Anti-wear device for composite packers and plugs

a composite packer and plug technology, applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., can solve the problems of compromising the design and functionality of the tool, increasing wear on the engineering grade plastic parts of the tool, etc., to minimize damage and minimize the damage to the components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

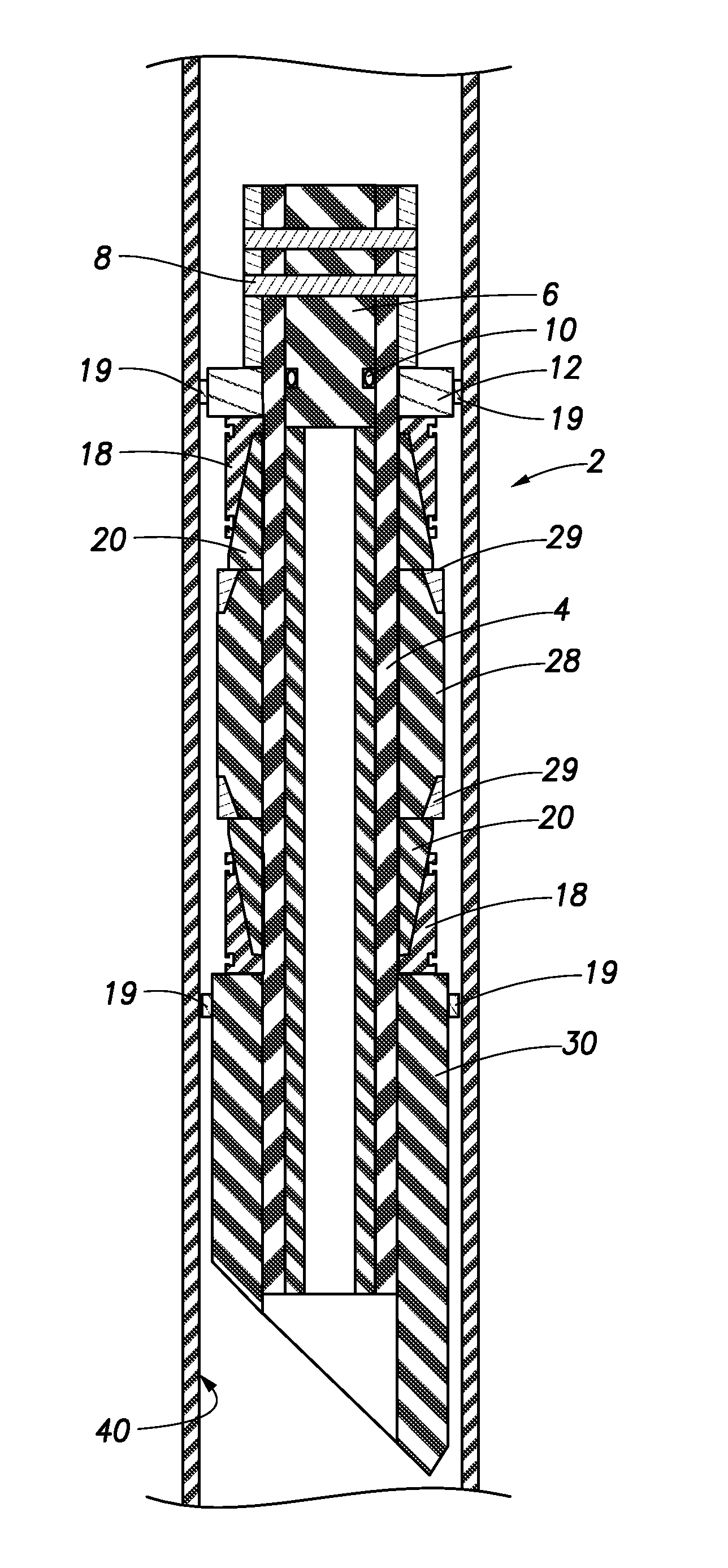

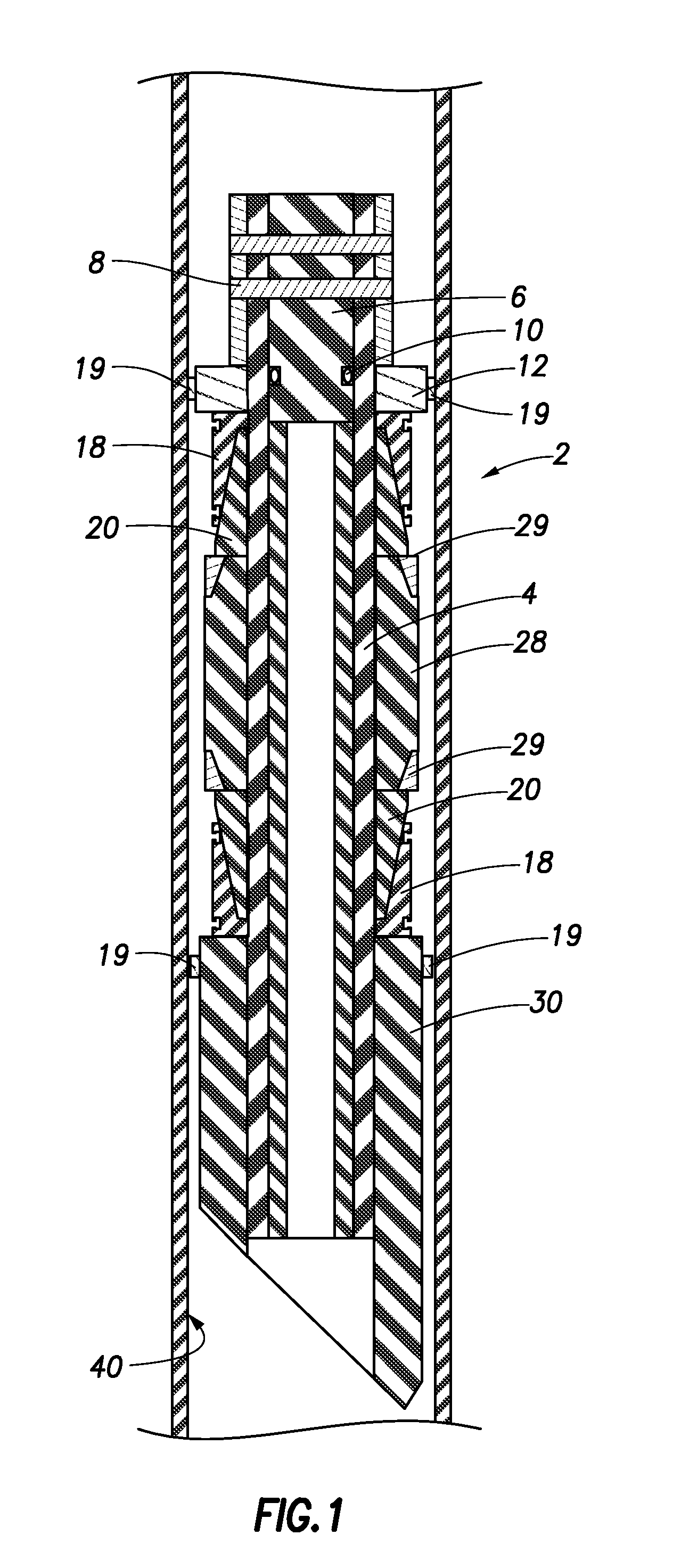

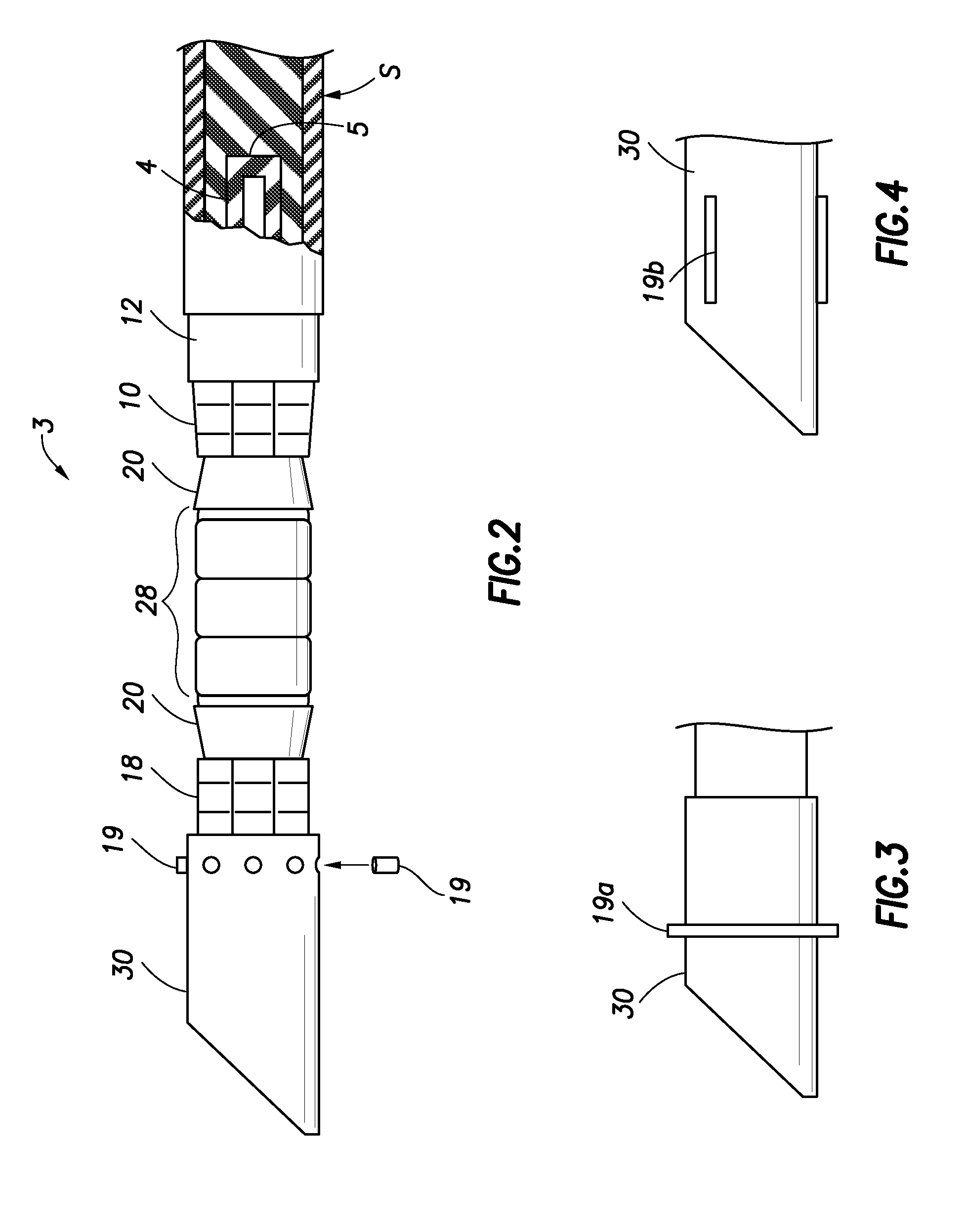

[0021]In the description that follows, like parts are marked throughout the specification and drawings with the same reference numerals, respectively. The drawings are not necessarily to scale and the proportions of certain parts have been exaggerated to better illustrate details and features of the invention. In the following description, the terms “upper,”“upward,”“lower,”“below,”“downhole” and the like as used herein shall mean in relation to the bottom or furthest extent of the surrounding wellbore even though the well or portions of it may be deviated or horizontal. The terms “inwardly” and “outwardly” are directions toward and away from, respectively, the geometric center of a referenced object. Where components of relatively well known designs are employed, their structure and operation will not be described in detail.

[0022]Referring now to FIGS. 1 and 2, representative downhole packer tool illustrated in the run state. The tool 2 has a hollow mandrel 4 extending through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com