Golf Shoe and Method for Manufacturing Same

a technology for golf shoes and manufacturing methods, applied in the field of golf shoes, can solve the problems of damage to the swing sensation, large number of foreign substances accumulated in the surface and groove, and large number of foreign substances accumulated in the surface and groove, and achieve the effect of enhancing athletic performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0031][First Embodiment]

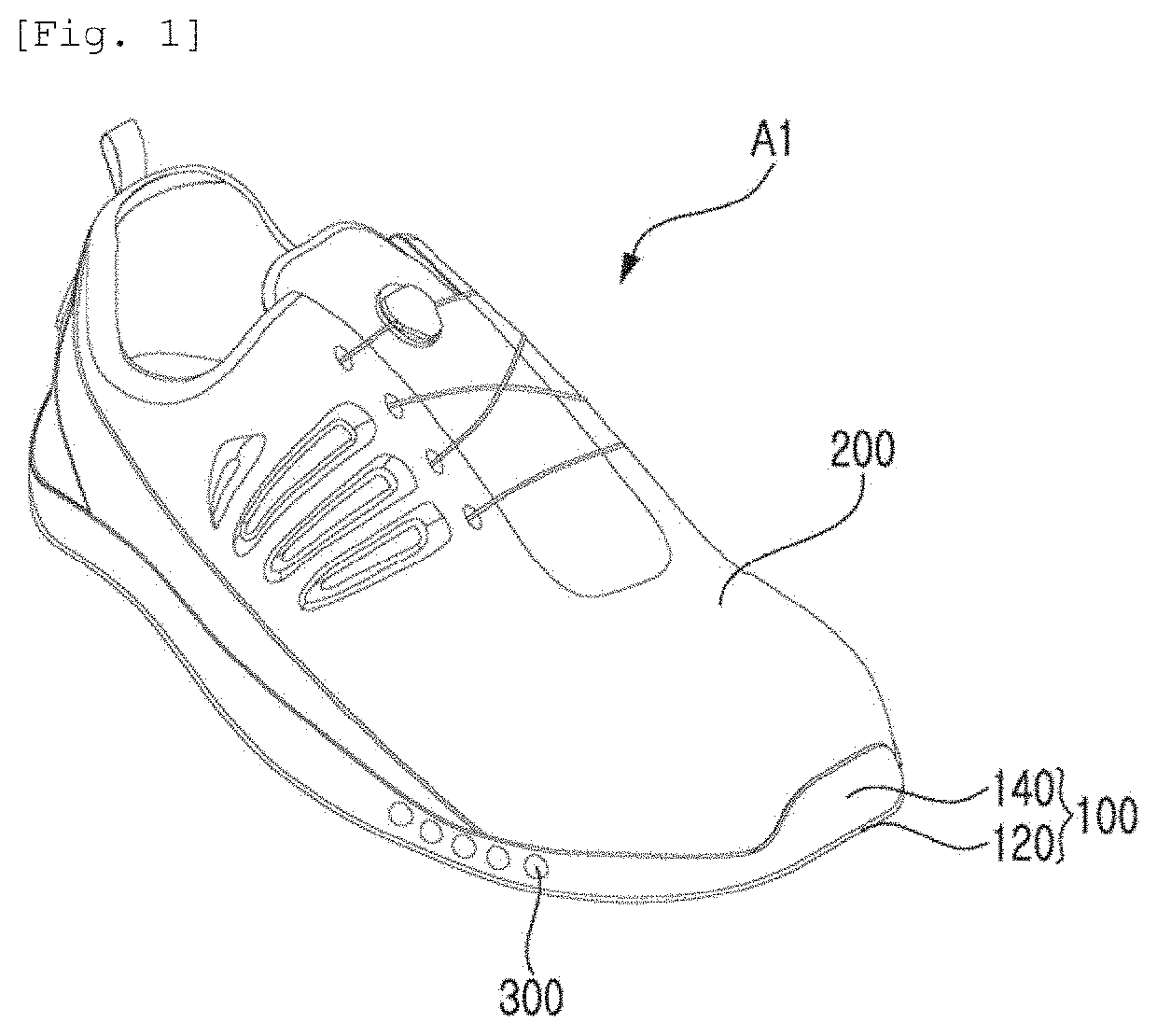

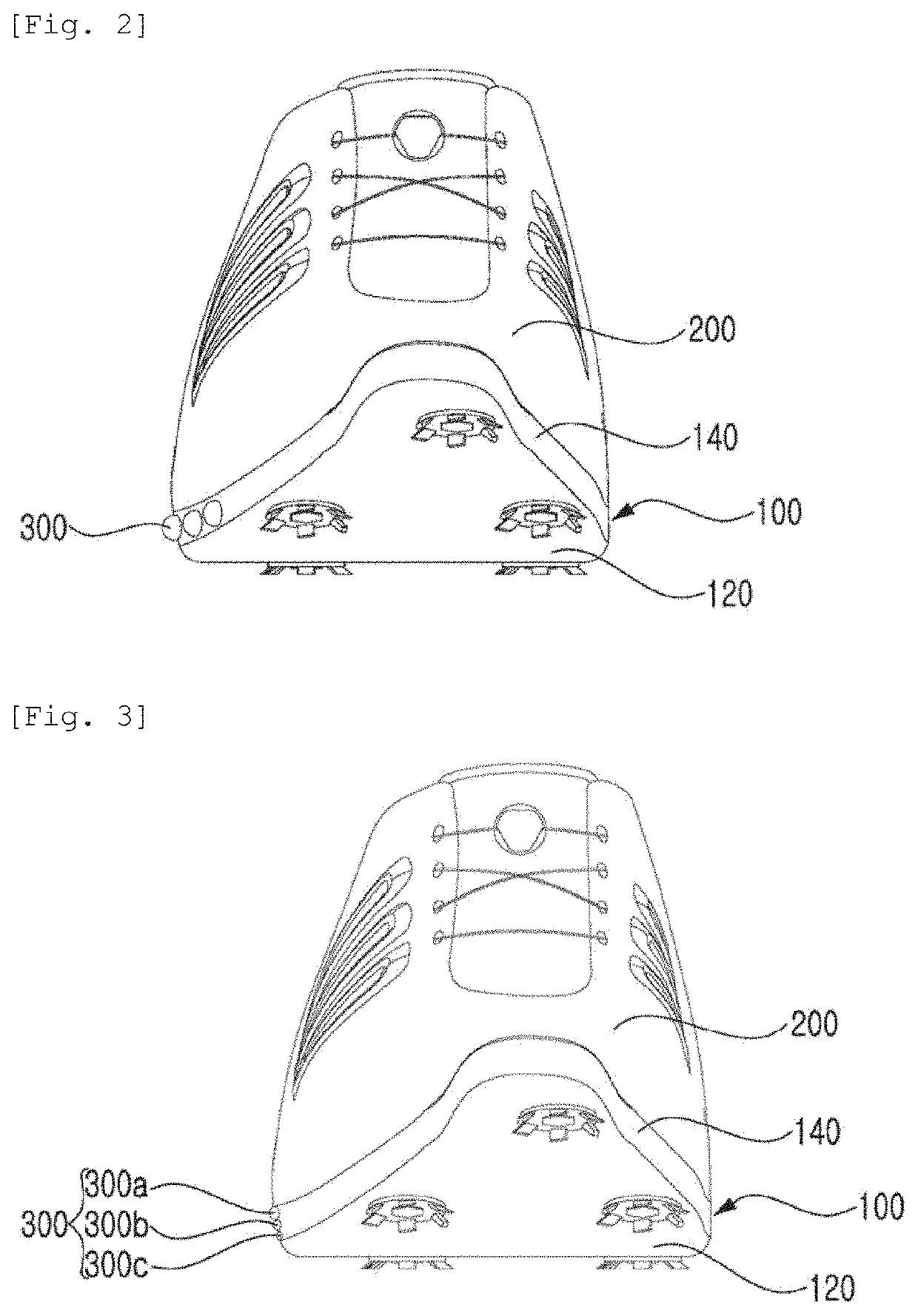

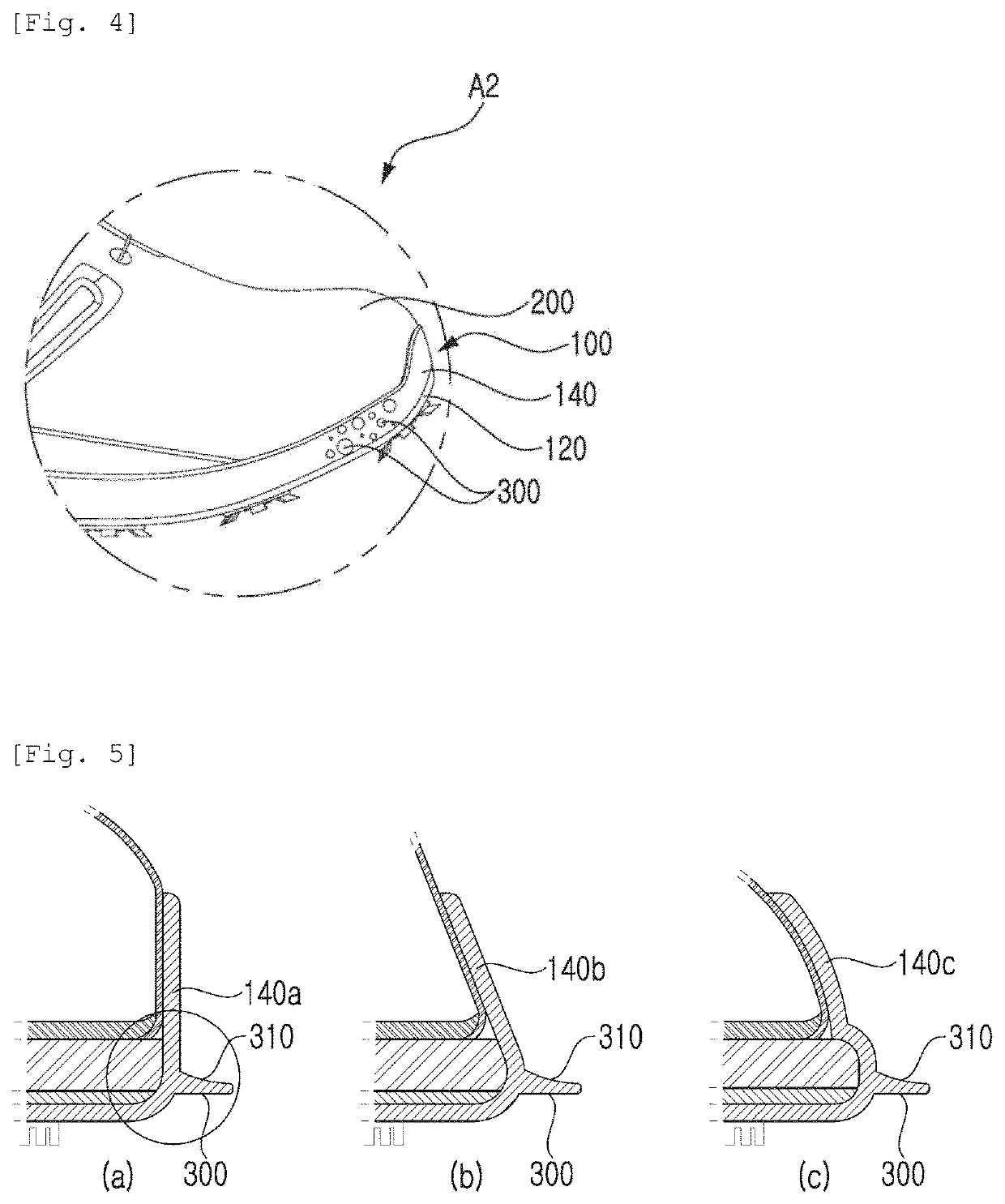

[0032]A method for manufacturing a golf shoe according to the first embodiment includes process a of injection molding a midsole 140, and process b of forming a plurality of protrusions 300 on a front- or rear-side of a lateral surface of the midsole 140. Here, the golf shoe includes a sole 100 composed of an outsole 120 and the midsole 140, and an upper 200 formed on a top portion of the sole 100.

[0033]The midsole 140 is formed by injecting a raw material into a mold of a molding apparatus.

[0034]A plurality of grooves is formed in the mold to form the protrusions 300. Thus, by injecting the raw material into the plurality of grooves, the protrusions 300 may be formed on the outer lateral surface of the midsole 140.

[0035]As shown in FIGS. 1 to 6, the golf shoe A1 according to the first embodiment includes the sole 100 composed of the outsole 120 and the midsole 140, and the upper 200 formed on the top portion of the sole 100. The plurality of protrusions 300 ...

second embodiment

[0058][Second Embodiment]

[0059]A method for manufacturing a golf shoe according to the second embodiment includes a process of injection molding a midsole 140, and a process of forming a plurality of protrusions 300 on a front- or rear-side of a lateral surface of the midsole 140 by double injection molding. Here, the golf shoe includes a sole 100 composed of an outsole 120 and the midsole 140, and an upper 200 formed on a top portion of the sole 100.

[0060]Preferably, the plurality of protrusions 300 is made of a material different from that of the midsole 140. For example, the protrusion 300 may be formed of a material having strength higher than that of the midsole 140.

[0061]As described above, the plurality of protrusions 300 is formed in one row or in multiple rows.

[0062]The plurality of protrusions 300 is formed to have the same protruding height or different protruding heights.

[0063]A golf shoe A2 according to the second embodiment includes the sole 100 composed of the outsole...

third embodiment

[0077][Third Embodiment]

[0078]A method for manufacturing a golf shoe according to a third embodiment includes a first process of injection molding a midsole 140; and a second process of planting brushes 500 into a front- or rear-side of a lateral surface of the midsole 140 before the midsole 140 is cured. Here, the golf shoe includes a sole 100 composed of an outsole 120 and the midsole 140, and an upper 200 formed on a top portion of the sole 100.

[0079]As shown in FIGS. 7 and 8, a golf shoe A3 according to the third embodiment includes the sole 100 composed of the outsole 120 and the midsole 140, and the upper 200 formed on the top portion of the sole 100.

[0080]The brushes 500 are formed on a front- or rear-side of an outer lateral surface of the midsole 140.

[0081]Preferably, the brushes 500 are formed in different thicknesses and lengths.

[0082]Thus, the surface of the clubface may be cleaned by rubbing the clubface (not shown) using the brushes 500 while slightly lifting the foot....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com