Treatment apparatus for treating a surface of a body

a treatment apparatus and body technology, applied in the direction of electric devices, basic electric elements, semiconductor/solid-state device manufacturing, etc., can solve the problems of ring chambers having to be moved, apparatus have considerable disadvantages, and the corresponding treatment steps cannot be carried out in a closed environment, so as to achieve simple and reliable exchange, flexible and simple in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

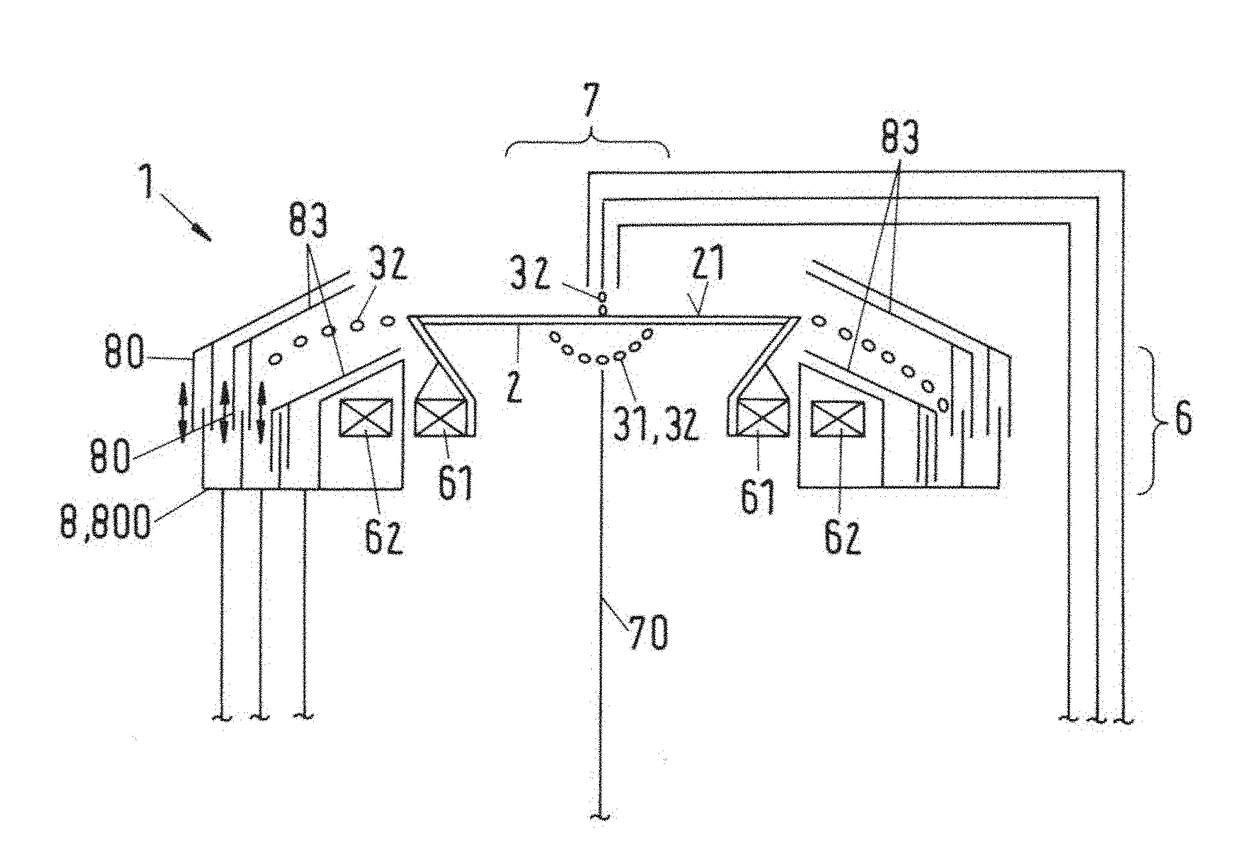

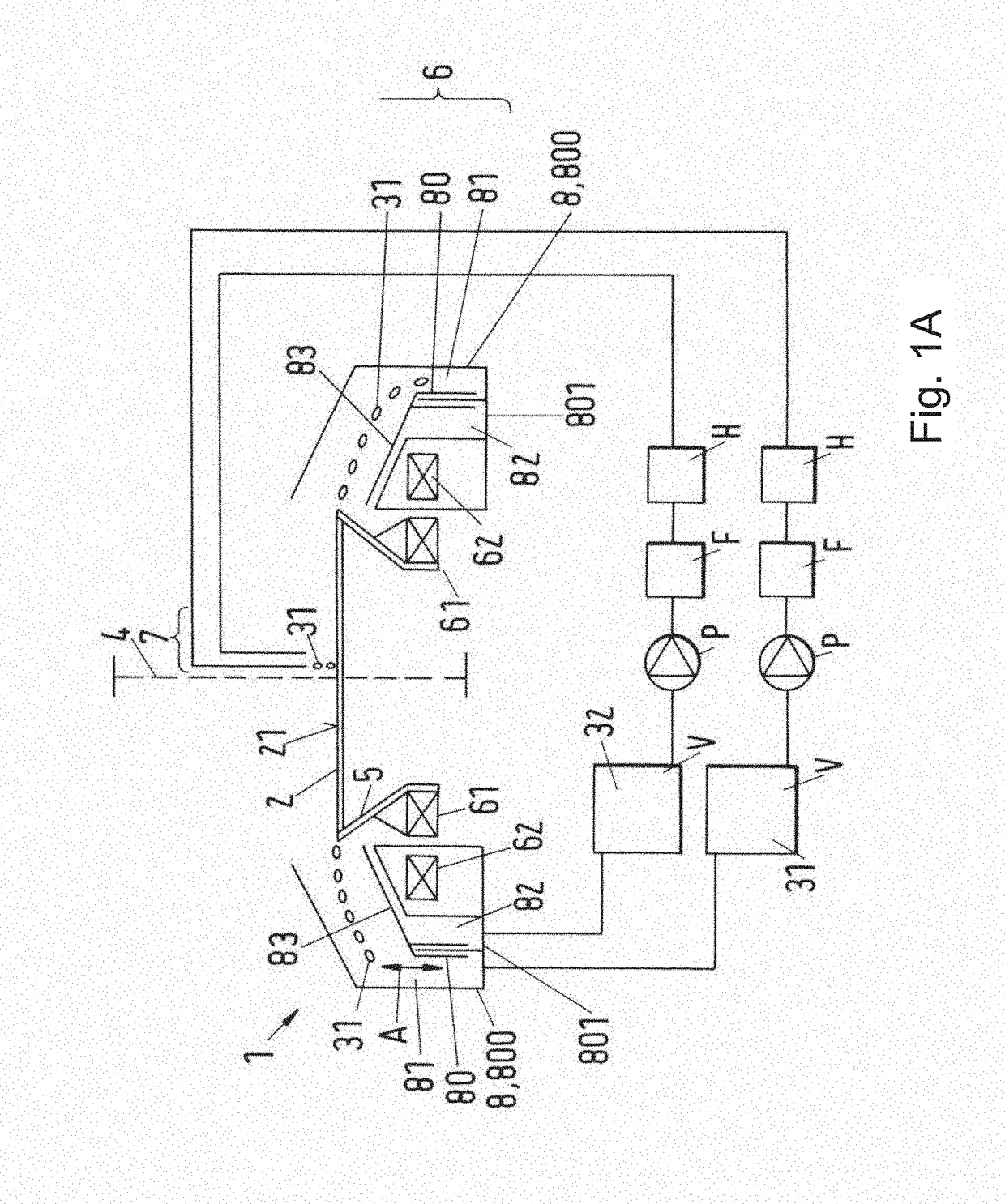

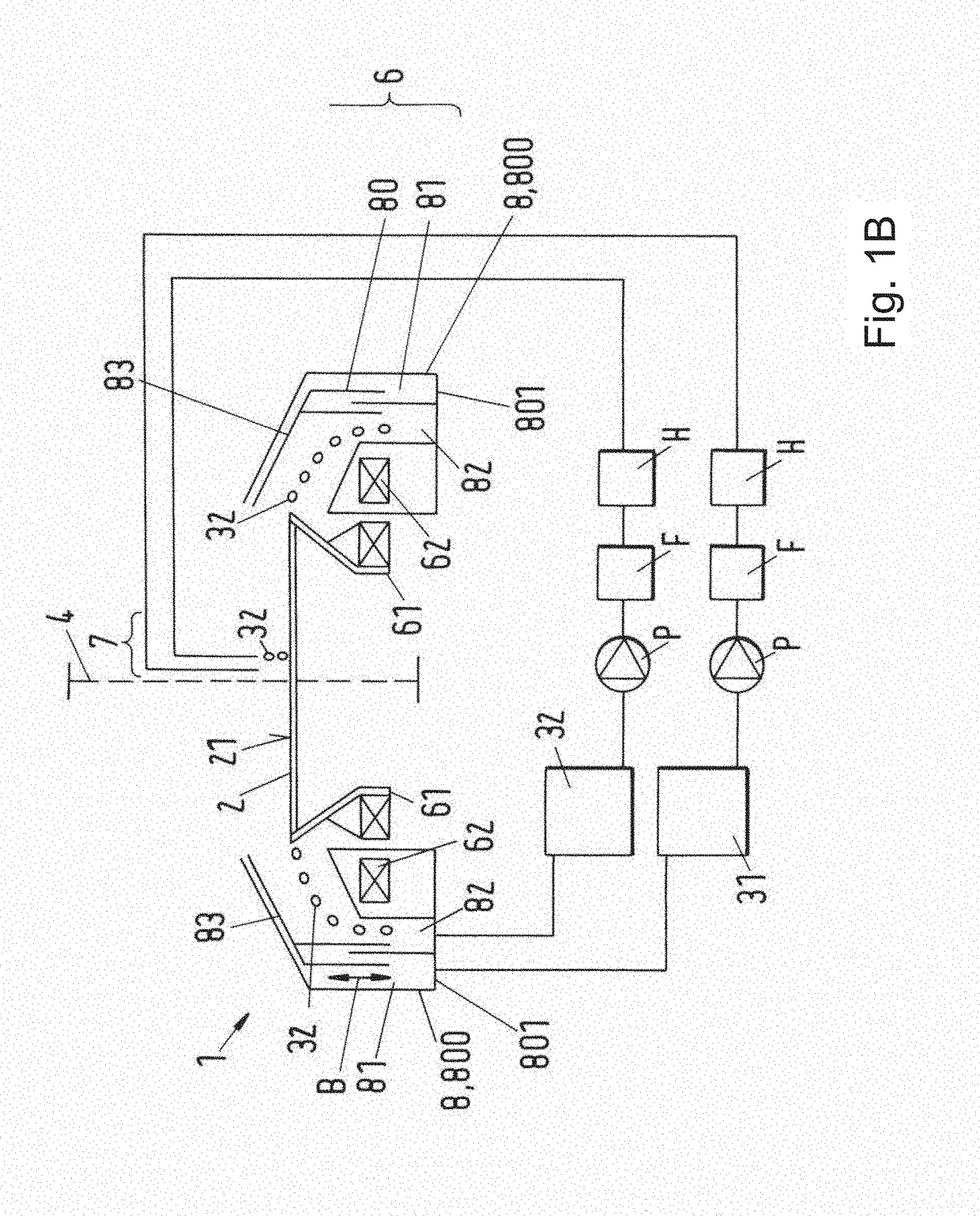

[0057]FIGS. 1A and 1B show in a schematic representation a treatment apparatus 1 in accordance with the invention having a bearingless motor 6. In this respect, FIG. 1A differs from FIG. 1B only in that in accordance with FIG. 1A the first treatment