Rotary latch device

a latch device and rotary technology, applied in the direction of flanged joints, pipe laying and repair, borehole/well accessories, etc., can solve the problems of affecting affecting the safety of personnel, and requiring personnel to be exposed to potentially hazardous conditions. , to achieve the effect of simplifying the connection and disconnection of the first mandrel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

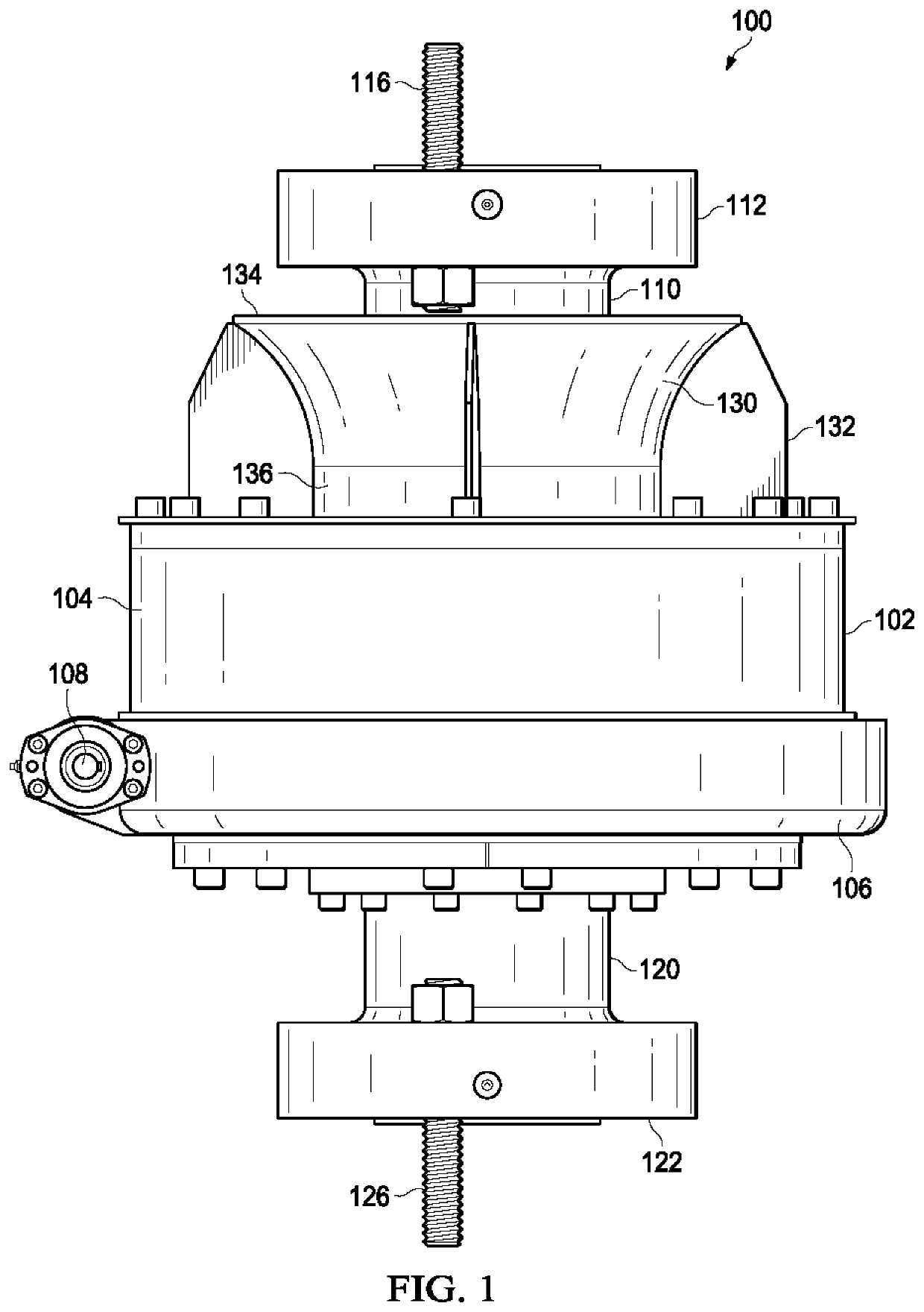

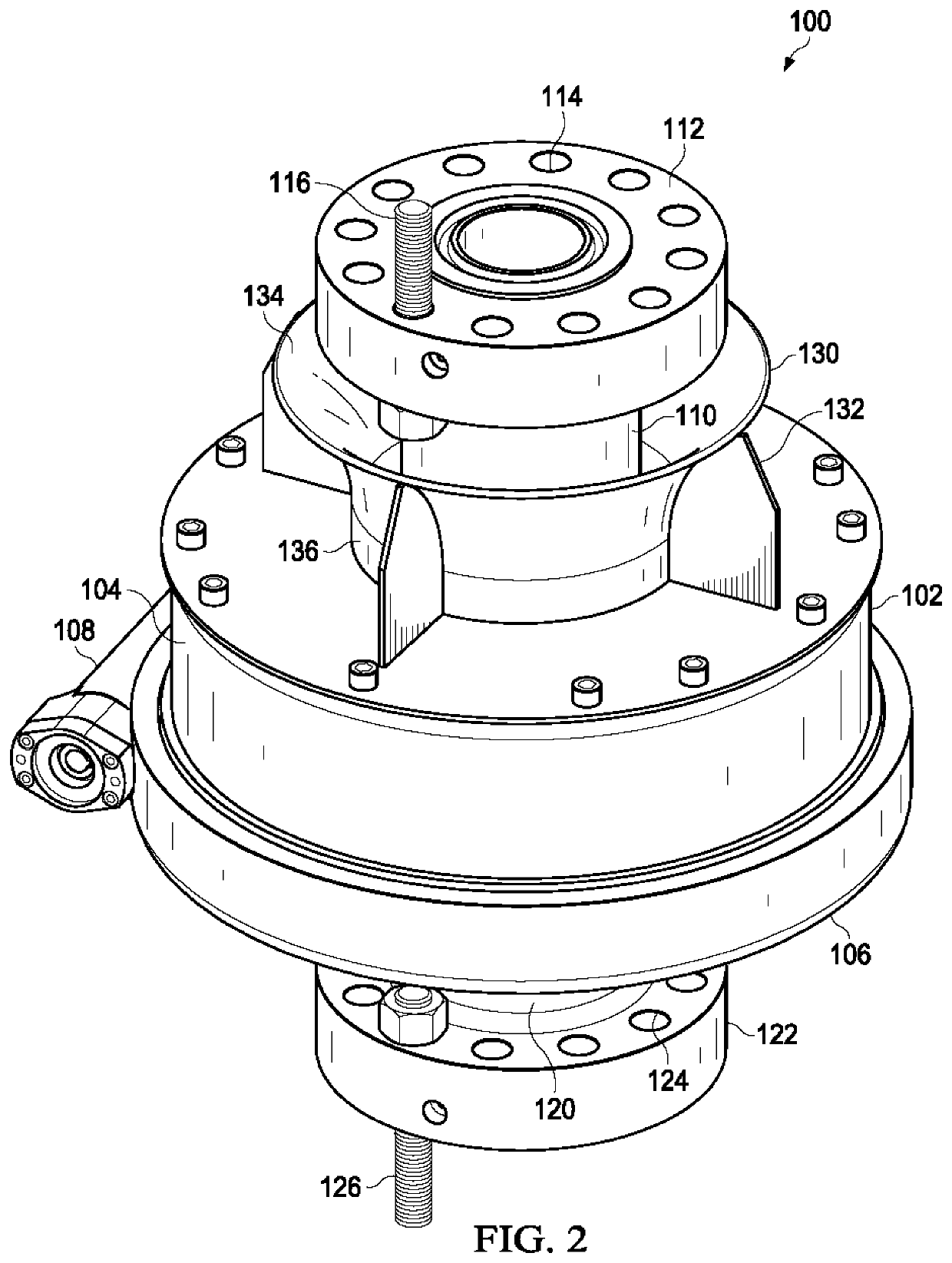

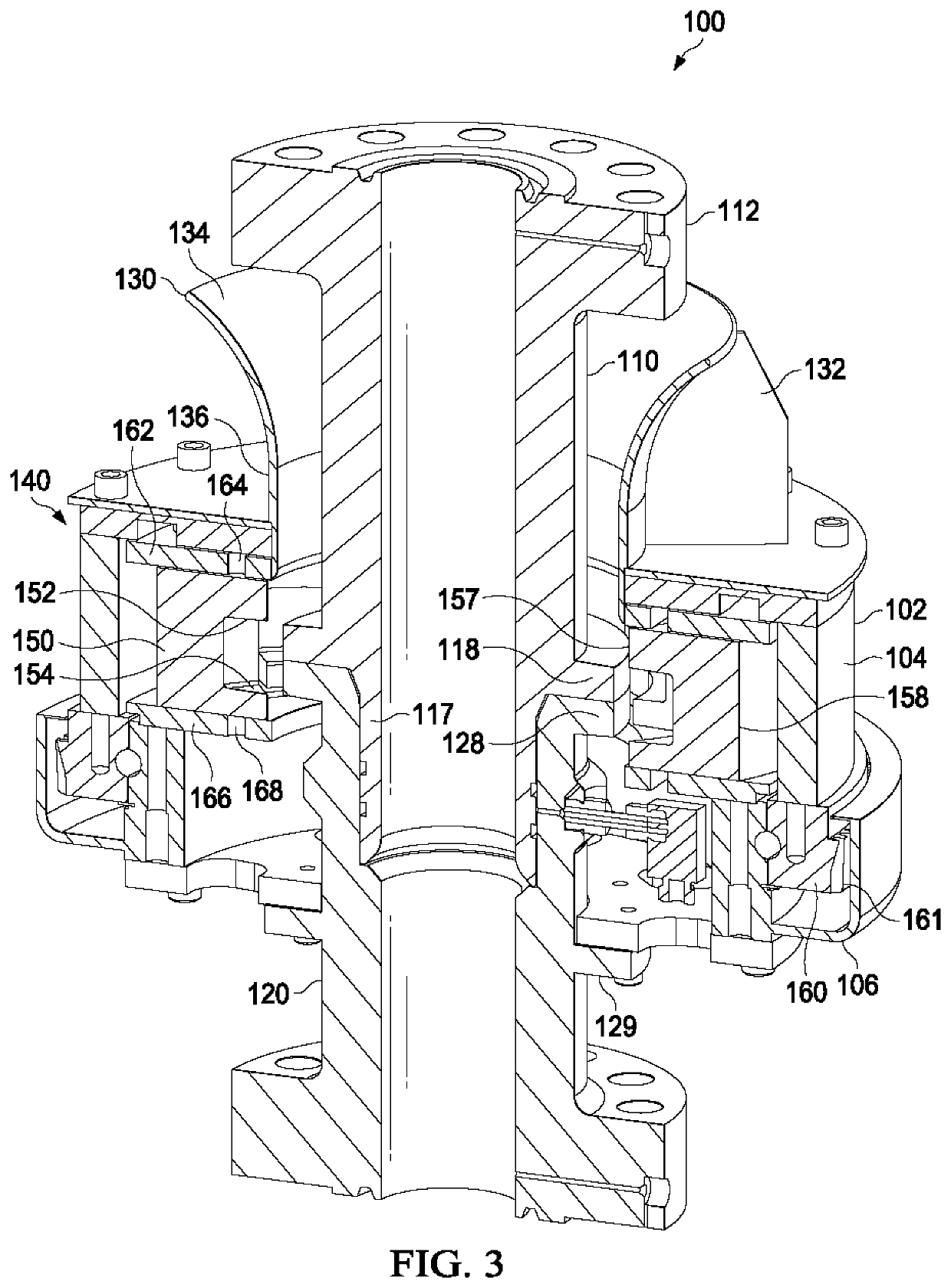

[0015]FIG. 1 is an elevation view of an embodiment of a rotary latch device 100. FIG. 2 is an isometric view of the rotary latch device 100 of FIG. 1. With reference to FIGS. 1 and 2, the rotary latch device 100 can receive a tool mandrel 110 and latch and / or engage the tool mandrel 110 to a wellhead connection mandrel 120.

[0016]In the depicted example, the rotary latch device 100 can be coupled to the wellhead connection mandrel 120. As illustrated, the wellhead connection mandrel 120 can be coupled to a lower portion 106 of the device housing 102. In some applications, the wellhead connection mandrel 120 can allow access to a wellbore via a wellhead in fluid communication with the wellhead connection mandrel 120. The wellhead connection mandrel 120 can be coupled to downstream wellbore components with a flange 122. Fasteners 126 can extend through fastener holes 124 to secure the flange 122 to downstream wellbore components. As described herein, the rotary latch device 100 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com