Wellbore leak detection systems and methods of using the same

a leak detection and optical fiber technology, applied in the field of optical fiber sensing systems, can solve the problems of contaminating the water and/or collecting in low lying surface areas with dangerous consequences, and the technique is not practical for monitoring a producing well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

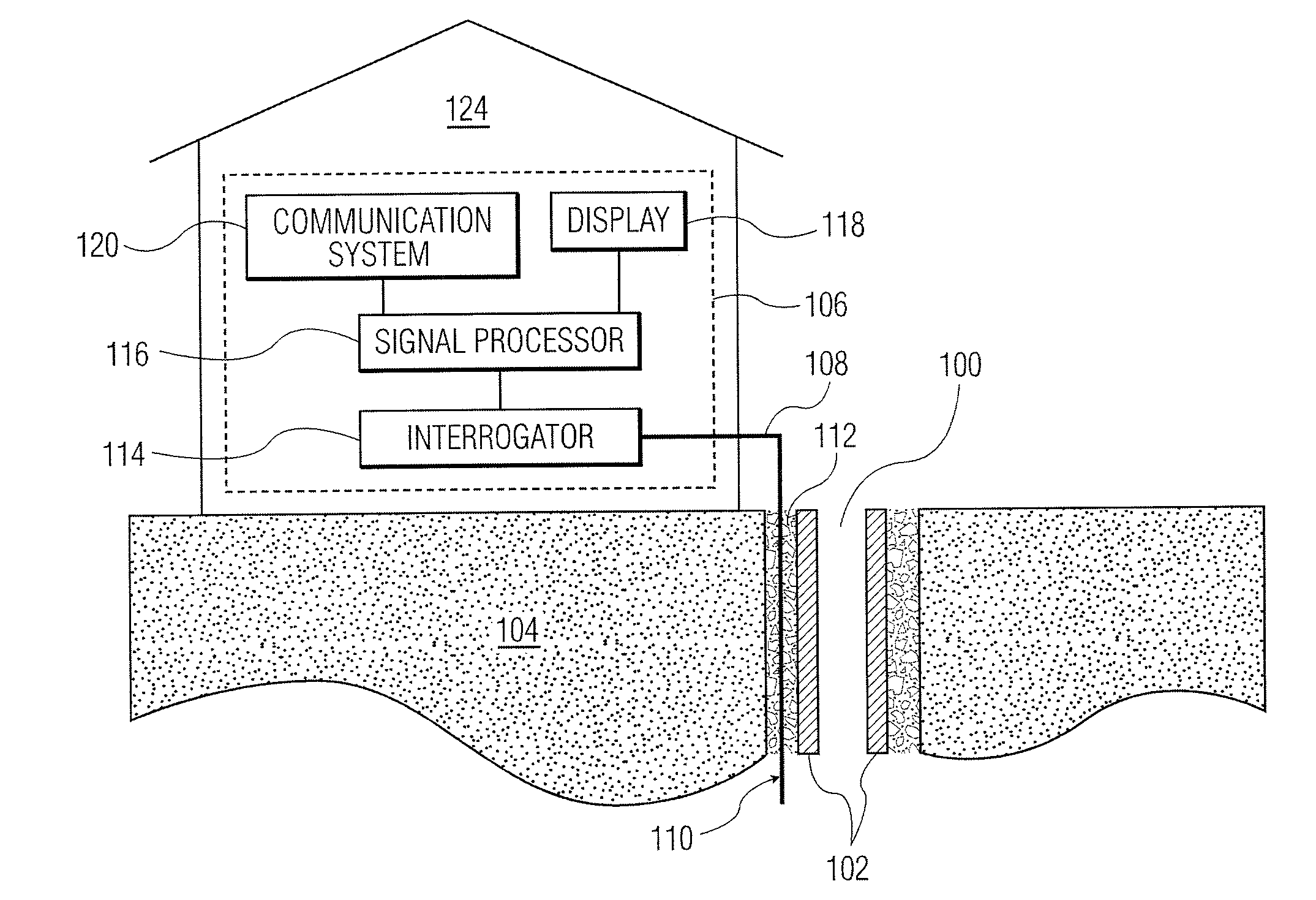

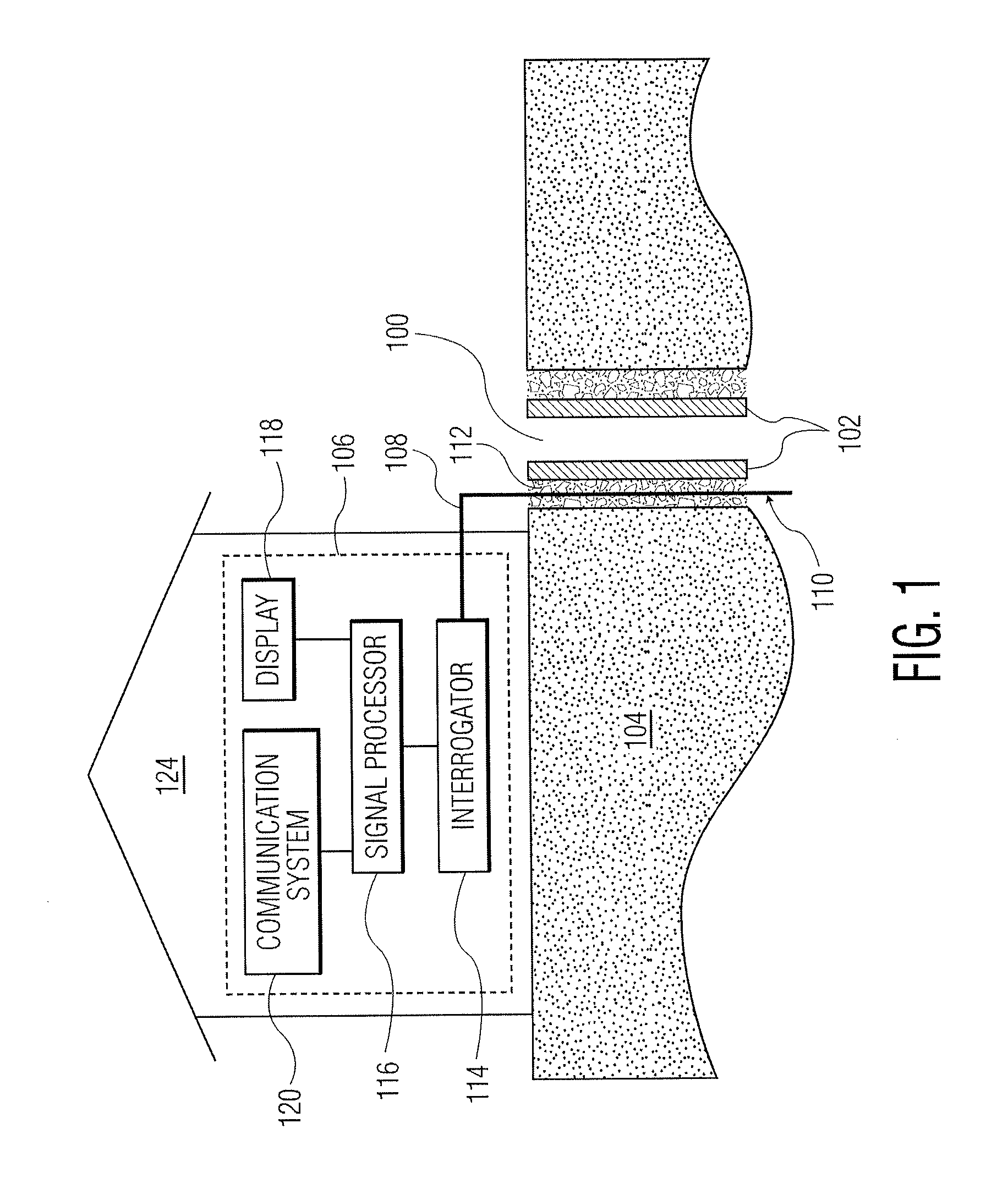

[0016]As used in this document, the term “wellbore casing” is intended to refer to any structure that separates a wellbore (e.g., the bore configured to house the fluid during transport) from the surrounding geological structure. Exemplary wellbore casings are formed of cement and steel, and may be layered wall structures. As is understood by those skilled in the art, as a fluid (e.g., natural gas, oil, etc.) travels through the wellbore, the wellbore casing often serves to protect aquifers from fluids migrating from within the wellbore casing to the aquifers.

