Patents

Literature

34results about How to "Eliminate failure modes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

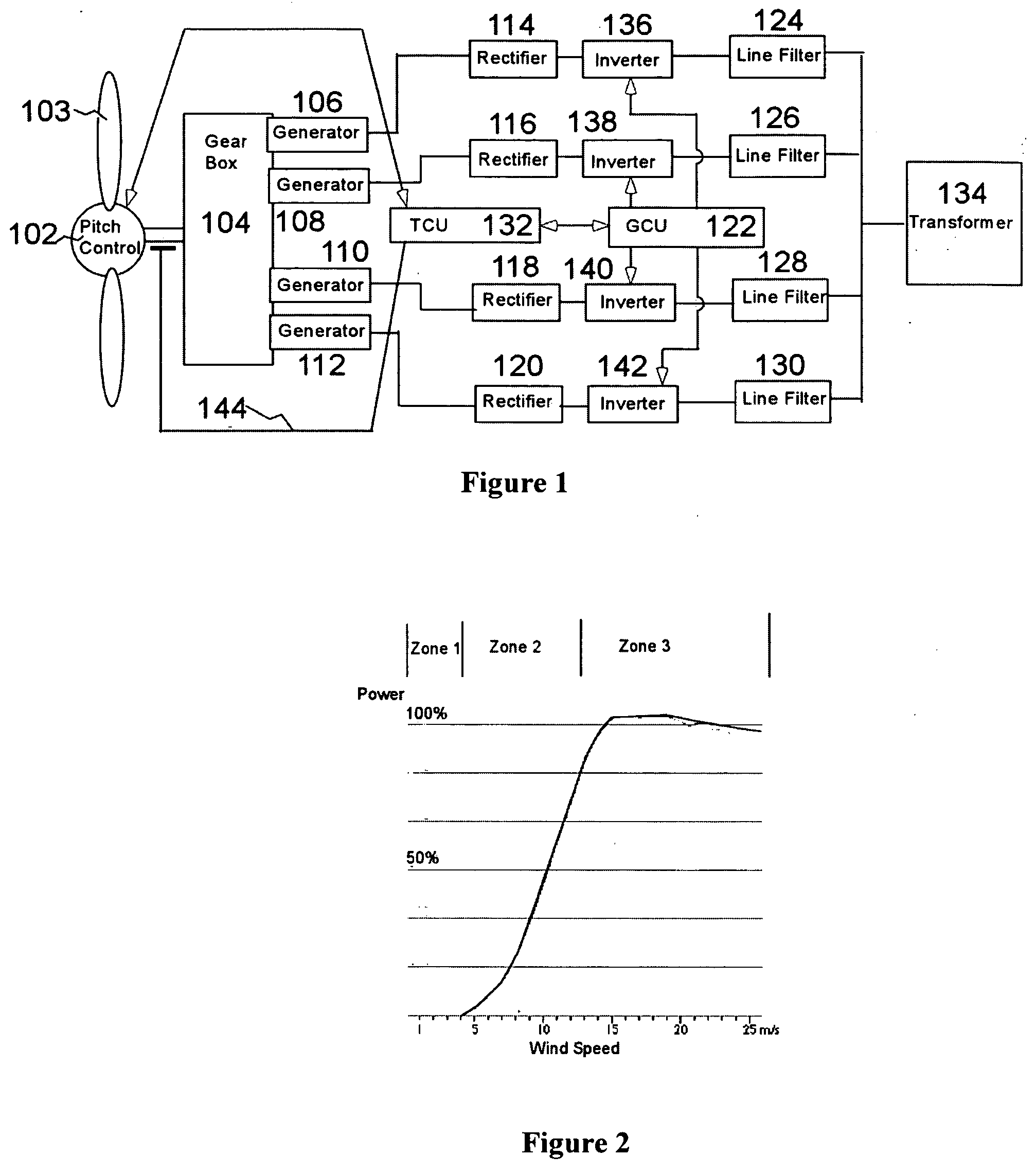

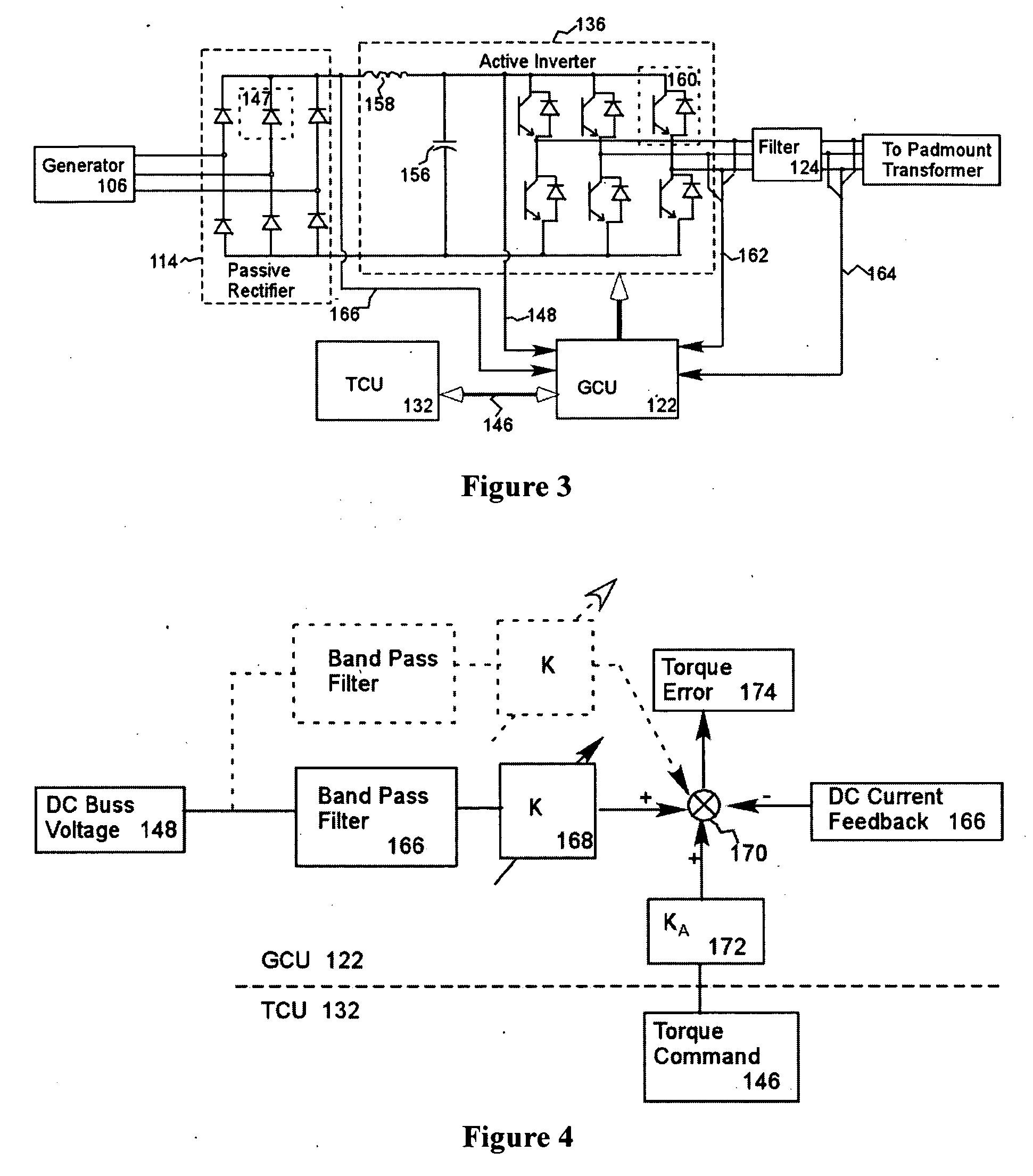

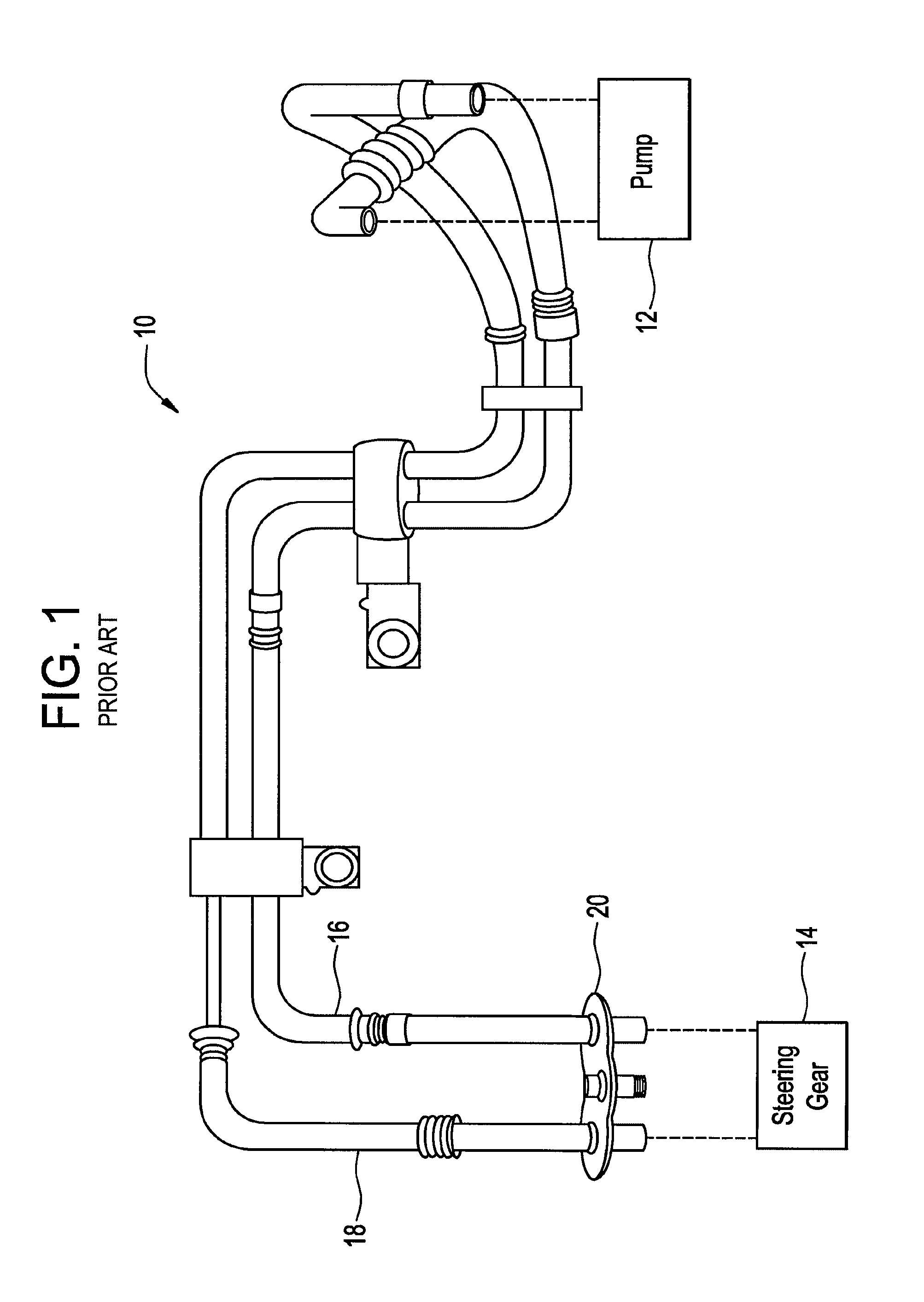

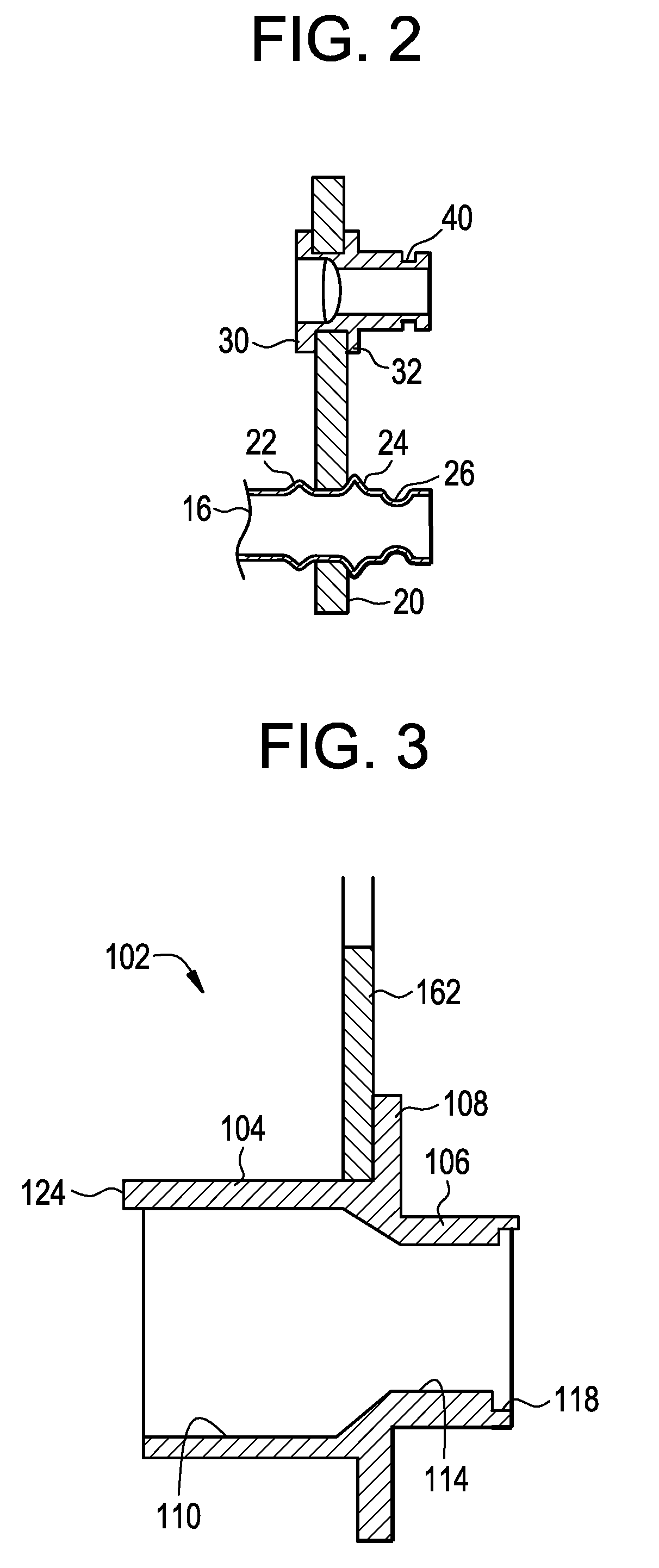

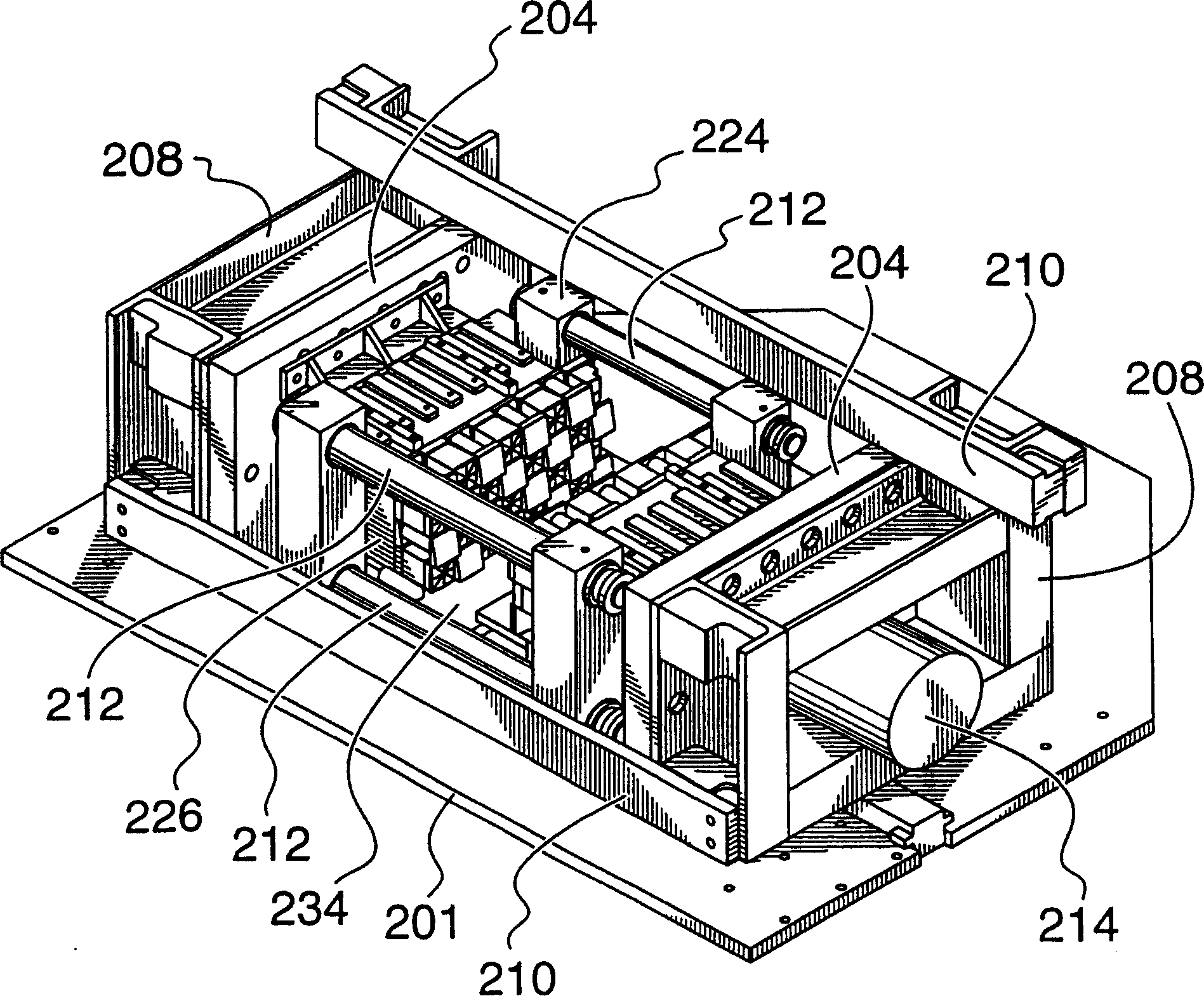

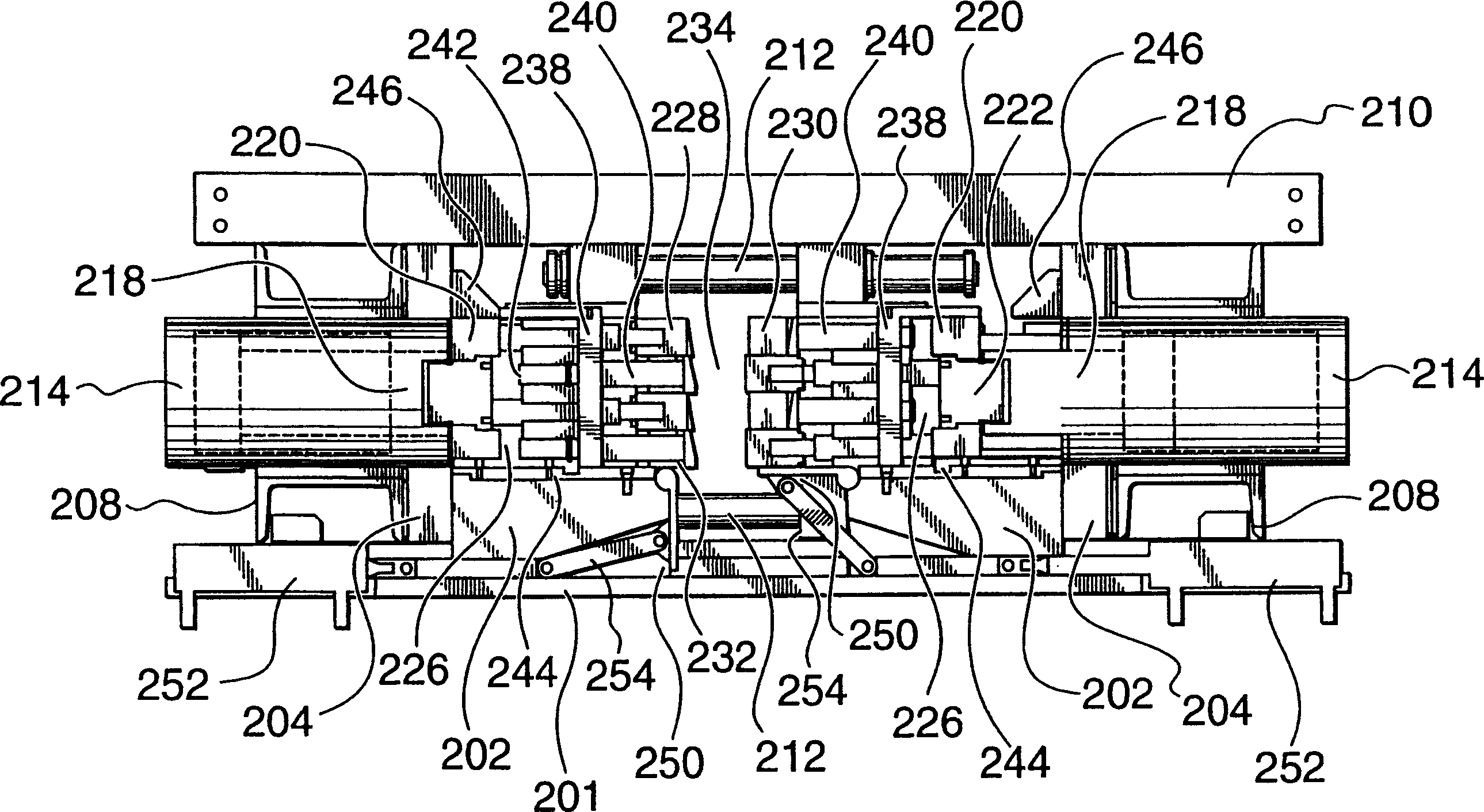

Variable speed distributed drive train wind turbine system

InactiveUS7042110B2Improve efficiencyImprove reliabilityWind motor controlEmergency protective circuit arrangementsPermanent magnet rotorDc current

