Length-adjustable film applicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

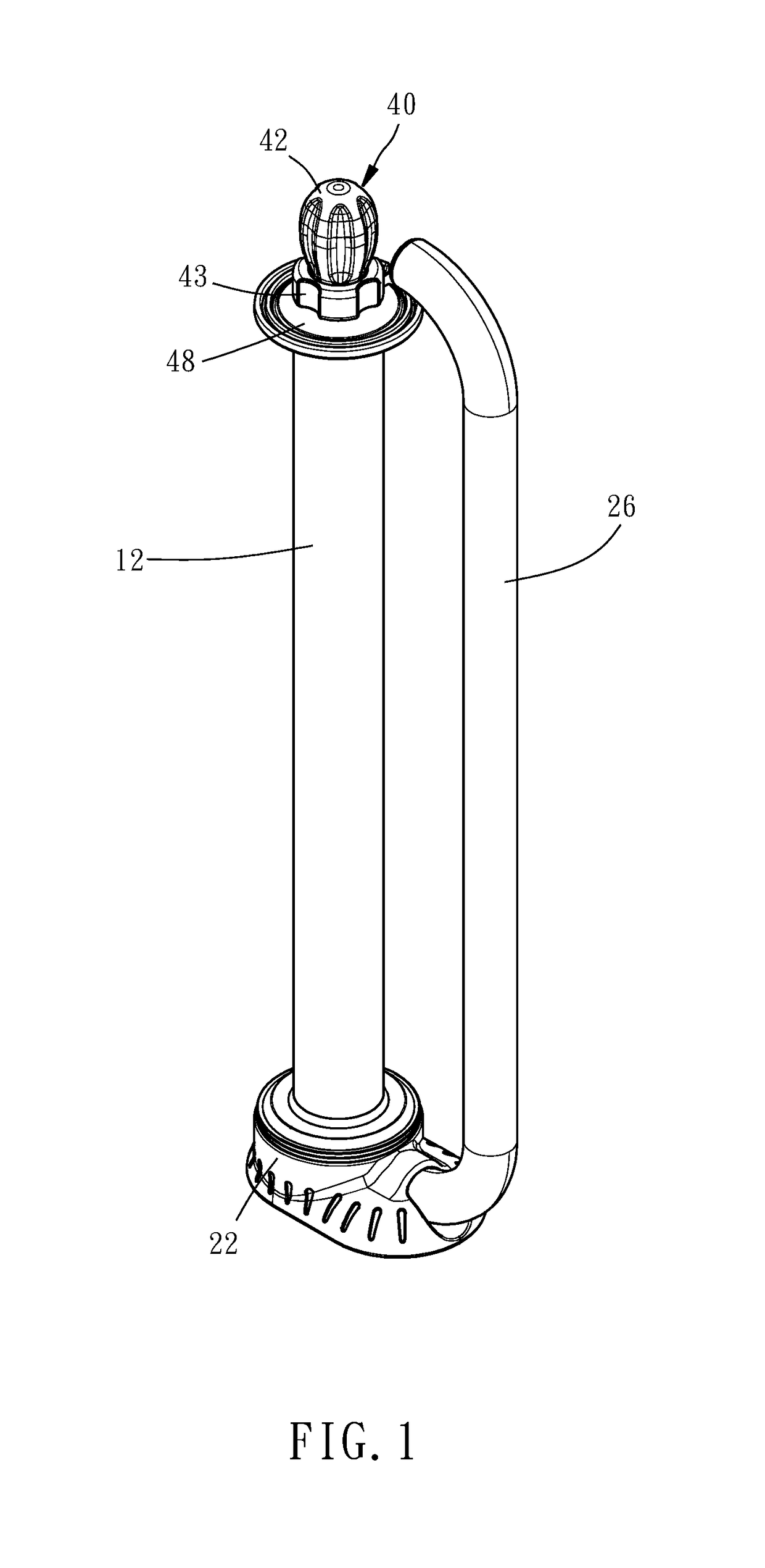

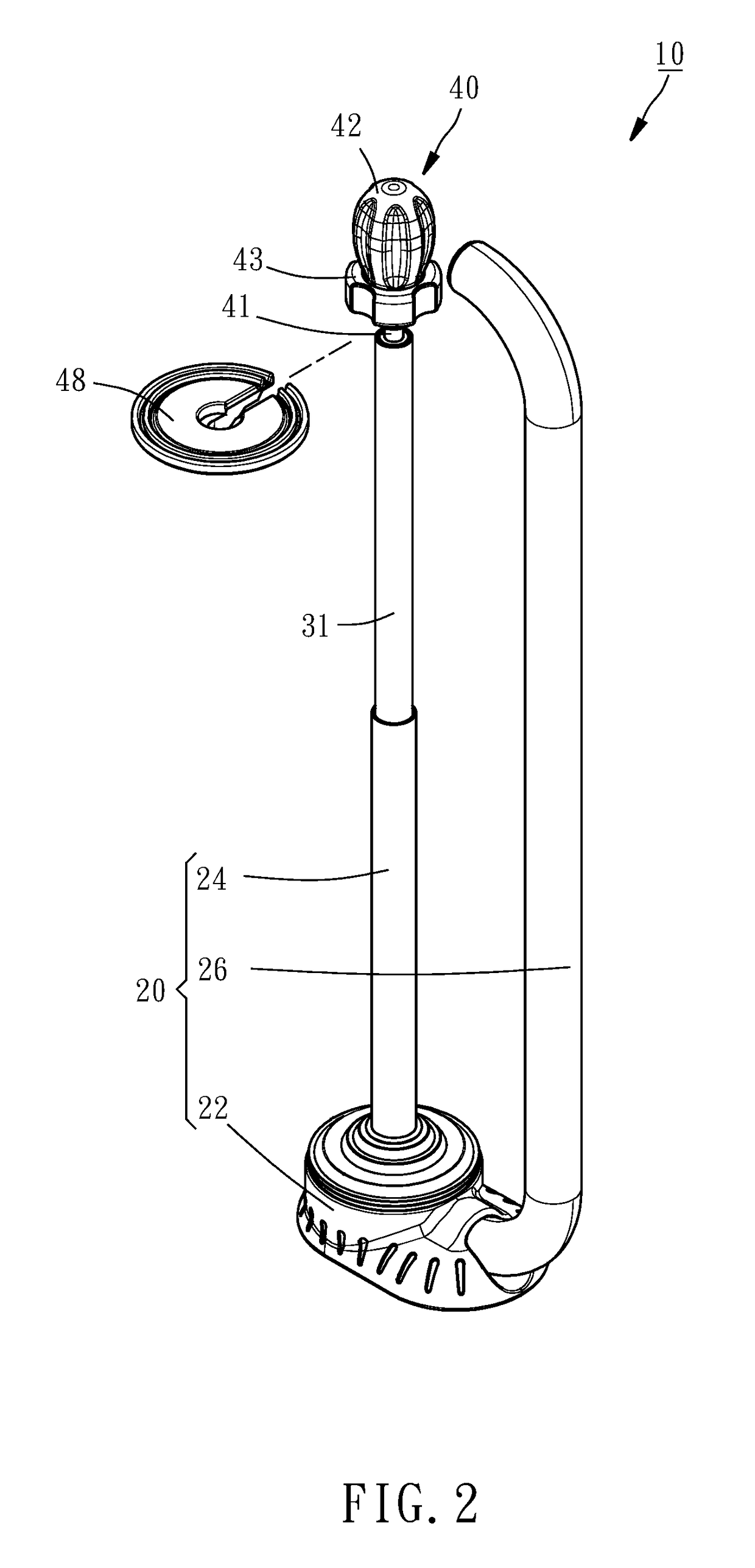

[0017]Referring to FIG. 1 to FIG. 3, the film applicator 10 according to an embodiment of the present invention includes a stand 20, an inner tube assembly 30, and an adjustment assembly 40.

[0018]The stand 20 has a supporting base 22, an outer tube 24, and a handle 26. The supporting base 22 is configured to support the bottom end of a roll of film 12. The outer tube 24 has one end fixed at the top side of the supporting base 22 and is so configured that the roll of film 12 can be mounted around the outer tube 24. The handle 26 has one end fixed at a peripheral portion of the supporting base 22 and is configured to be held with both hands.

