Method for producing a pressurised air gas by means of cryogenic distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

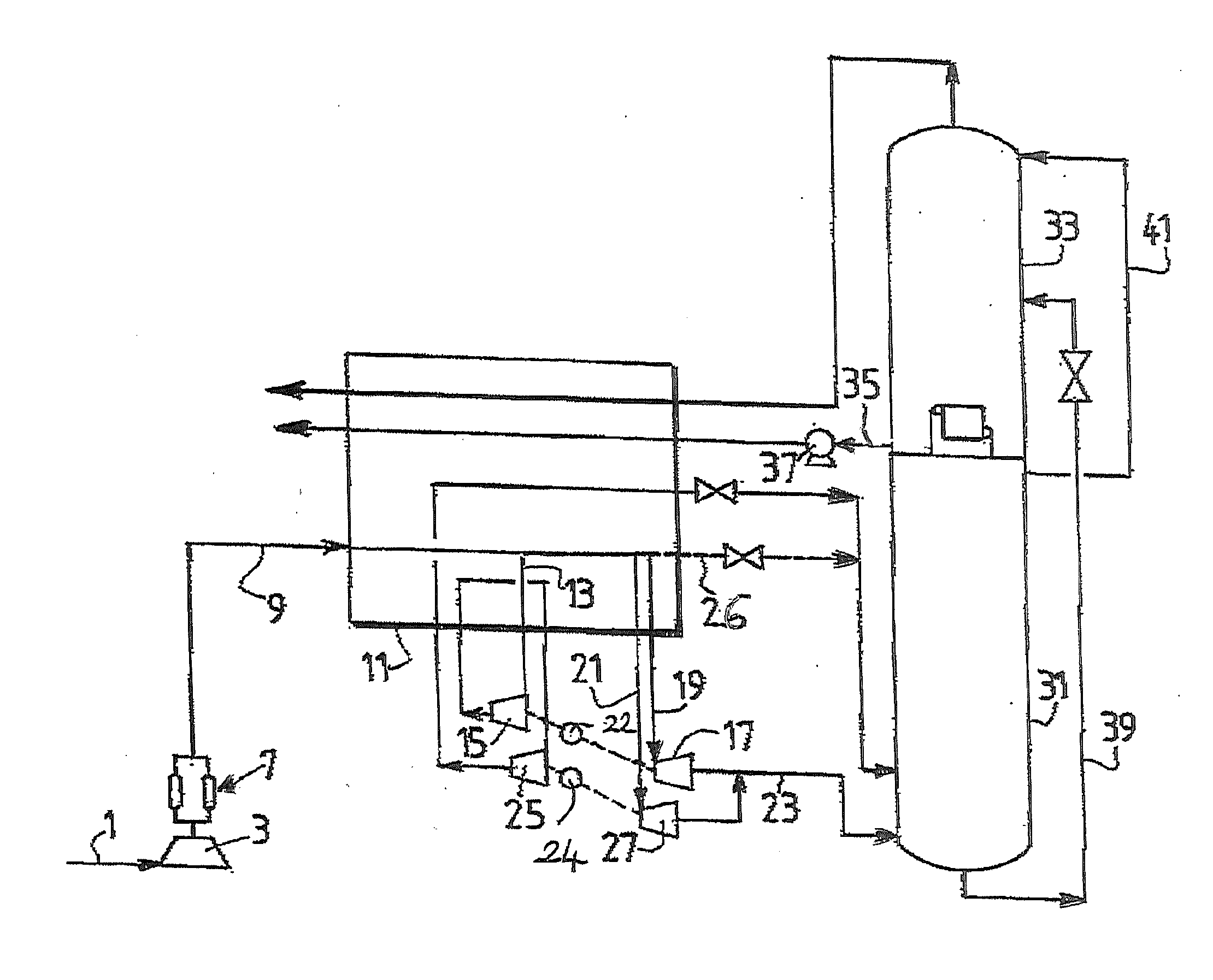

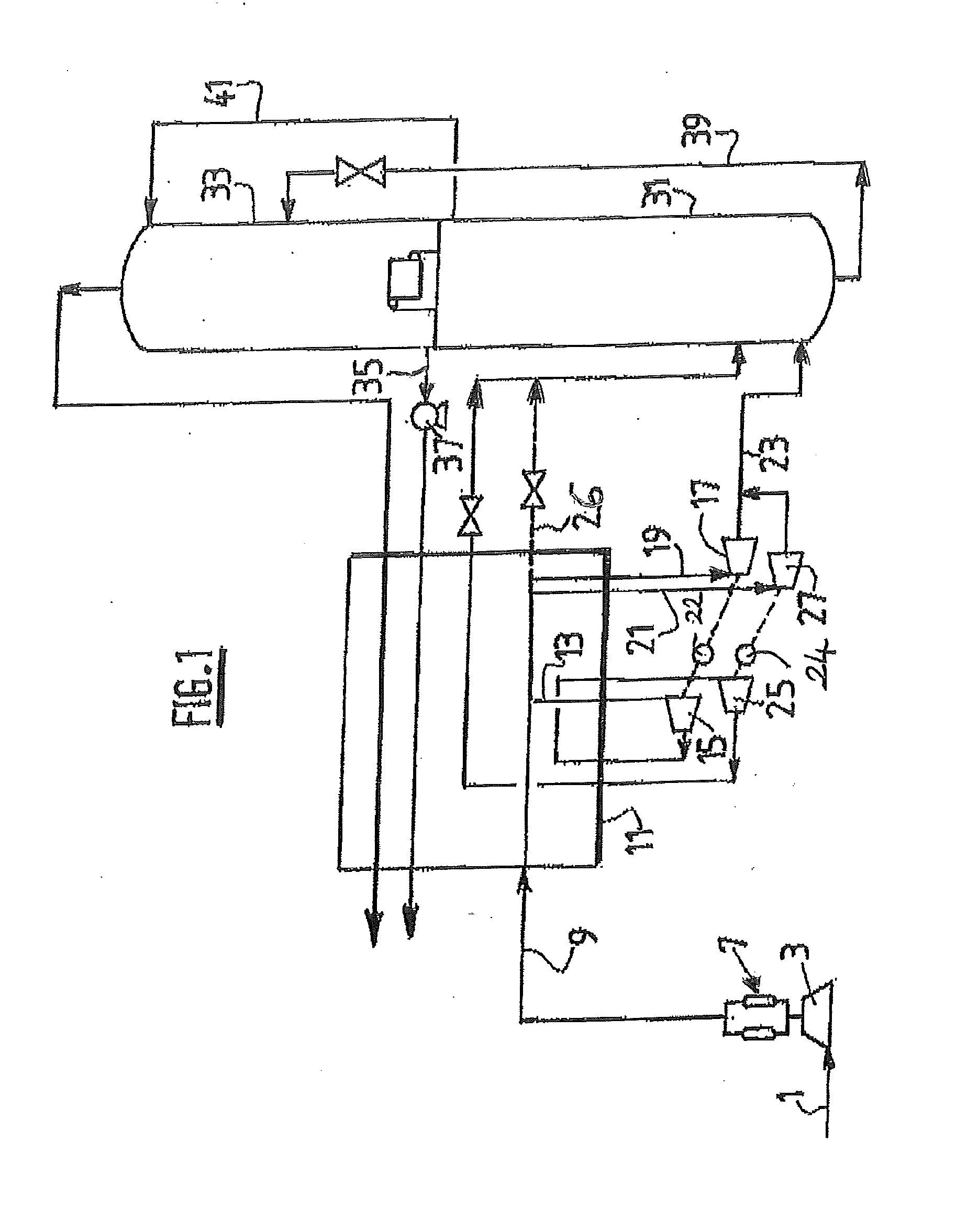

[0038]The invention shall be described in more detail by referring to the figure which shows a method for separating air according to the invention.

[0039]An airflow is compressed in a main compressor 3 to a pressure at least 3 bars above the pressure of the column 31, which is the medium-pressure column of a double column for separating air by means of cryogenic distillation. The compressed air is purified in a purification unit 7 in order to form the purified flow 9. The purified flow is sent to the exchange line 11 without having been cooled and in the exchange line it is cooled to a first intermediate temperature. At this temperature, the air is divided into a portion 13 and a portion 14. The portion 13 enters into a single first single-stage booster 15 at the first intermediate temperature wherein it is boosted. The boosted air is sent to the exchange line 11 wherein it is cooled again to a second intermediate temperature, lower than the first intermediate temperature. At this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com