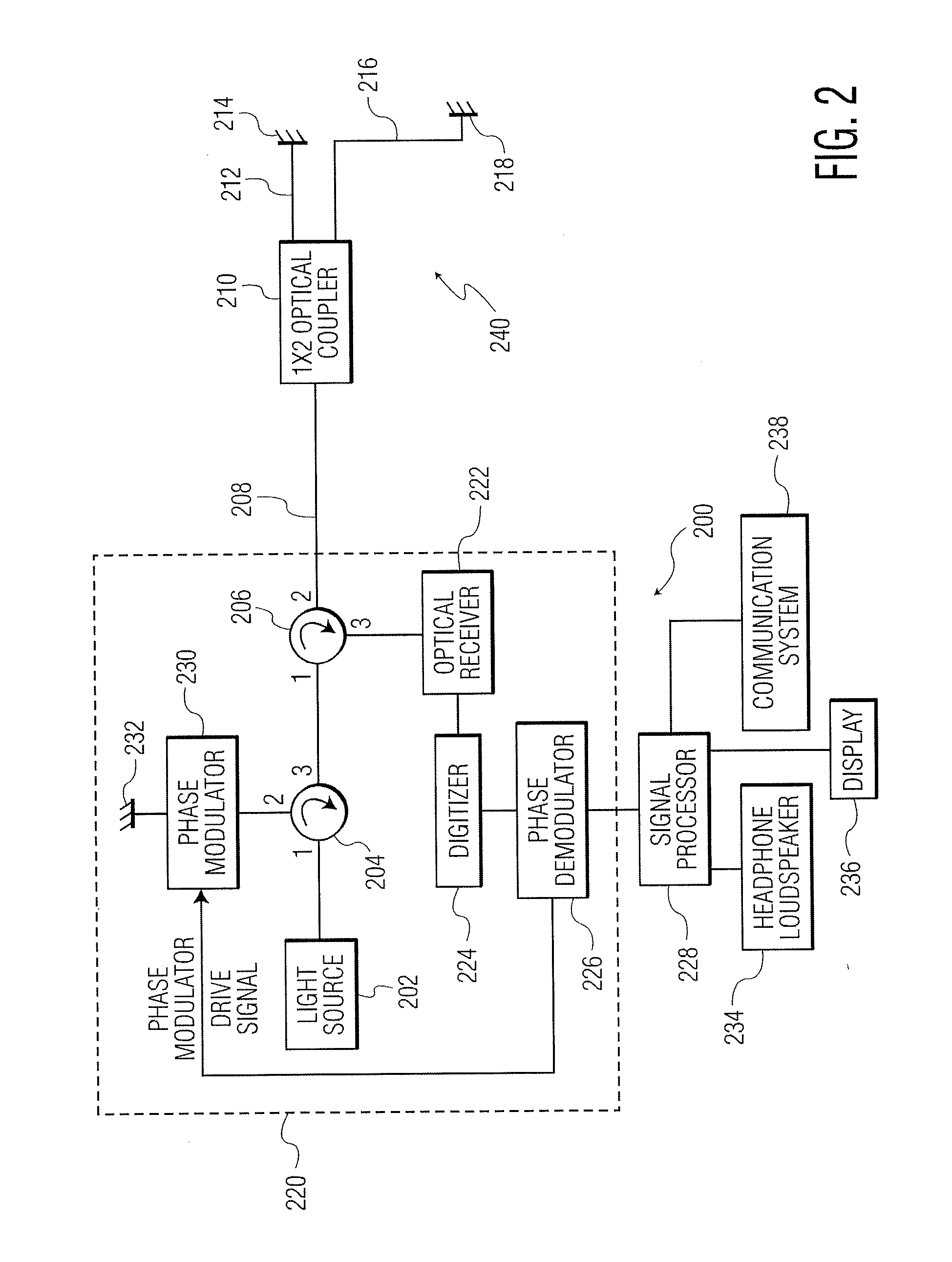

[0017]The present invention relates to systems and methods utilizing a plurality of optical fiber sensors installed outside of a wellbore casing (e.g., embedded within the wellbore casing cement) for the detection of fluid (e.g., liquid, gas, etc.) migration such as a fluid leak through the wellbore casing. The optical fiber sensors may be installed, for example: (1) against the wellbore casing; or (2) in an area between the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com