Dent Removing Apparatus

a technology for removing equipment and dents, which is applied in the direction of positive displacement liquid engines, pumps, machines/engines, etc., and can solve the problems of higher labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

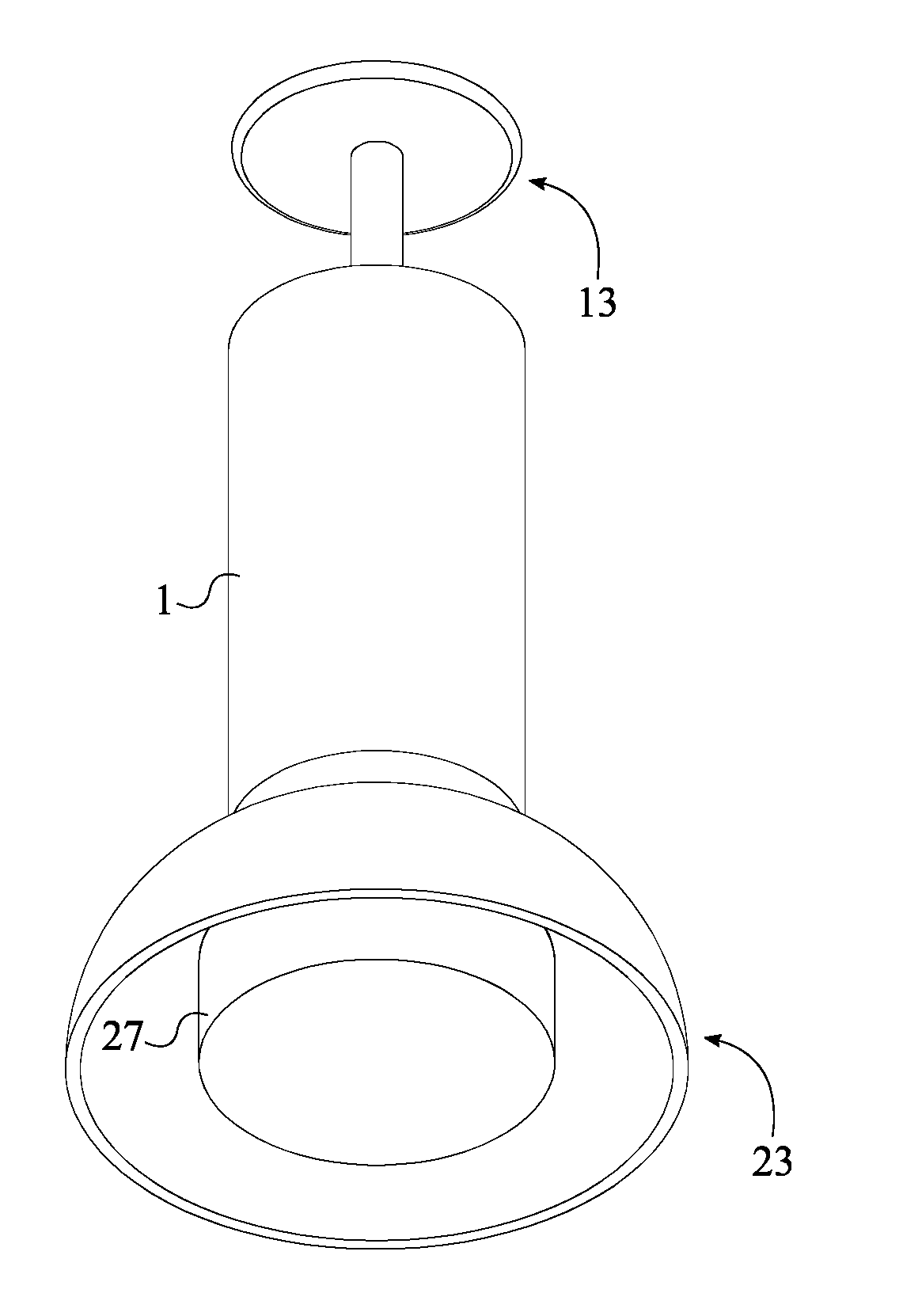

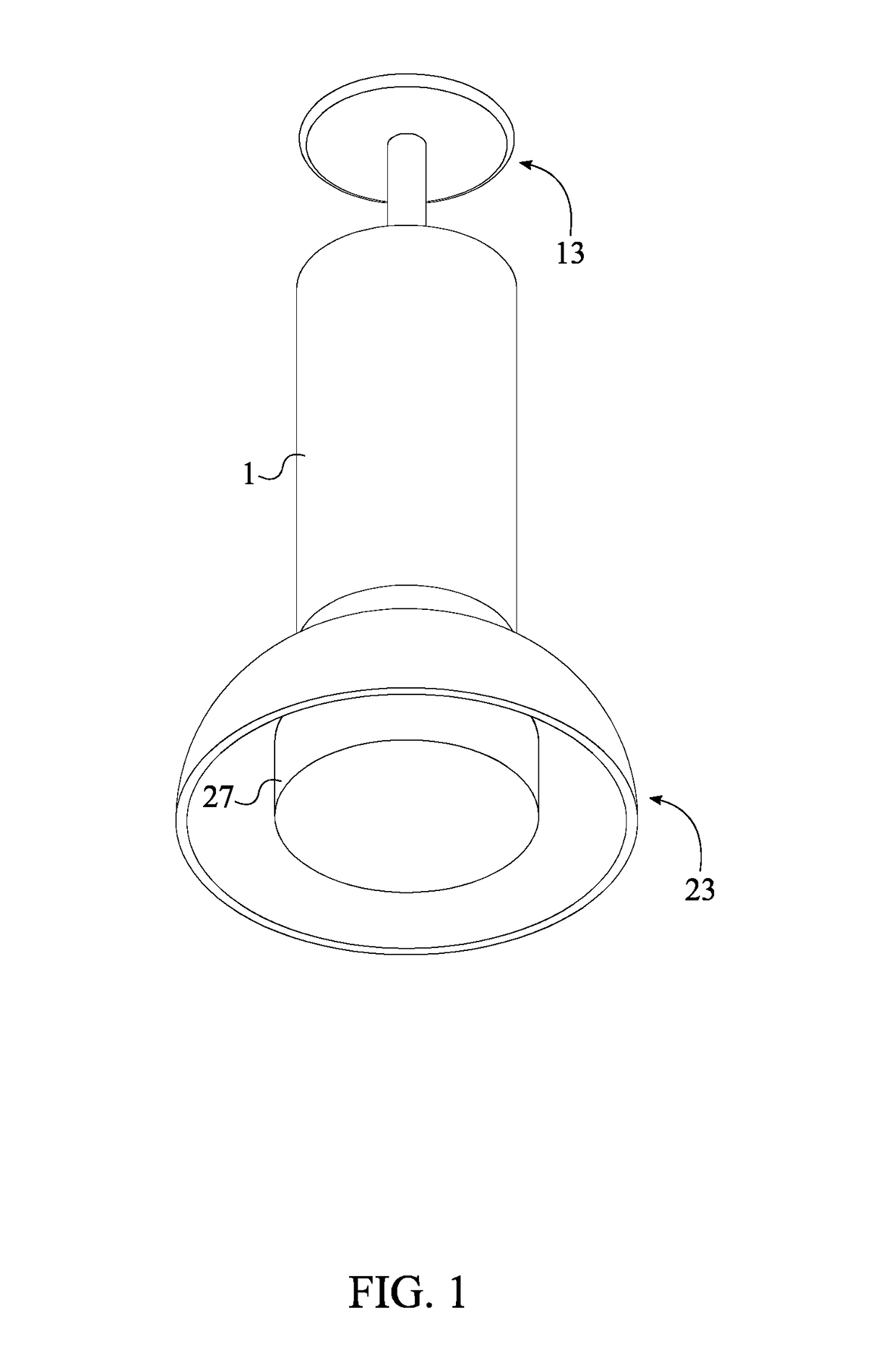

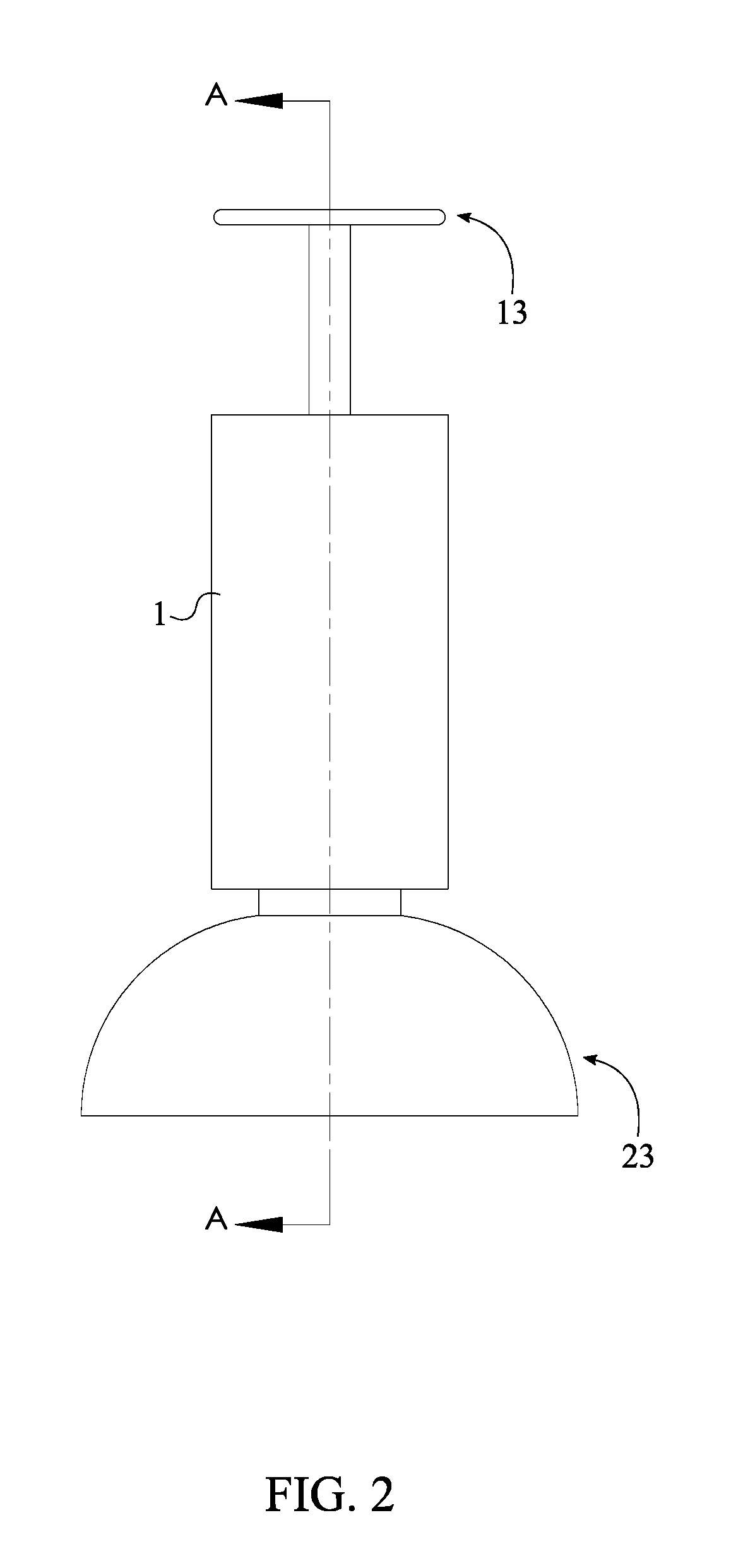

[0022]All illustrations of the drawings are for the purpose of describing selected versions of the present invention and are not intended to limit the scope of the present invention.

[0023]The present invention is a dent removing apparatus that uses piston 19 technology along with magnetism to remove dents, while cutting down labor time, physical labor, and completing a paint-less dent removal process. The present invention creates suction force along with magnetic force to pull or push dents even with the surrounding surface. The suction force can be generated with verity of different actuating methods as some of the components of the present invention changes according to the respective actuating method. More specifically, the present invention can be manually, pneumatically, and electrically actuated to complete a dent removal process. The present invention removes dinks and dents without having to puncture, cosmetically change, damage, or disassemble the object being worked on wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap