Composite bat with varying barrel thicknesses

a composite bat and barrel thickness technology, applied in the field of softball bats, can solve the problems of certain metal bats, painful vibrations in the hands and arms of batters, and vibrations upon impact, and achieve the effect of greater impact absorption and resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

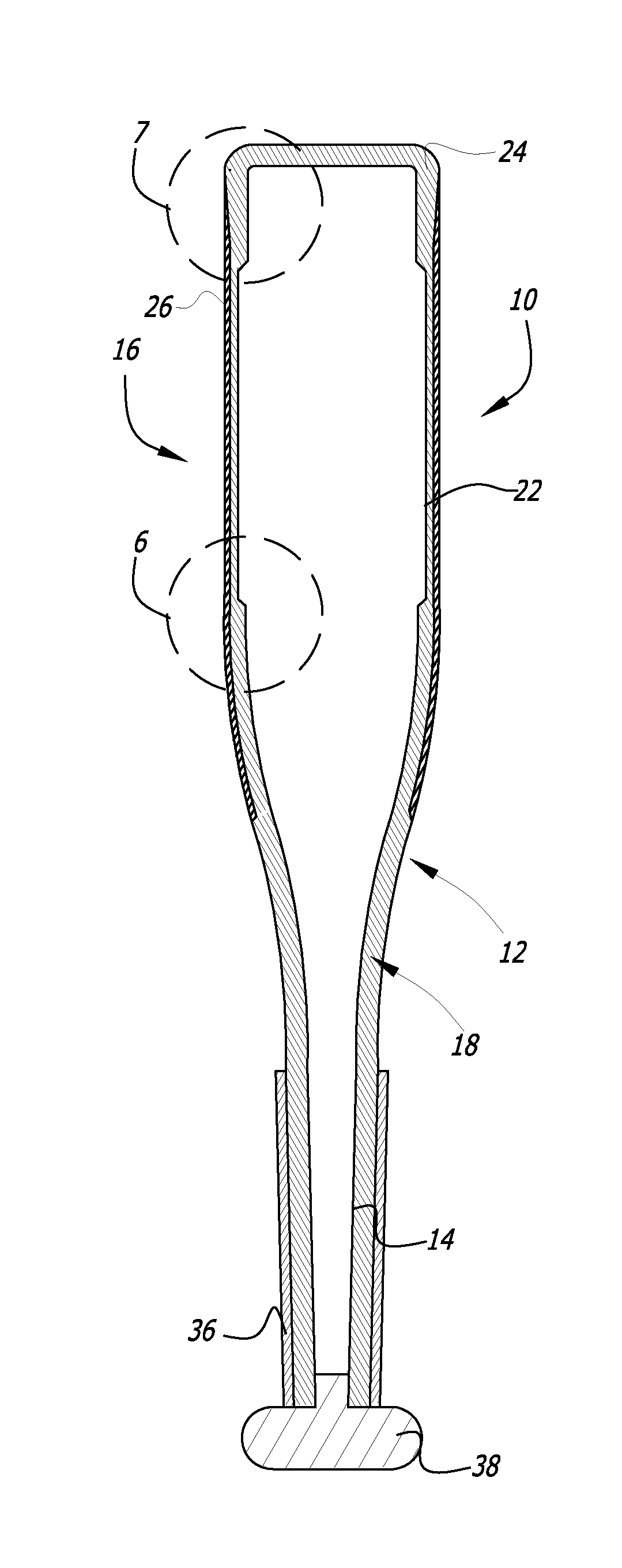

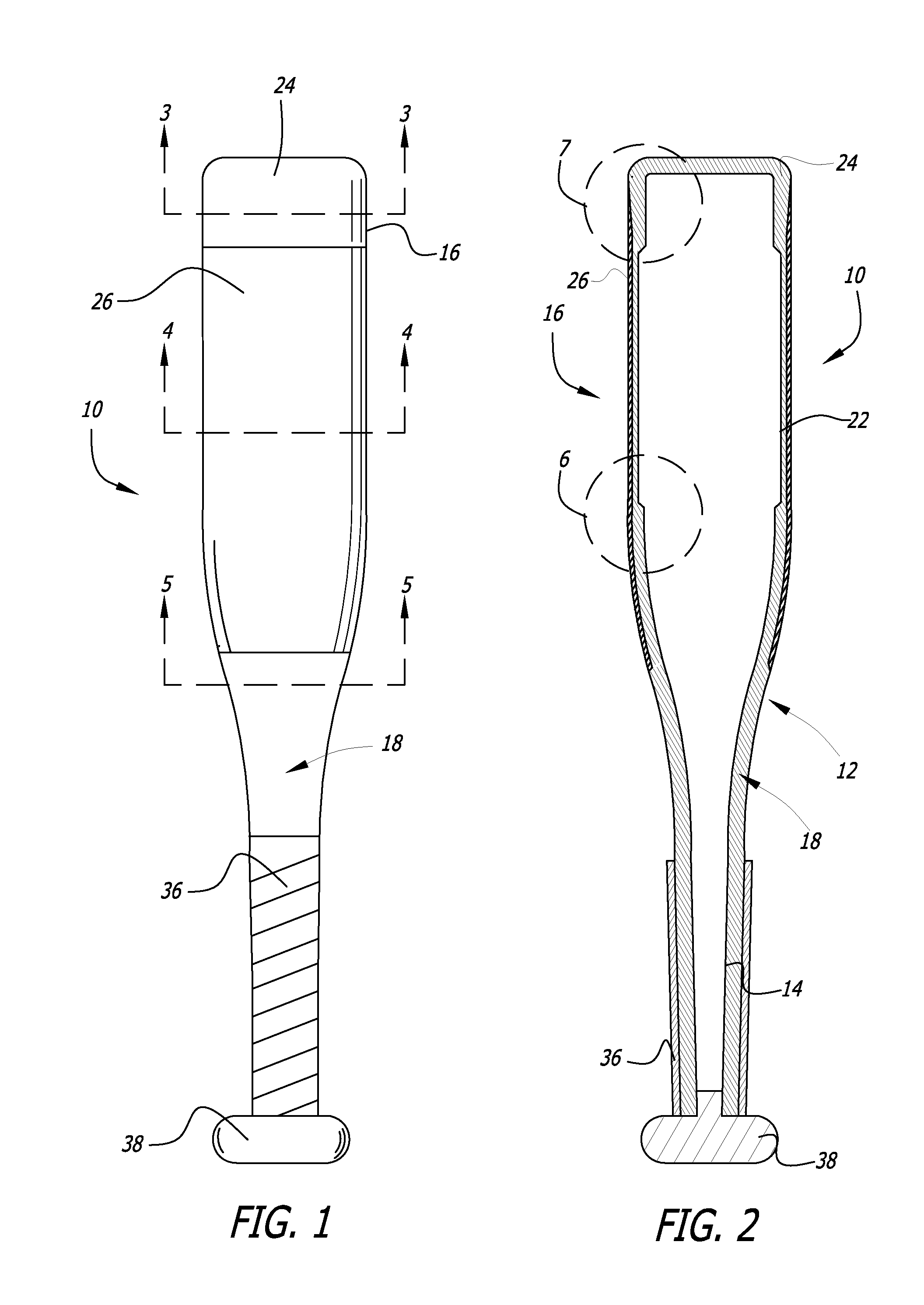

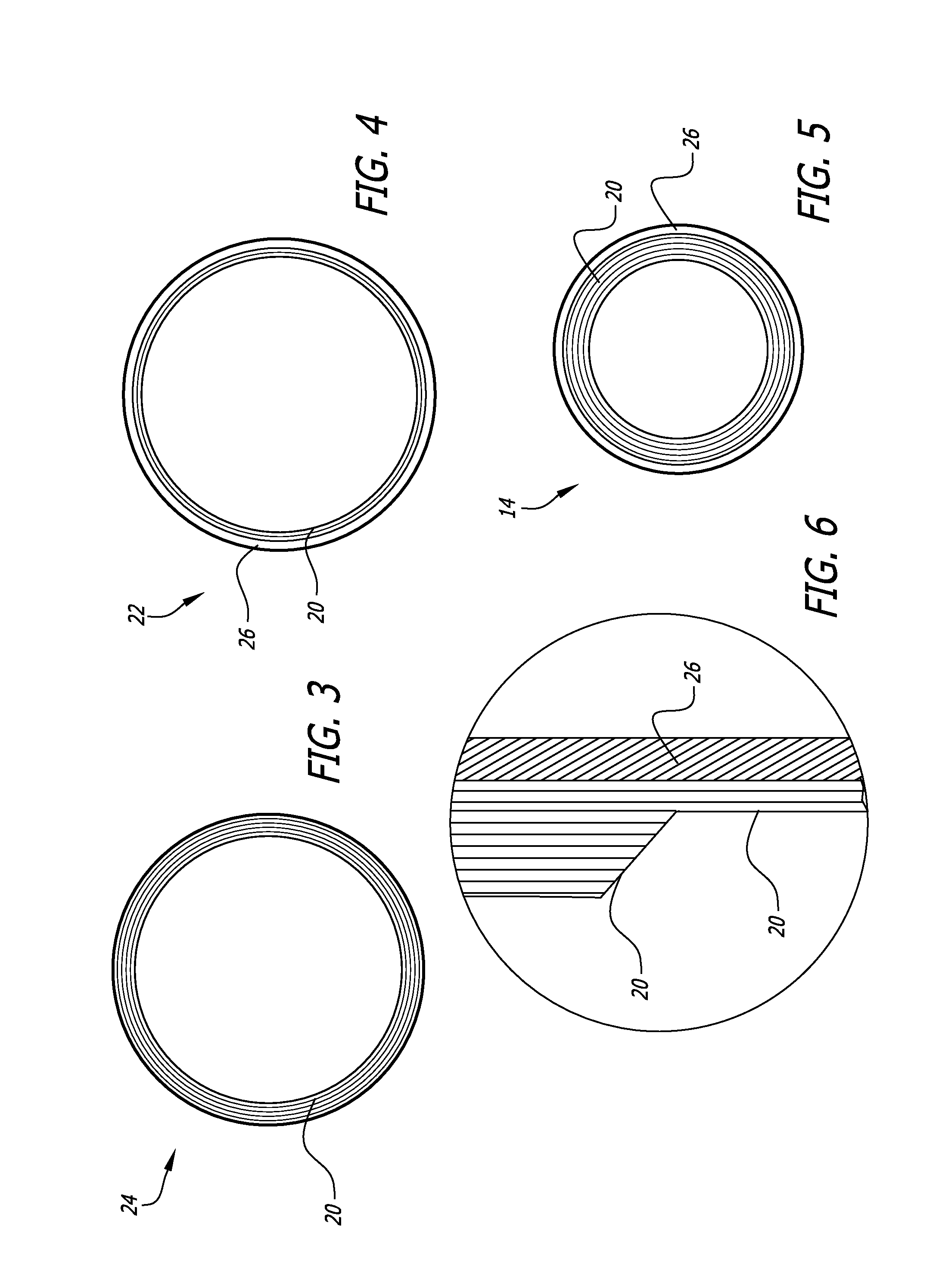

[0030]As shown in the accompanying drawings, for purposes of illustration, the present invention is concerned with a bat 10 for use in baseball or softball. With reference now to FIGS. 1 and 2, the bat 10 comprises a composite bat body 12 which includes a handle portion 14 at one end thereof and a barrel portion 16 at a generally opposite end thereof. The handle 14 and barrel 16 portions are integrally connected to one another, such that the barrel portion 16 extends from the handle 14. Typically, as illustrated, the handle portion 14 is of a much smaller diameter than the barrel portion 16, and thus there can be considered to be a generally tapered portion 18 intermediate the handle 14 and barrel 16 portions.

[0031]The bat body 12 is preferably made from a composite material, e.g., fiberglass, carbon fibers, or a combination of glass and carbon fibers. For example, 80% glass to 20% carbon will make a very flexible bat, whereas 20% glass to 80% carbon makes a very stiff bat, or any o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| resilient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com