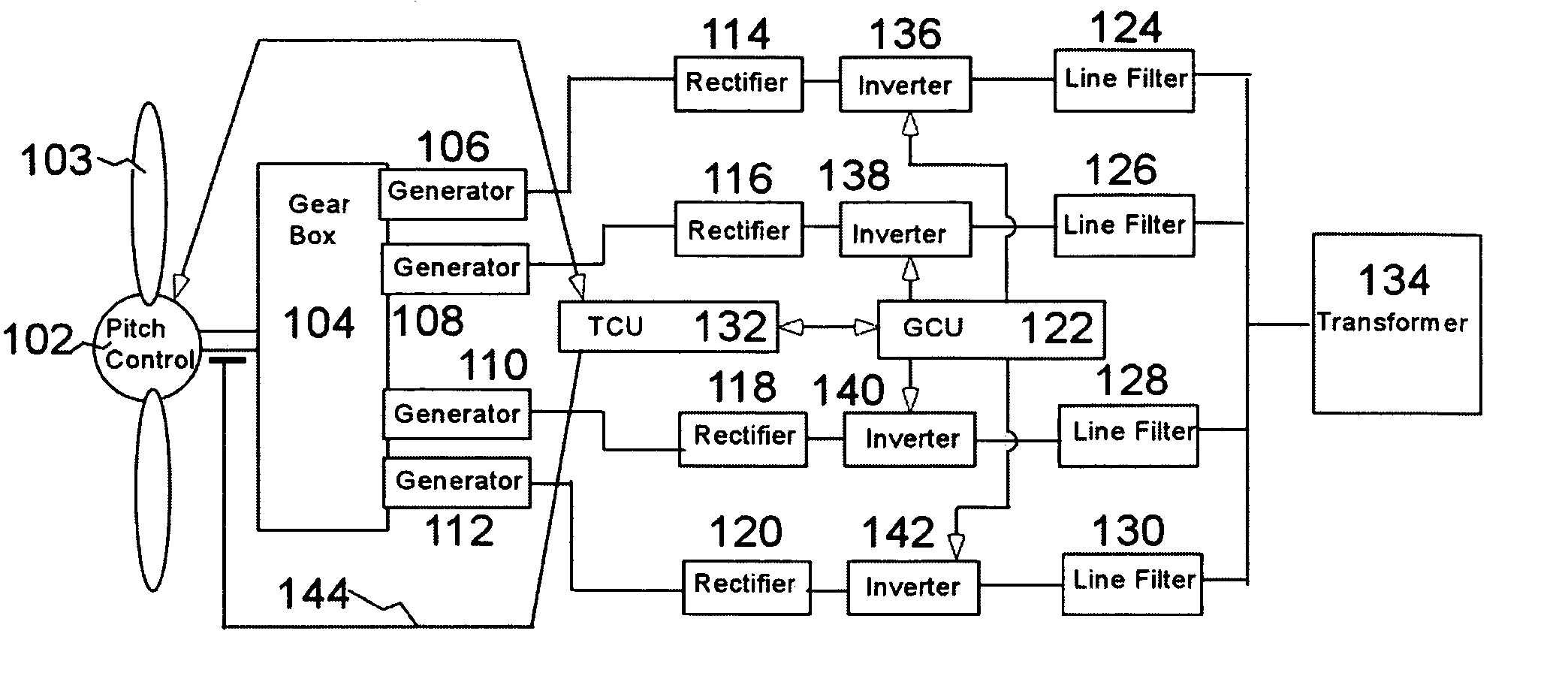

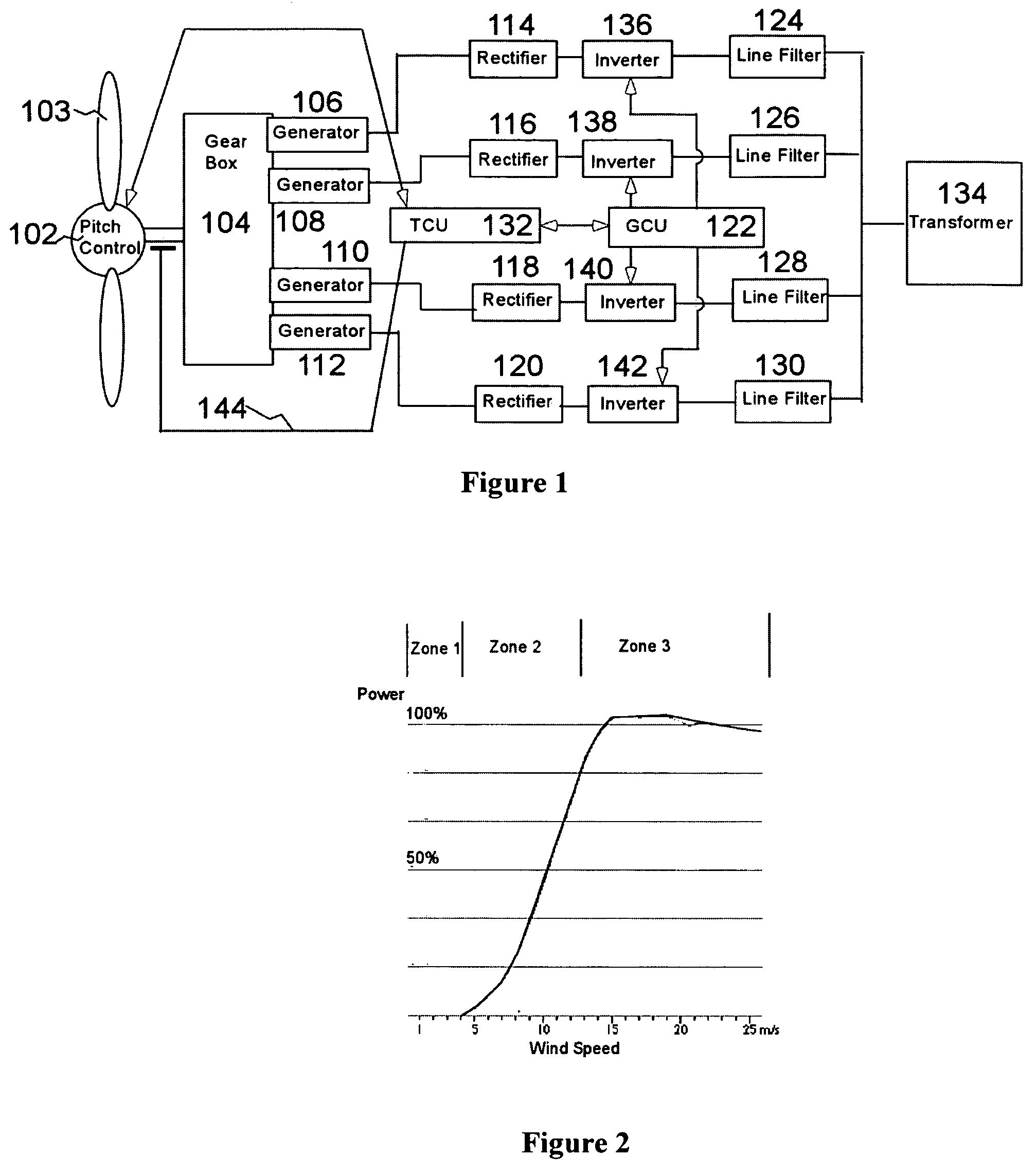

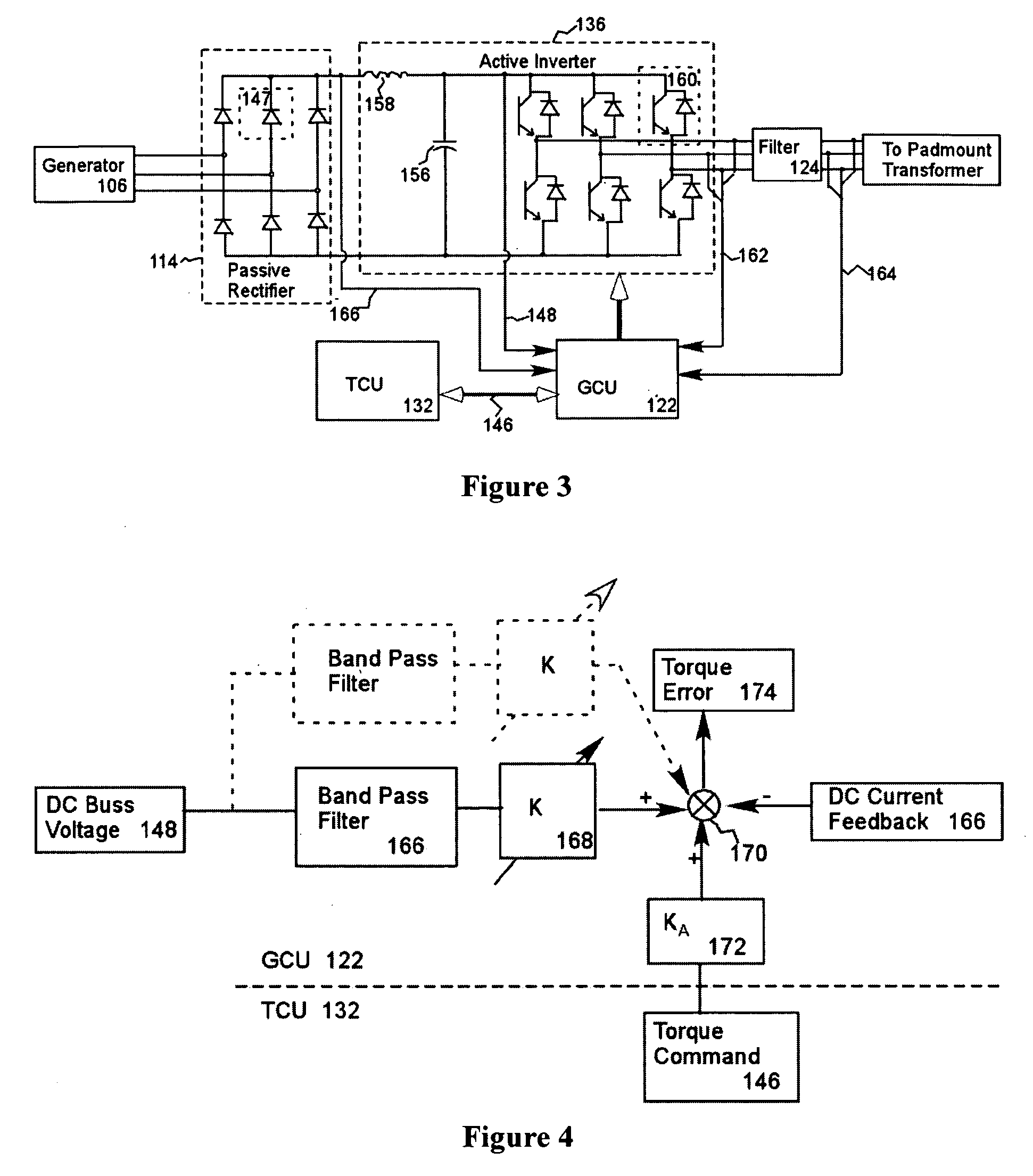

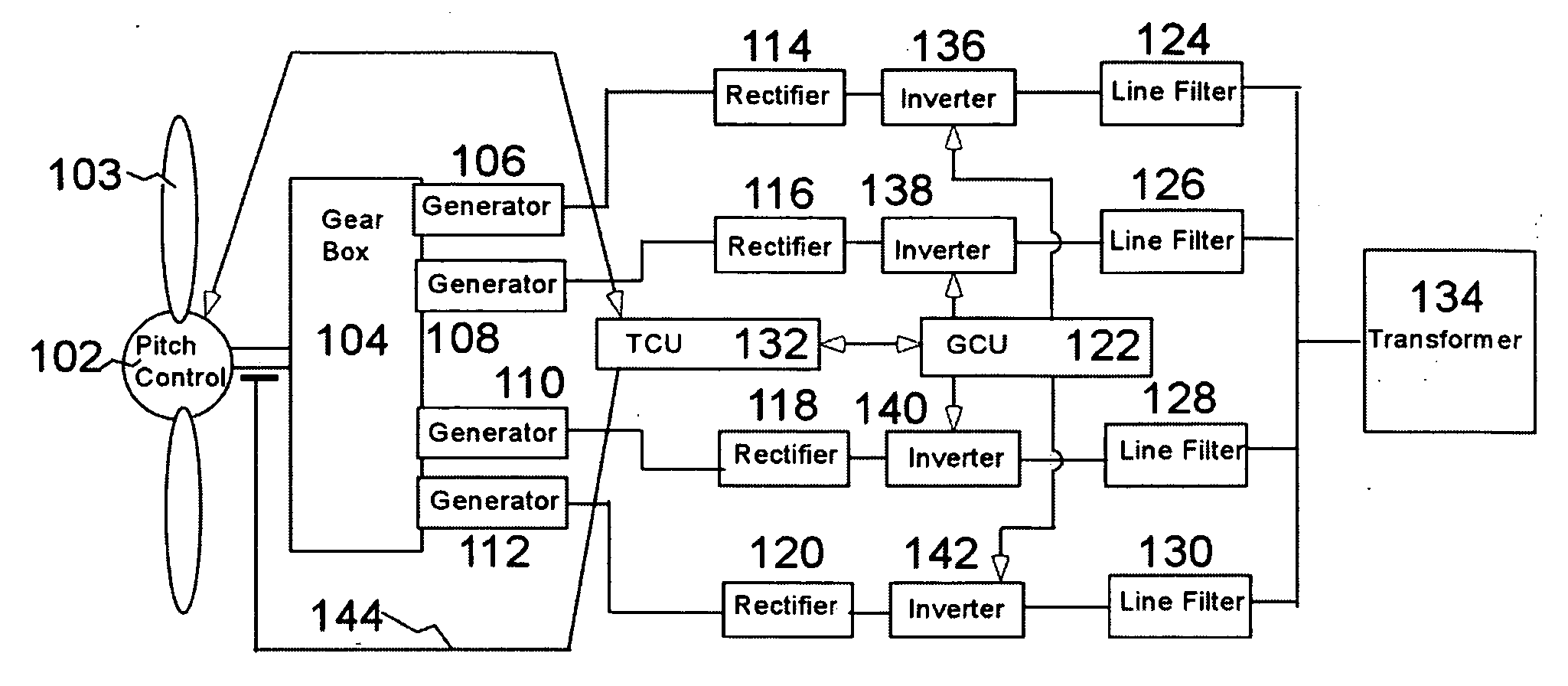

A variable speed wind turbine employing a rotor connected to a multiplicity of synchronous generators with wound field or permanent magnet rotors. A passive rectifier and an inverter are used for power transfer back to the grid. A Turbine Control Unit (TCU) commands a required generator torque based on rotor speed and power output of the turbine inverters. Torque is controlled by regulating the DC current by control of the inverter. A main-shaft-damping filter is provided by measurement of the DC bus voltage. In high winds the turbine remains at a constant average output power through a constant torque command and a varying pitch command to a rotor pitch servo system. A set point is fixed at the inverter output such that output VAR load is minimized running the turbine at very nearly unity power factor. Dynamic VAR and power factor control is provided by a separate VAR apparatus.

Owner:UNITED TECH CORP

Variable speed distributed drive train wind turbine system

InactiveUS20050012339A1Improve efficiencyImprove reliabilityWind motor controlWorking fluid for enginesElectric power transmissionPermanent magnet rotor

A variable speed wind turbine employing a rotor connected to a multiplicity of synchronous generators with wound field or permanent magnet rotors. A passive rectifier and an inverter are used for power transfer back to the grid. A Turbine Control Unit (TCU) commands a required generator torque based on rotor speed and power output of the turbine inverters. Torque is controlled by regulating the DC current by control of the inverter. A main-shaft-damping filter is provided by measurement of the DC bus voltage. In high winds the turbine remains at a constant average output power through a constant torque command and a varying pitch command to a rotor pitch servo system. A set point is fixed at the inverter output such that output VAR load is minimized running the turbine at very nearly unity power factor. Dynamic VAR and power factor control is provided by a separate VAR apparatus.

Owner:UNITED TECH CORP

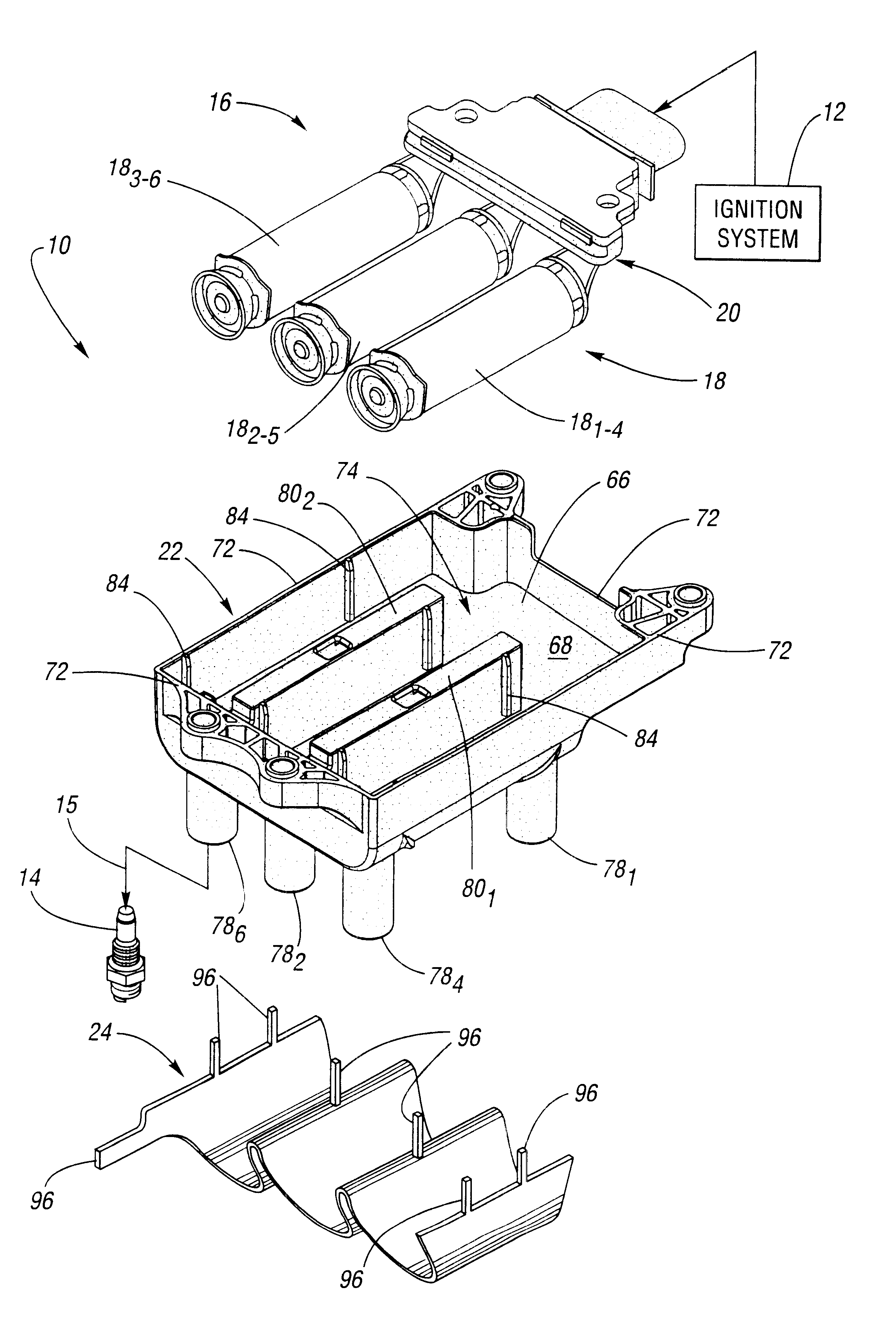

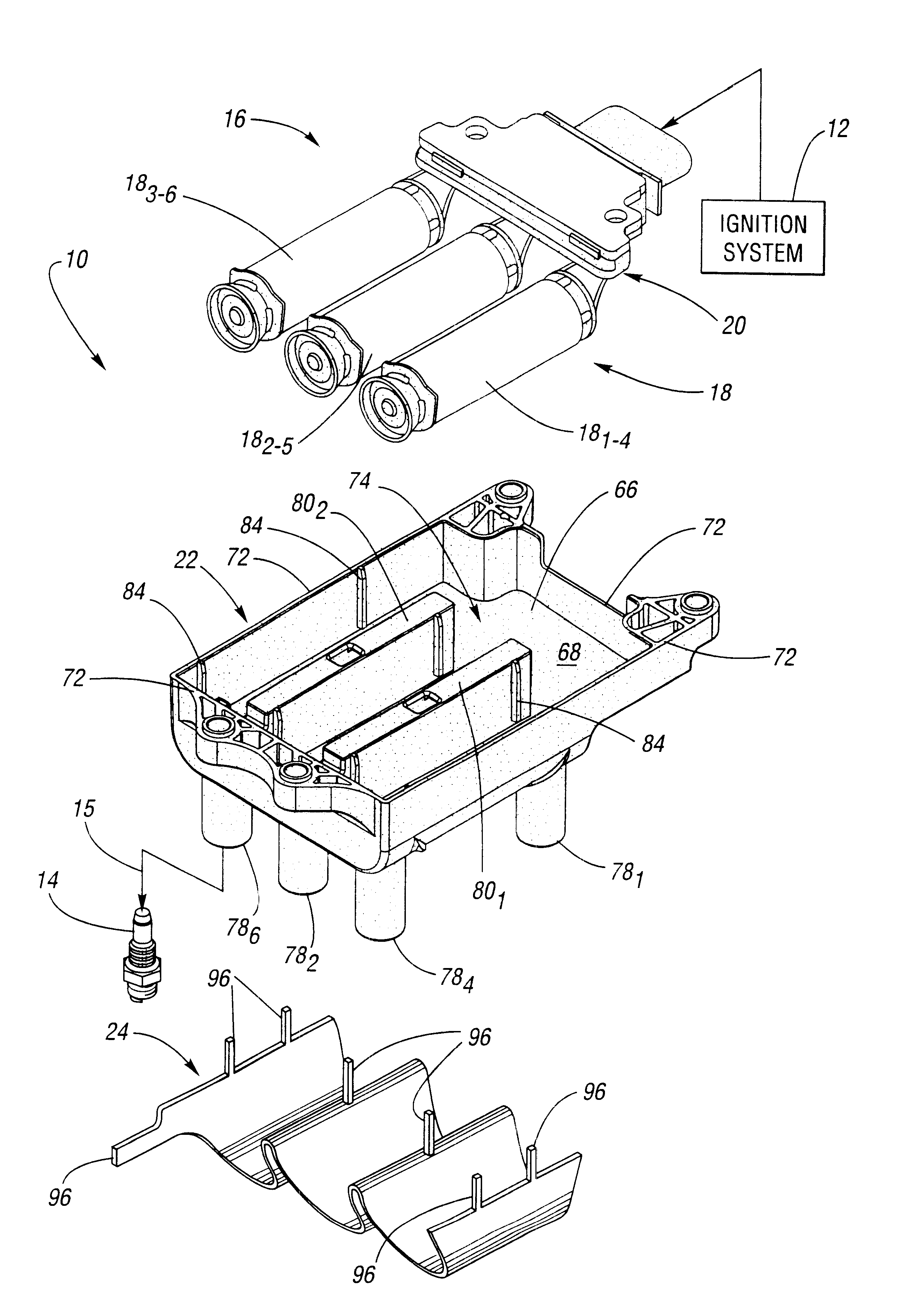

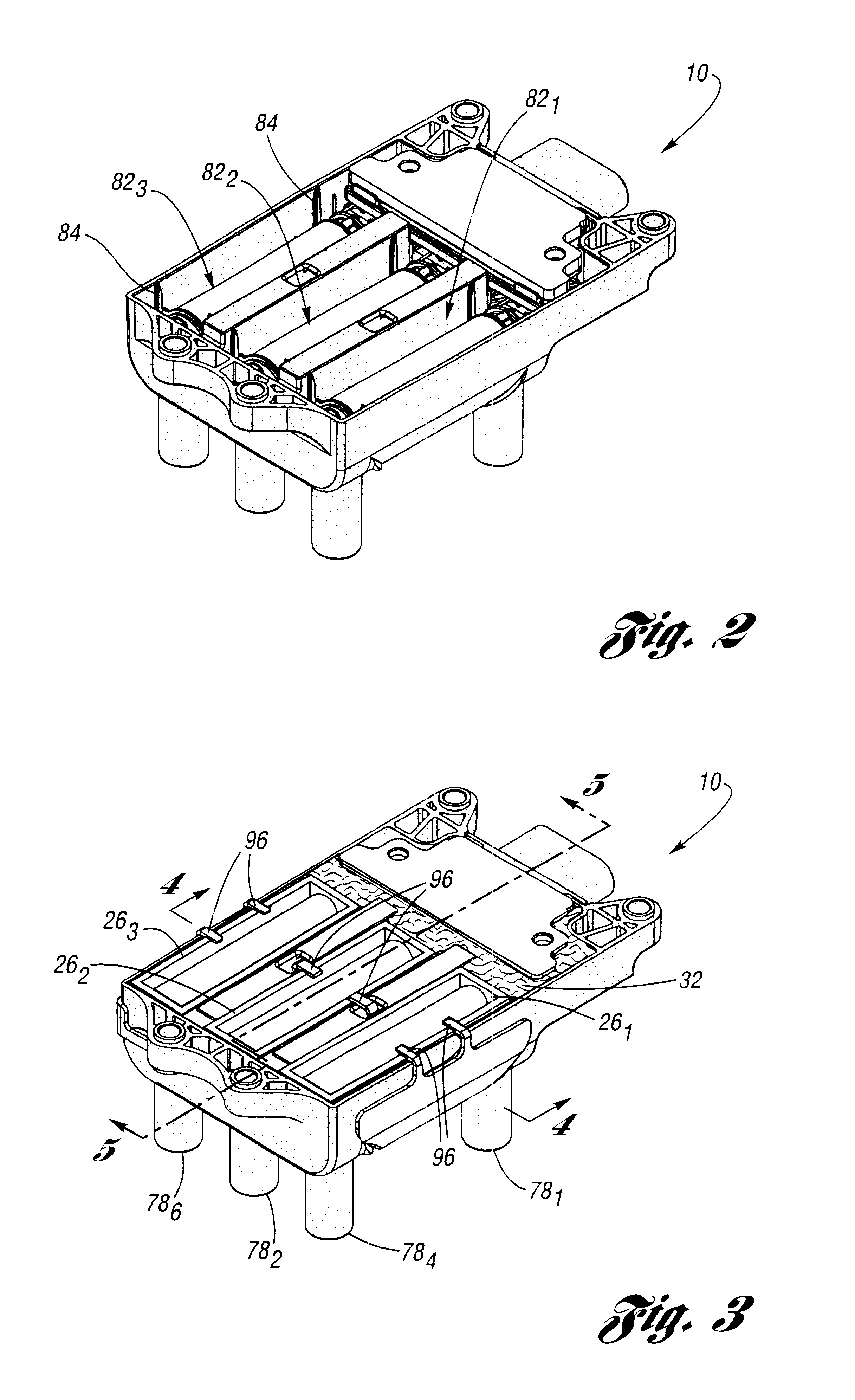

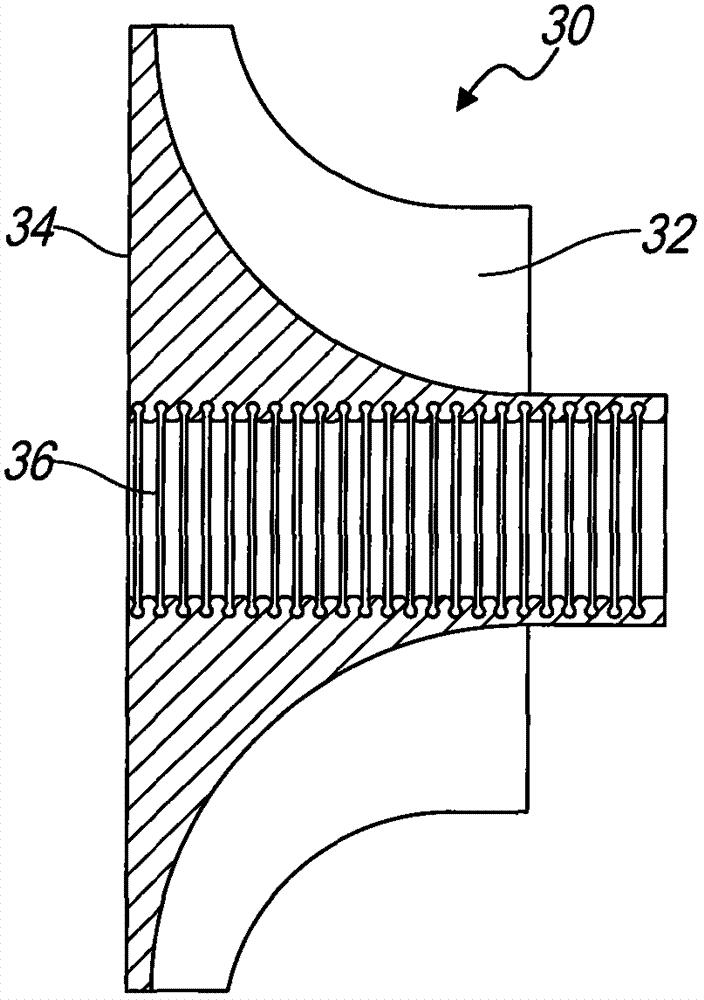

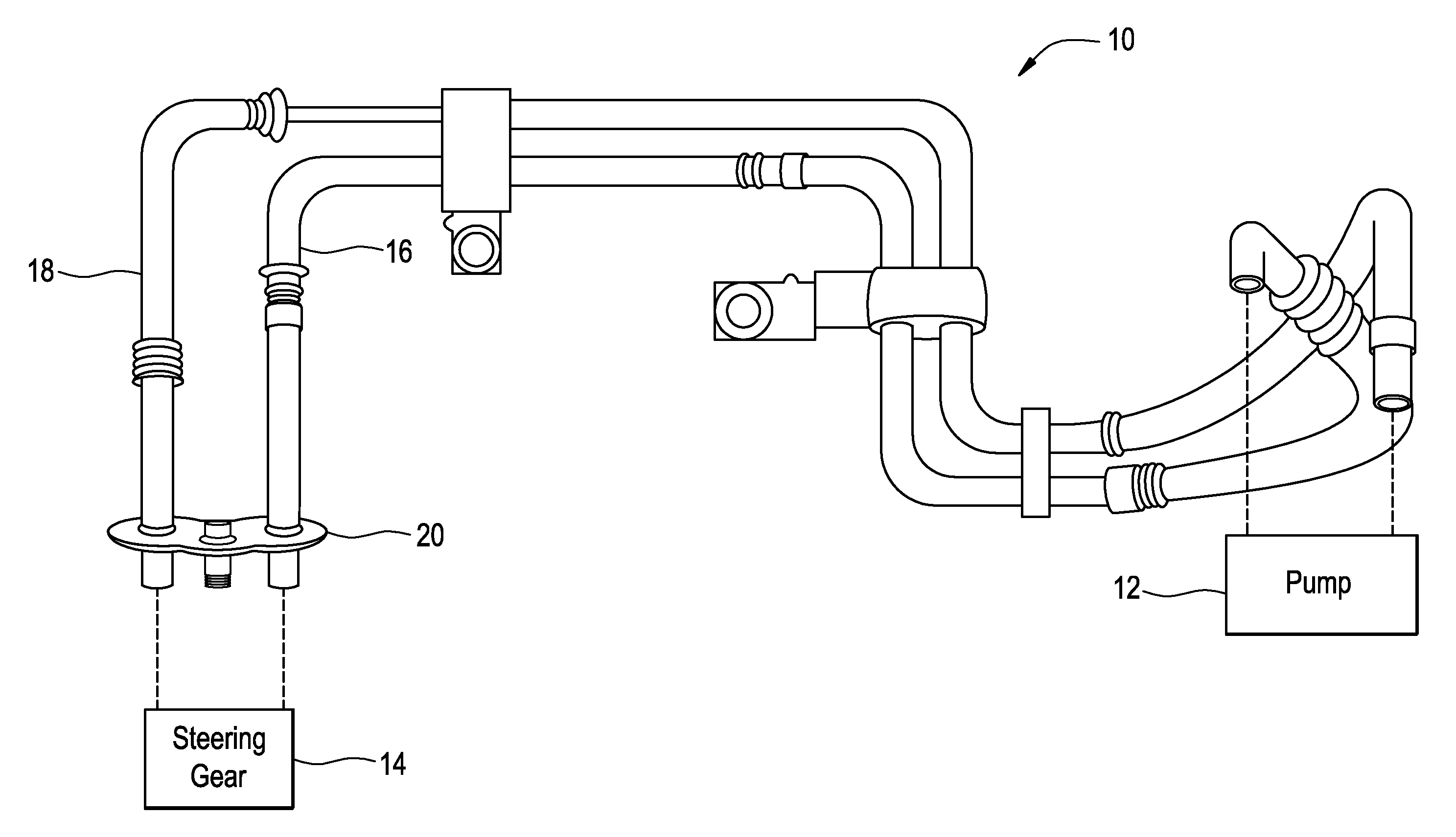

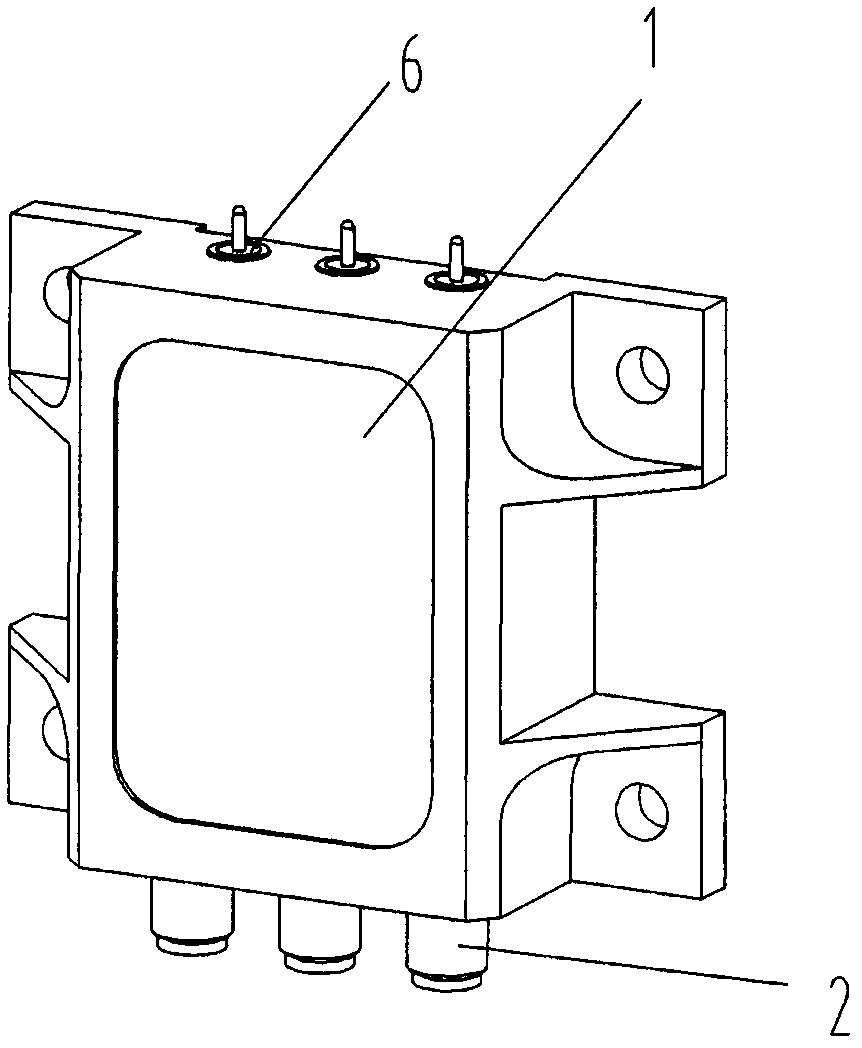

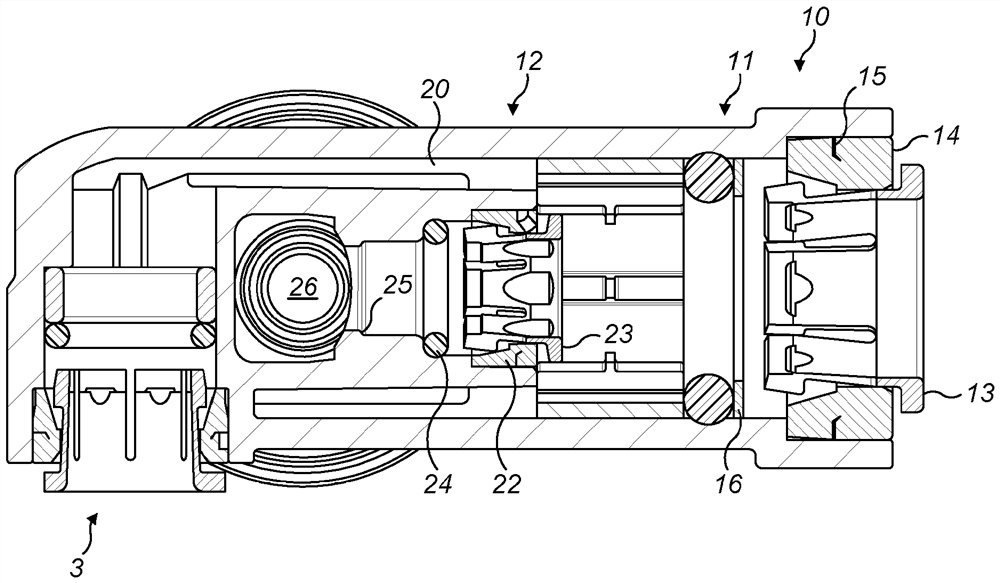

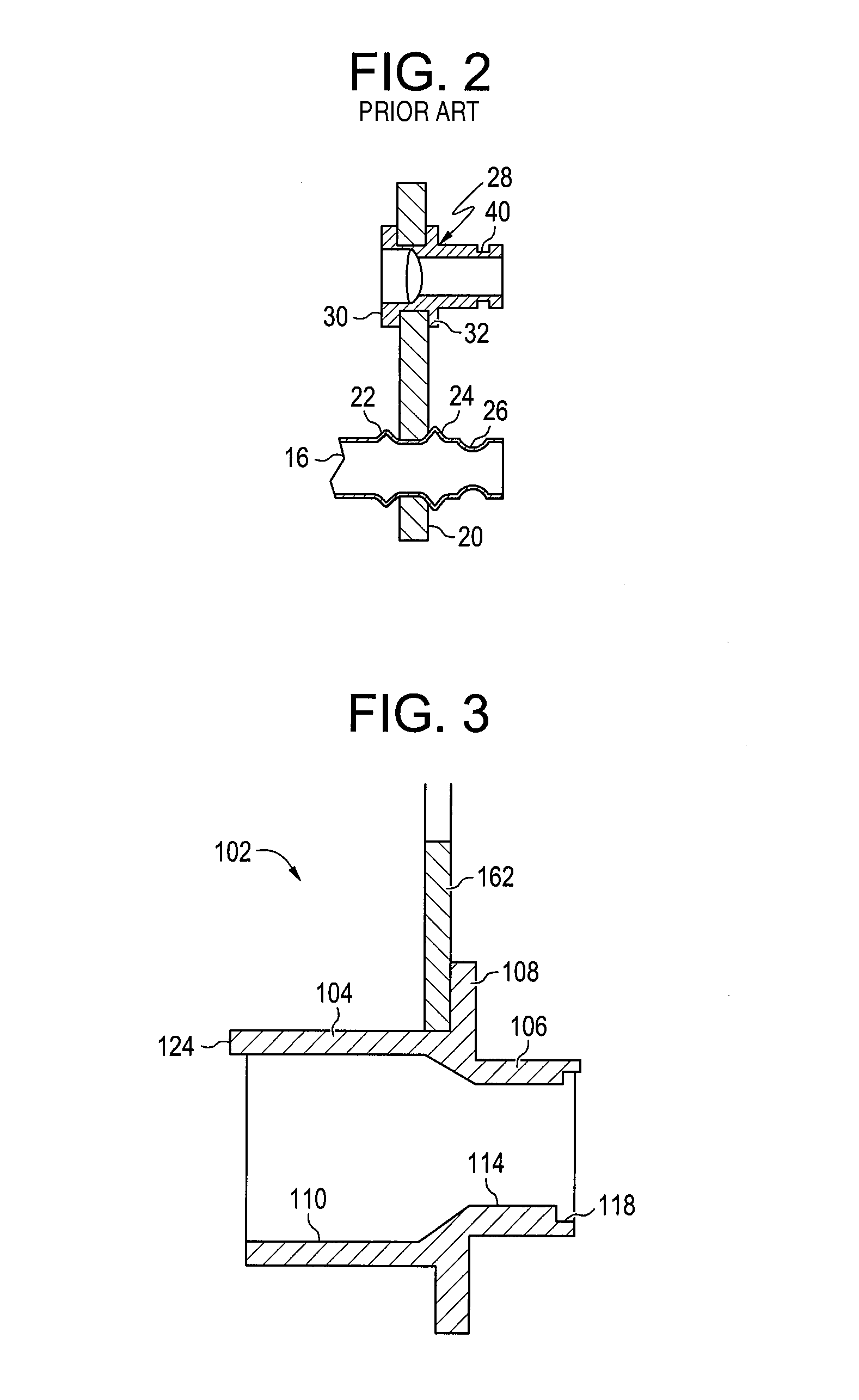

Separate mount ignition coil utilizing a progressive wound secondary winding

InactiveUS6556118B1Eliminate failure modesSmall sizeTransformersTransformers/inductances casingsElectricityIgnition coil

An ignition coil assembly includes a core formed of magnetically-permeable material extending along a main axis, a primary winding disposed about the core, a secondary winding disposed on a secondary winding spool wherein at least one of the secondary winding leads is connected to a high-voltage connector terminal portion of the ignition coil assembly configured for connection to a remotely disposed spark plug, a case formed of electrical insulating material, and a magnetically-permeable shield disposed outwardly of the case. The secondary winding is progressively wound on the secondary winding spool, thereby eliminating failure modes associated with the segment-wound secondary windings, and, eliminating the need for pole pieces in the magnetic circuit, thereby reducing components, cost, weight, and size of the ignition coil assembly.

Owner:DELPHI TECH INC

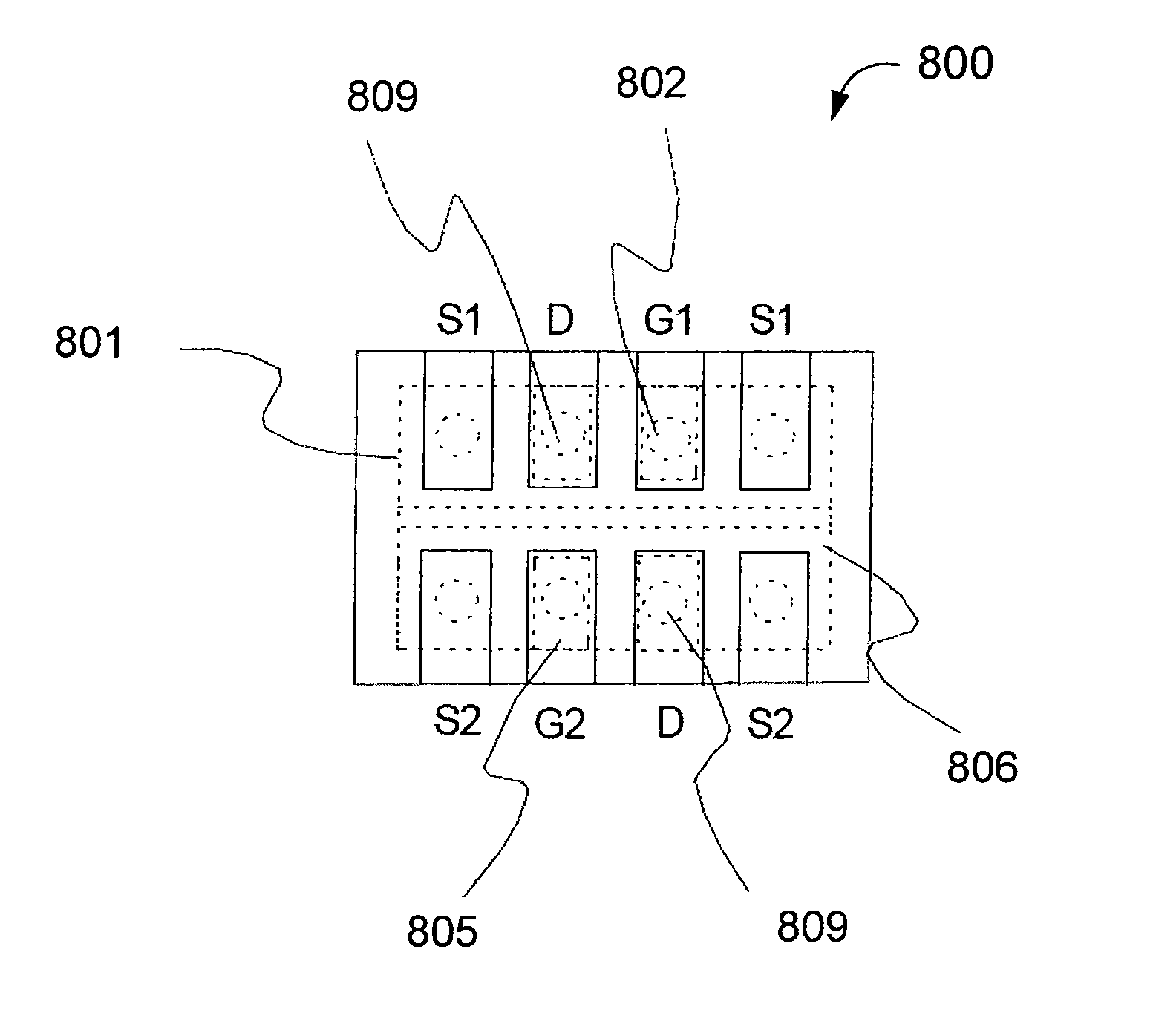

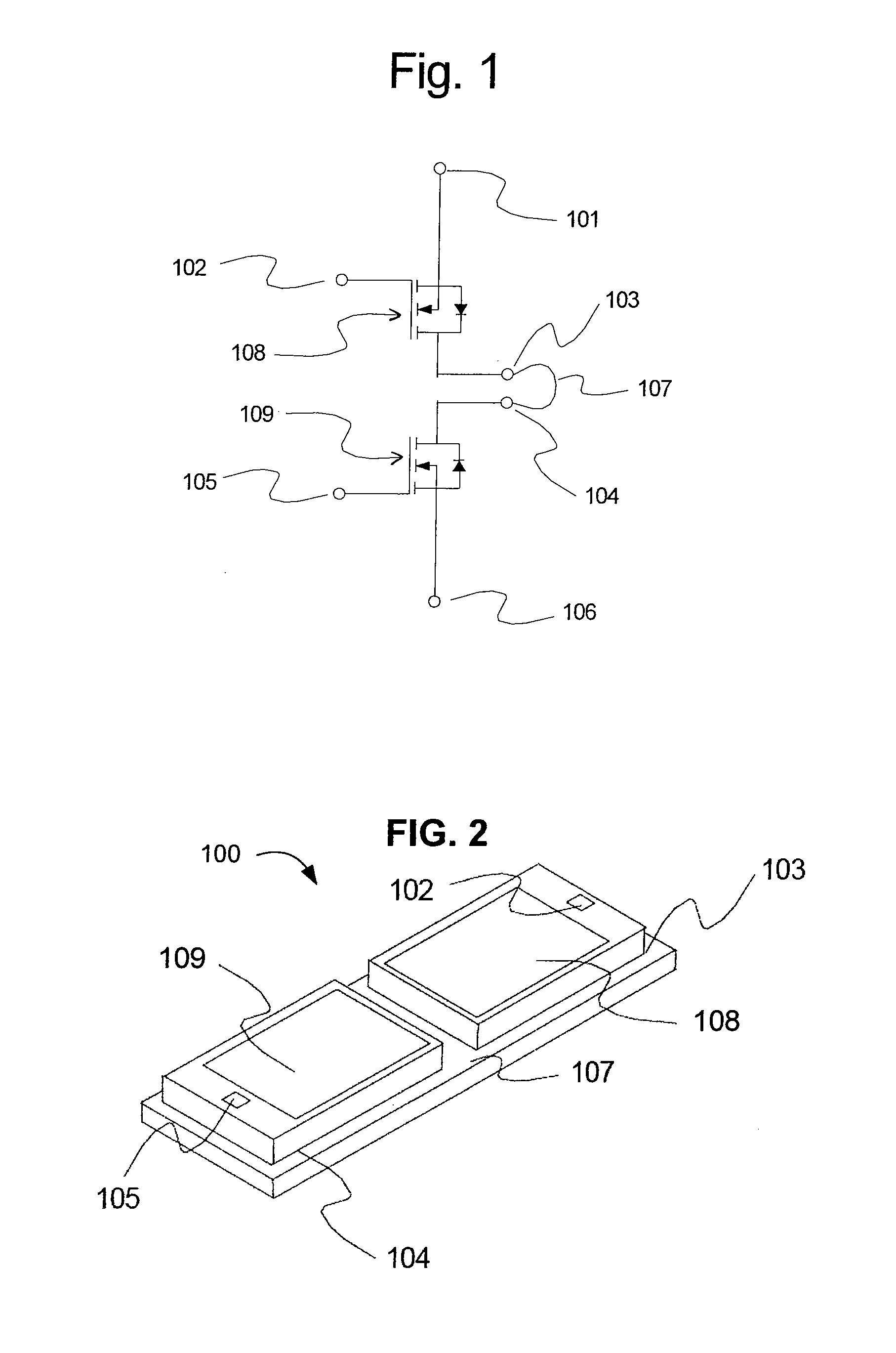

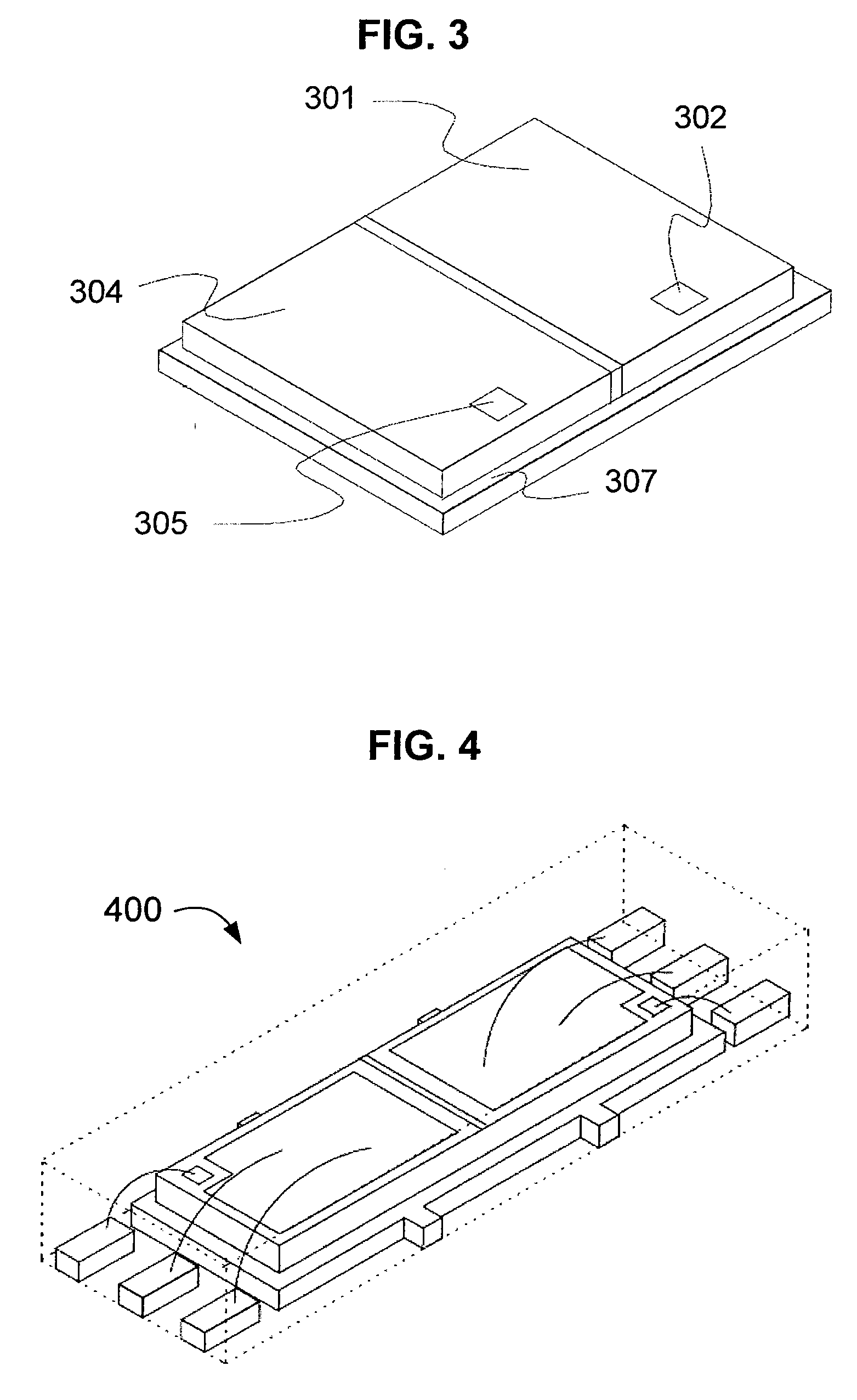

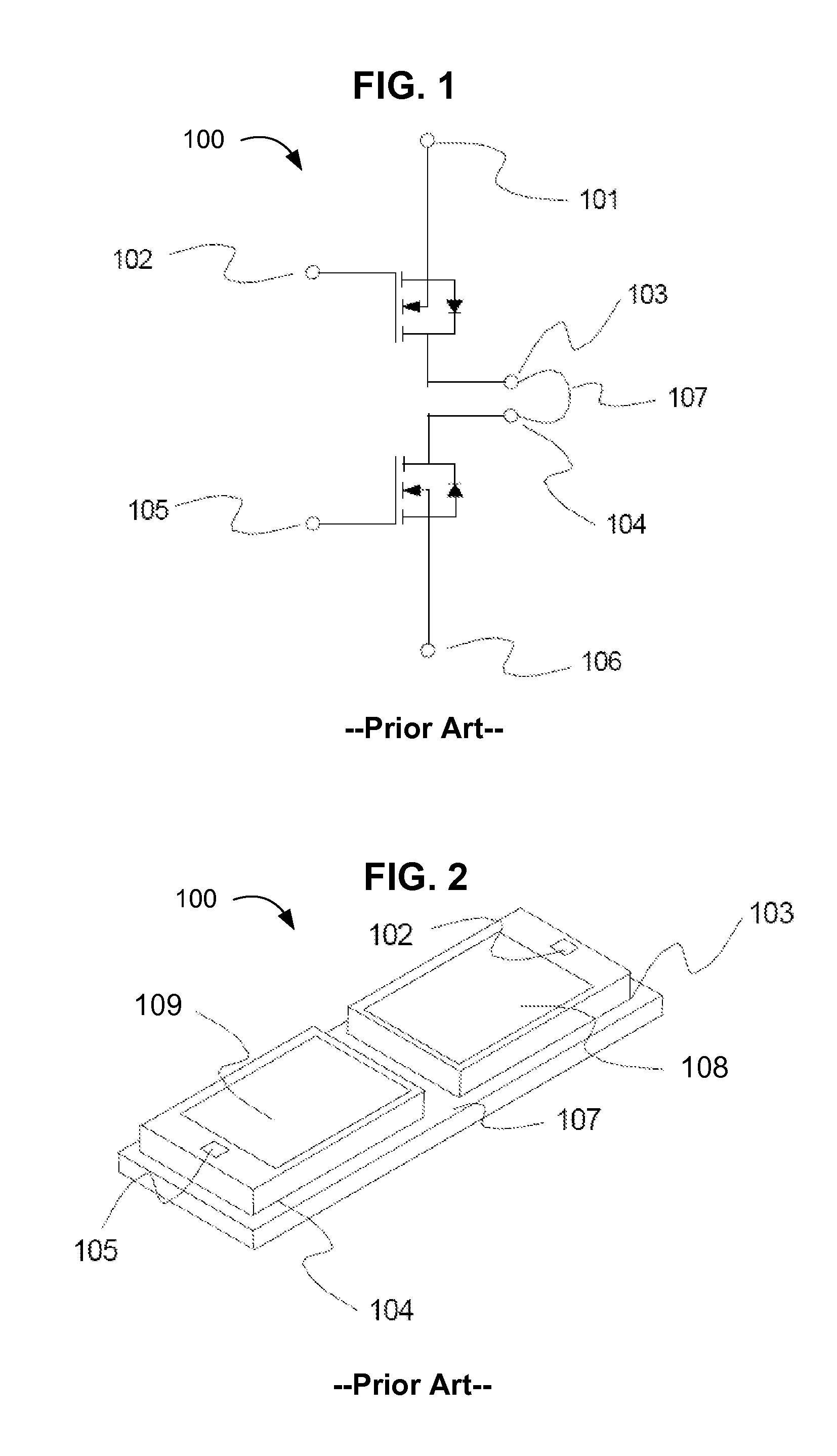

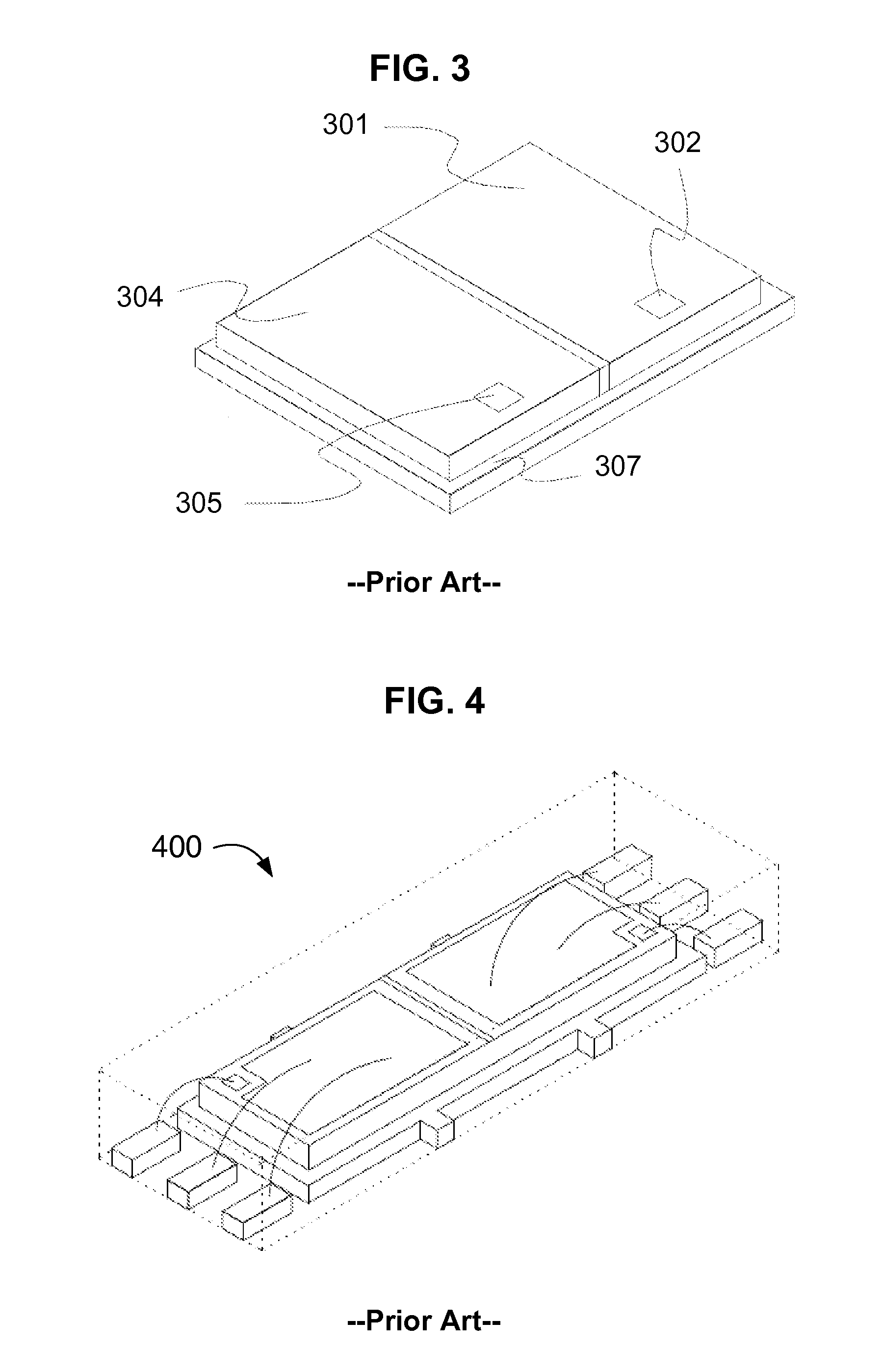

Bi-directional, reverse blocking battery switch

ActiveUS20090179265A1Reduce switchMinimize die costTransistorSemiconductor/solid-state device detailsBackplaneHigh current

Embodiments of the present invention relate to an improved die layout for a bi-directional and reverse blocking battery switch. According to one embodiment, two switches are oriented side-by-side, rather than end-to-end, in a die package. This configuration reduces the total switch resistance for a given die area, often reducing the resistance enough to avoid the use of backmetal in order to meet resistance specifications. Elimination of backmetal reduces the overall cost of the die package and removes the potential failure modes associated with the manufacture of backmetal. Embodiments of the present invention may also allow for more pin connections and an increased pin pitch. This results in redundant connections for higher current connections, thereby reducing electrical and thermal resistance and minimizing the costs of manufacture or implementation of the die package.

Owner:GEM SERVICES

Engine braking method

InactiveCN104454178AEliminate high oil pressureEliminate high distortionValve arrangementsOutput powerValve actuatorChain type

The invention discloses an engine braking method. A cam roller is moved by an axial driving mechanism of the cam roller from a first axial position to a second axial position on a roller shaft, connection between the cam roller and a conventional ignition cam is switched into connection between the cam roller and an engine braking cam, movement of a conventional ignition valve stops, and movement of a braking valve of an engine is generated. The axial driving mechanism of the cam roller can be integrated in a valve actuator such as a rocker arm and can also be located outside the valve actuator; for example, the axial driving mechanism of the cam roller is fixed to the engine. By means of the engine braking method, high-power braking generated by the special braking cam is obtained, the special braking cam can only comprise a braking exhaust cam body and can also comprise the braking exhaust cam body and a braking admission cam body at the same time, engine braking is constructed as non-hydraulic fixed-chain type bearing, and the efficacy losing mode of hydraulic bearing is avoided. The braking control is simple, the braking performance is excellent, the structure is simple and compact, manufacturing and assembling are easy, and the application range is wide.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

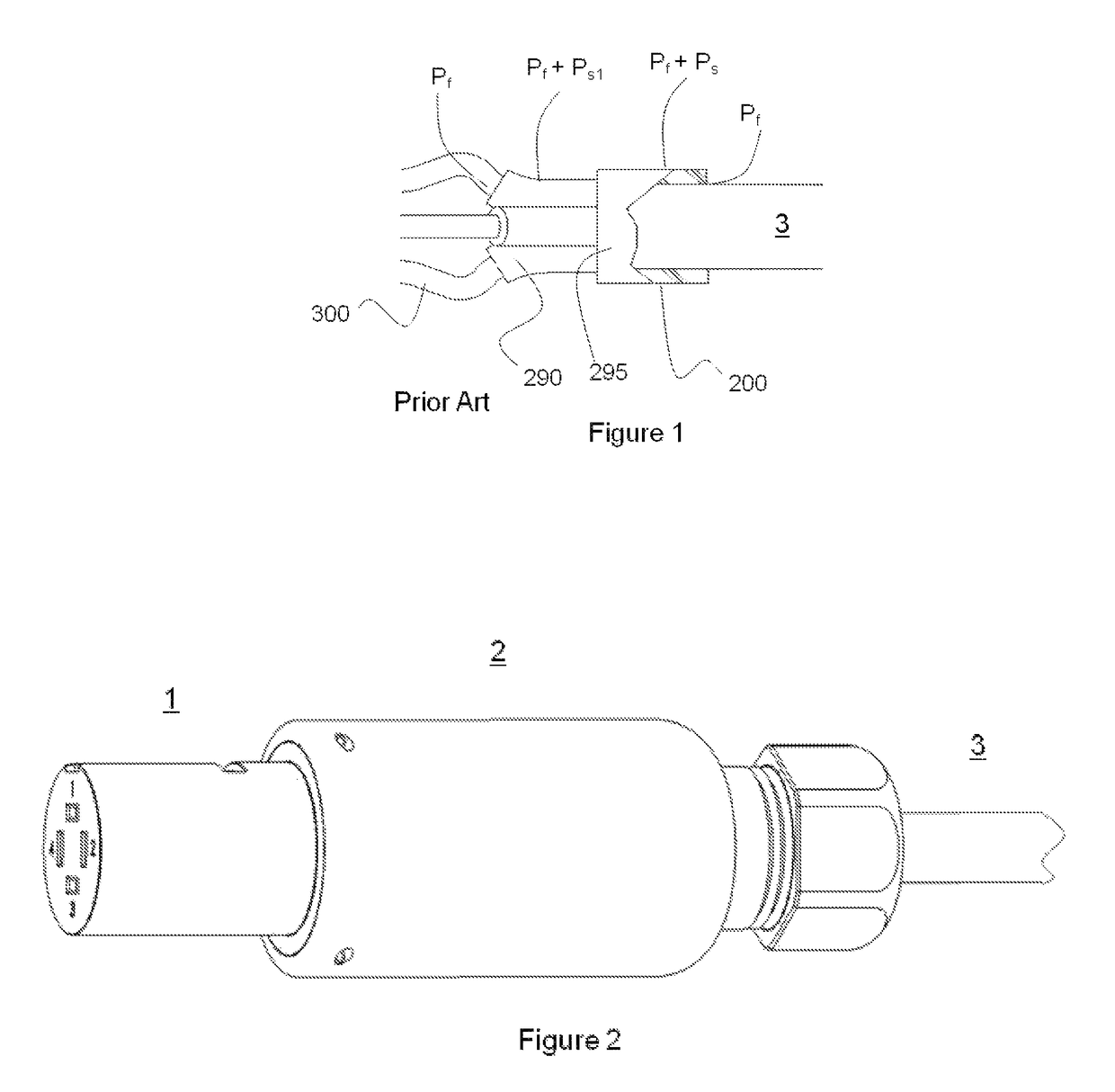

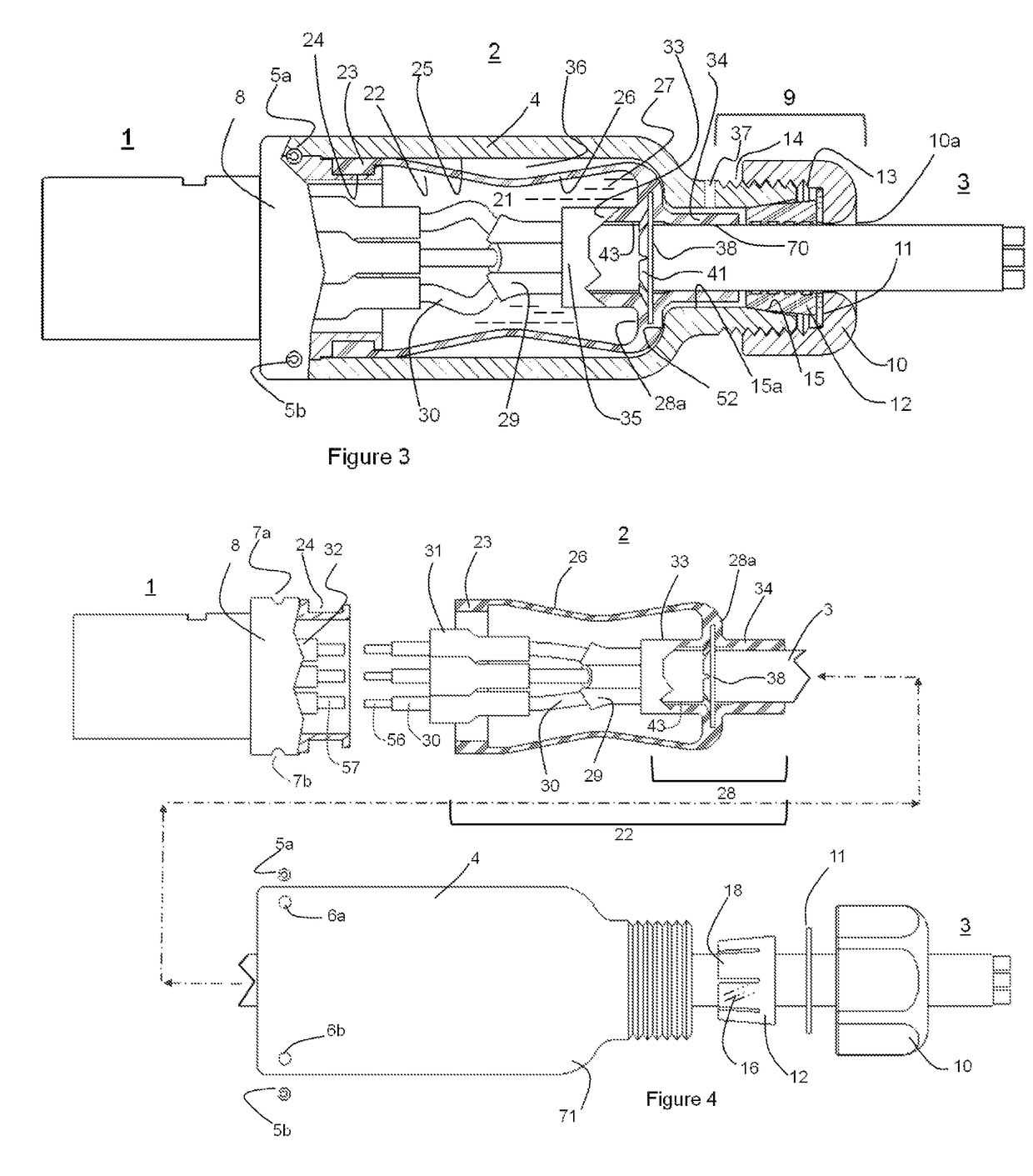

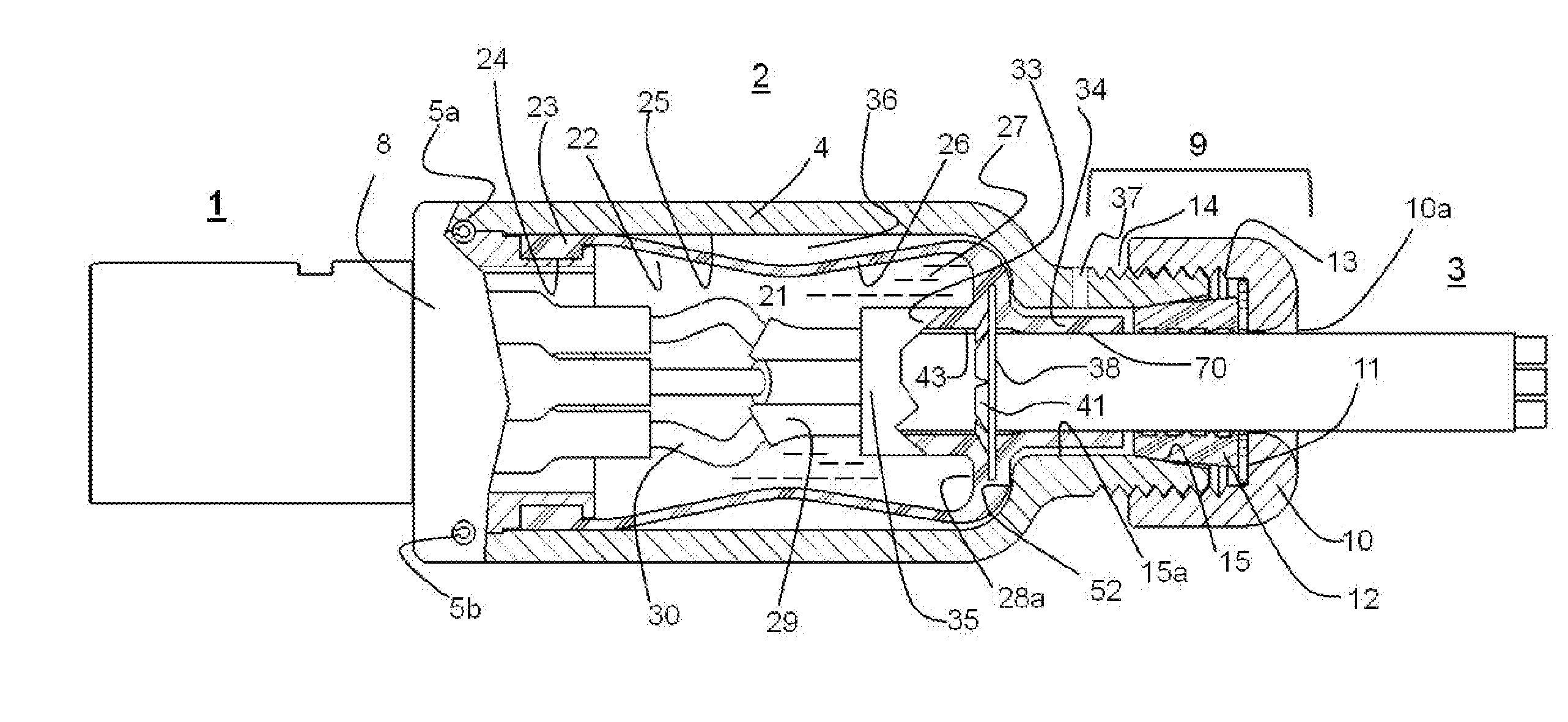

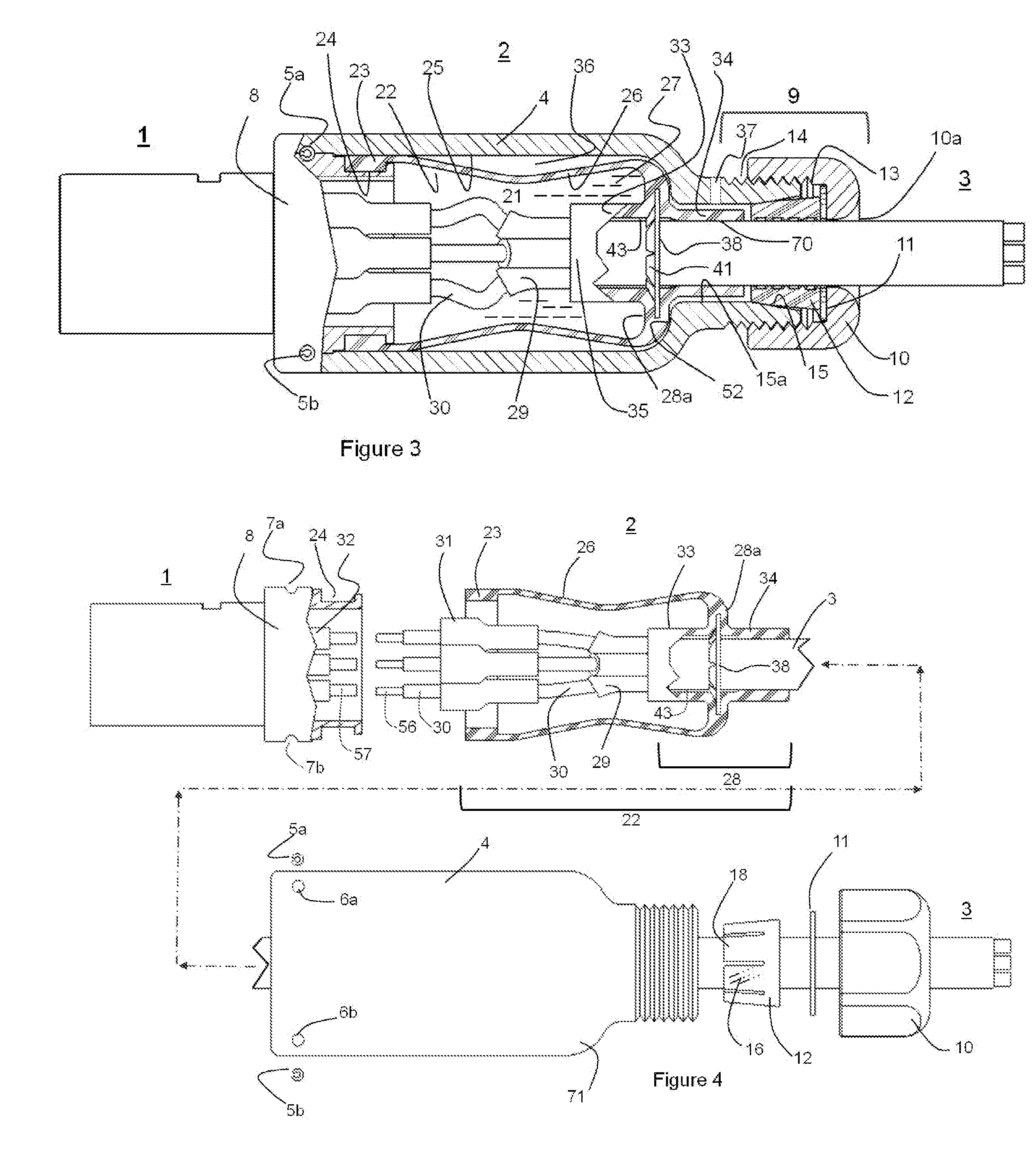

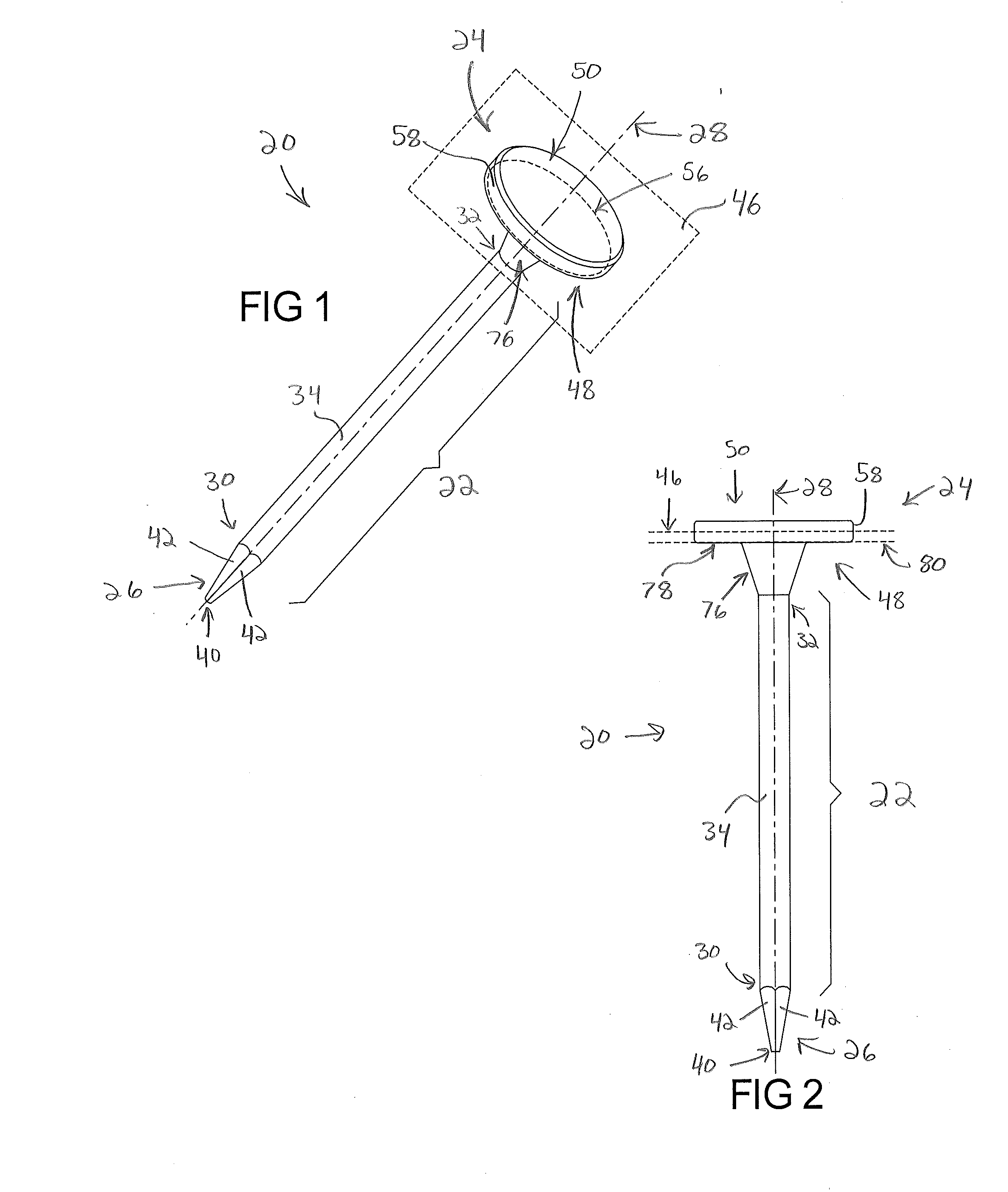

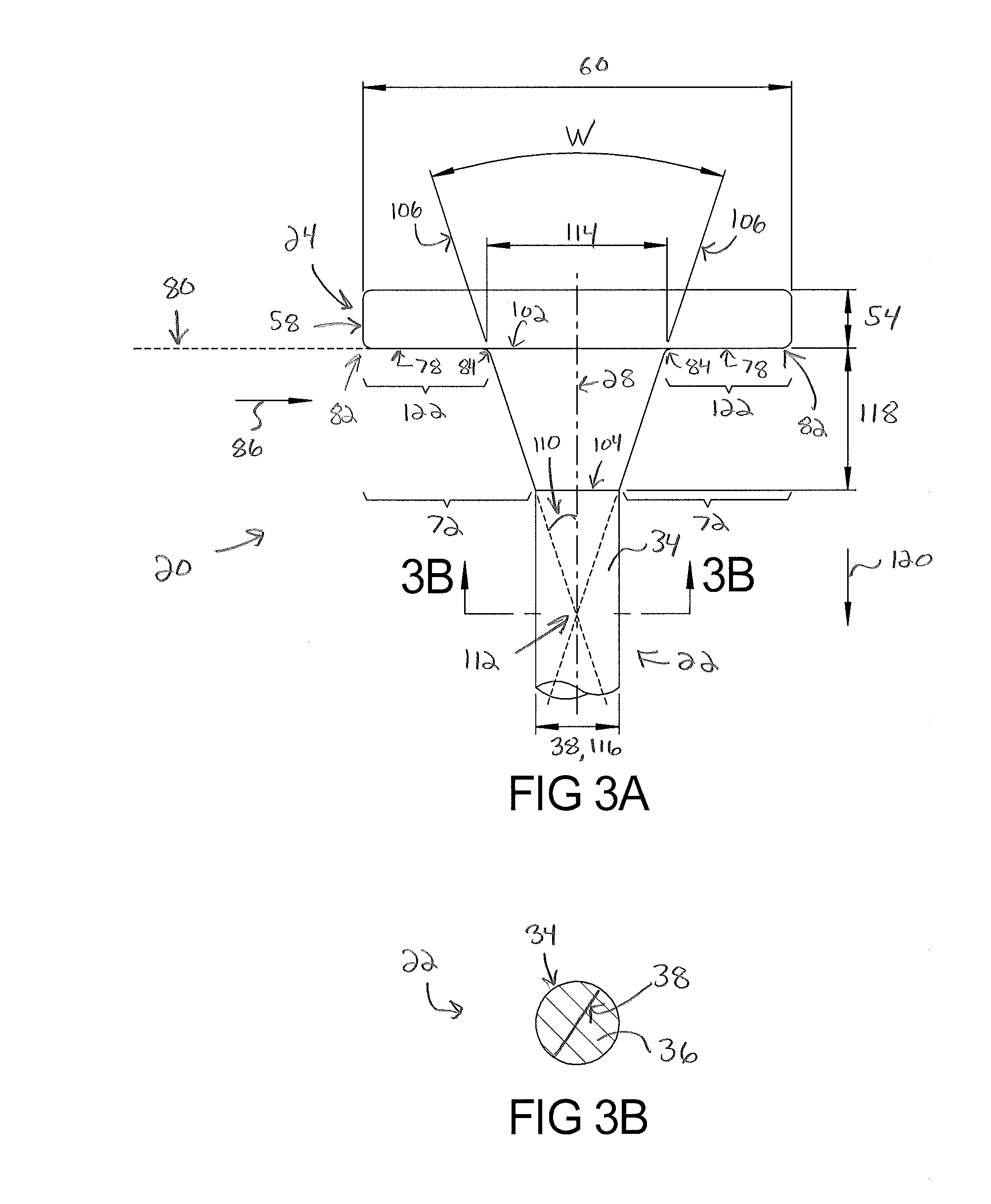

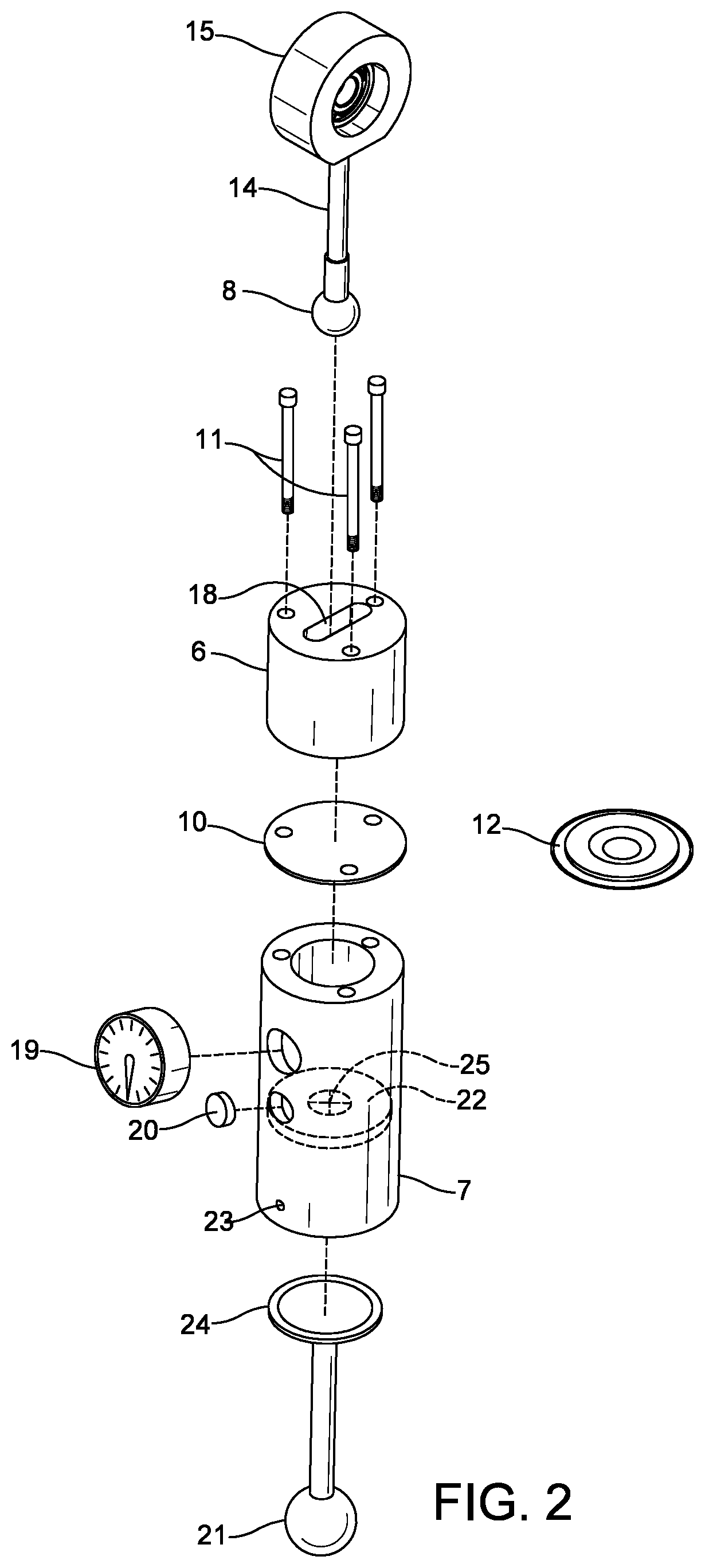

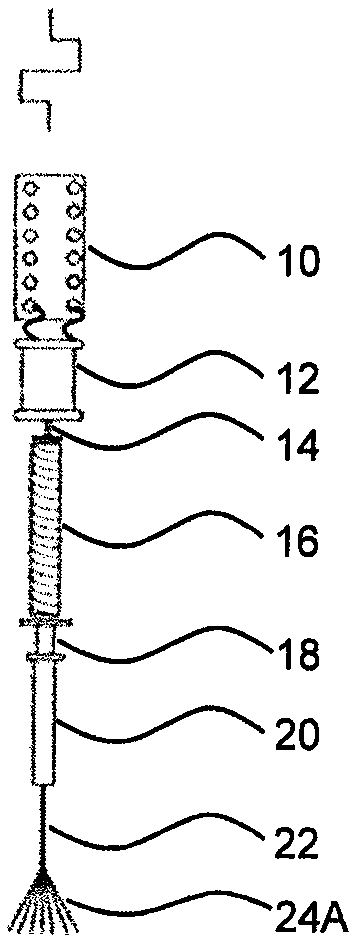

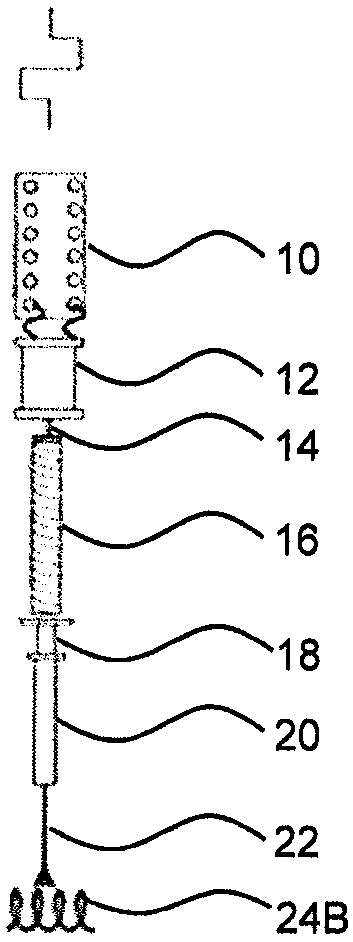

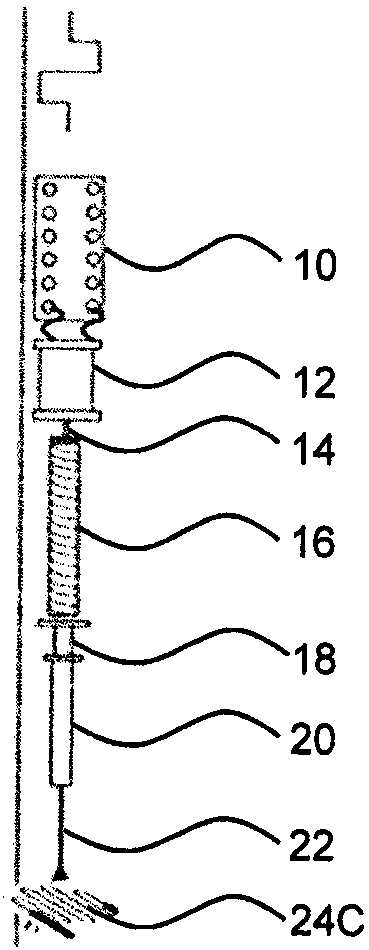

Cable termination

ActiveUS9715068B2Simple structureQuickly and easily installableCouplings bases/casesCoupling light guidesElastomerElectrical conductor

The cable termination may include a housing and a cable having at least one conductor disposed within the housing with an elastomeric body disposed in the housing and constrictively stretched over a portion of the cable. A retainer may be disposed around a portion of the cable for retaining the elastomeric body on the cable. The cable termination may also include an enclosure capable of changing volumetrically in response to fluctuating pressure disposed in the housing and around a portion of the cable.

Owner:PONTUS SUBSEA CONNECTORS LLC

Cable termination

ActiveUS20170003455A1Simple structureQuickly and easily installableCoupling device detailsCoupling light guidesElastomerElectrical conductor

The cable termination may include a housing and a cable having at least one conductor disposed within the housing with an elastomeric body disposed in the housing and constrictively stretched over a portion of the cable. A retainer may be disposed around a portion of the cable for retaining the elastomeric body on the cable. The cable termination may also include an enclosure capable of changing volumetrically in response to fluctuating pressure disposed in the housing and around a portion of the cable.

Owner:PONTUS SUBSEA CONNECTORS LLC

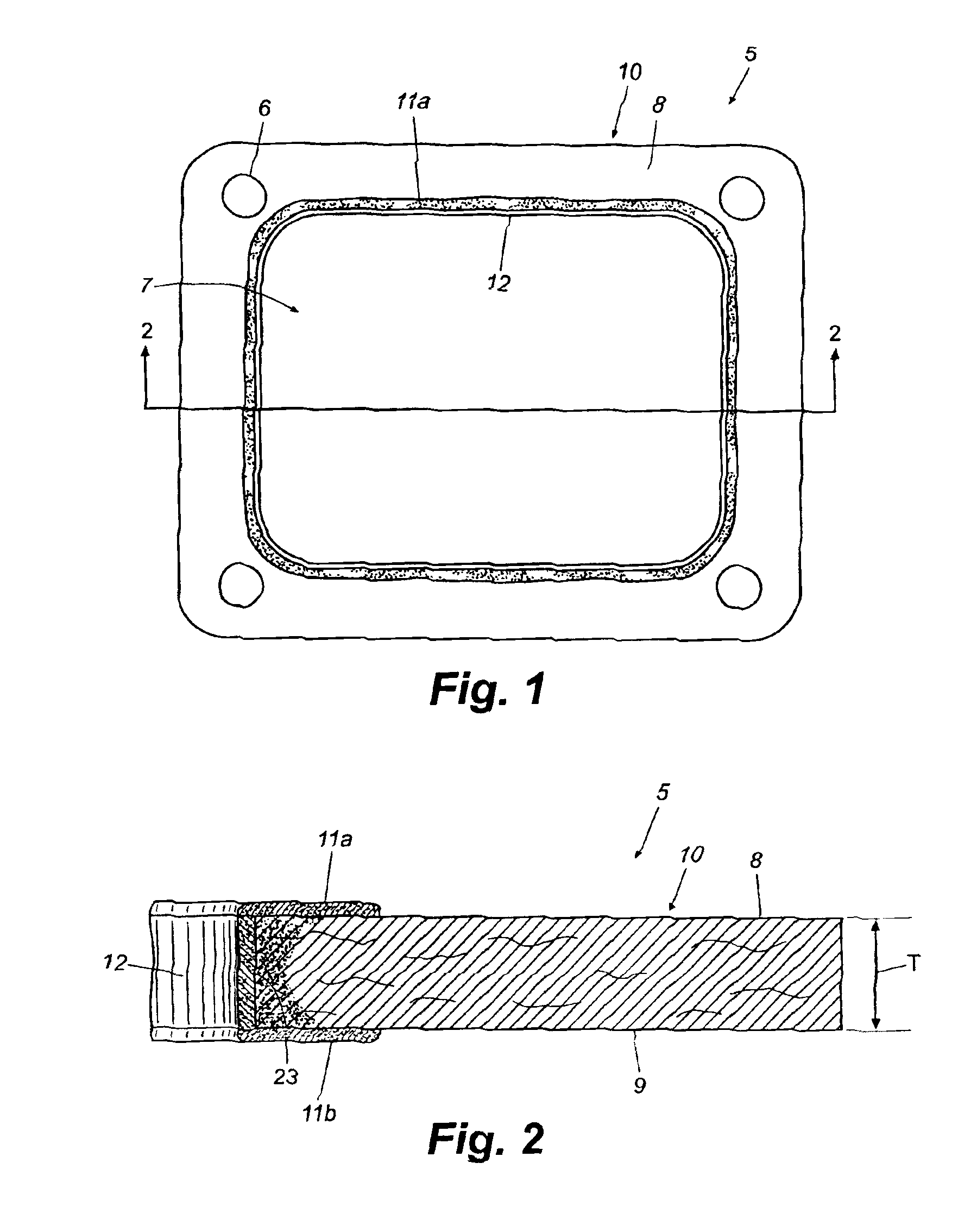

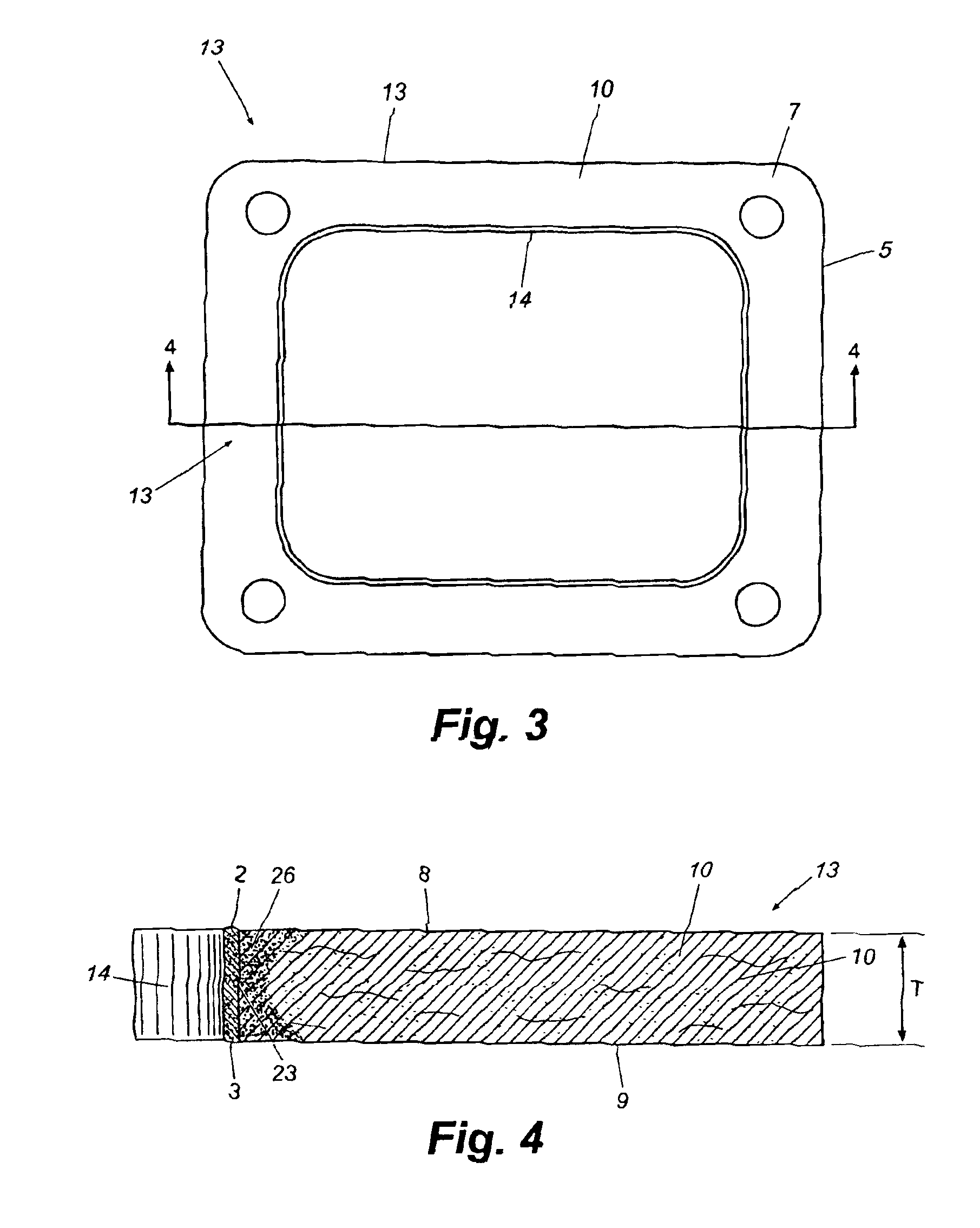

Edge coated gaskets and method of making same

InactiveUS6923998B2Improve sealingEliminate failure modesEngine sealsSealing arrangements for enginesFacial planeEngineering

An edge coated gasket includes a base sheet made of compressible gasket material and having opposed faces and an interior edge surrounding and defining an aperture. An edge coating of polymer or other material is disposed on and seals the interior edge of the base sheet and may project beyond the facial planes of the base sheet to define protruding rims extending around the aperture. Face coatings may also be applied to one or more of the faces extending in relatively narrow strips around the aperture of the base sheet. When clamped between flange surfaces, the edge coating engages, conforms to, and seals against the flange surfaces to provide a seal against both interfacial and intersticial migration of fluid past the gasket. At the same time, the inherently good compression failure resistance of the compressible gasket material of the base sheet is preserved. Thus, a gasket with enhanced sealability and compression failure resistance is provided. A unique method of making such an edge coated gasket is also disclosed.

Owner:LYDALL PERFORMANCE MATERIALS US INC

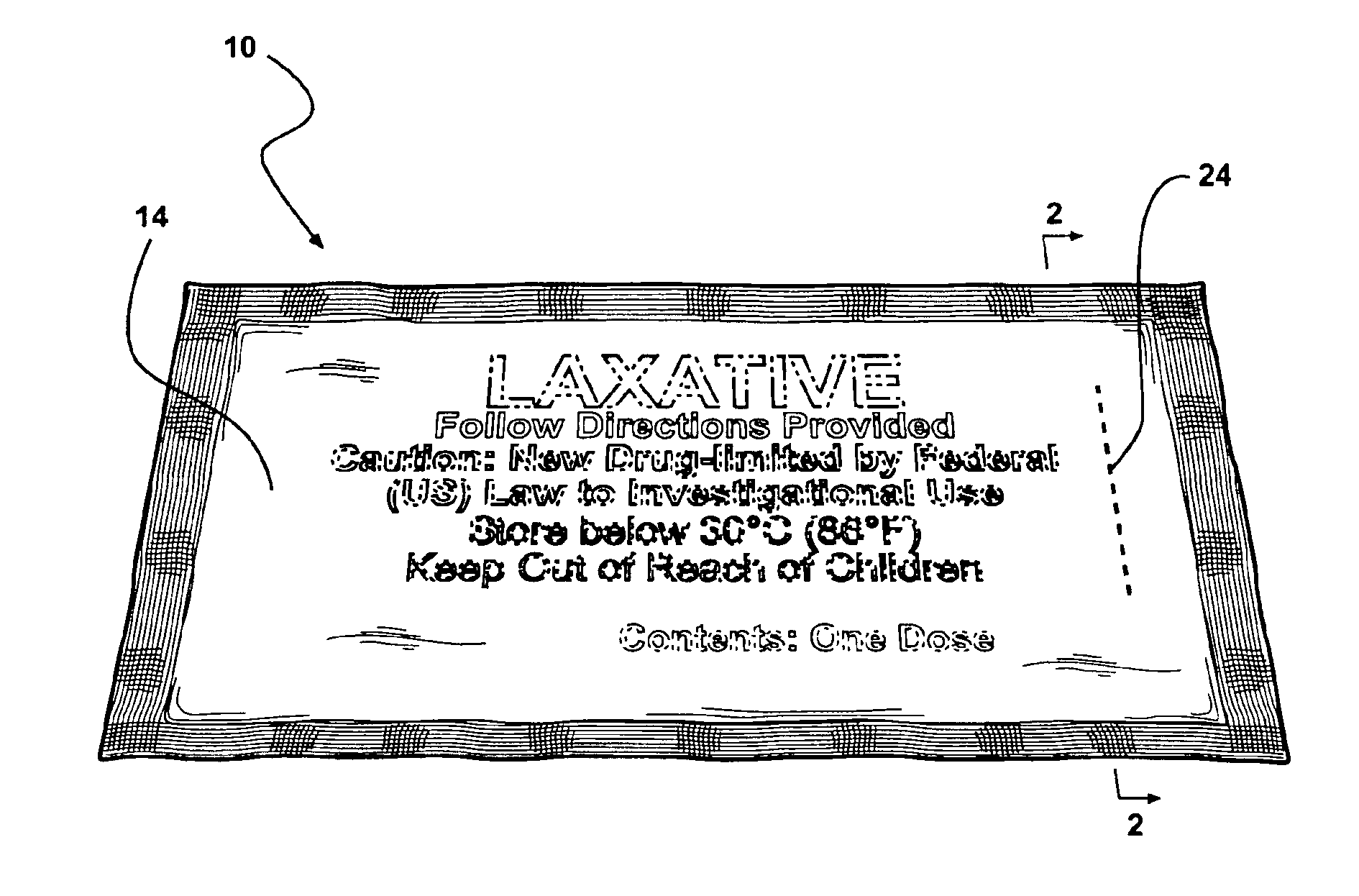

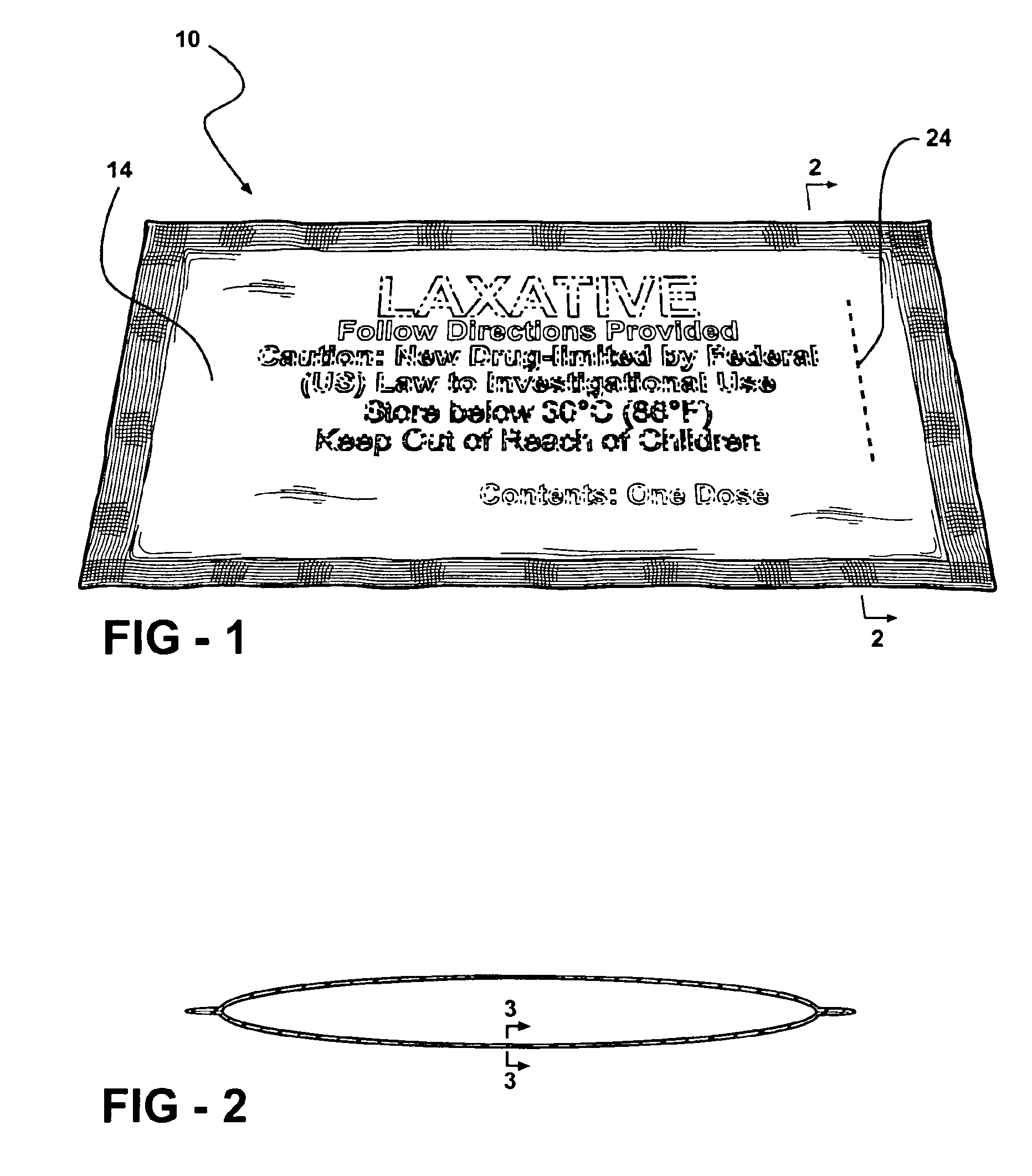

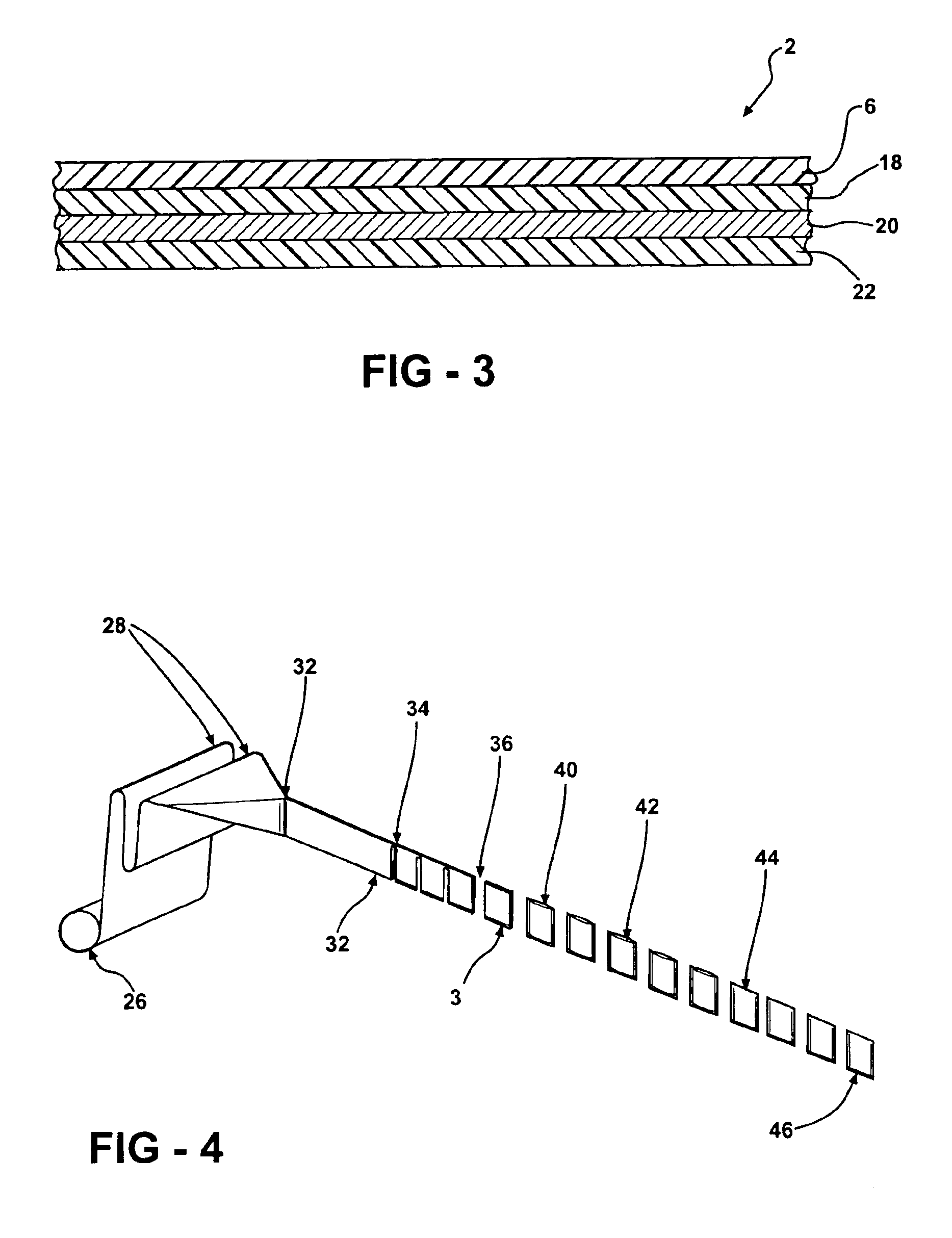

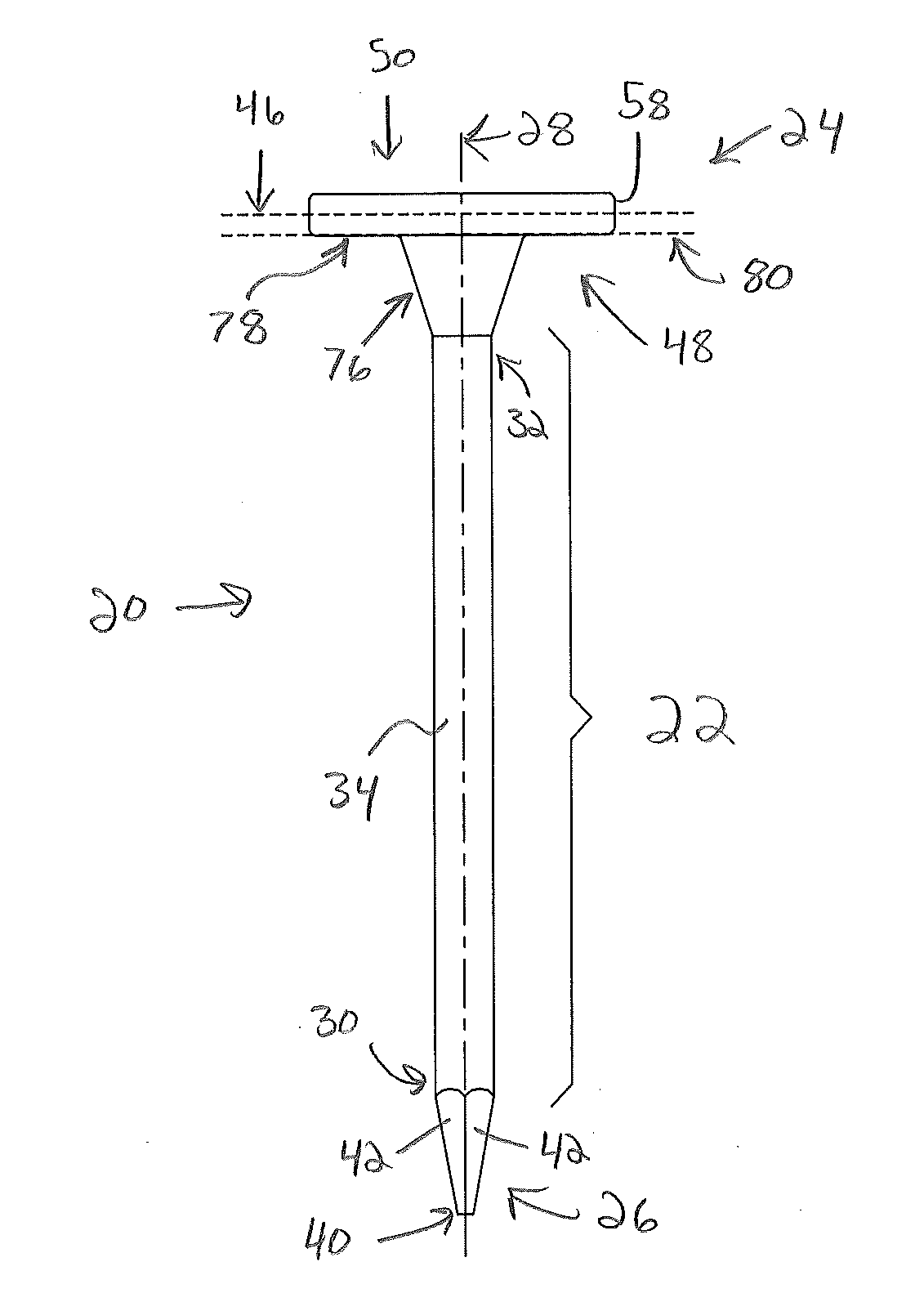

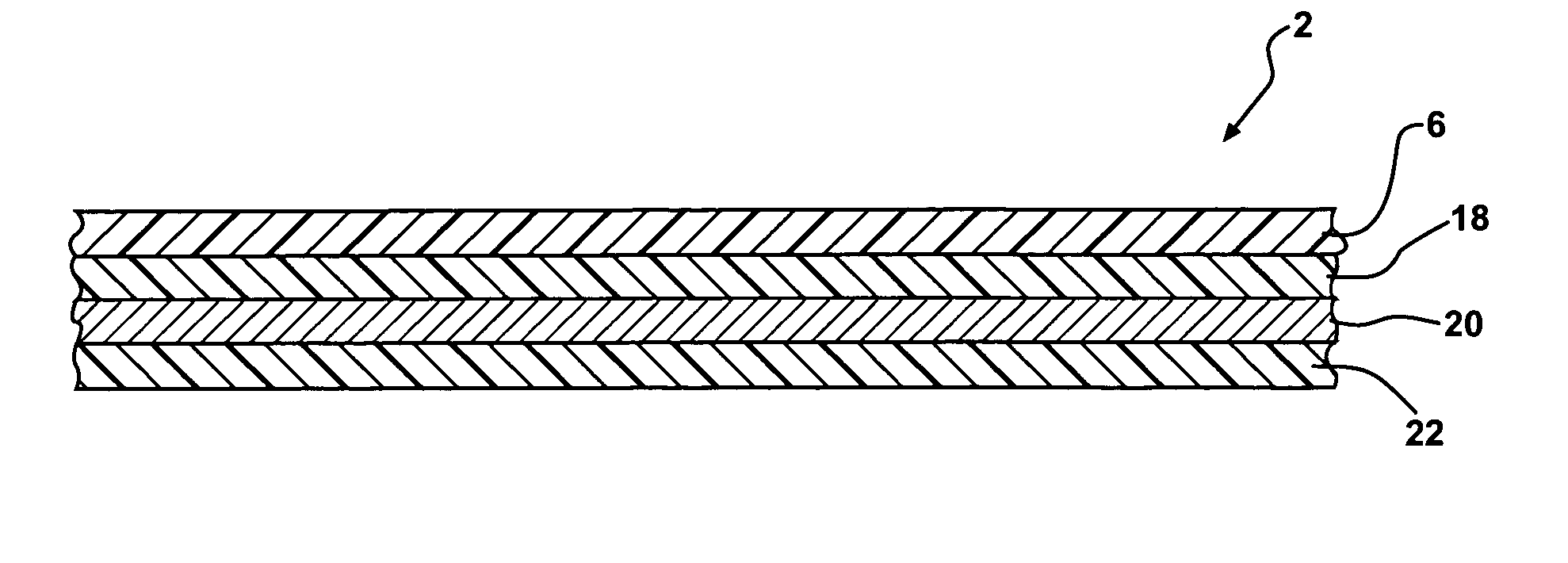

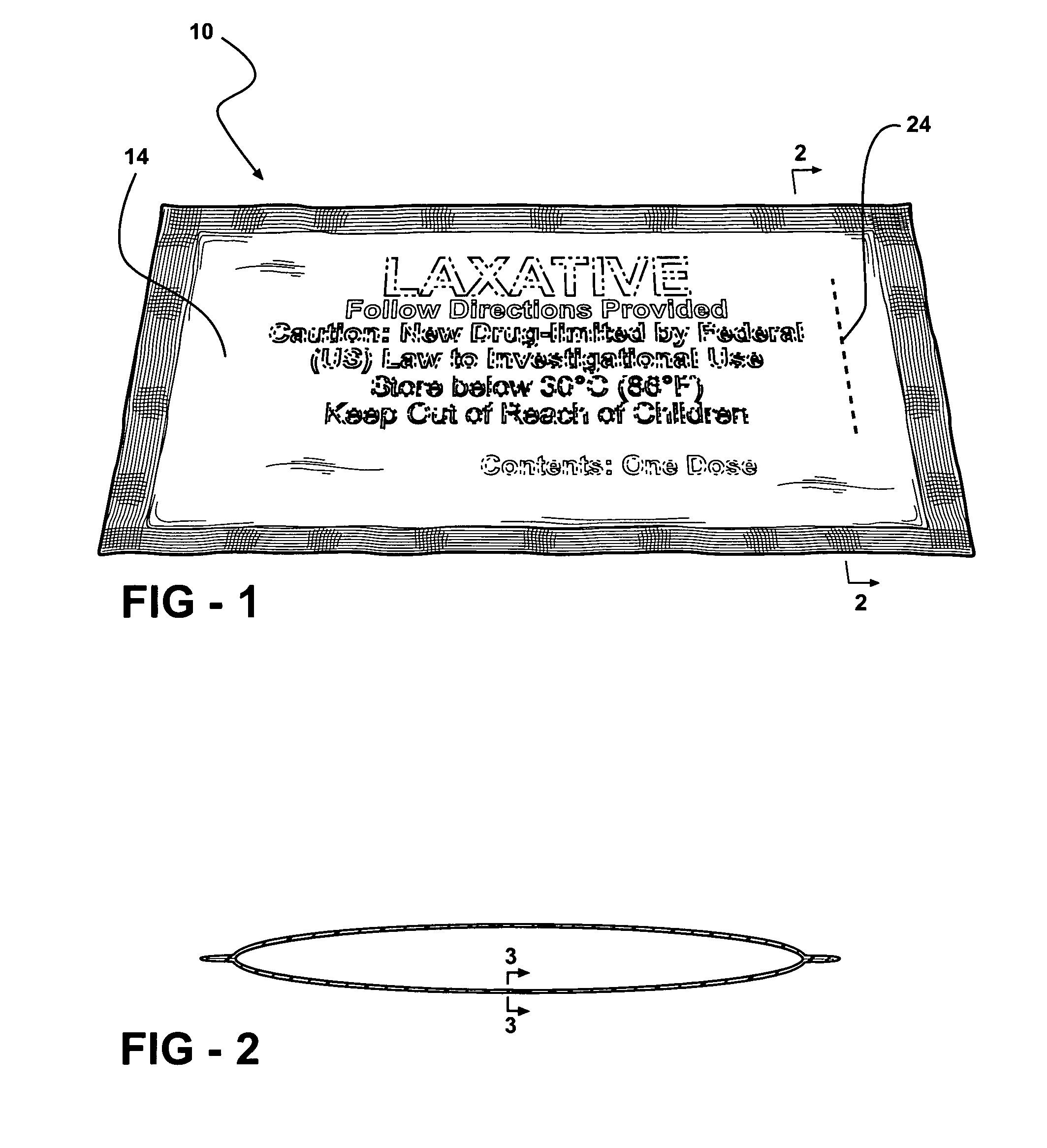

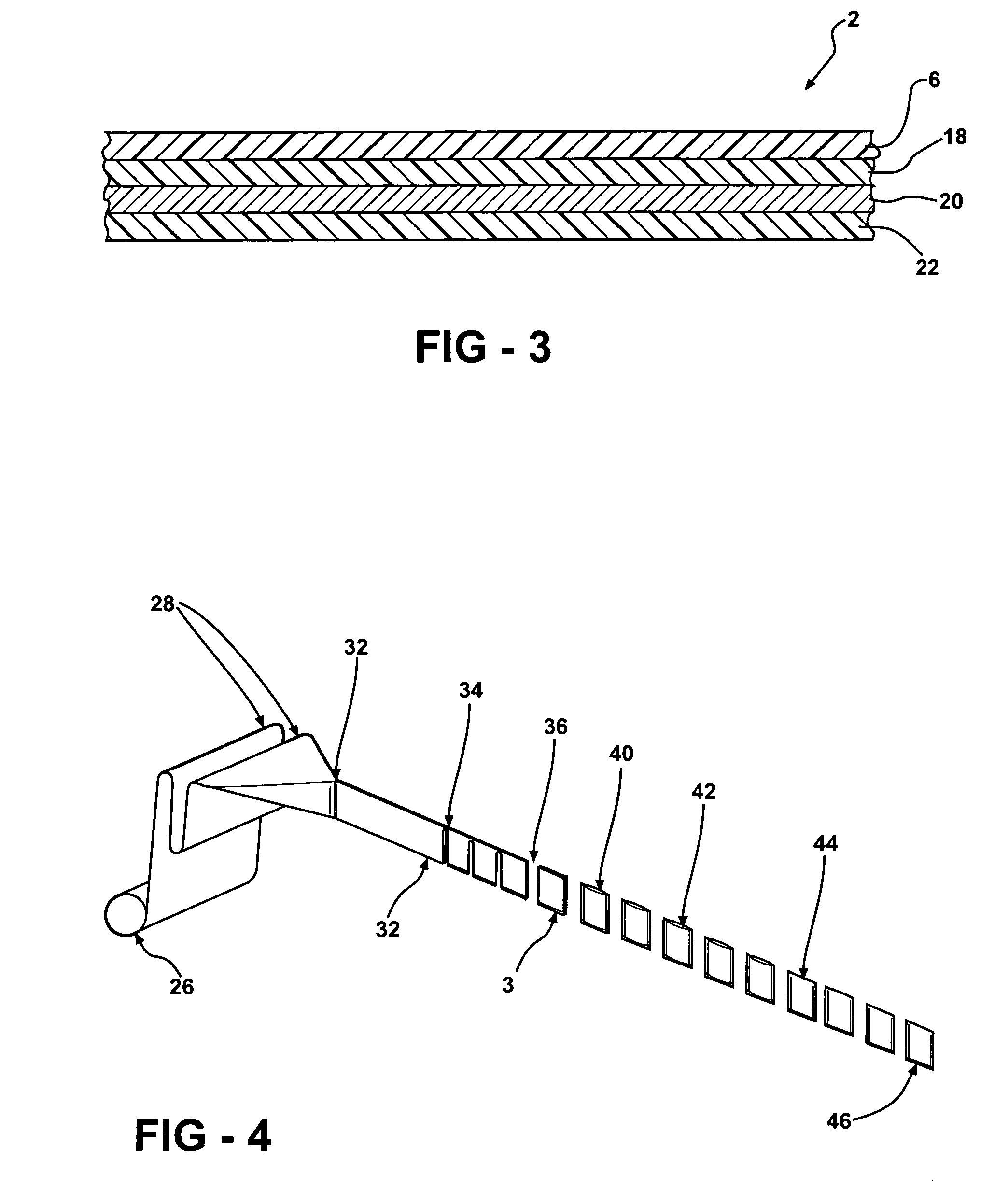

No tear pharmaceutical pouch

InactiveUS6936318B2Negating tear resistance of filmEliminate failure modesSynthetic resin layered productsPharmaceutical containersHigh densityHermetic seal

Owner:REYNOLDS PACKAGING

Compression indentation fastener device

An enlarged head fastener device and method for manufacturing the same is described. The enlarged head fastener device includes a shank and a head. The head extends outwardly from the shank in a transverse plane to define a head periphery. The head has an anterior side and a posterior side. The anterior side includes a bearing surface and a convergent transition portion that reinforces the head. The convergent transition portion extends between a large end adjacent the bearing surface to a small end adjacent the shank. At least one ridge formation projects from the anterior side of the head providing additional reinforcement. The ridge formation extends continuously between an outboard end positioned on the anterior side of the head adjacent the head periphery and an inboard end positioned on the shank. The head may be centered or offset relative to the shank.

