Extruded shape inlaid into a concrete mass, for the construction of balcony railings and dividing panels

a concrete mass and extruded technology, applied in the direction of handrails, balconies, building components, etc., can solve the problems of increasing the total cost of fittings, safety problems, aesthetics, termination and technical inconveniences, and increasing the labor and component costs of securing said frames and plates to frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

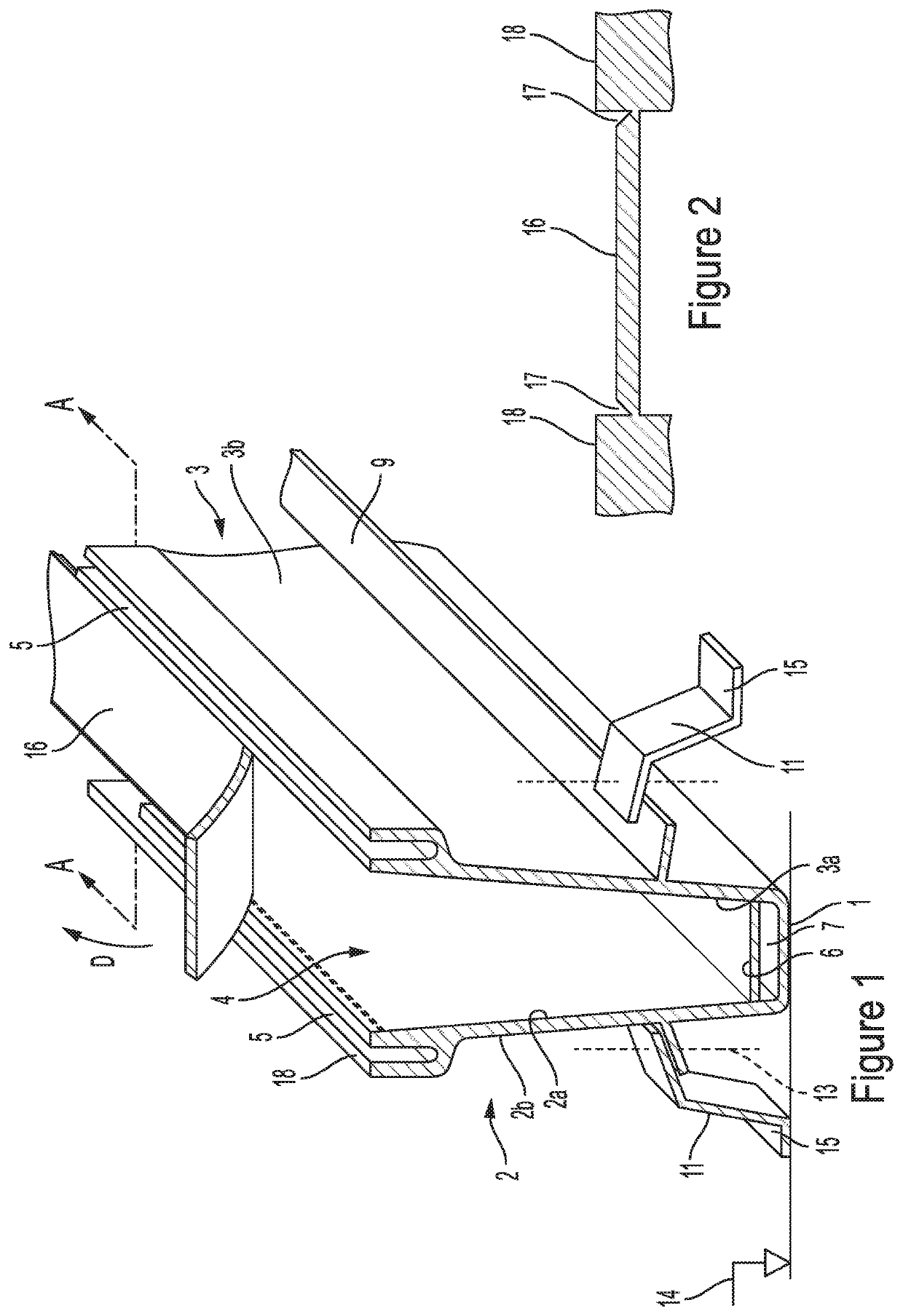

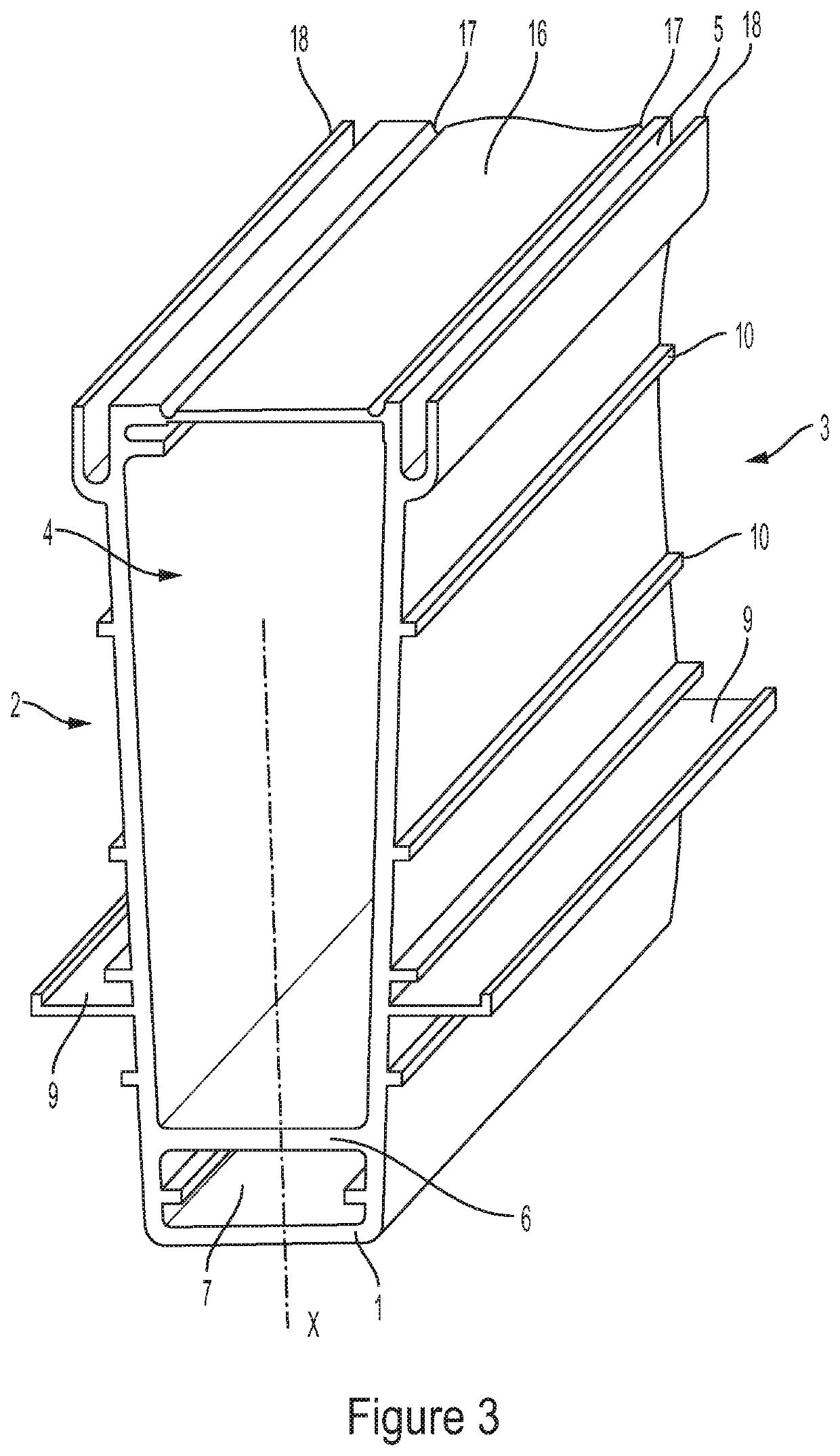

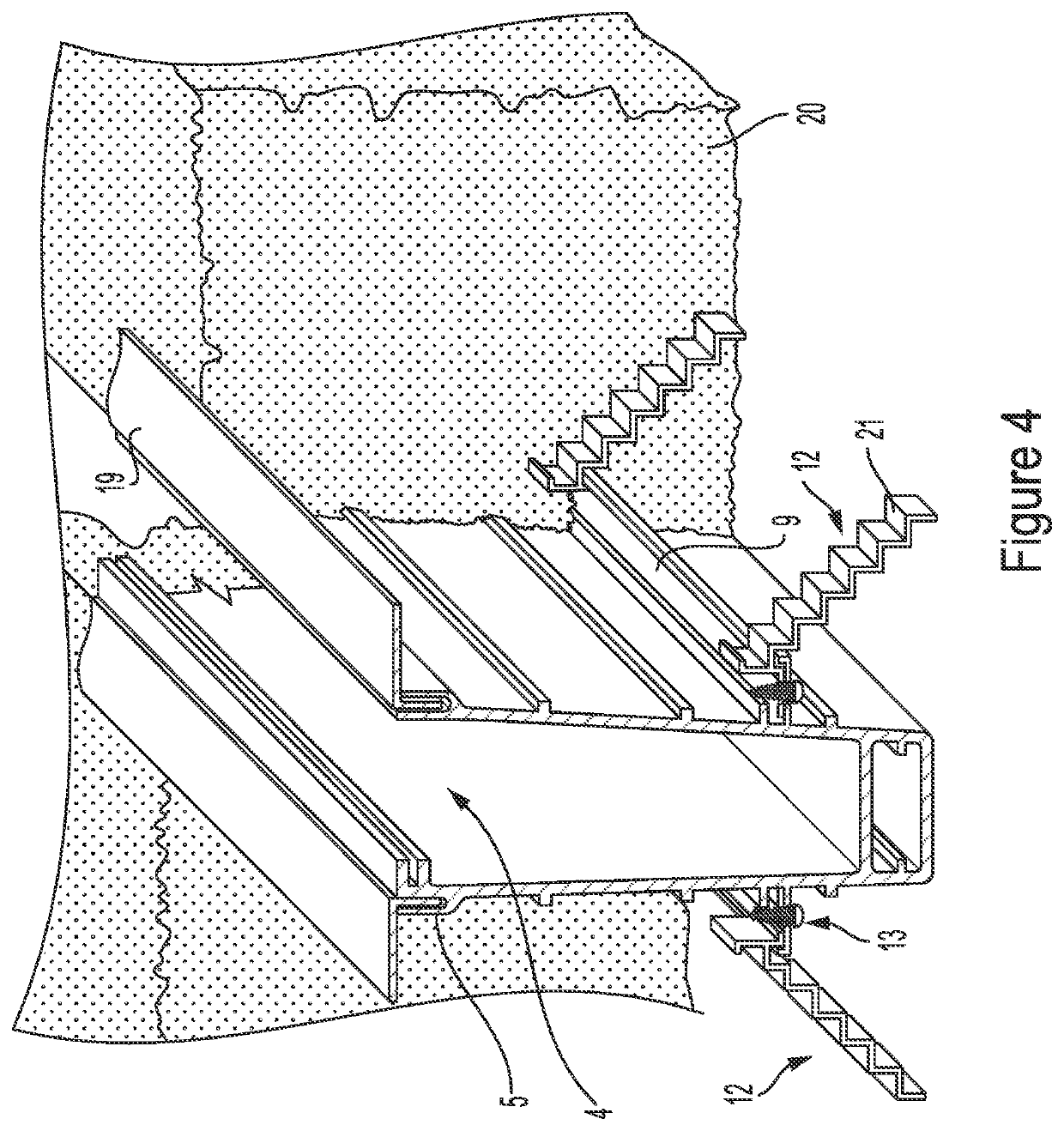

[0031]For the purposes of exemplifying the preferred embodiments of the present invention, attached are the following drawings illustrating same, in support of the below given description thereof, being these embodiment interpreted as one of the many possible constructions of the invention, hence it is not appropriate to assign any limiting value thereto, including within the scope of protection of the invention the possible equivalent means to those illustrated, while being determined the scope of the present invention by the attached claims in the corresponding Claims chapter. Likewise, in these Figures, the same references identify equal and / or equivalent means.

[0032]The profiled shape shown in FIG. 1 is based on a known rectilinear and constant cross section shape, consisting in a bottom (1) and side walls (2, 3). Preferably this bottom and side walls are monolithic, product of the extrusion in a non-ferrous material through a matrix. Each side wall (2, 3) is preferably slightly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap