Blower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

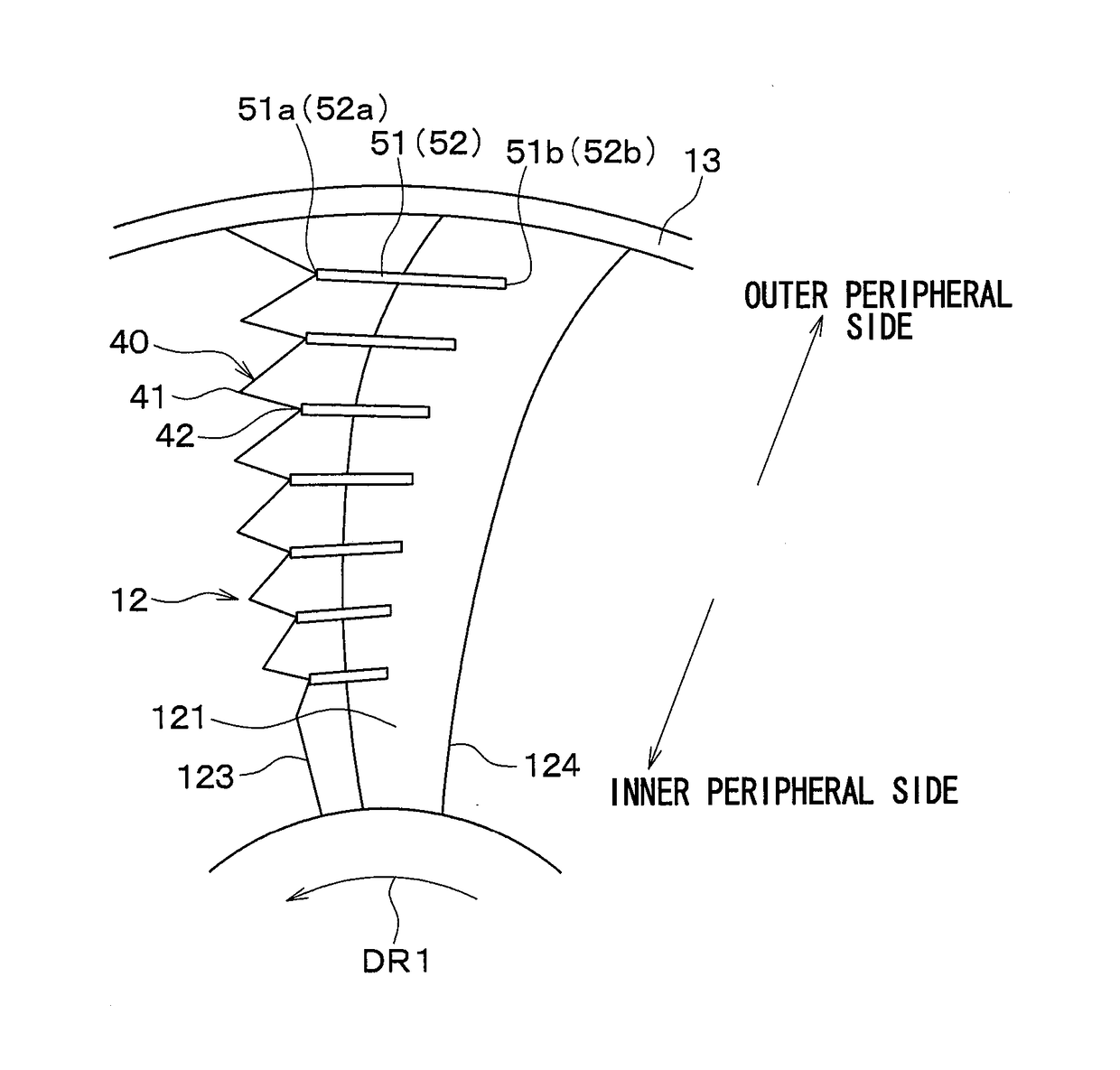

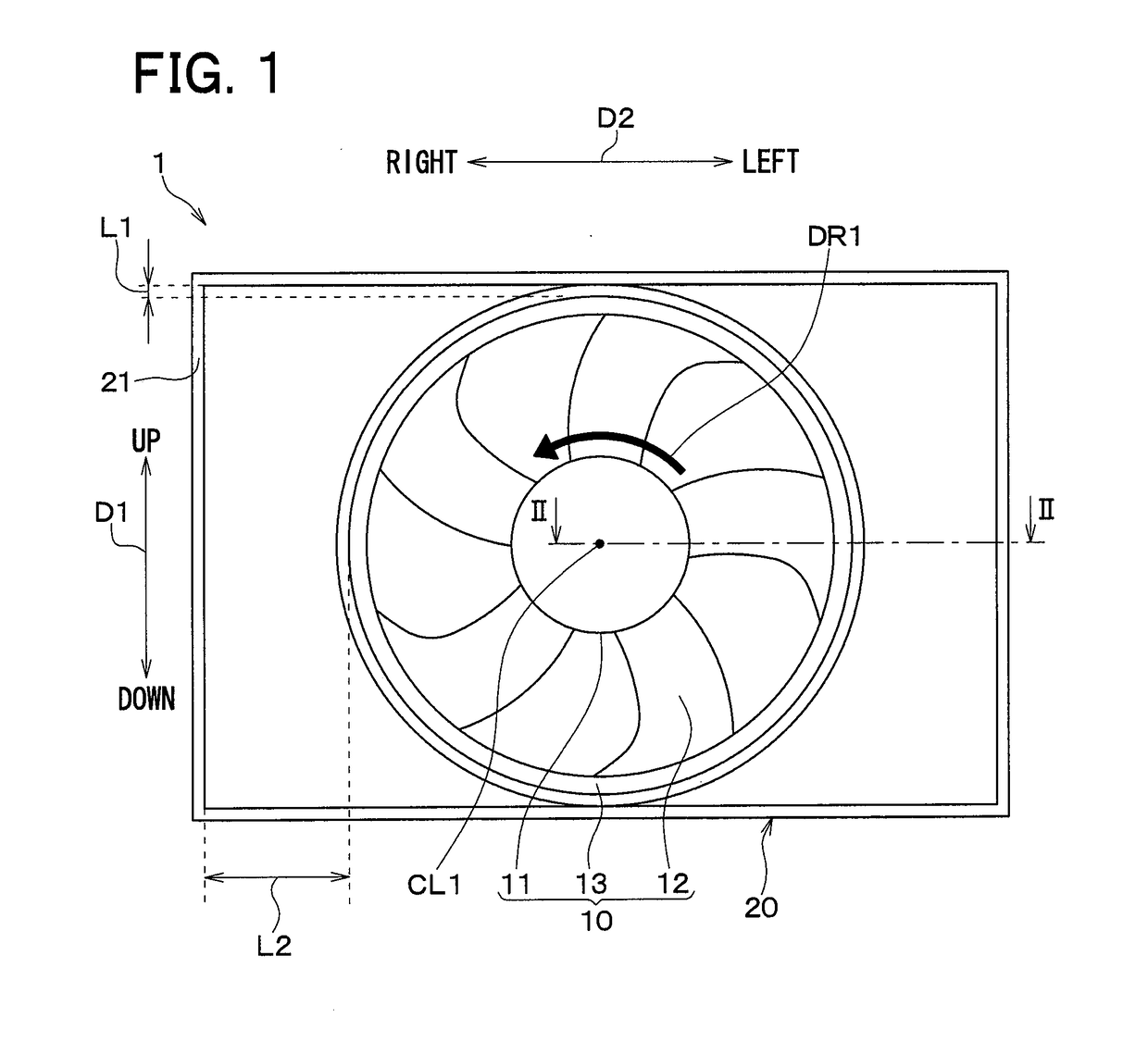

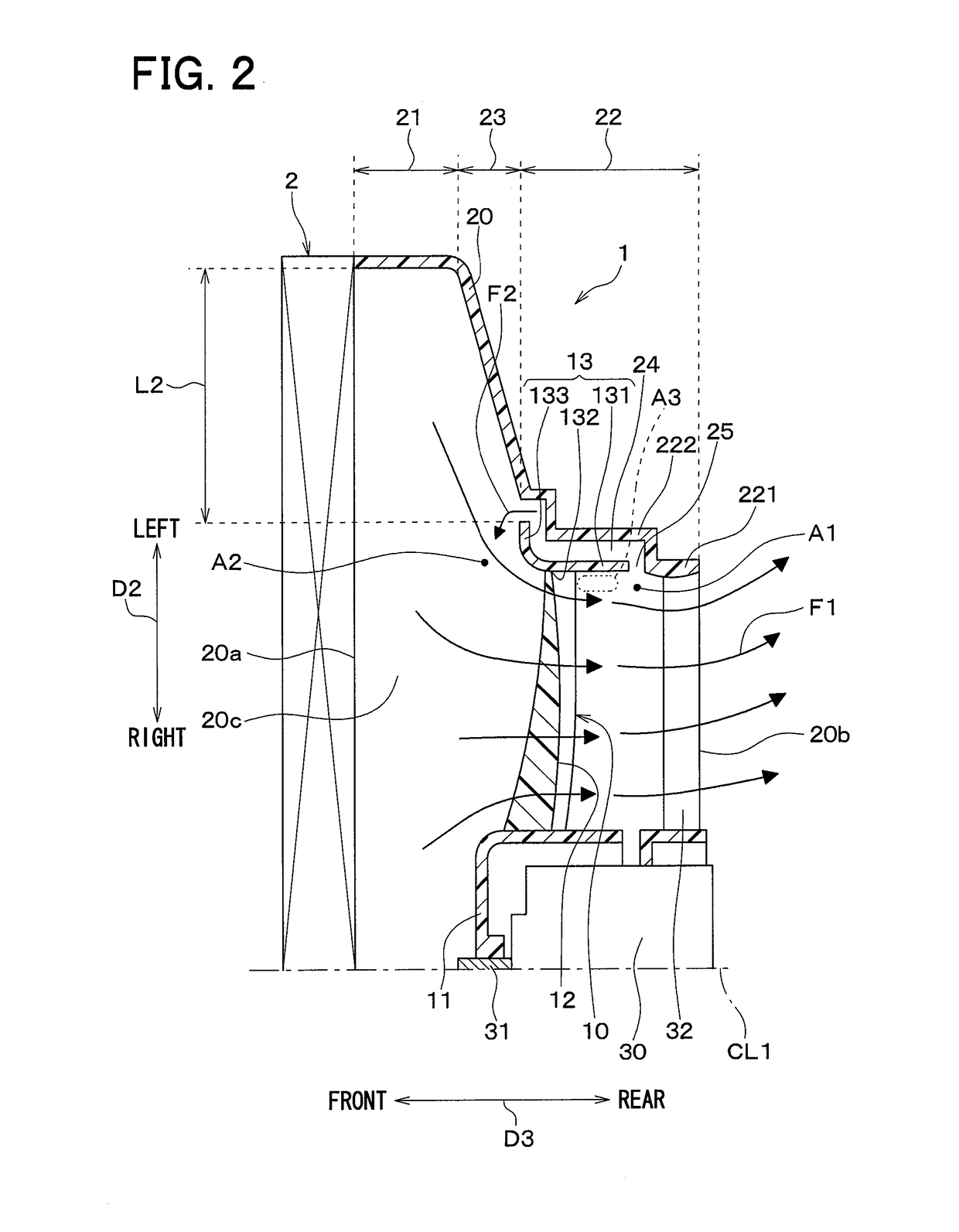

[0034]In the present embodiment, a description will be given using an example where a blower according to the present disclosure is applied to an axial blower 1 that blows air in an axial direction. First, referring to FIGS. 1, 2, the overall configuration of the axial blower 1 according to the present embodiment will be described. FIG. 1 is a front view of the axial blower 1 viewed from the upstream of air flow. In FIGS. 1, 2, a double-headed arrow D1 indicating an up-down direction, a double-headed arrow D2 indicating a left-right direction, and a double-headed arrow D3 indicating a front-rear direction are viewed when the axial blower 1 is mounted in a vehicle.

[0035]The axial blower 1 according to the present embodiment is a blower for a vehicle. Specifically, the axial blower 1 is mounted in a radiator 2 for a vehicle and supplies air to the radiator 2. The radiator 2 is a heat exchanger that cools coolant water through heat exchange between air and coolant water for an engine u...

second embodiment

[0075]The quantity of the ribs 51 in the present embodiment is smaller than in the first embodiment, but the other configurations in the present embodiment are identical to those in the first embodiment.

[0076]As shown in FIG. 9, in the present embodiment, ribs 51 are provided only for every other recessed portion 42 of recessed portions 42 of the serration 40. As just described, according to the present embodiment, a quantity of the recessed portions 42 and a quantity of the ribs 51 are not equal to each other such that the quantity of the ribs 51 is smaller than the quantity of recessed portions 42.

[0077]Even if the quantity of the ribs 51 is smaller than the quantity of recessed portions 42 as in the present embodiment, the effect of restricting separation of main flows F4 on the negative pressure surfaces 121, which is caused by downward flows F5 created by the serration 40, can be exhibited fully, compared to a case where ribs 51 are not provided on the negative pressure surface...

third embodiment

[0080]As with the second embodiment, the quantity of the ribs 51 in the present embodiment is smaller than that in the first embodiment. In addition, the quantity of the ribs 51 on the outer peripheral portion of the serration 40 is larger than the quantity of the ribs 51 on the outer peripheral portion of the serration 40. Other configurations in the present embodiment are identical to those in the first embodiment.

[0081]As shown in FIG. 10, in the present embodiment, ribs 51 are provided in recessed portions 42 located in the first to fifth positions from the outer peripheral side, other than recessed portions 42 located in the first and second positions from the inner peripheral side.

[0082]Here, the inner-peripheral-side portion of an axial fan 10 from the position of the radial center of the axial fan 10 in the area in which the serration 40 is formed is referred to as an inner peripheral portion of the serration 40. The outer-peripheral-side portion of the axial fan 10 from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com