Owner:SR SYST

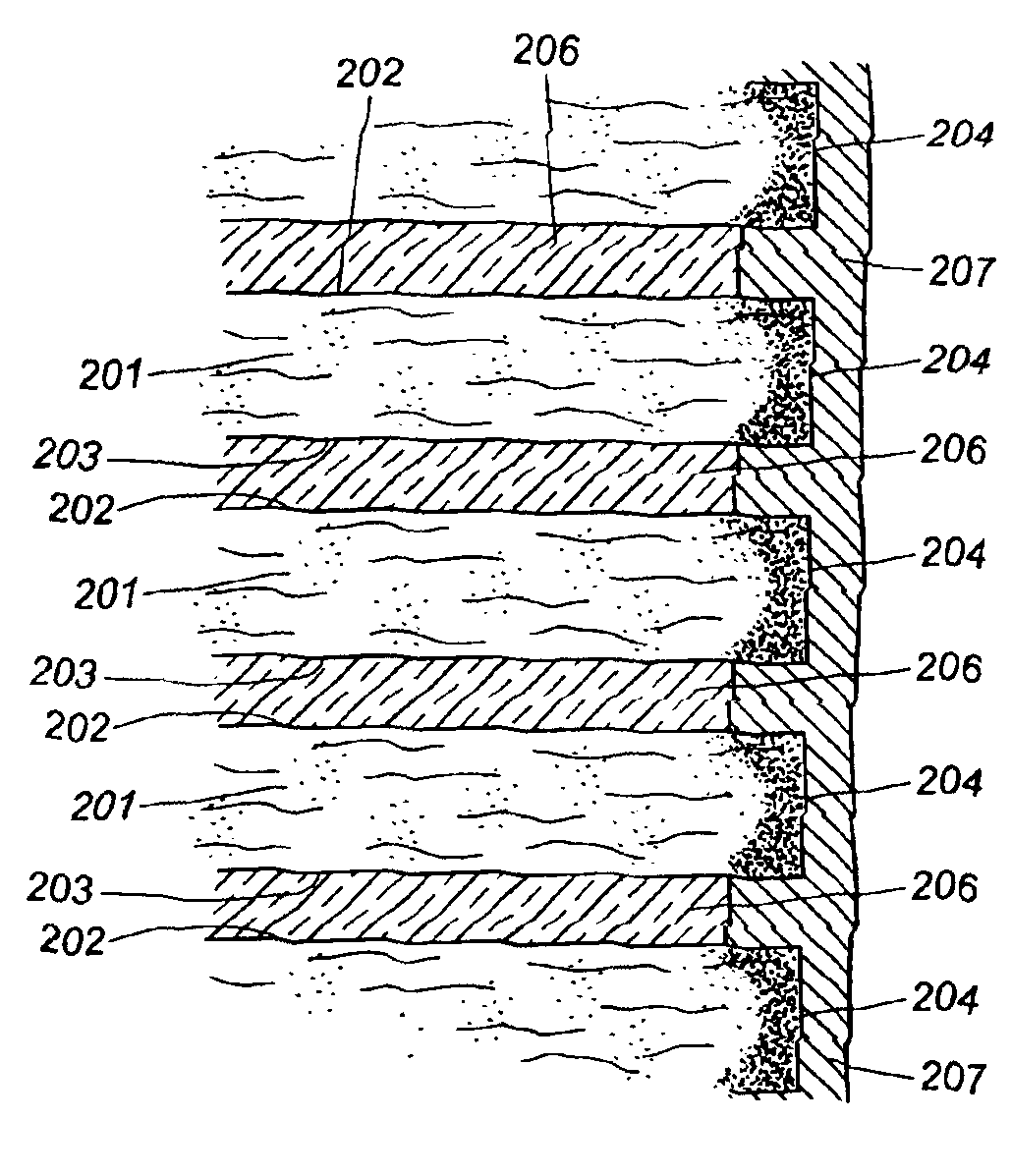

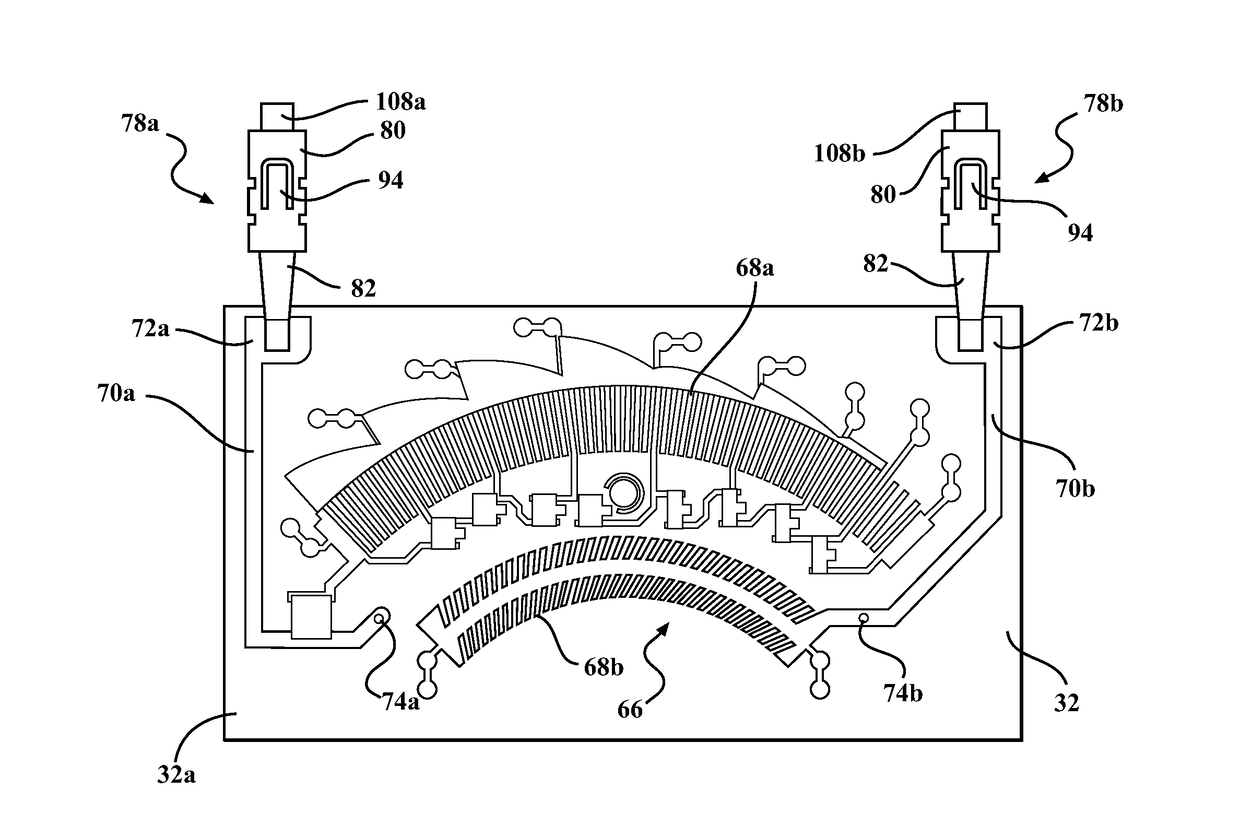

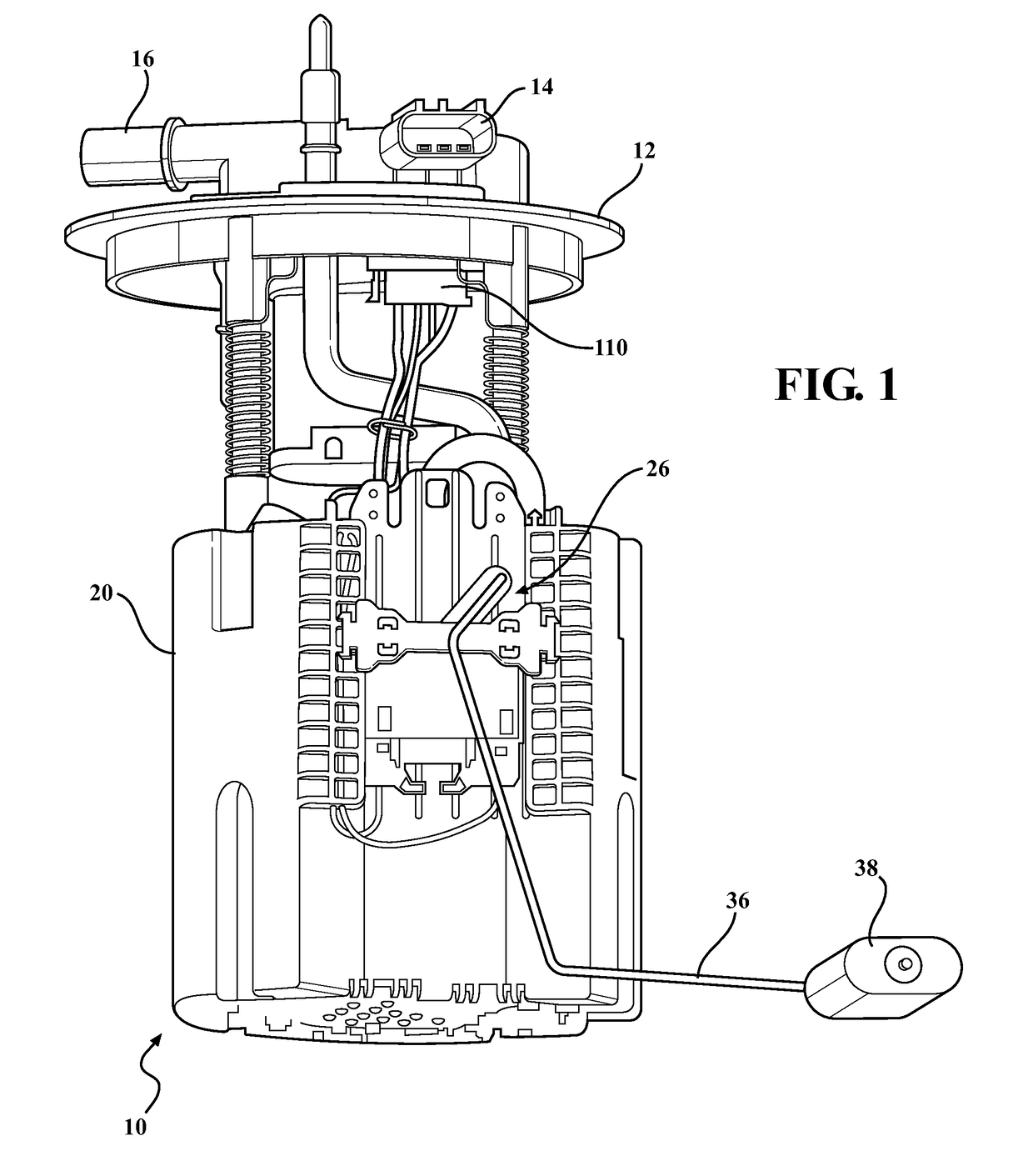

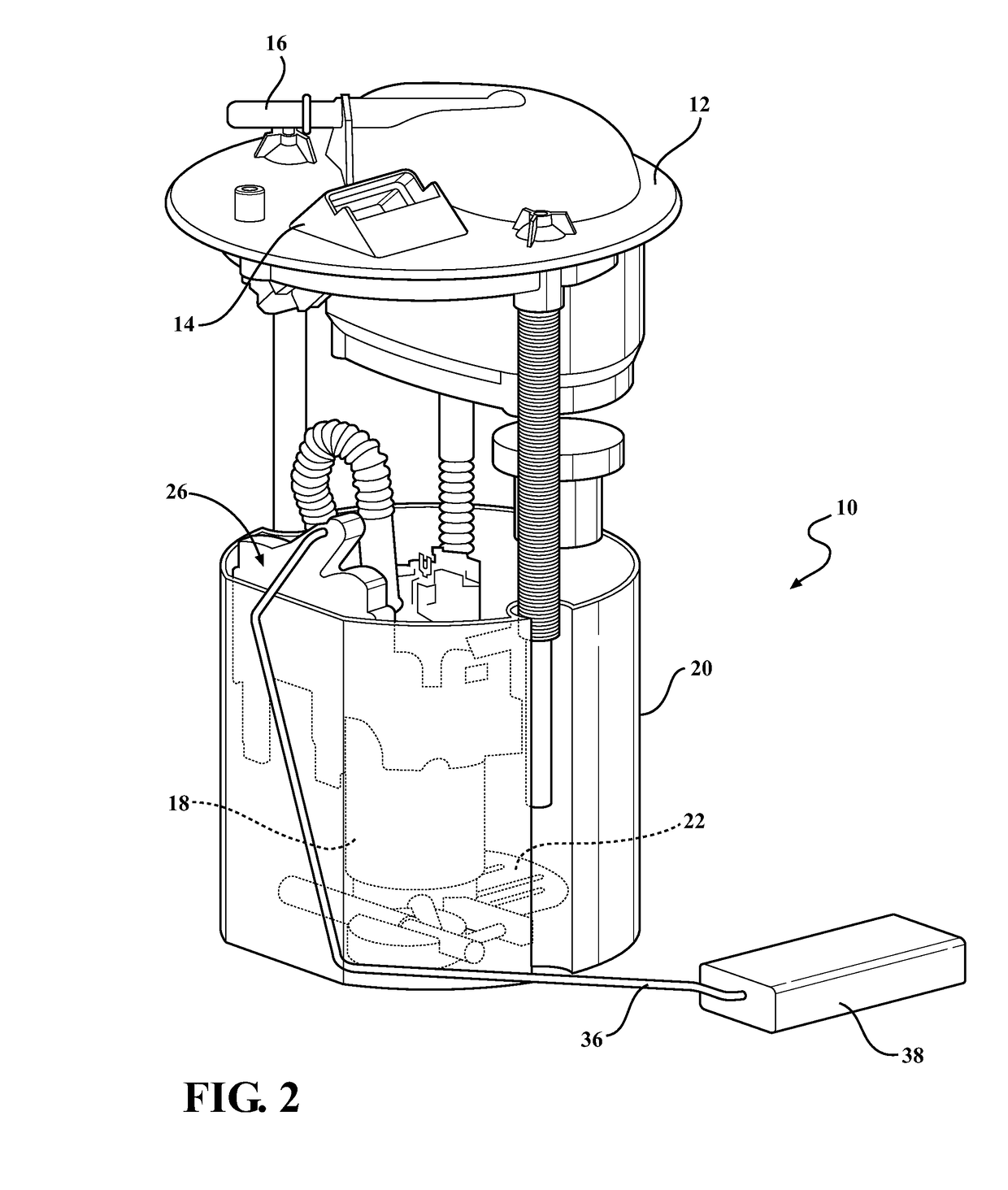

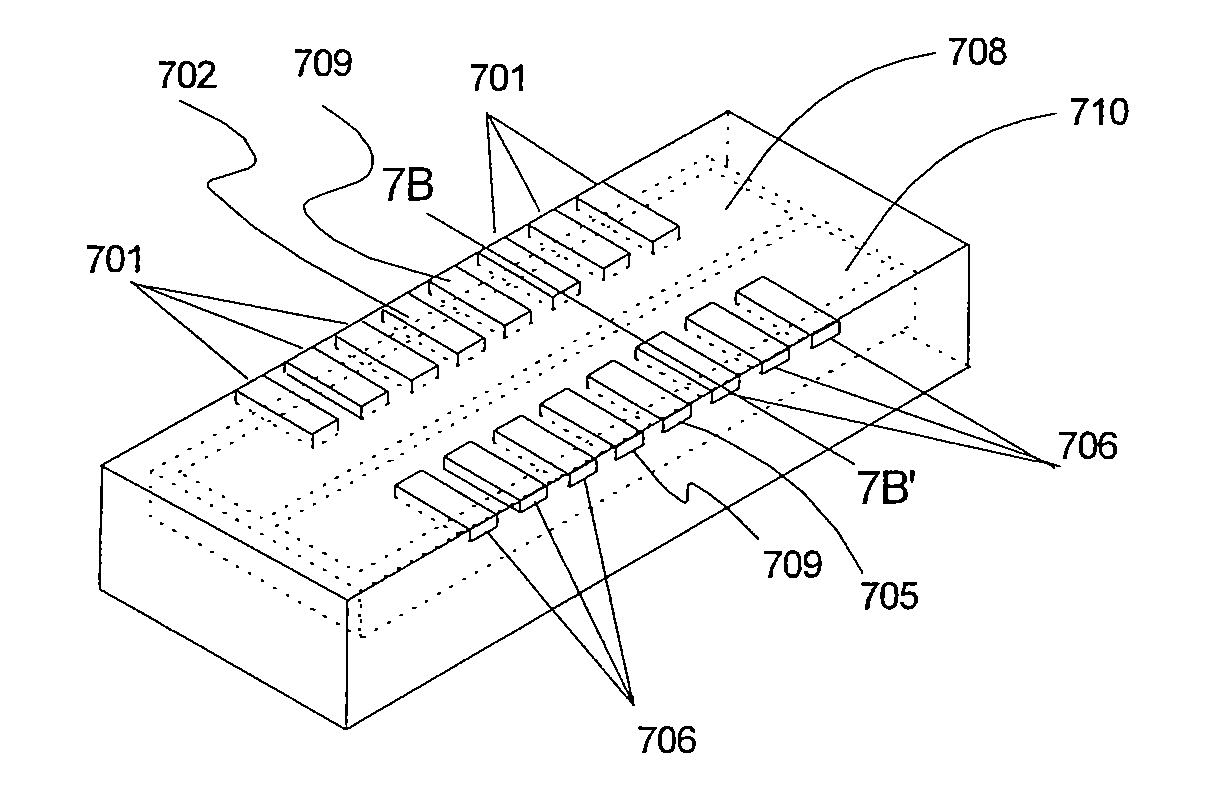

Double-side thick film network on ceramic card

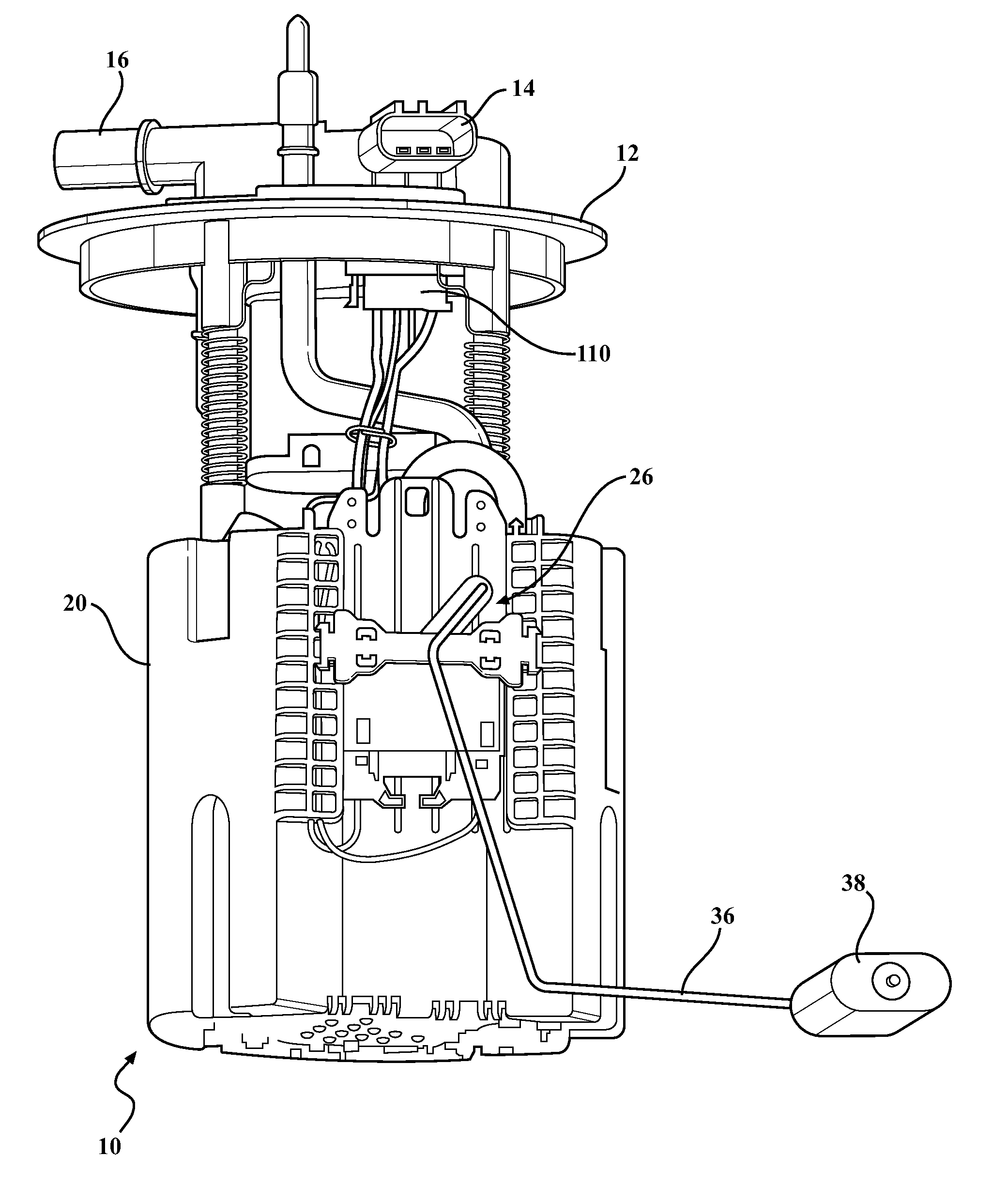

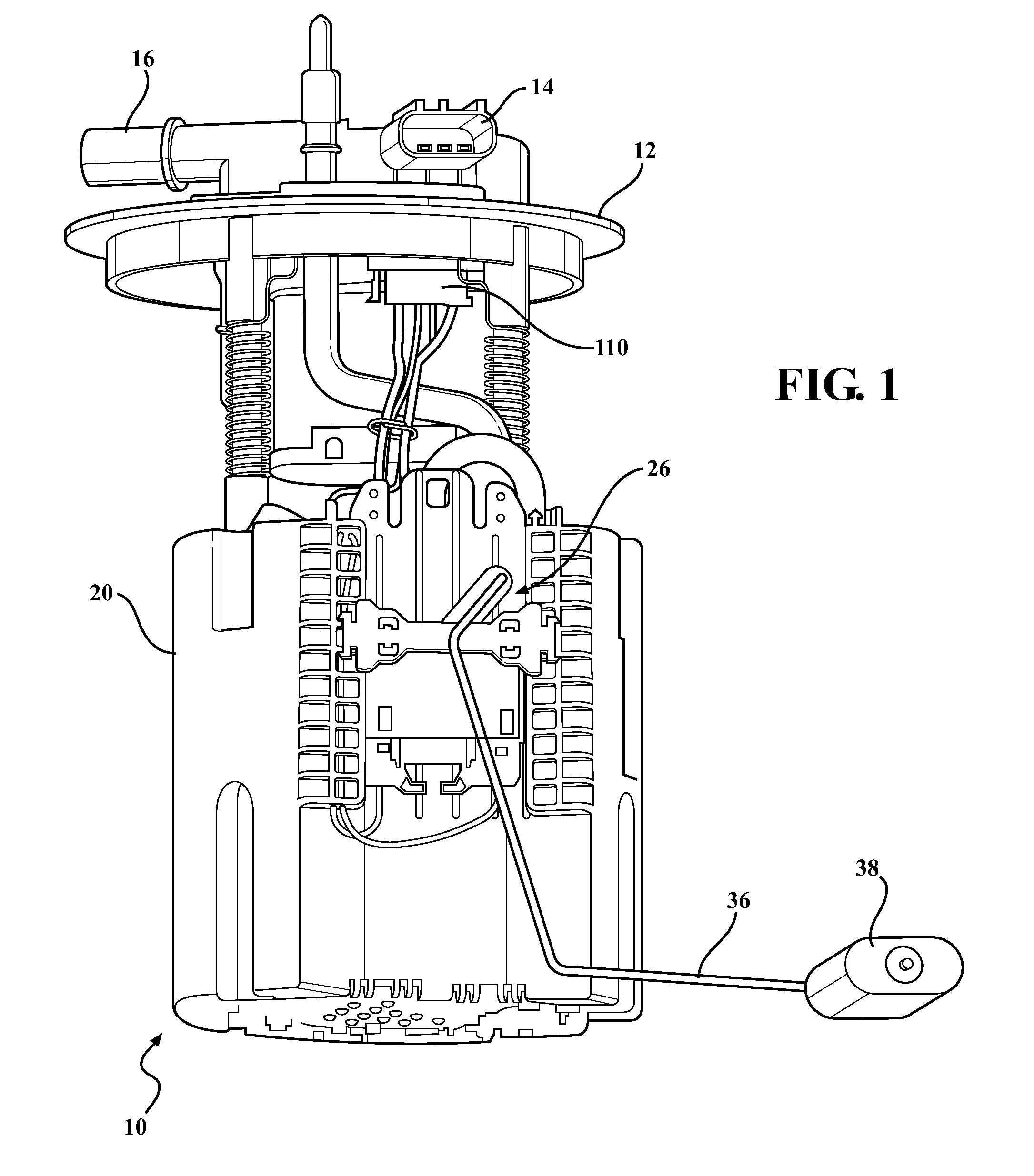

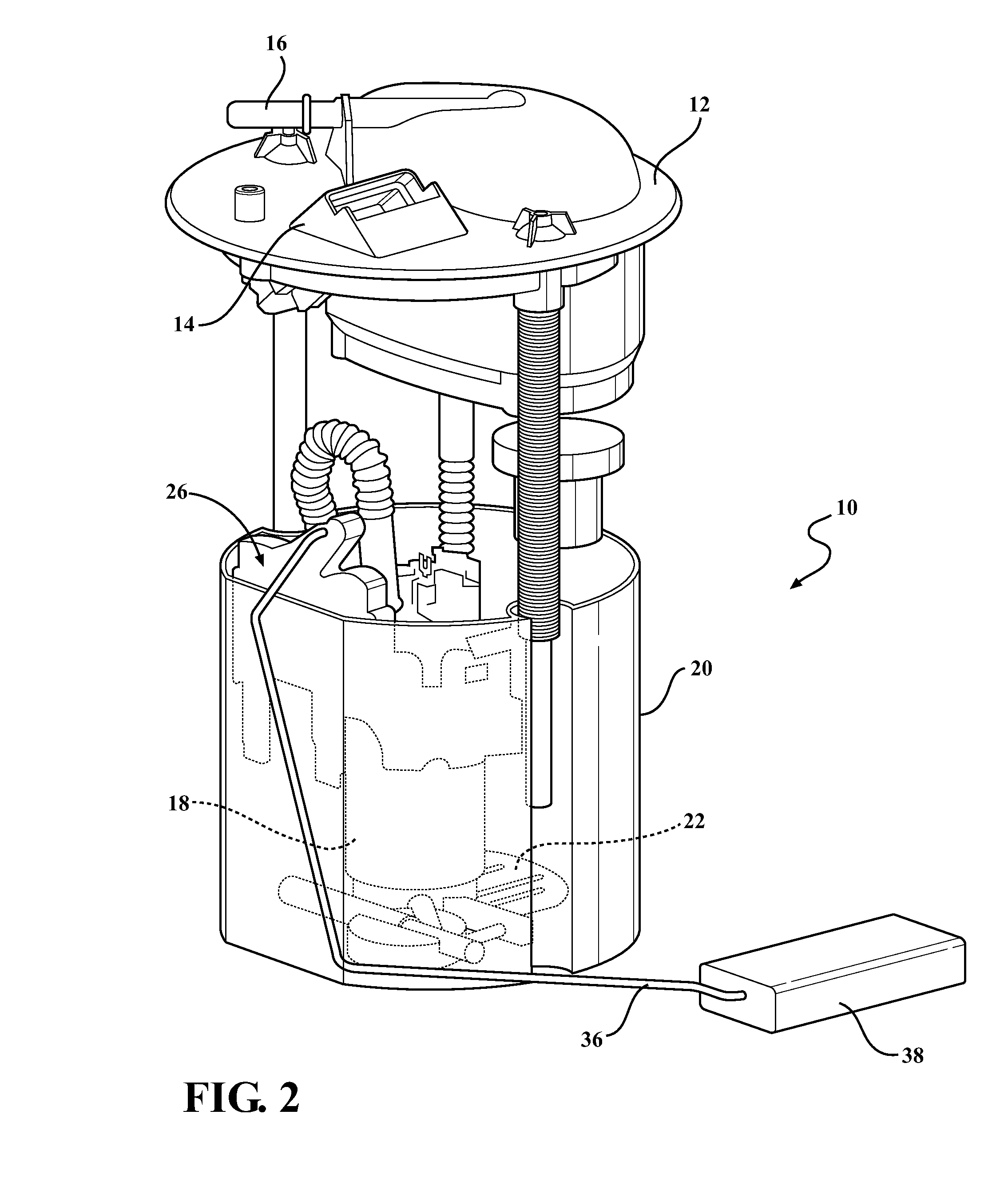

ActiveUS20150338264A1Keep in touchEliminate failure modesEmergency actuatorsCoupling device detailsElectricityNetwork on

A ceramic card having a thick film network, with conductive vias formed as part of the card. Each of the vias is in electrical communication with both sides of the thick film network, allowing the pads and the pad senders to be formed on both sides of the card. This configuration maintains the contact when one of the connectors is subjected to bending force or is otherwise displaced, maintaining contact with at least one of the pads, and allowing the system to still function. The double sided thick film network allows for each connector to touch both sides of one of the pads, and still maintain electrical communication with the level sender, thus eliminating the failure mode of intermittent contact with the thick film network resulting from movement of the connector.

Owner:VITESCO TECH USA LLC

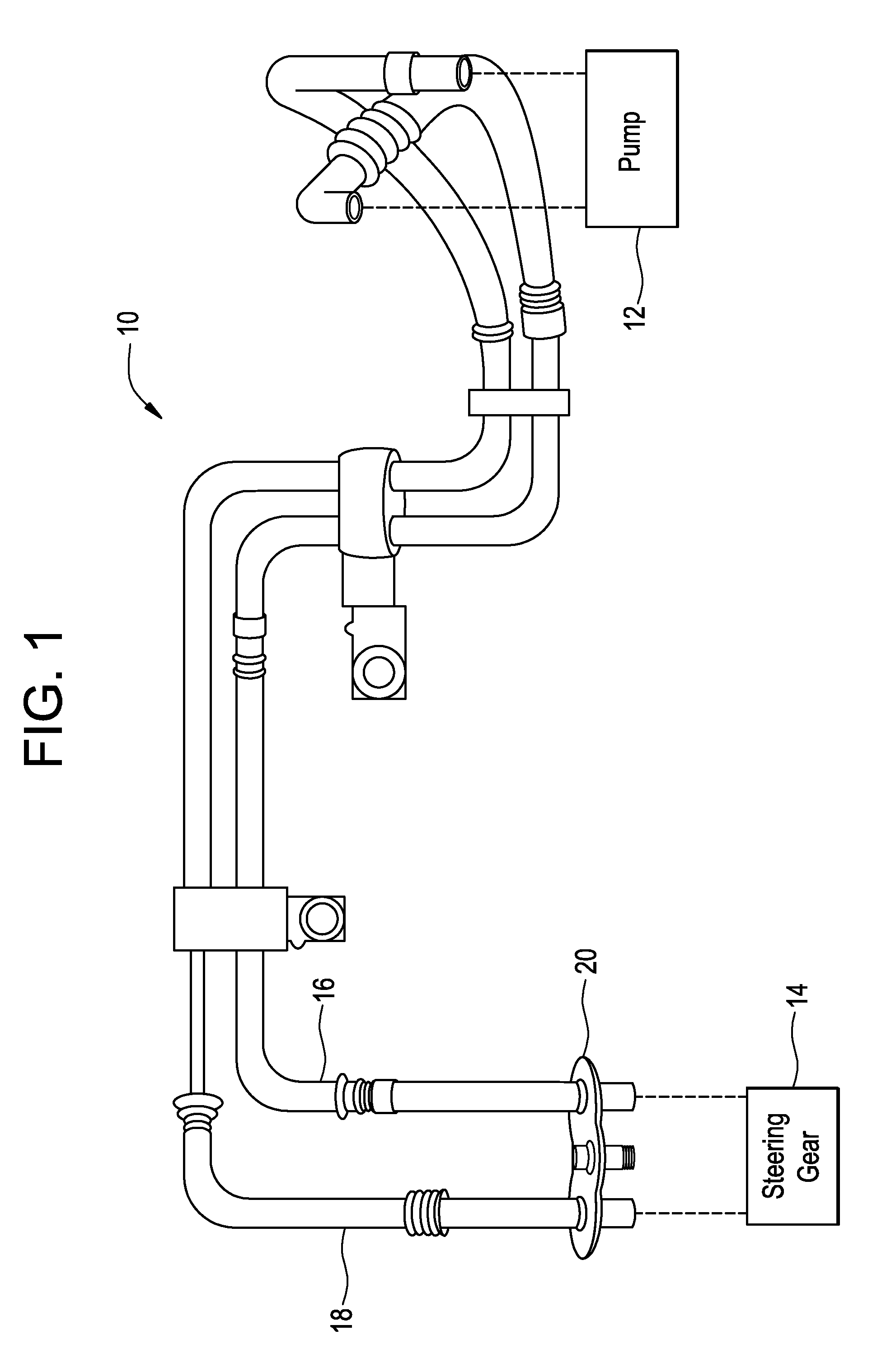

Process of endforming a tubular assembly

InactiveUS7870655B2Improve sealing propertiesAvoid vertical movementJoints with sealing surfacesRopes and cables for vehicles/pulleyHigh pressureBiomedical engineering

Owner:YH AMERICA

No tear pharmaceutical pouch

InactiveUS20050058788A1Negating tear resistance of filmEliminate failure modesSynthetic resin layered productsPharmaceutical containersHigh densityMetal foil

A multi-layered pouch capable of holding pharmaceutical related items. The pouch includes first and second sides engaged along a plurality of extending and interconnected edges thereof and in order to define a hermetically sealed interior for holding the items. Each of the sides exhibits a multi-layered construction including an outer high density polymer film, coated with a clay material, a lower density polymer film secured to an exposed side of the high density polymer film, a metal foil layer secured to an exposed inner facing side of the lower density film, and a sealant resin layer secured to an exposed facing side of the foil layer. In use, the pouch exhibits tear resistant properties and such as which prevents a child from biting into and opening the pouch.

Owner:REYNOLDS PACKAGING

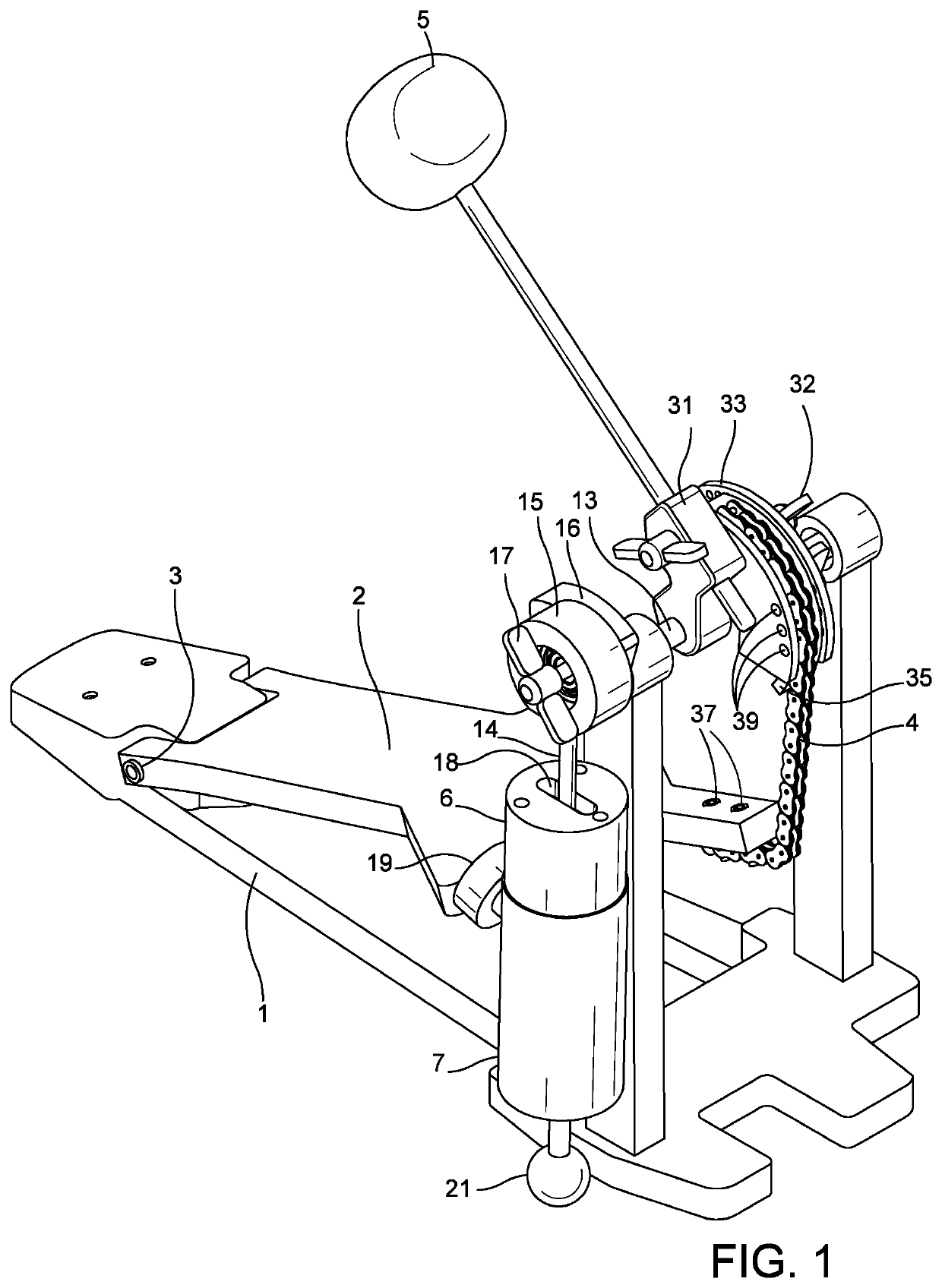

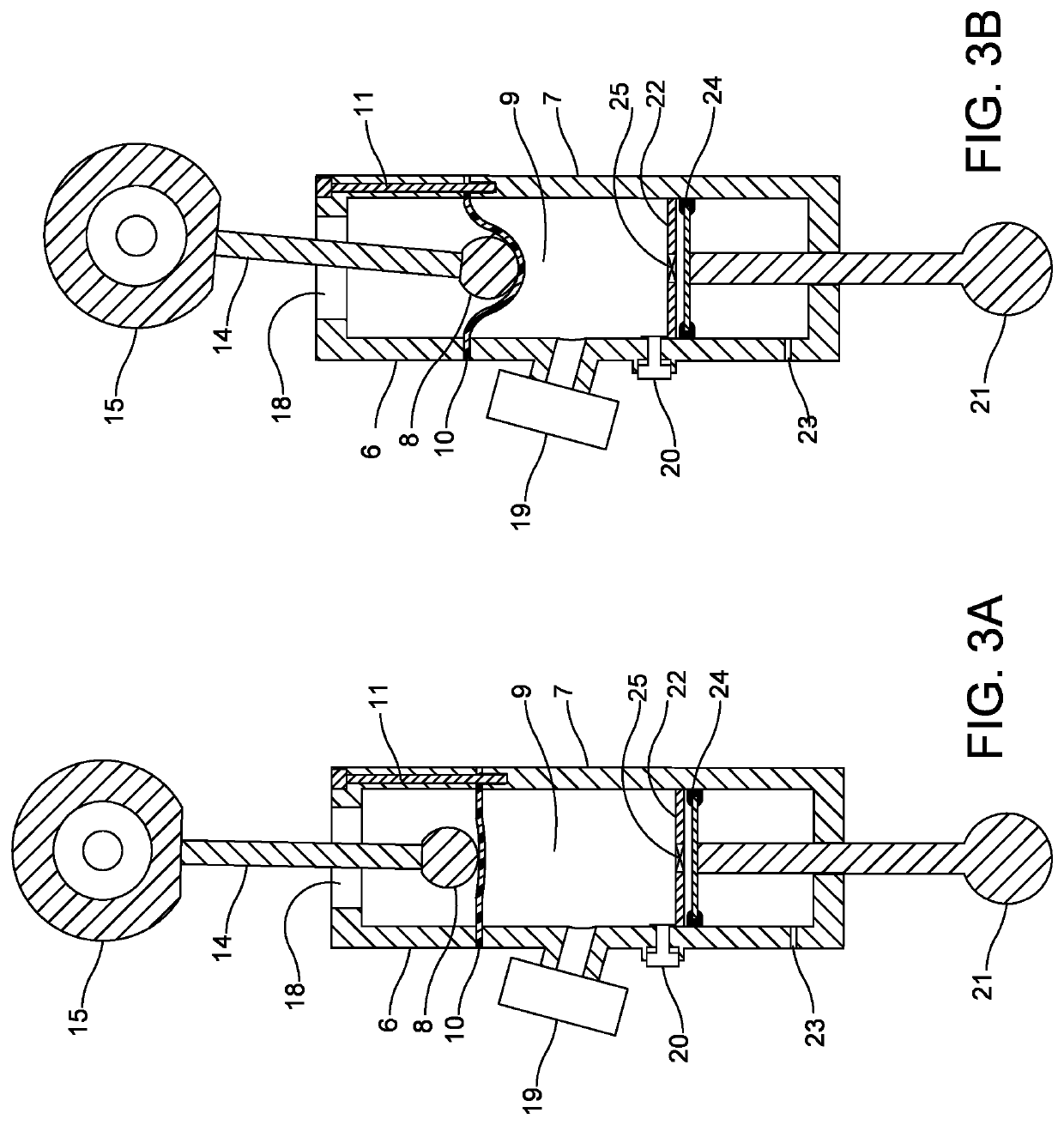

Pneumatic return for foot pedals associated with percussion instruments

ActiveUS11450299B1Improve reliabilityReduce frictionPercussion musical instrumentsEngineeringFoot boards

This improvement to a pneumatic return mechanism for percussion foot pedals incorporates a flat or bowl-shaped diaphragm rather than a rolling diaphragm, and a piston which is spherical rather than cylindrical, producing a bouncy feel for the player. A further improvement to the track hub of a percussion foot pedal enables bump fasteners to be removably inserted, to add lift and alter beater acceleration. A further improvement is a removable stiffener which prevents slack in the connector between the footboard and track hub of the percussion foot pedal, which may occur during fast drumming.

Owner:RUPRECHT DAVID S

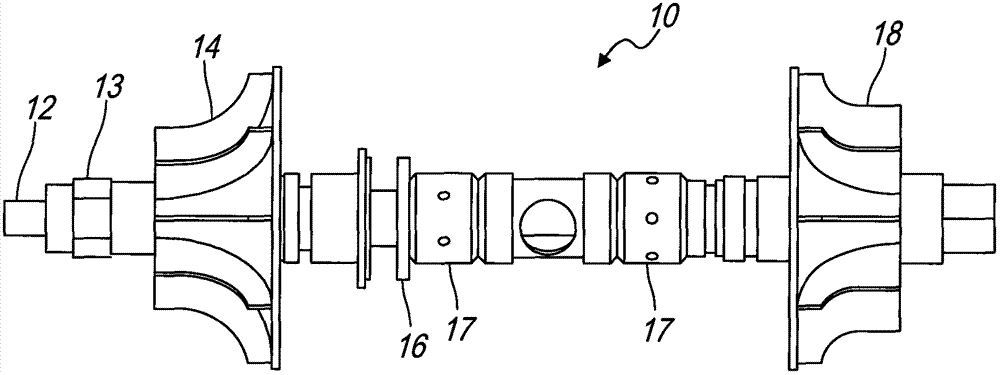

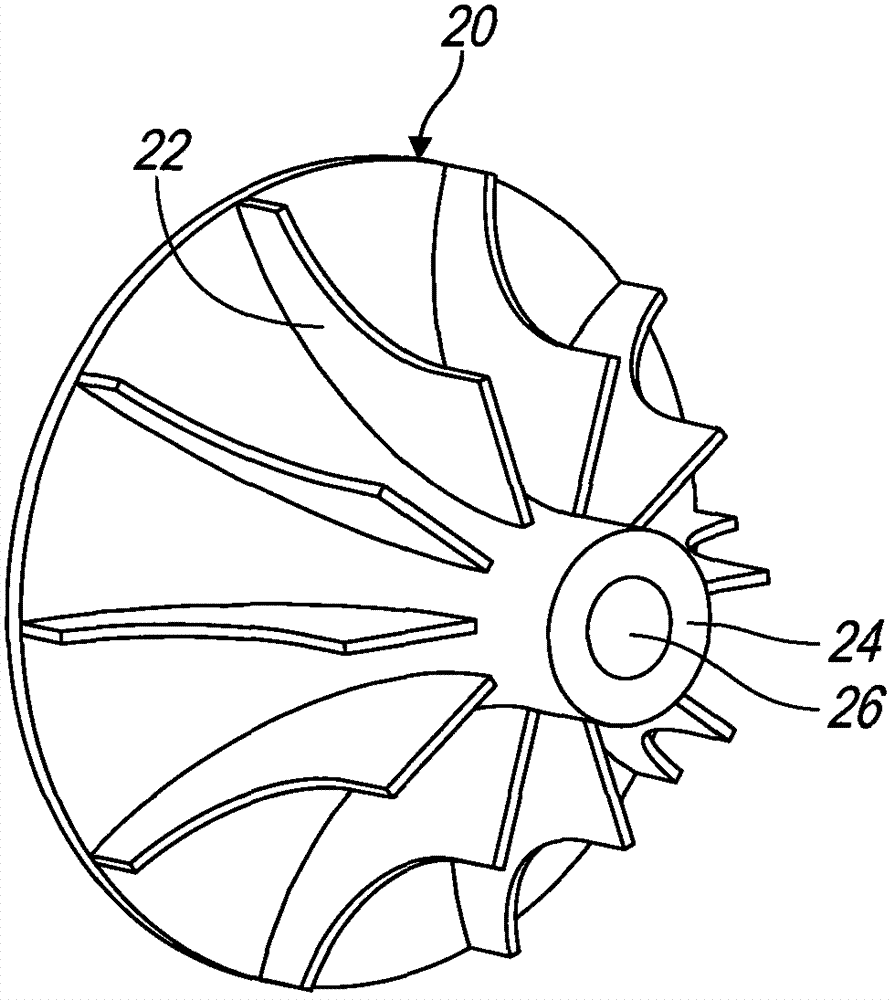

Bimetallic compressor wheel and a method of manufacture thereof

InactiveCN103133408ASmall moment of inertiaPrevent flexPump componentsBlade accessoriesAluminiumTitanium

The performance and durability of compressor wheels coupled to turbocharger shafts are at odds with each other in that a higher rotational speed can be accommodated by an aluminum compressor wheel. But, aluminum has a low yield strength which causes the compressor wheel to expand outwardly at high rotational speeds such that the slip fit on the shaft no longer prevents wobble at high rotational speeds. To at least partially address this issue, the compressor wheel has two portions: an inner portion made of steel or titanium that has a relatively higher yield strength and a blade portion made of a lightweight, castable material. The inner portion is manufactured with grabbing features on its periphery, placed in a die, and the blade portion is cast over the grabbing features to yield a compressor wheel of two materials that provides sufficient shaft stiffening without high rotational inertia.

Owner:艾克莫特公司

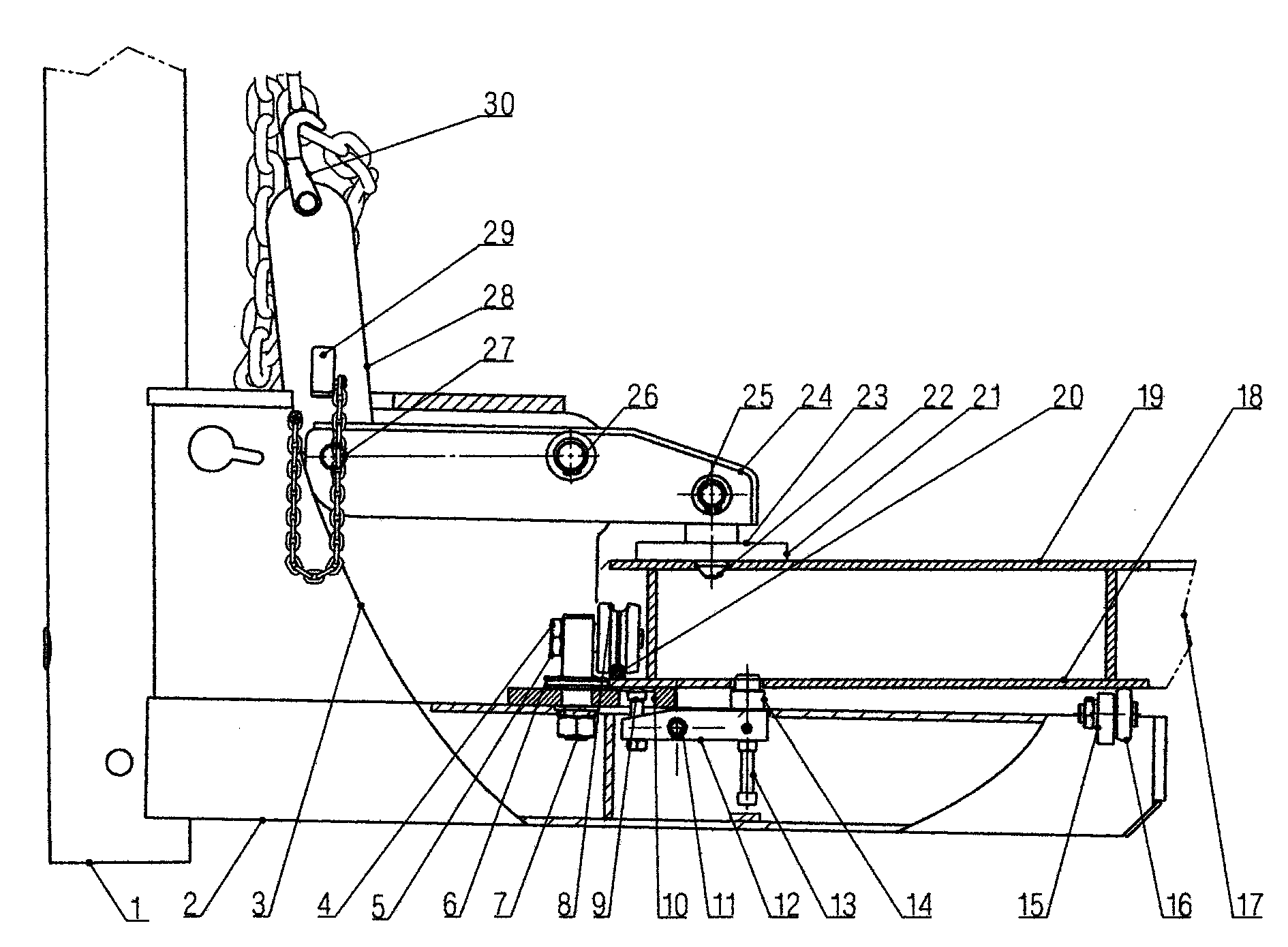

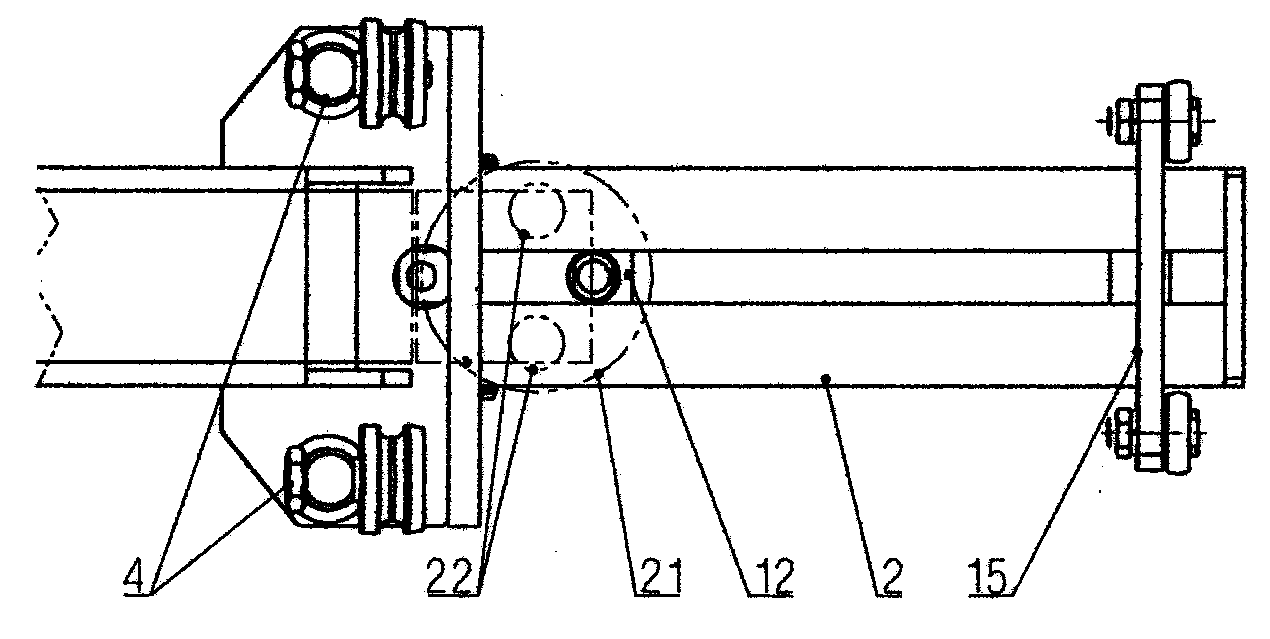

Wedge-lock-type bidirectional locking mechanism of pull tower

The invention discloses a wedge-lock-type bidirectional locking mechanism of a pull tower. The wedge-lock-type bidirectional locking mechanism comprises a lower arm connected on a tower arm through a hinging shaft and an upper arm connected with an upper frame through a hinging shaft in the middle, a collision pin used for being wedged in a baseplate locking hole of a platform during locking is mounted at the top of one end of the lower arm, an upper lock head is connected at the front end of the upper arm through a hinging shaft and provided with a cone head used for being buckled in a lock hole of the platform, the lower end, longitudinally penetrating a notch arranged on the top face of the upper frame, of a wedge hole lock plate is connected with the rear end of the upper arm through a fourth hinging shaft, a chain grapnel used for being in suspended connection with a stretching chain is hinged to the upper end of the wedge hole lock plate, the wedge hole lock plate is provided with a wedge hole, and a wedge block is mounted in the wedge hole in a locked state and saddles on wall plates on two sides of the upper frame. The pull tower is enabled to closely cling to a lock face of the platform with the help of thrust of a stretching oil cylinder of the pull tower, the pull tower is locked on the platform through up-down meshing of double pins arranged at the top and the collision pin arranged at the bottom, and the locking state is maintained by means of manual wedge lock.

Owner:烟台三重技术股份有限公司

Double-side thick film network on ceramic card

ActiveUS9719835B2Keep in touchEliminate failure modesCoupling device connectionsLevel indicators by floatsNetwork onEngineering

A ceramic card having a thick film network, with conductive vias formed as part of the card. Each of the vias is in electrical communication with both sides of the thick film network, allowing the pads and the pad senders to be formed on both sides of the card. This configuration maintains the contact when one of the connectors is subjected to bending force or is otherwise displaced, maintaining contact with at least one of the pads, and allowing the system to still function. The double sided thick film network allows for each connector to touch both sides of one of the pads, and still maintain electrical communication with the level sender, thus eliminating the failure mode of intermittent contact with the thick film network resulting from movement of the connector.

Owner:VITESCO TECH USA LLC

Bi-directional, reverse blocking battery switch

ActiveUS8097945B2Reduces total switch resistanceReduce tooling costsSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductancePower flow

Embodiments of the present invention relate to an improved die layout for a bi-directional and reverse blocking battery switch. According to one embodiment, two switches are oriented side-by-side, rather than end-to-end, in a die package. This configuration reduces the total switch resistance for a given die area, often reducing the resistance enough to avoid the use of backmetal in order to meet resistance specifications. Elimination of backmetal reduces the overall cost of the die package and removes the potential failure modes associated with the manufacture of backmetal. Embodiments of the present invention may also allow for more pin connections and an increased pin pitch. This results in redundant connections for higher current connections, thereby reducing electrical and thermal resistance and minimizing the costs of manufacture or implementation of the die package.

Owner:GEM SERVICES

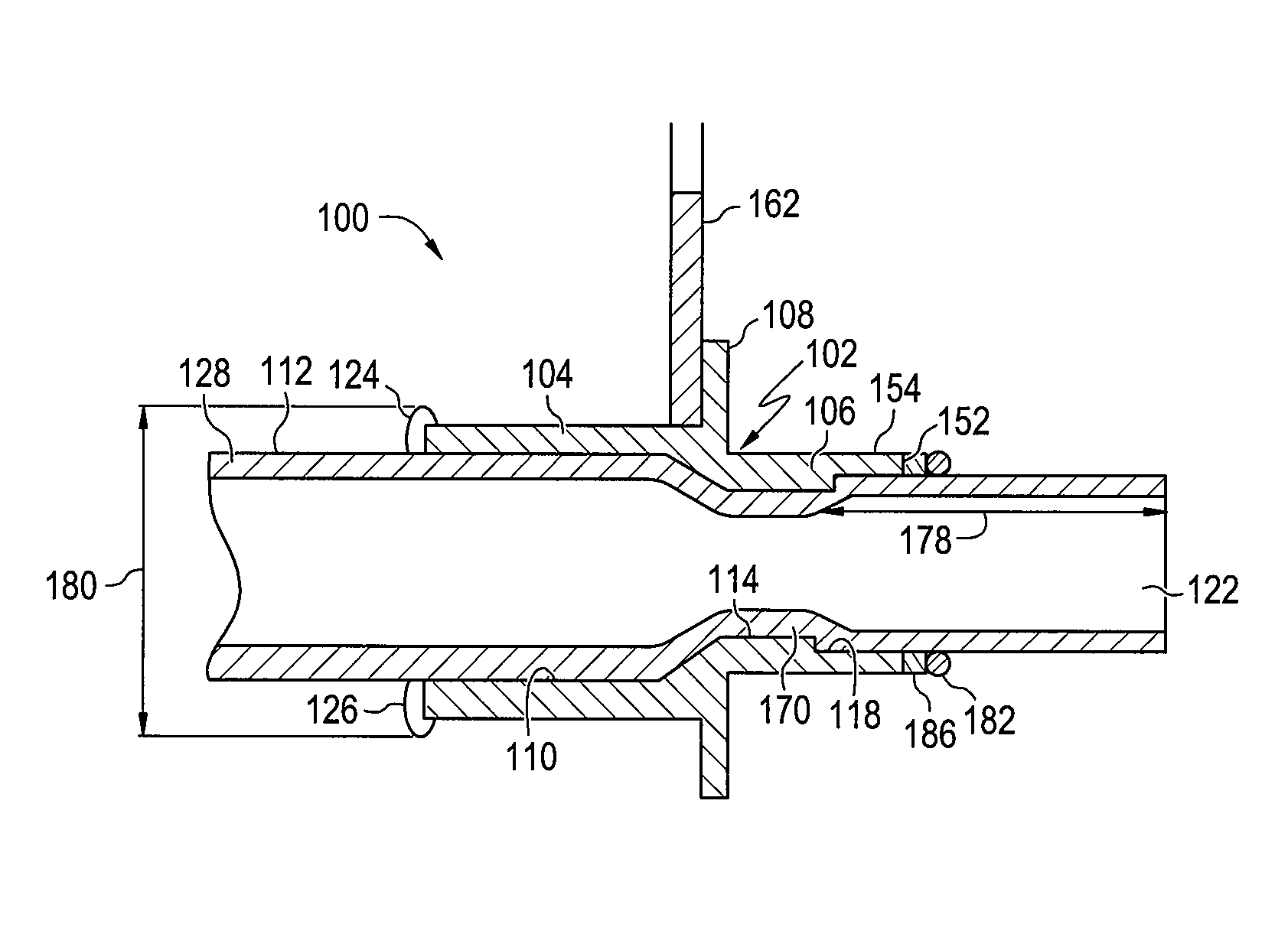

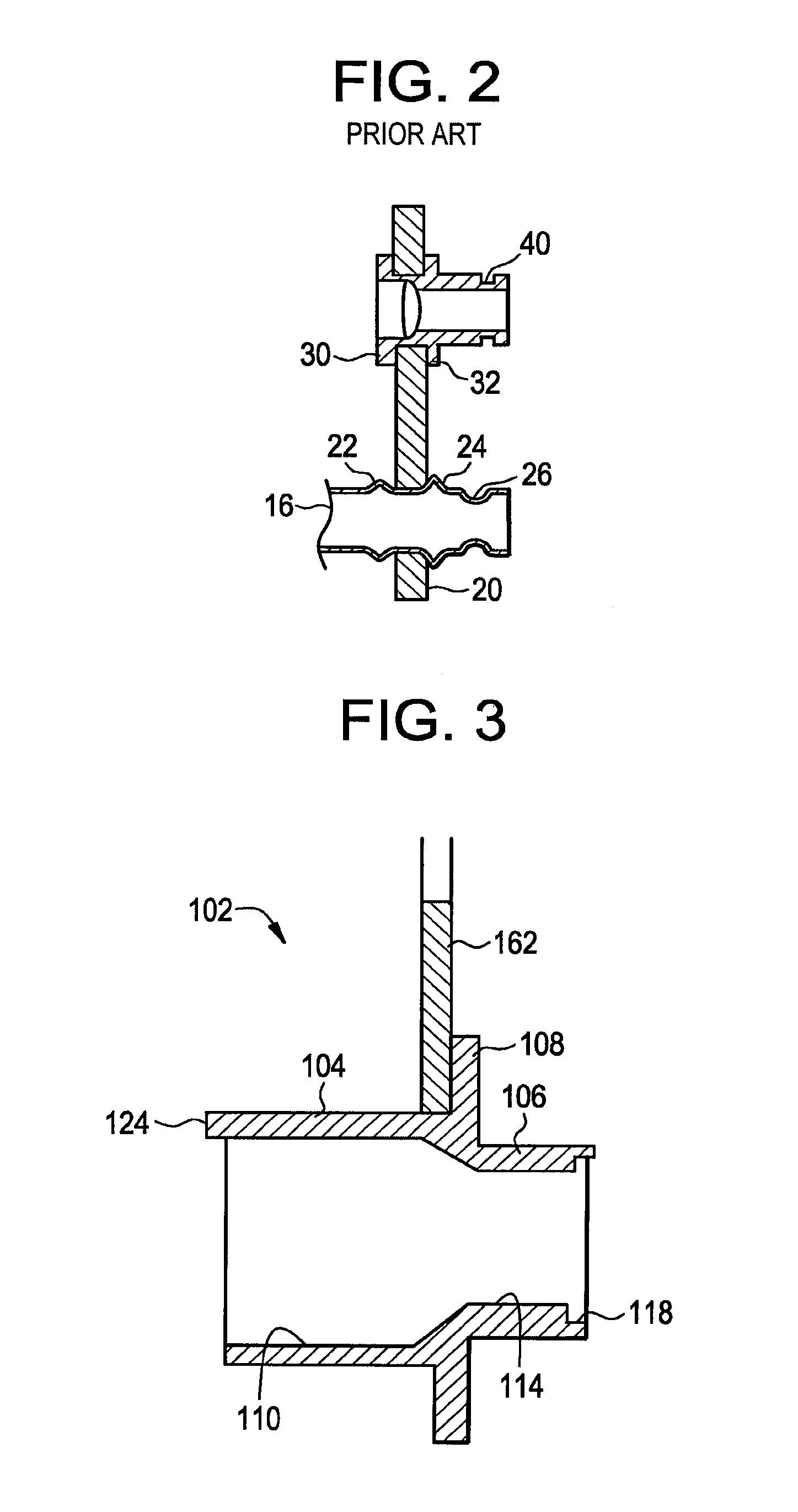

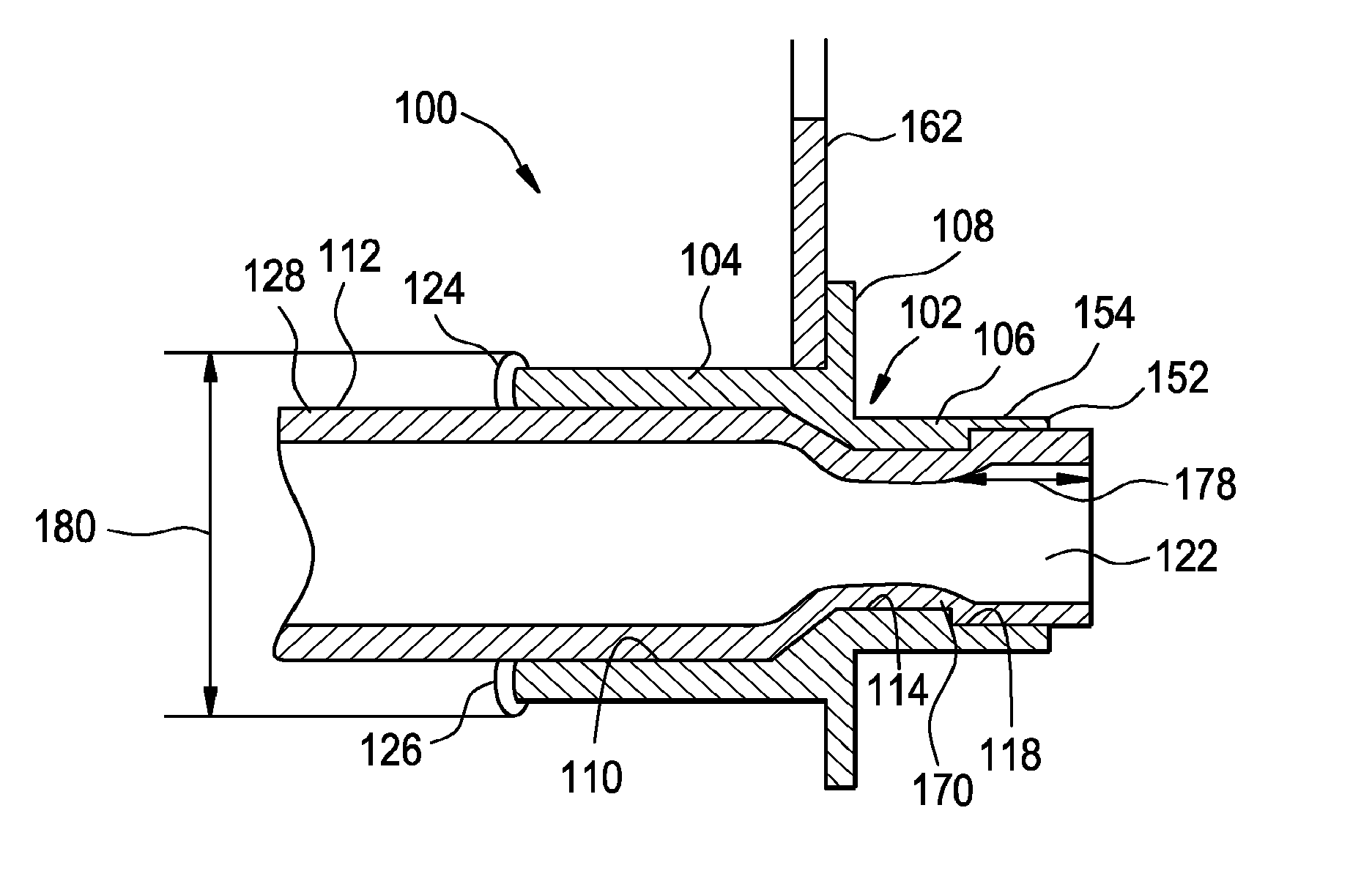

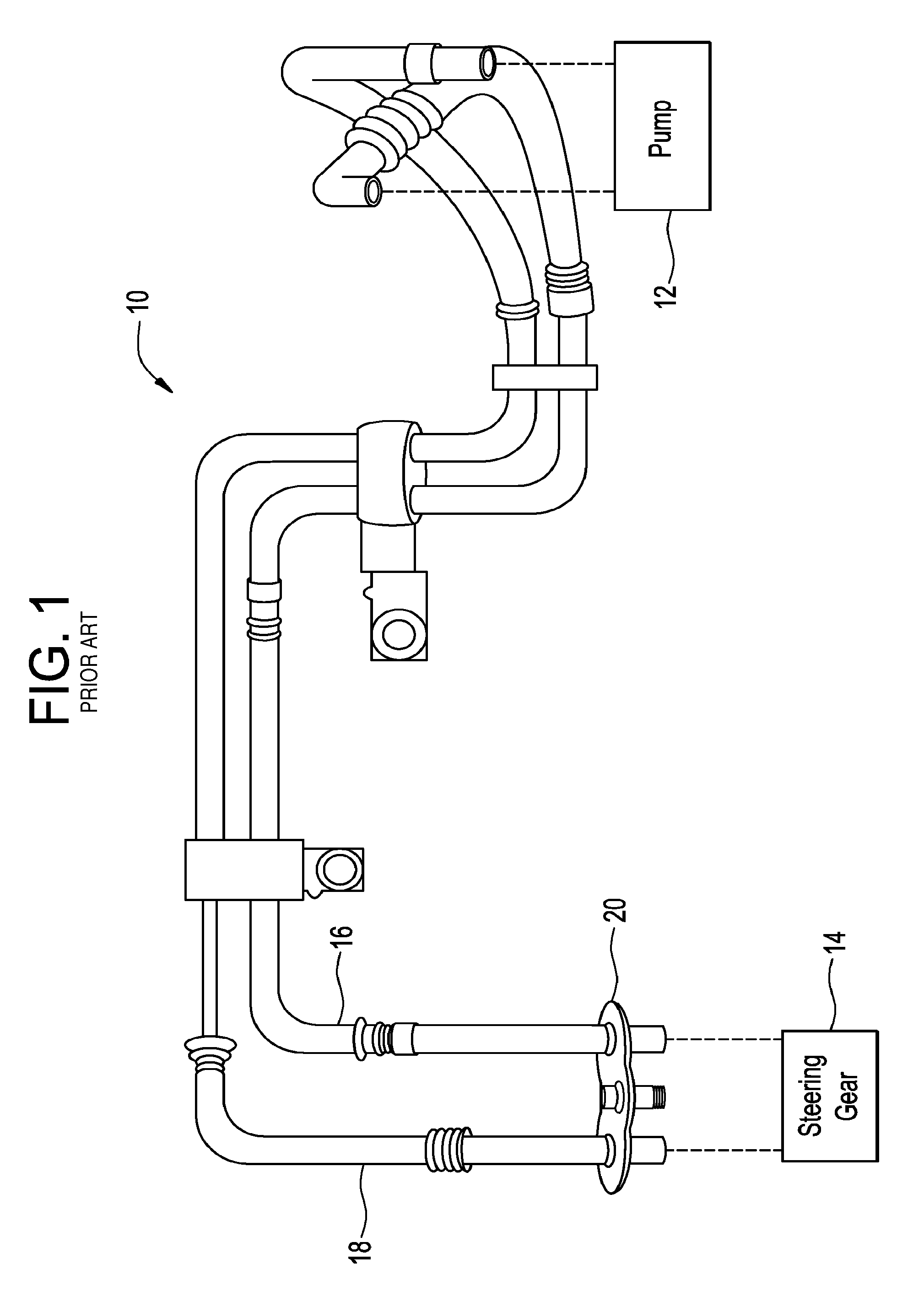

Process of endforming a tubular assembly

InactiveUS20090000856A1Improve sealing propertiesAvoid vertical movementPipe elementsBuilding constructionsHigh pressureBiomedical engineering

A method for endforming a tubular member for use assembly for a hydraulic system comprises (1) a connector member having an inner surface exhibiting a stepped configuration and a fixing member at the distal end thereof, and (2) an endform tubular member having an outer surface corresponding to the inner surface of the connector member, wherein the endform tubular member mates with inner surface of the connector member to provide an endform tubular assembly having an improved design for conveying fluids in a hydraulic system. The endform tubular assembly has inherent features therein that are measured to provide quantified values for assessing the robustness of the assembly and predict the performance of such assembly in high pressure applications for prolonged periods of time.

Owner:YH AMERICA

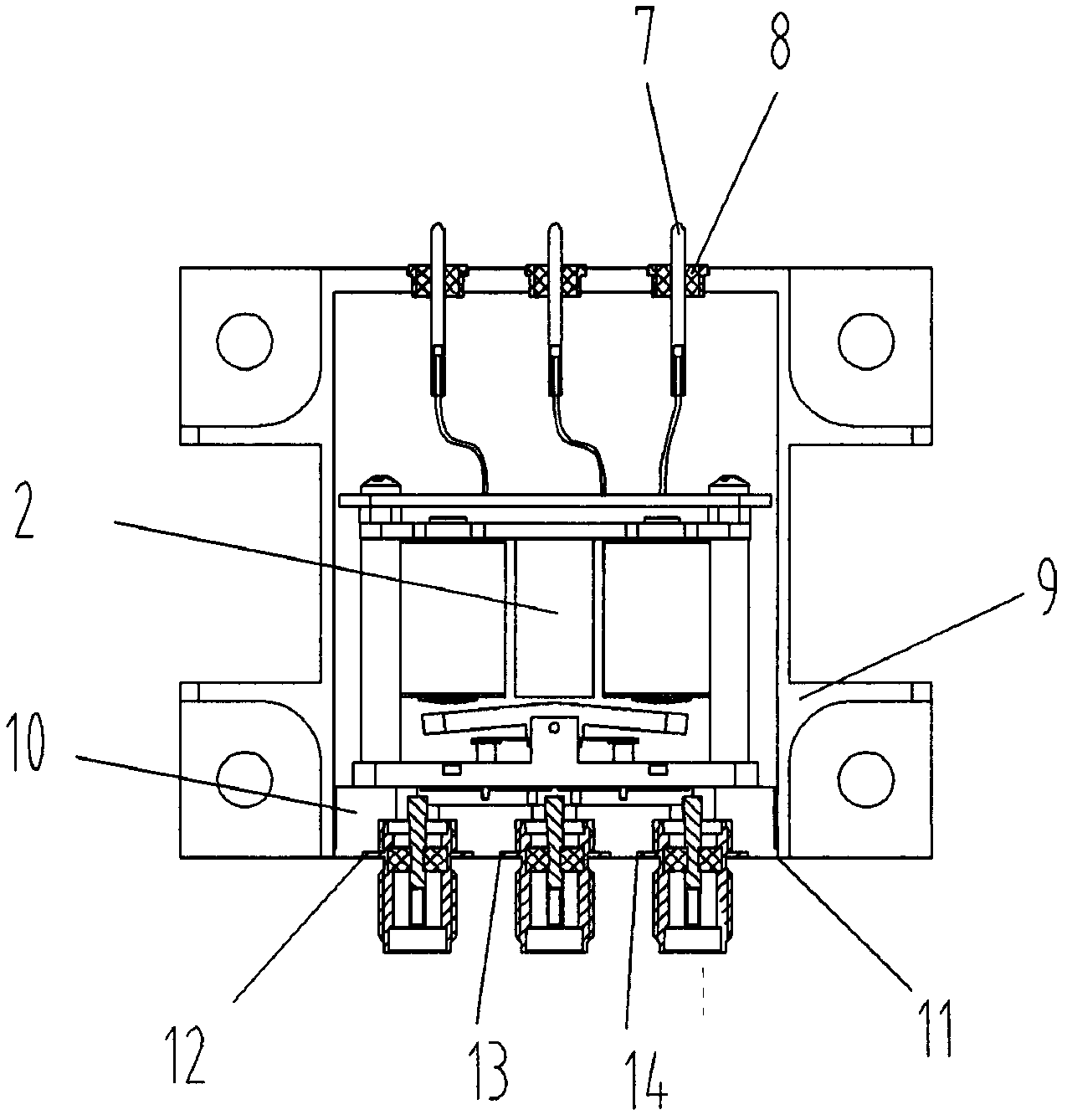

Microwave switch for sealed space

InactiveCN102569948AImprove thermal conductivityEliminate vacuum micro-discharge phenomenonWaveguide type devicesRadio frequencyEngineering

A microwave switch for a sealed space comprises a microwave switch body used for the sealed space and a sealed casing. A radio frequency connector in the body fixes an inner conductor and an outer conductor in an insulating material sintering mode, the connector and a guiding seat are sealed and connected by a sealing process, and the guiding seat and the casing are sealed and connected through laser welding or brazing. A control signal leading-out end and the insulating material are connected in a sintering mode, and the control signal leading-out end and the insulating material are finally fixed on the casing. By the above sealing mode, an integrated sealed structure of the microwave switch is achieved, gas are filled inside for protection. The microwave switch for the sealed space can effectively improve interior heat conduction capacity of the microwave switch, eliminates vacuum micro-discharge and vacuum cold welding, and can bed improved in power load capacity in vacuum environment.