medium 32 is led into the first chamber 81 in a first workstep, whereas in FIG. 1A the first method step is already concluded and a second method step is shown in which an outflow of the second treatment medium 32 into the second chamber 82 is just being shown.

[0058]The specific embodiment of a treatment apparatus 1 in accordance with the invention for treating a surface 21 of a body 2 with a first treatment medium 31 and a second treatment medium 32 includes a holding device 5 rotatable about an axis of rotation 4 for receiving and holding the body 2 which in the present example is a wafer 2 for manufacturing microelectronic components. The treatment device 1 further includes a rotor 61 of the rotary drive 6, said rotor being rotational...

second embodiment

[0064]It is self-explanatory in this respect that the invention is not restricted to treatment apparatus 1 with which only two different treatment media 31, 32 can be separately collected. A second embodiment in accordance with FIG. 1A and FIG. 1B respectively having three chambers is thus shown schematically with reference to FIG. 2 with which three different treatment media can be separately collected. The skilled person immediately understands how the treatment chamber 1 is to be modified so that four or even more different treatment media can also be separately collected.

[0065]It is also possible, as already mentioned further above, that the wafer 2 has the treatment medium 31, 32 applied from both sides and is processed on both sides. This is possible in accordance with FIG. 2A in that an annular rotor 61 is used, wherein a further supply device 70, in addition to the supply device 7 which is above the wafer 2, is arranged beneath the wafer 2 on the oppositely disposed side. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com