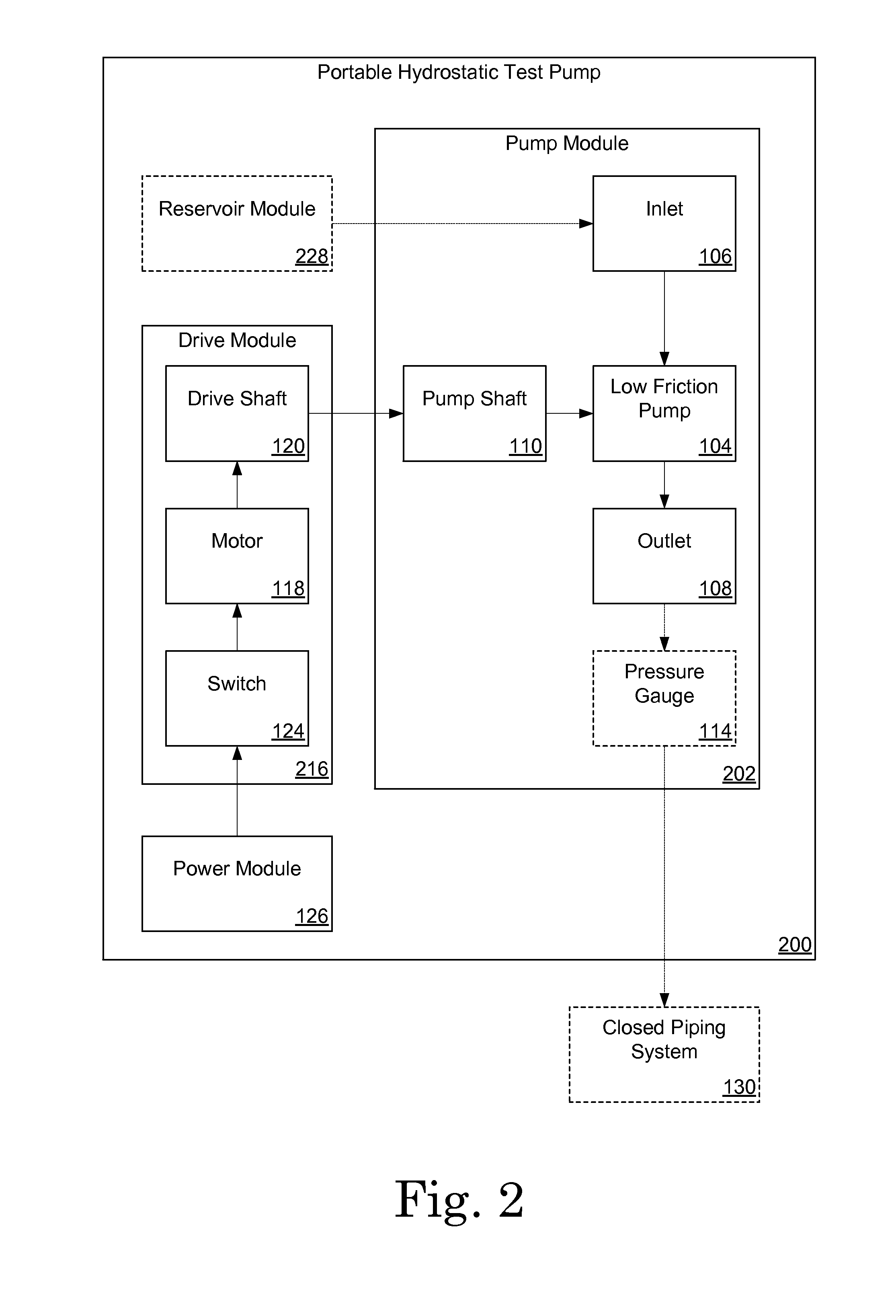

[0010]A portable hydrostatic test pump and a system incorporating the portable hydrostatic test pump to pressurize a closed piping system for leak testing purposes is described herein and illustrated in the accompanying figures. The portable hydrostatic test pump includes a compact, lightweight, low power pump module operable using a portable power source. This allows the portable hydrostatic test pump to be used for testing closed piping systems located in areas that are physically difficult to access and / or without access to a permanent power source.

[0011]FIG. 1 is a block diagram of one embodiment of the portable hydrostatic test pump 100. The portable hydrostatic test pump is a modular apparatus that includes a pump module 102. The pump module 102 is compact and lightweight making it highly portable and transportable. In various embodiments, the pump module weighs approximately 2.26 kg (5 lb) or less and is hand held. Some embodiments of the pump module include an optional press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap