Supporting element for tobacco industry machine

a technology of supporting elements and tobacco industry, which is applied in the direction of metal working apparatus, tobacco, food science, etc., can solve the problems of unfulfilled adhesives, and achieve the effect of improving cutting quality and increasing tobacco quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

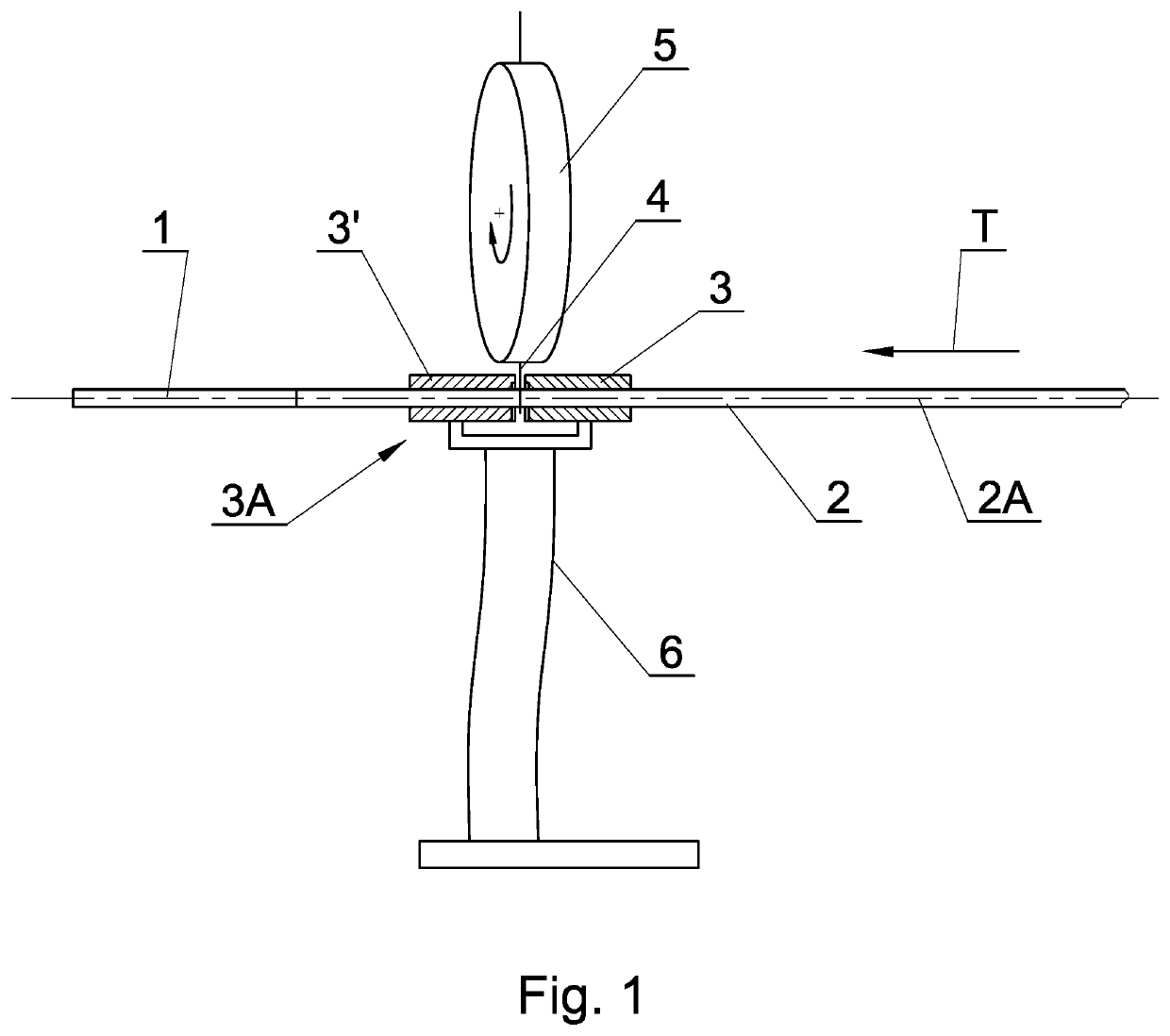

[0023]FIG. 1 shows a fragment of a machine for manufacturing rods 1 of a continuous rod 2 moving axially and lengthwise. The continuous rod 2 is conveyed in the direction T shown with the arrow and moves through cutting sleeves 3, 3′ which are mechanically connected with each other and constitute a supporting unit 3A designed to support the continuous rod 2 during cutting. The cutting sleeves 3, 3′ may be identical. The sleeves 3, 3′ may be mounted to flexible springy elements 6 or in any other way typical for rod manufacturing machines of the tobacco industry. A drive mechanism designed to put the sleeves 3, 3′ into reciprocating motion in the direction of movement of the continuous rod 2 is not shown in the drawing. The cutting sleeves and other elements fulfilling the same function will be hereinafter referred to as supporting elements.

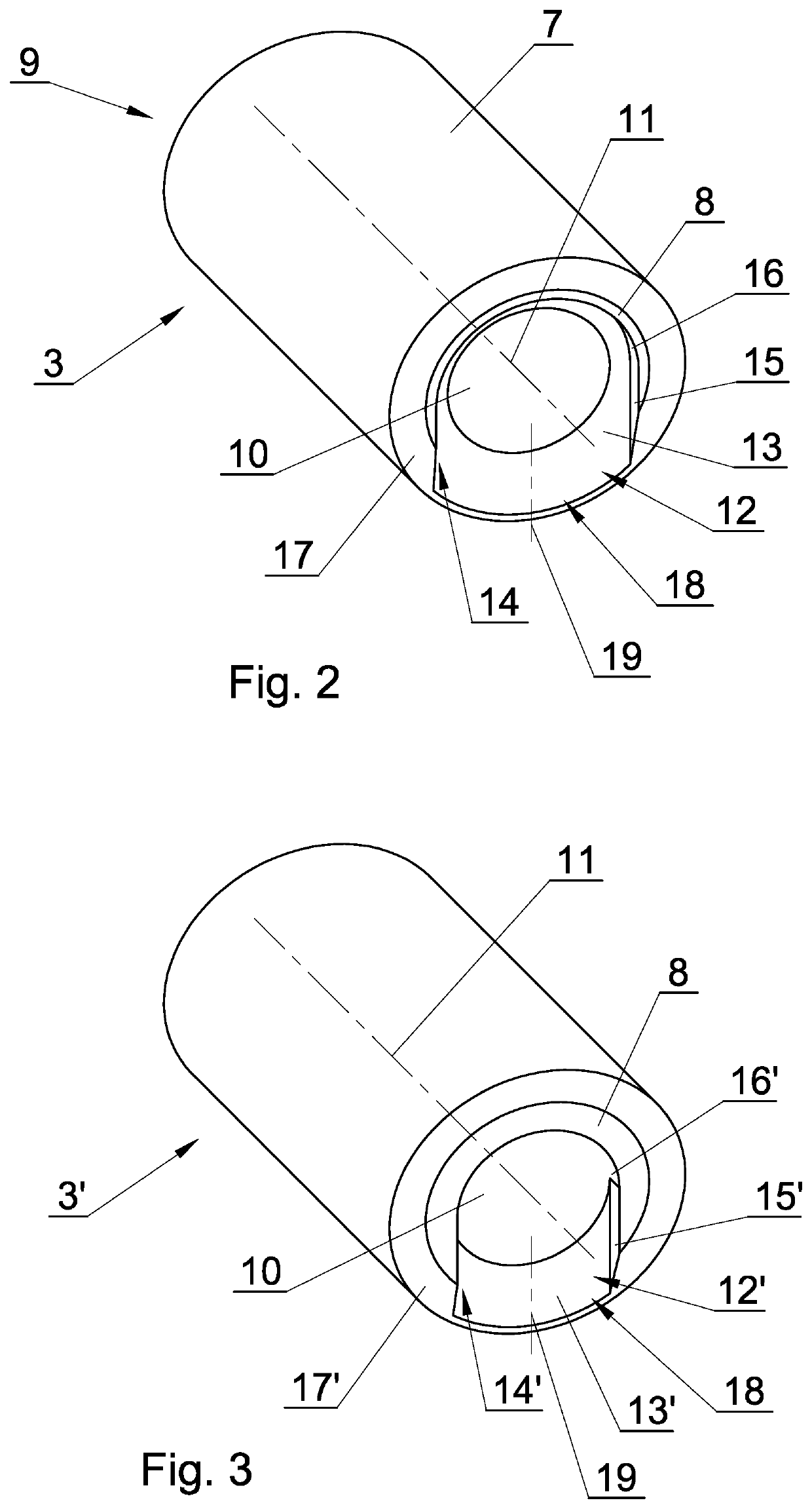

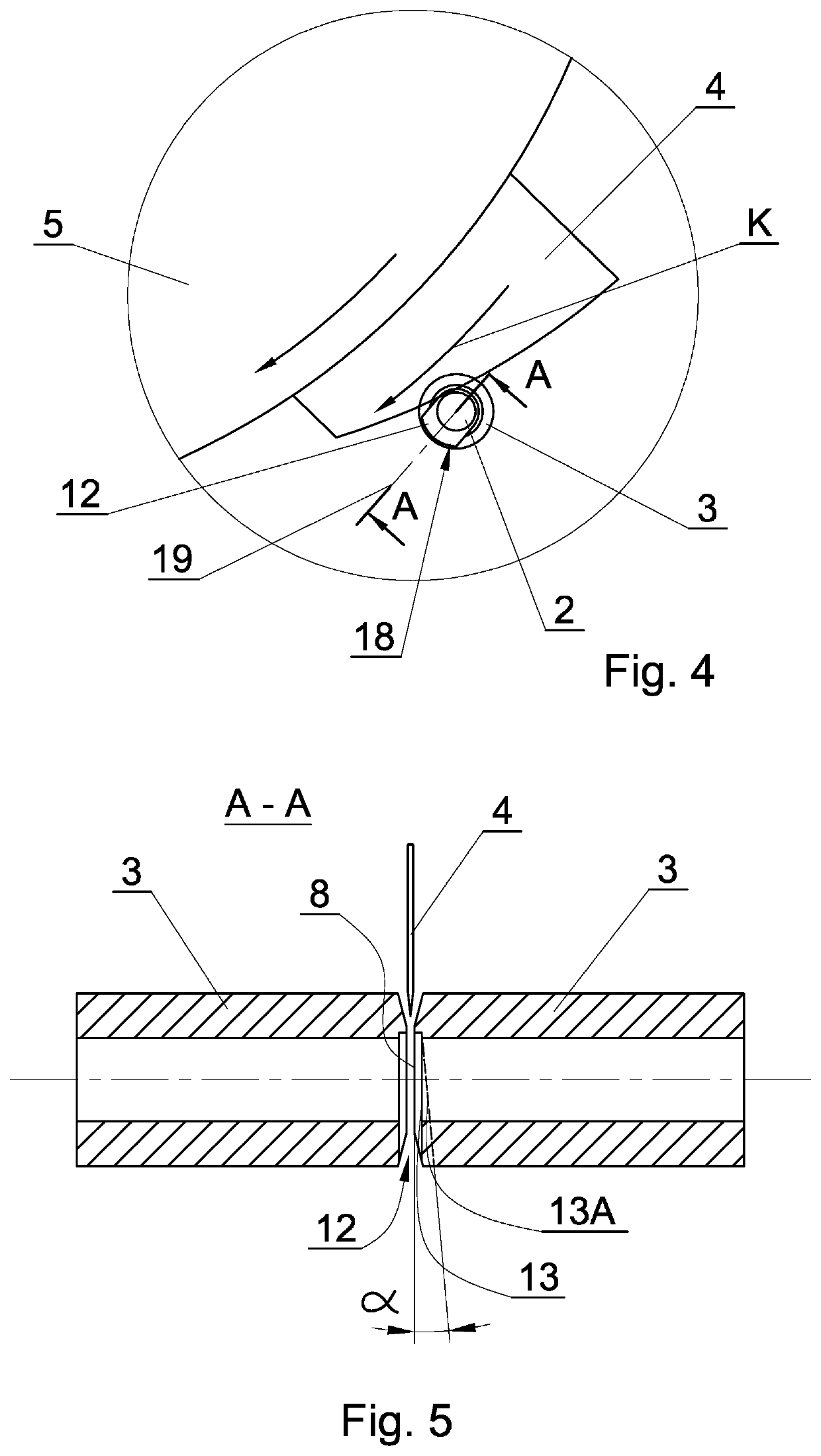

[0024]The supporting element 3 shown in FIG. 2 has a cylindrical outer surface 7 and two front surfaces 8 and 9. The supporting element 3 has a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com