Apparatus and method for engine backpressure reduction

a backpressure reduction and engine technology, applied in combination devices, exhaust treatment, liquid separation agents, etc., can solve the problems of significant reduction of engine power and increase fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

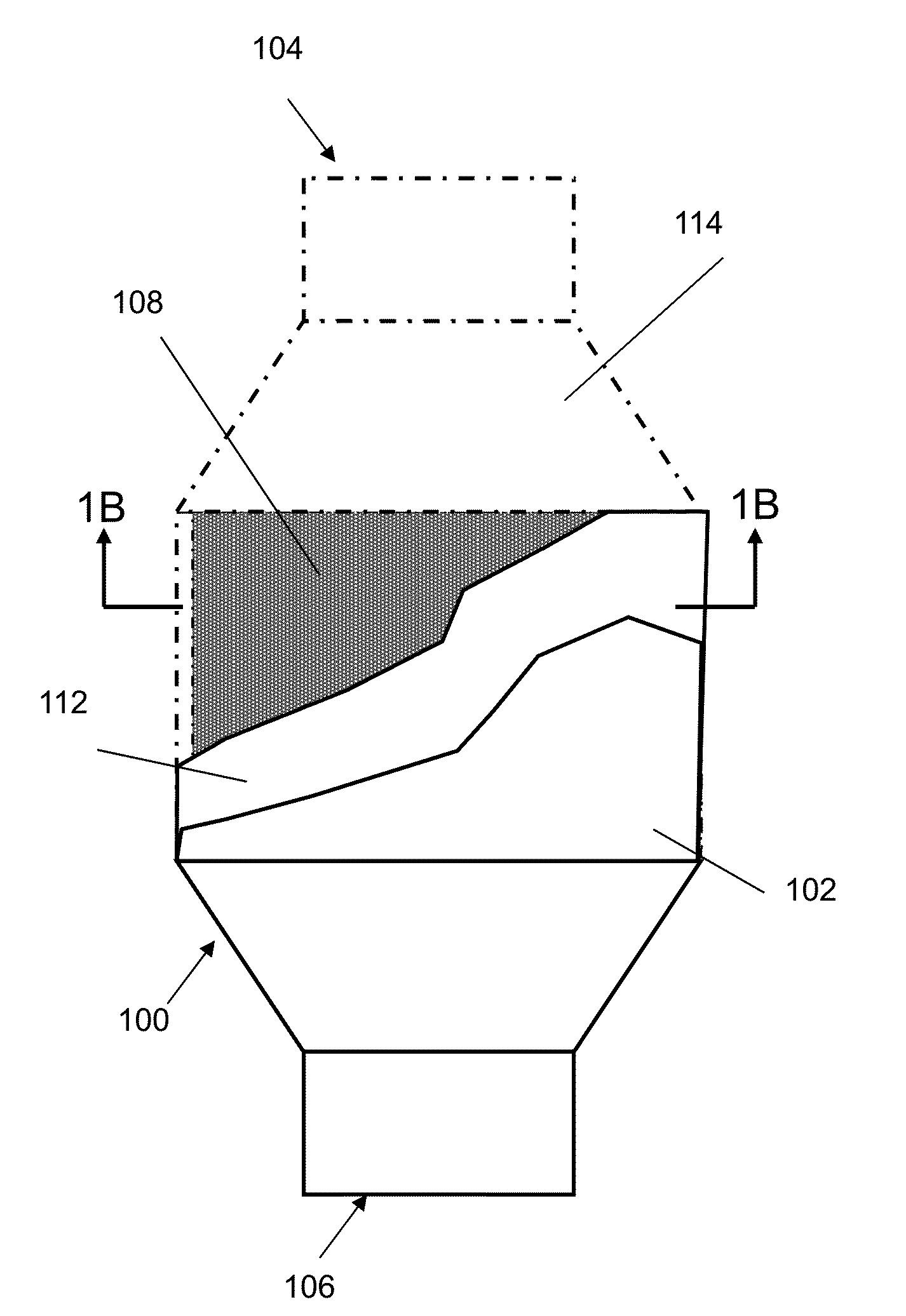

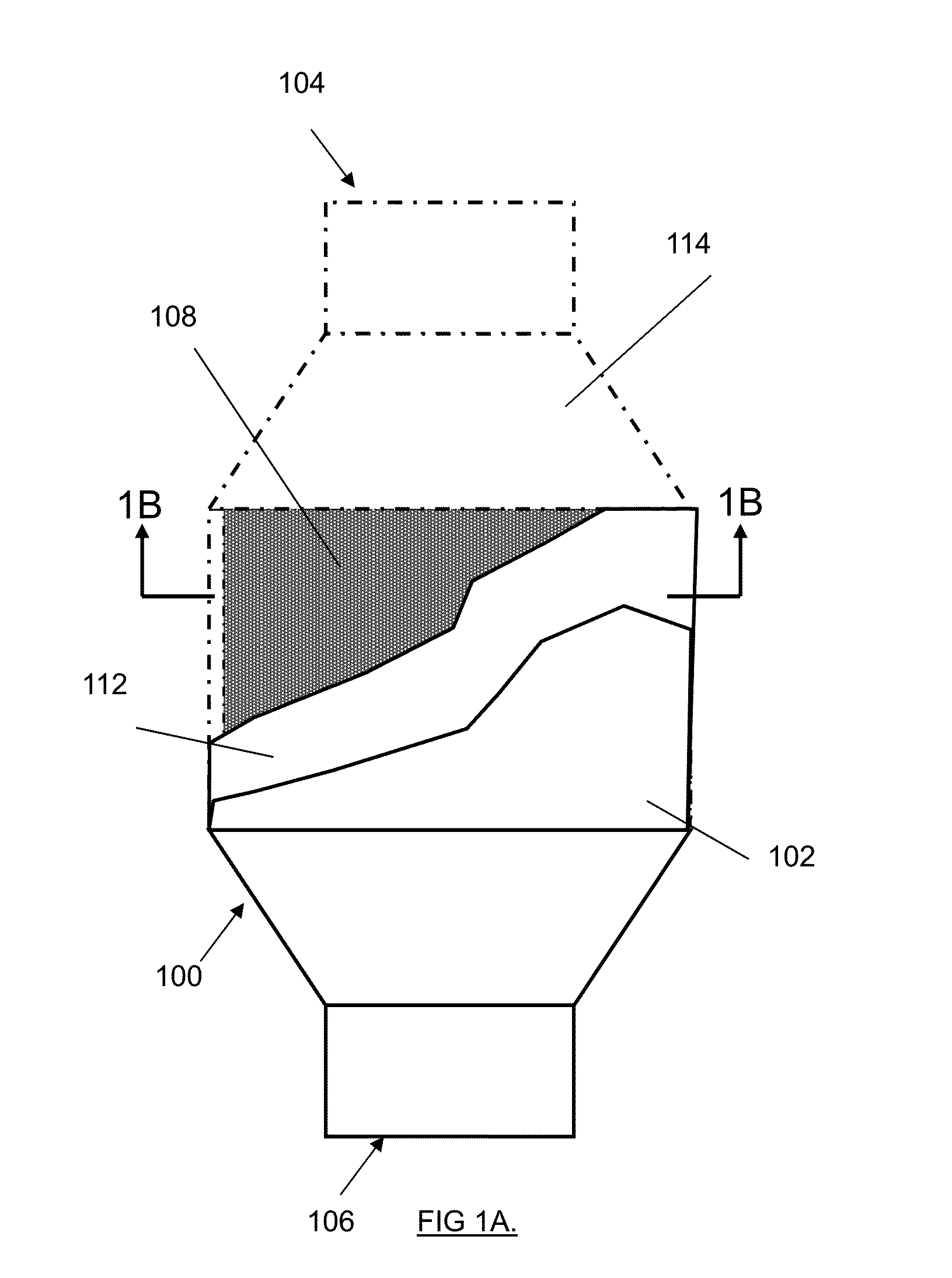

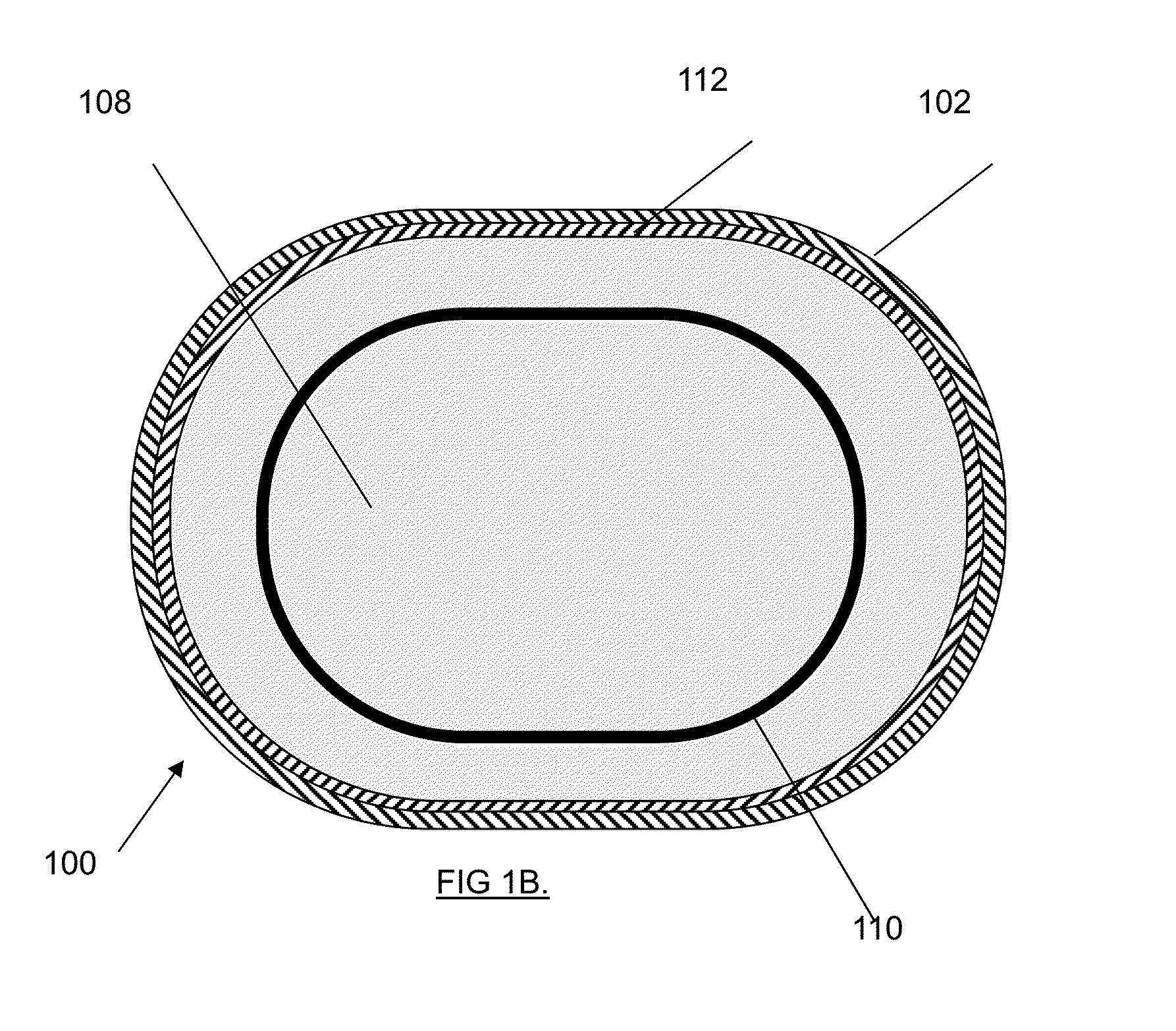

[0056]Exemplary embodiments of the invention are shown in FIGS. 1A through 2A.

[0057]FIGS. 1A, 1B and 2A show a catalytic converter apparatus 100 according to the first exemplary embodiment of the invention.

[0058]This apparatus 100 is for use in an exhaust system of an internal combustion engine (not shown) and will be seen to include a housing 102, a gas inlet 104, a gas outlet 106 spaced apart from the inlet 104 and an oval substrate element 108 that substantially fills the housing 102 in a radial or lateral dimension relative to an axis of gas flow from the inlet 104 to the outlet 106. The substrate element 108 contains an oval flow redistribution element 110 made out of an insulative material that thermally and physically separates the substrate into a central zone and a tubular outer zone surrounding the central zone. Each of the central zone and the outer zone is an extruded ceramic honeycomb coated with catalytic material and, but for the shapes and orientation to one another,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com