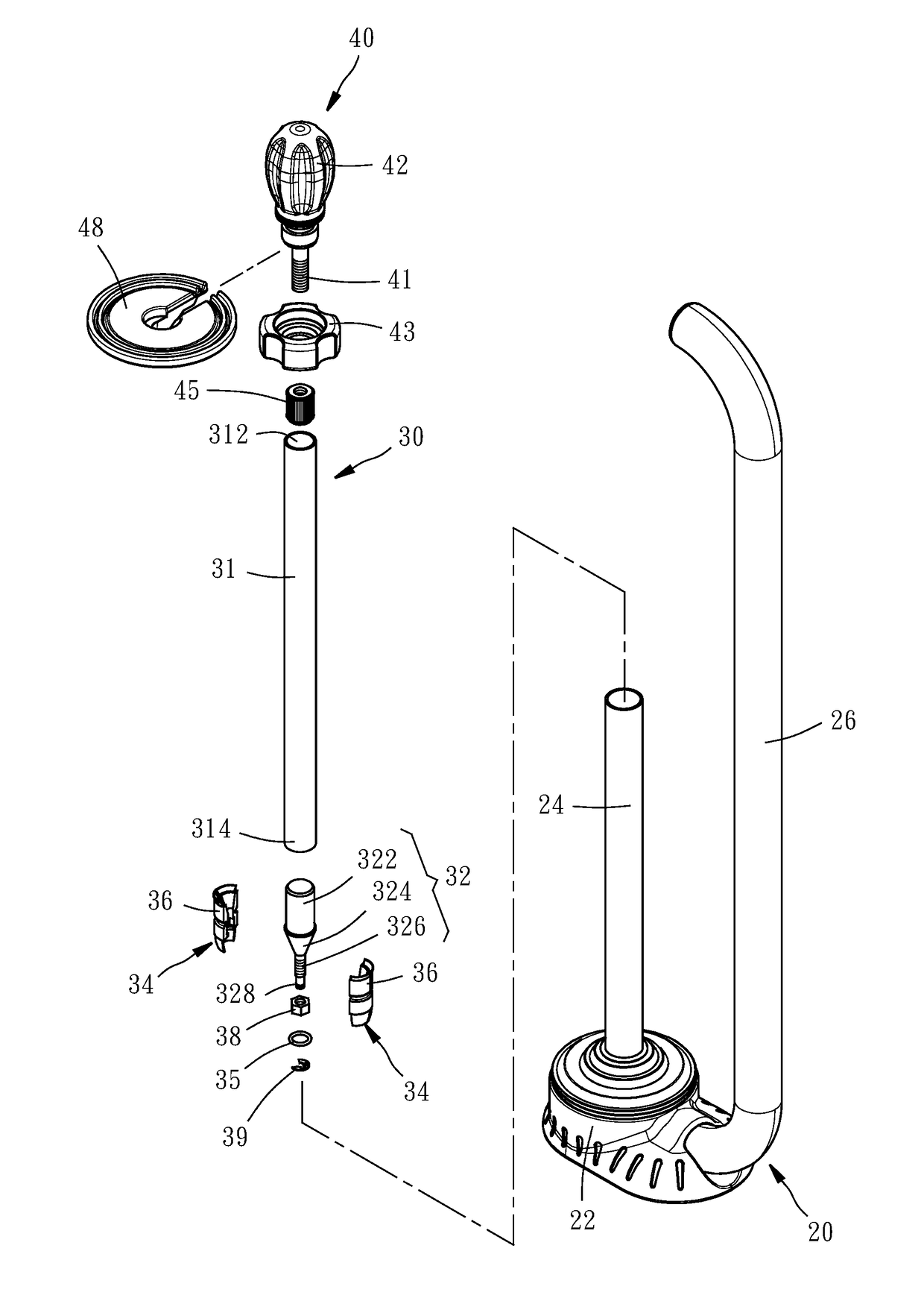

[0019]As shown in FIG. 3 to FIG. 5, the inner tube assembly 30 has an inner tube 31, a positioning column 32, and a positioning sleeve 33. The inner tube 31 is provided in the outer tube 24 of the stand 20 in a rotatable and axially displaceable manner and is so configured that the roll of film 12 can be mounted around the inner tube 31, too. The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap