Improved Toilet Flushing System

a technology for toilets and flushing systems, applied in flushing devices, water installations, constructions, etc., can solve problems such as leakage of water fill valves, water wastage, and flapper valve leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

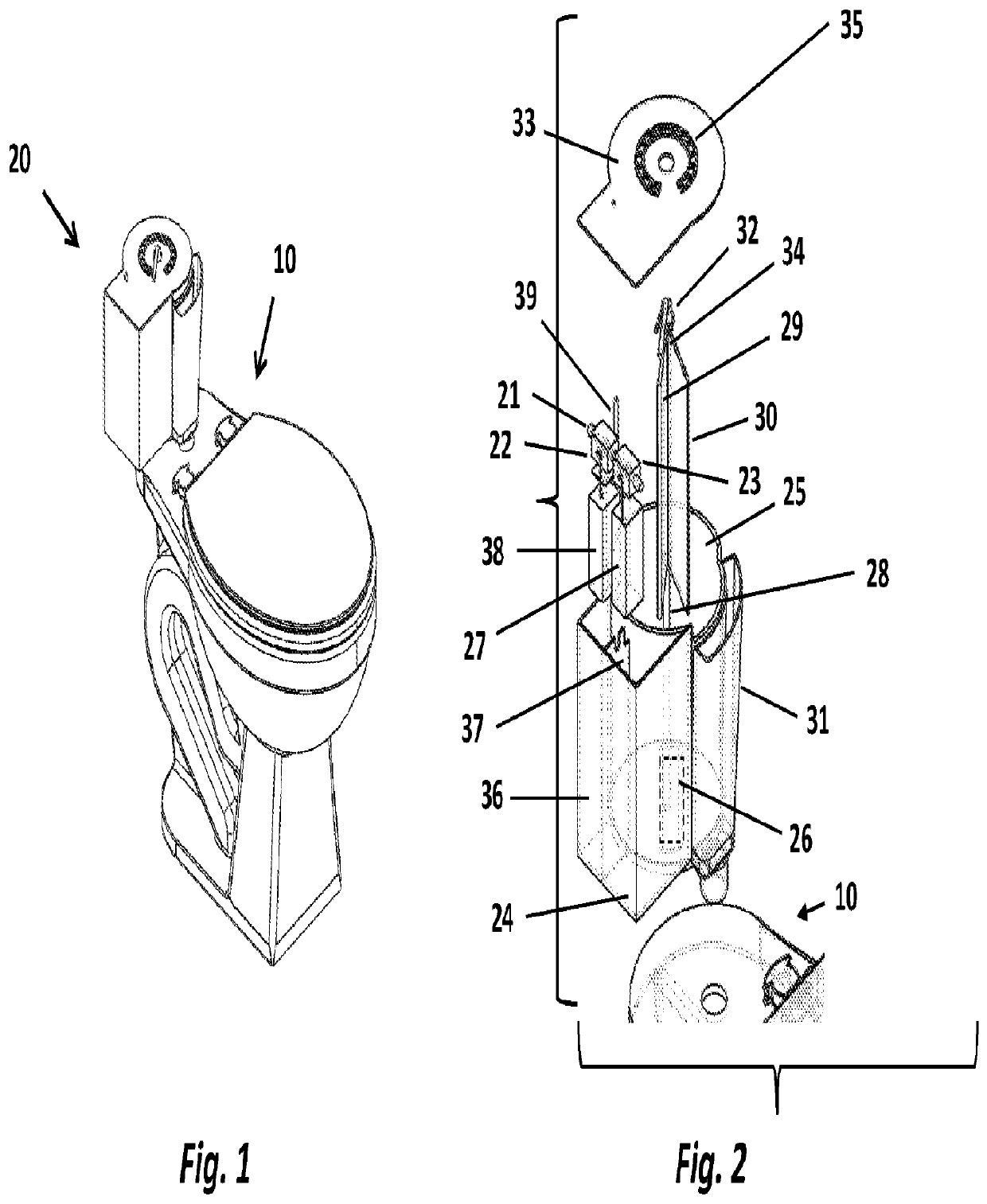

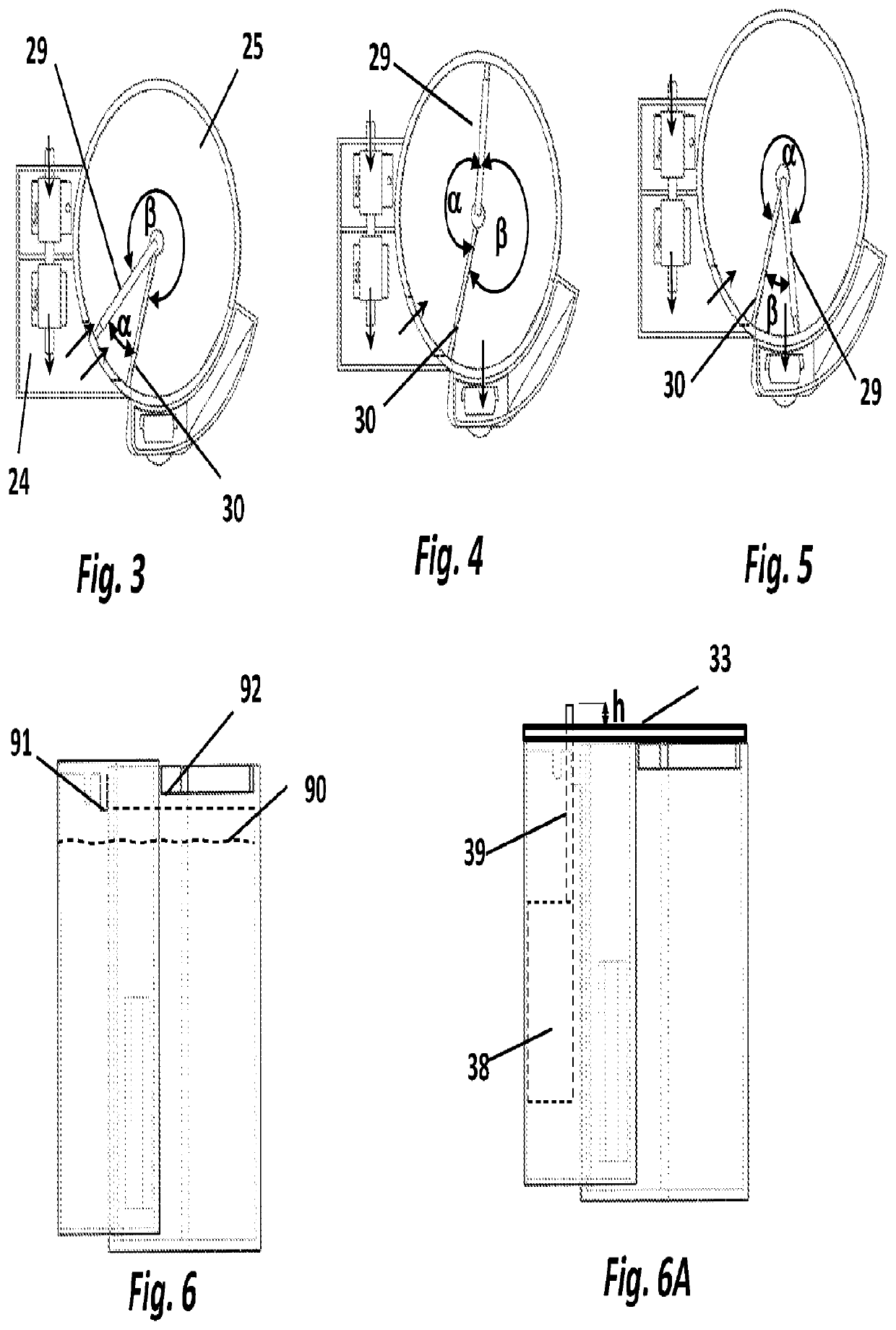

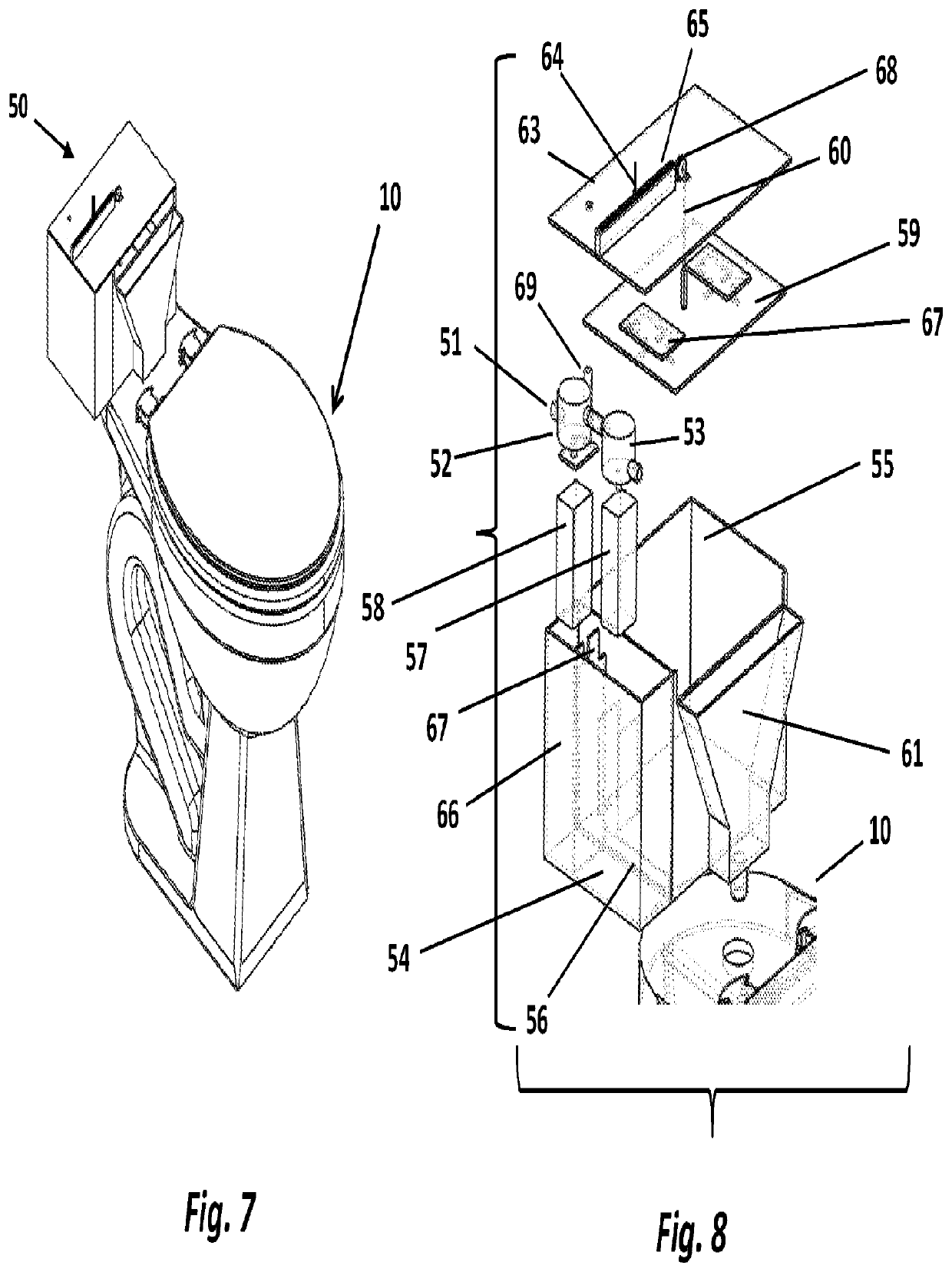

[0080]The components used in this invention include a receiver, displacer, master valve, fill valve, leak arrest system and alert-reset. These components can be assembled in numerous combinations. The difference the types of each component and the method in which they are linked contribute to the variations in the multitude of embodiments.

[0081]The following are the variations in the components in the system.

[0082]The receivers and displacers can be of different shapes and sizes.

[0083]The methods of displacing water from the receiver for flushing such as tilting the receiver or using a displacer. The actuation mechanisms of flushing using a handle, or a motor operated by a switch or an electronic control system. The electronic control system with inputs including push buttons, touch screen, voice, light, radio signals, blue tooth, etc.

[0084]Valve types include plug valve, diaphragm valve, globe valve, gate valve that are operated mechanically or electromechanically.

[0085]The means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com