Lubricating compositions for preventing or reducing pre-ignition in an engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The percentages given below correspond to weight percentages of active material.

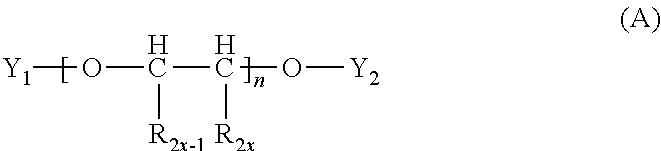

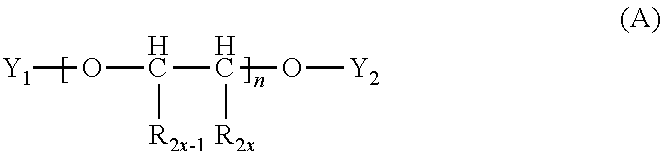

[0041]The lubricating composition used in the invention comprises at least one polyalkylene glycol (PAG) obtained by polymerisation or copolymerisation of alkylene oxides having 3 to 8 carbon atoms, including at least one butylene oxide.

[0042]The PAG may be a polymer or copolymer (statistical or block) of alkylene oxides, that can particularly be prepared following methods described in application WO 2009 / 134716, page 2 line 26 to page 4 line 12, for example via attack by an alcohol initiator on the epoxy bond of an alkylene oxide and propagation of the reaction.

[0043]In one embodiment of the invention, the PAG is obtained by polymerisation or copolymerisation of alkylene oxides having 3 to 8 carbon atoms, including at least one butylene oxide, particularly selected from among 1,2-butylene oxide or 2,3-butylene oxide, preferably 1,2-butylene oxide.

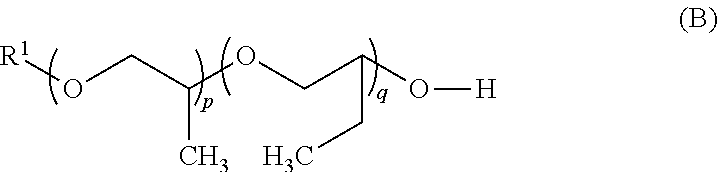

[0044]Among these PAGs, the copolymers of butylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com