Owner:CHINA AEROSPACE TIMES ELECTRONICS +1

Aerosol-generating system with motor

ActiveCN108367128AProgramming doesn't have to be that complicatedEliminate cloggingRespiratorsTobacco treatmentDrive shaftEngineering

The present invention relates to an aerosol-generating system comprising a liquid storage portion for storing liquid aerosol-forming substrate, wherein the liquid storage portion comprises a movable wall and an outlet, a vaporiser comprising a heating element having a structure defining an open-ended internal passage for heating deposited liquid aerosol-forming substrate, a pump configured for delivering liquid aerosol-forming substrate from the outlet of the liquid storage portion to the internal passage of the heating element, the pump comprising a micro stepper motor with a drive shaft thatis configured to rotate for a predetermined amount upon performing one step of the micro stepper motor, a piston connected to the movable wall, and a lead screw connecting the drive shaft to the piston and configured to translate a rotation of the drive shaft into an axial movement of the piston and a corresponding axial movement of the movable wall, wherein the vaporiser is configured for heating the delivered liquid aerosol-forming substrate in the internal passage to a temperature sufficient to volatilize at least a part of the delivered liquid aerosol-forming substrate. The present invention further relates to a cartridge for an aerosol-generating system, wherein the cartridge comprises the liquid storage portion, the piston, and the lead screw. The present invention further relates to a method for generating aerosol.

Owner:PHILIP MORRIS PROD SA

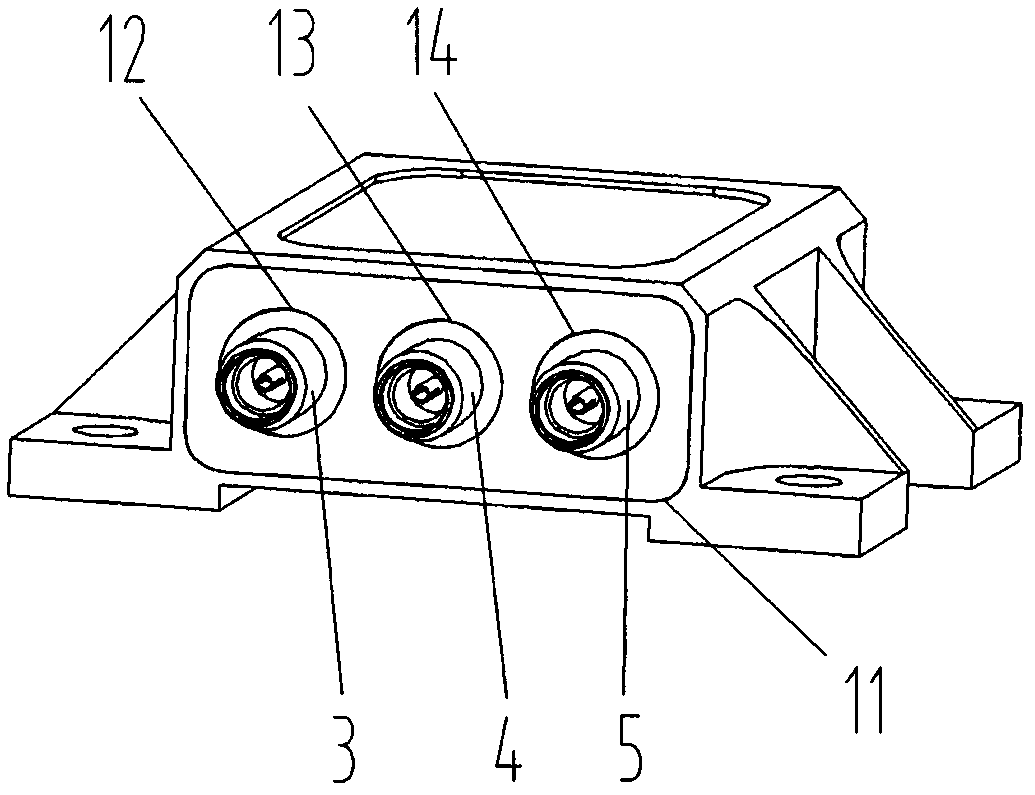

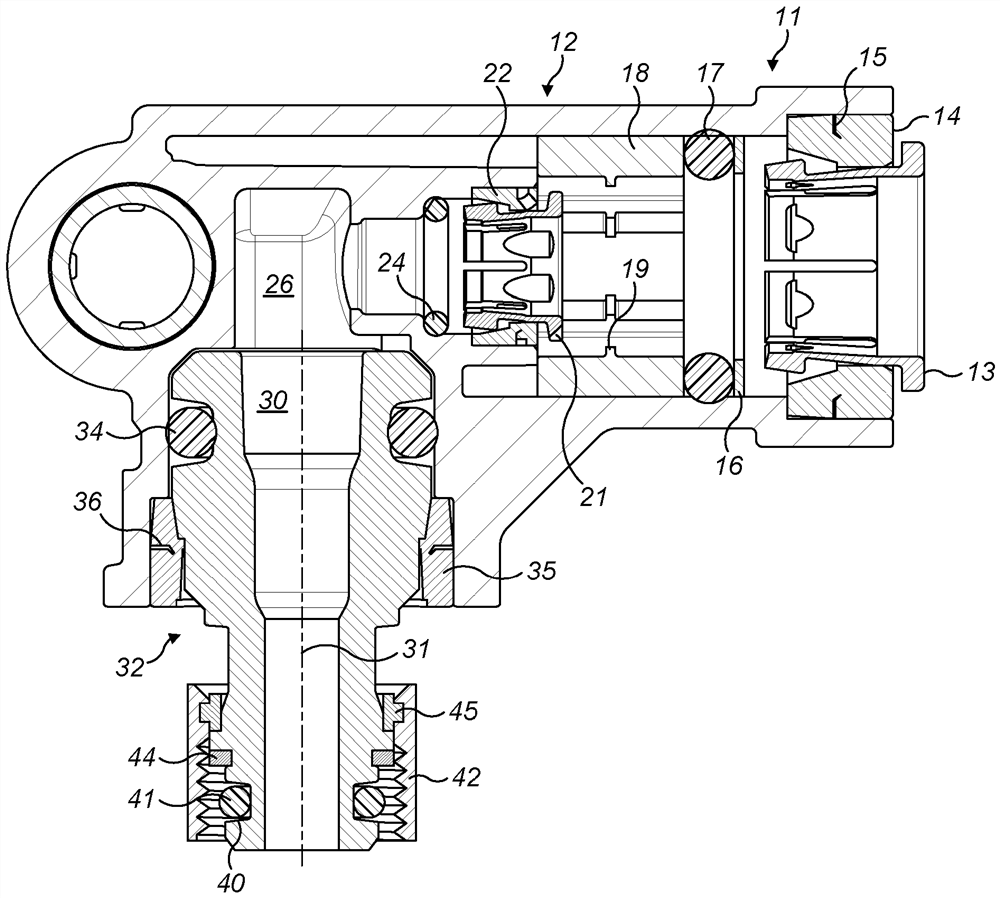

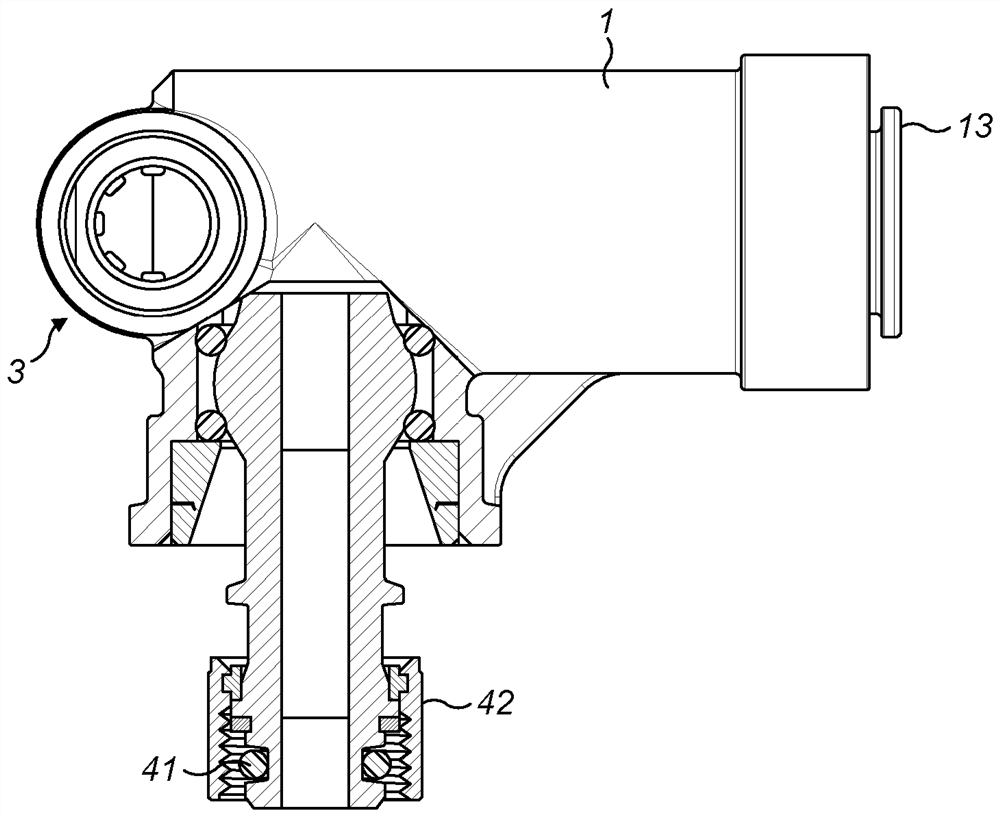

Coaxial beverage keg connector comprising a ball joint

ActiveCN113165862AExtend your lifeEliminate failure modesSimultaneous aerial operationsJoints with sealing surfacesBall jointElectrical and Electronics engineering

An coaxial keg connector comprising a main body (1) made of plastic and having a first inlet port (3) and a second inlet port (3) receiving a stem (2). A coaxial outlet (10) comprises an outer outlet port (11) in communication with the first inlet port (3) and an inner outlet port (12) in communication with the second inlet port. The stem (2) comprises a tubular body with a main axis (31) with an inlet and a connector for attachment to the keg at one end. The second end of the stem opposite to the first end has an outlet in fluid communication with the inner outlet port (12) and comprises a ball joint (61) rotatably mounted in and sealed with respect to the main body (1) so as to be rotatable (12) about the main axis (31) of the tubular body and rotatable (67, 68) to a limited extent about axes perpendicular to the main axis.

Owner:JOHN GUEST INT LTD

Method of determining the robustness of endformed tubular assembly and predicting the performance of such assembly in high pressure applications

InactiveUS7837041B2Reliable, non-destructiveAvoid vertical movementPipe couplingsBranching pipesEngineeringHigh pressure

A method is provided for determining the robustness of a tubular assembly in a fluid flow assembly for a hydraulic system and predicting the performance of the endform tubular assembly in high pressure applications, wherein the tubular assembly has inherent features therein that are measured to provide quantified values for assessing the robustness of the assembly and predict the performance of such assembly in high pressure applications for prolonged periods of time.

Owner:YH AMERICA

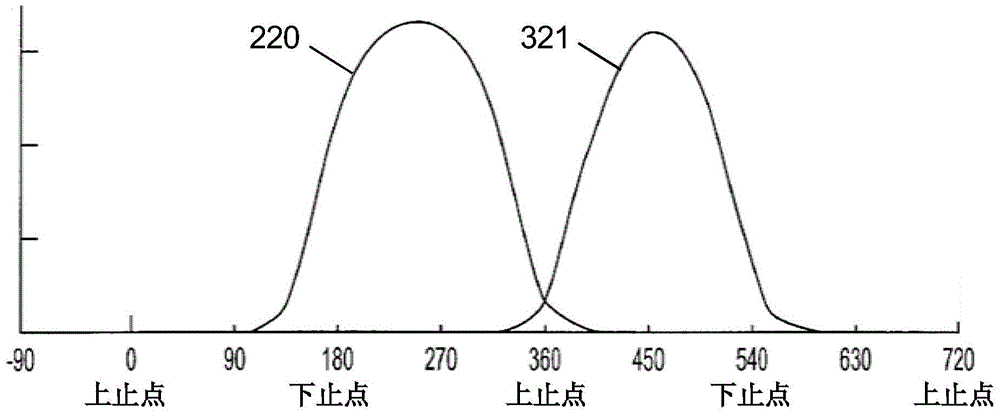

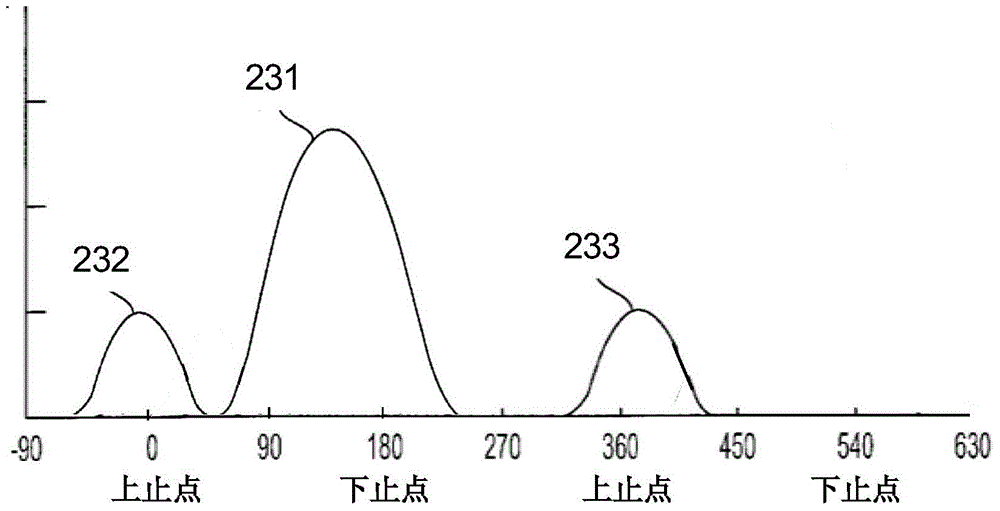

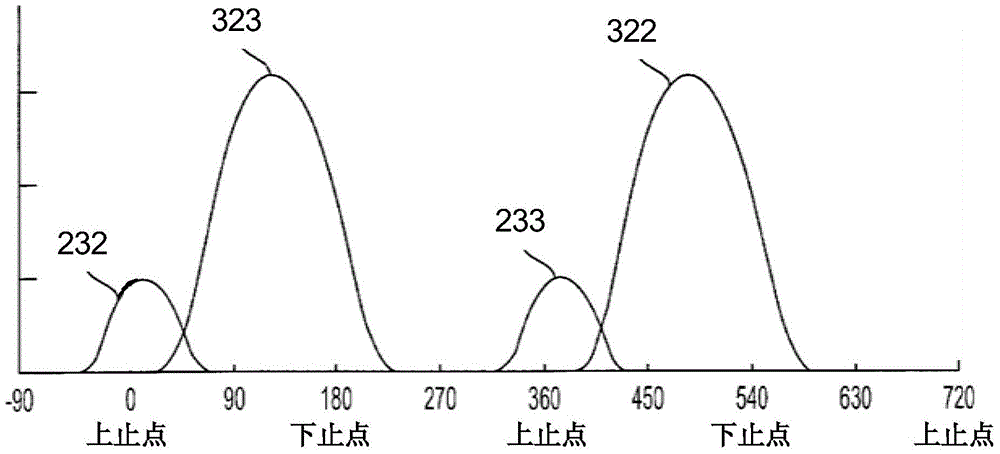

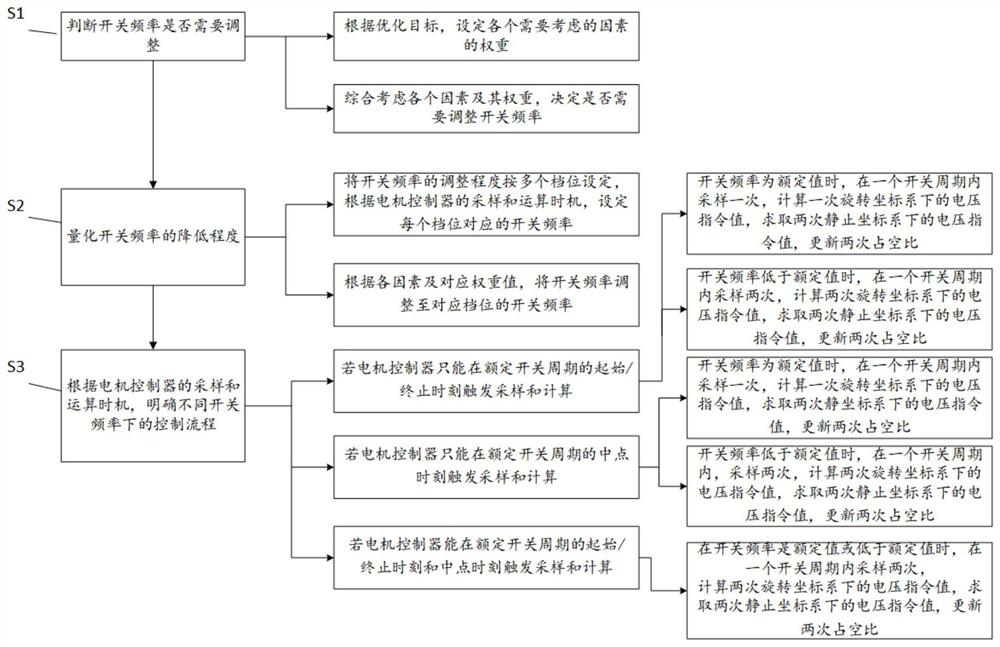

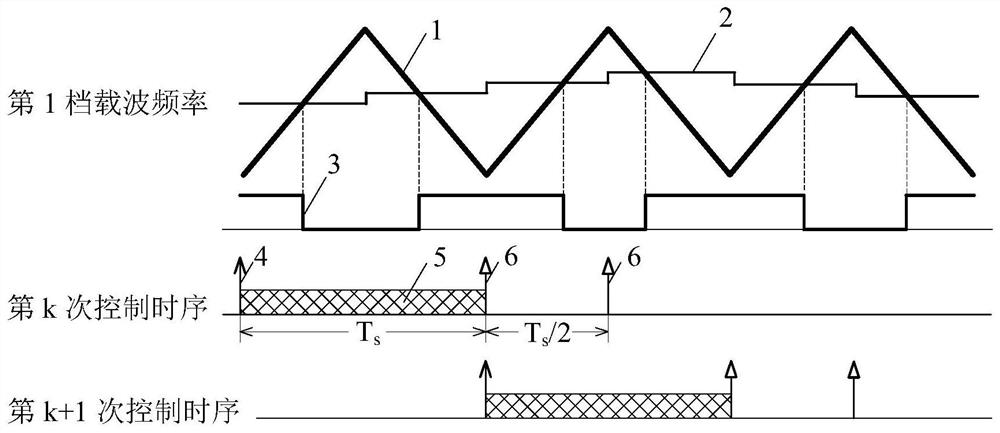

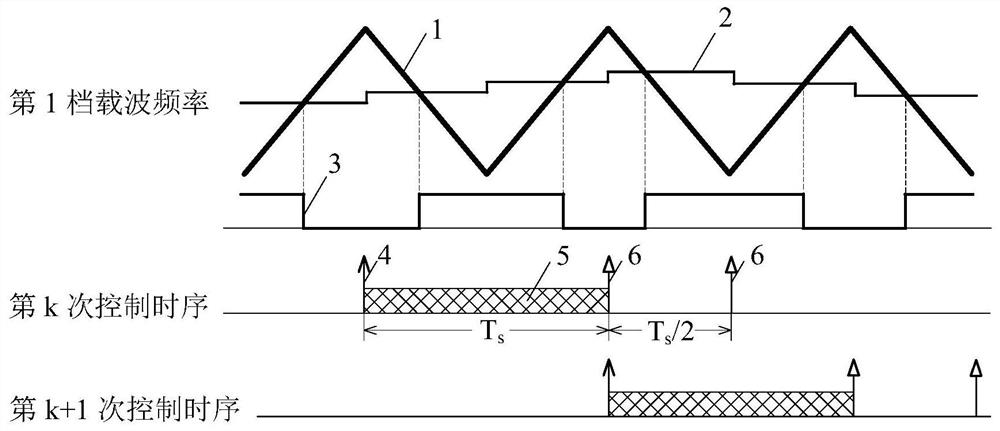

A Pulse Width Modulation Method Applicable to Vehicle Motor Controller

ActiveCN112217441BMaster the real operating statusReasonable judgmentGeneral control strategiesElectric energy managementPower switchingIn vehicle

The present invention provides a pulse width modulation method suitable for a vehicle-mounted motor controller, comprising: taking the instructions of the motor controller, the state quantities of the motor controller and the motor as factors, and taking the temperature of the power switching device and the efficiency of the motor controller as factors At least one of them is used as the optimization target, according to the relationship between the factors and the optimization target, set the weight positive / negative sign and weight value of the corresponding factor; according to each factor and the corresponding weight value, determine whether to adjust the switching frequency; The adjustment degree is set according to the gear position. According to the sampling and operation timing of the motor controller, the switching frequency corresponding to each gear position is set. Finally, the switching frequency is adjusted to the switching frequency of the corresponding gear position according to each factor and the corresponding weight value. The method aims at minimizing the control delay, determines the reduction degree of the switching frequency, improves the update rate of the output duty cycle, improves the sine degree of the output voltage / current, and reduces the harmonic content.

Owner:LEADRIVE TECH (SHANGHAI) CO LTD

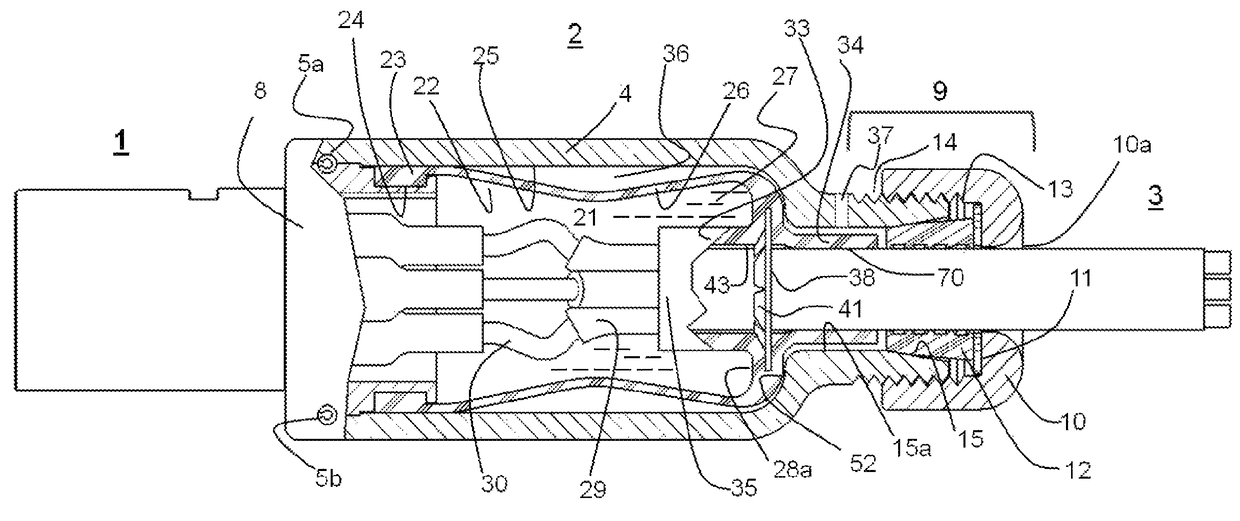

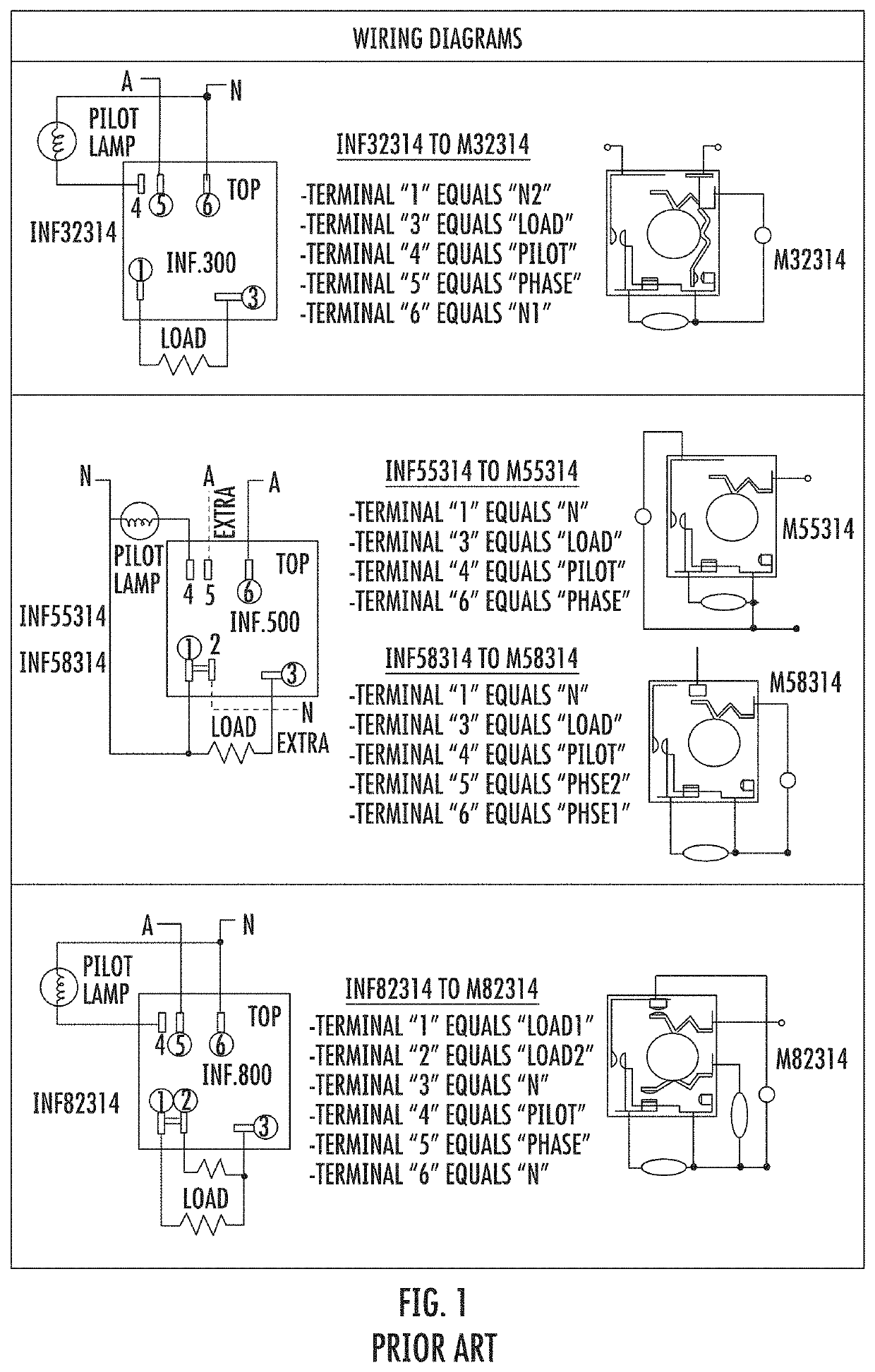

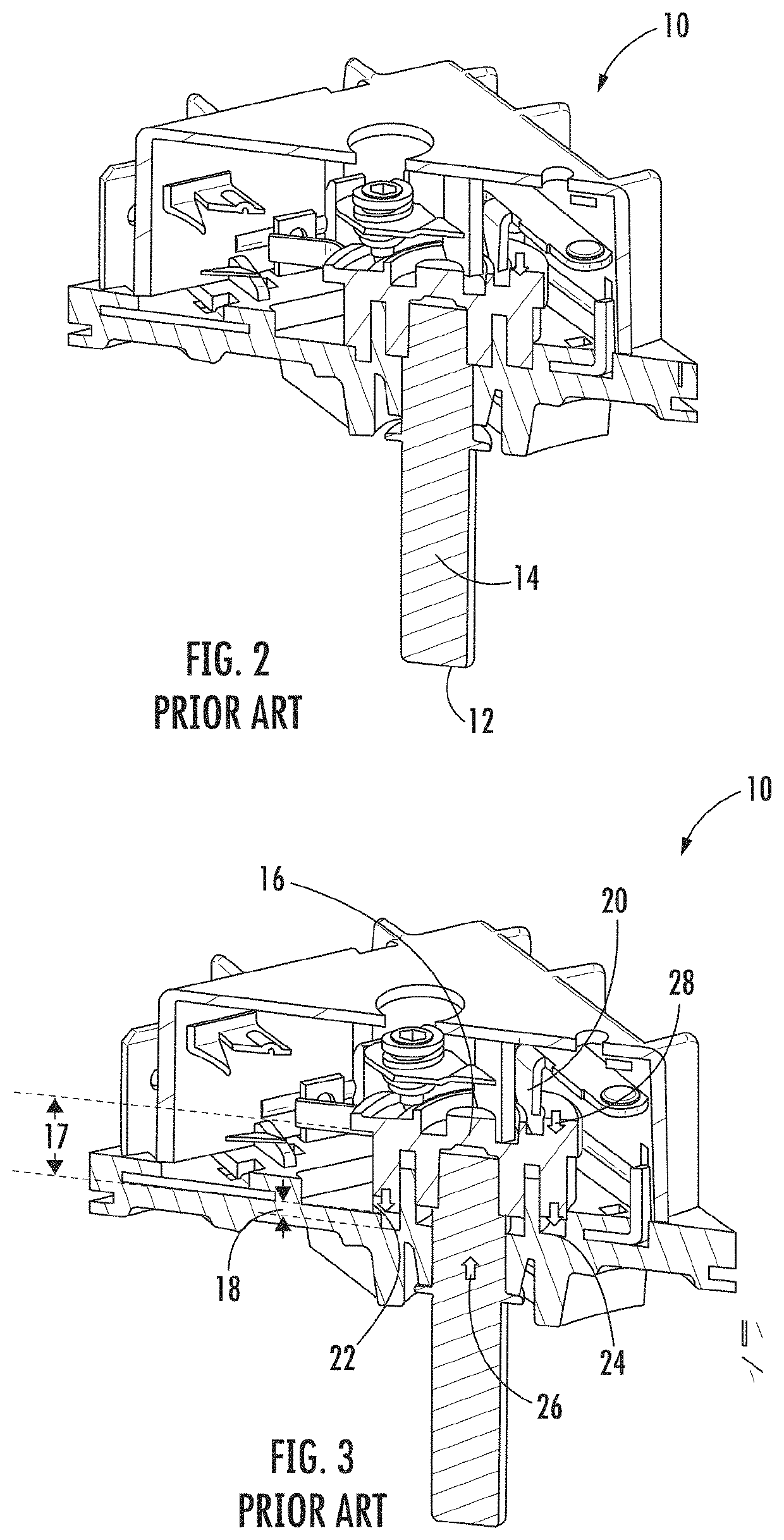

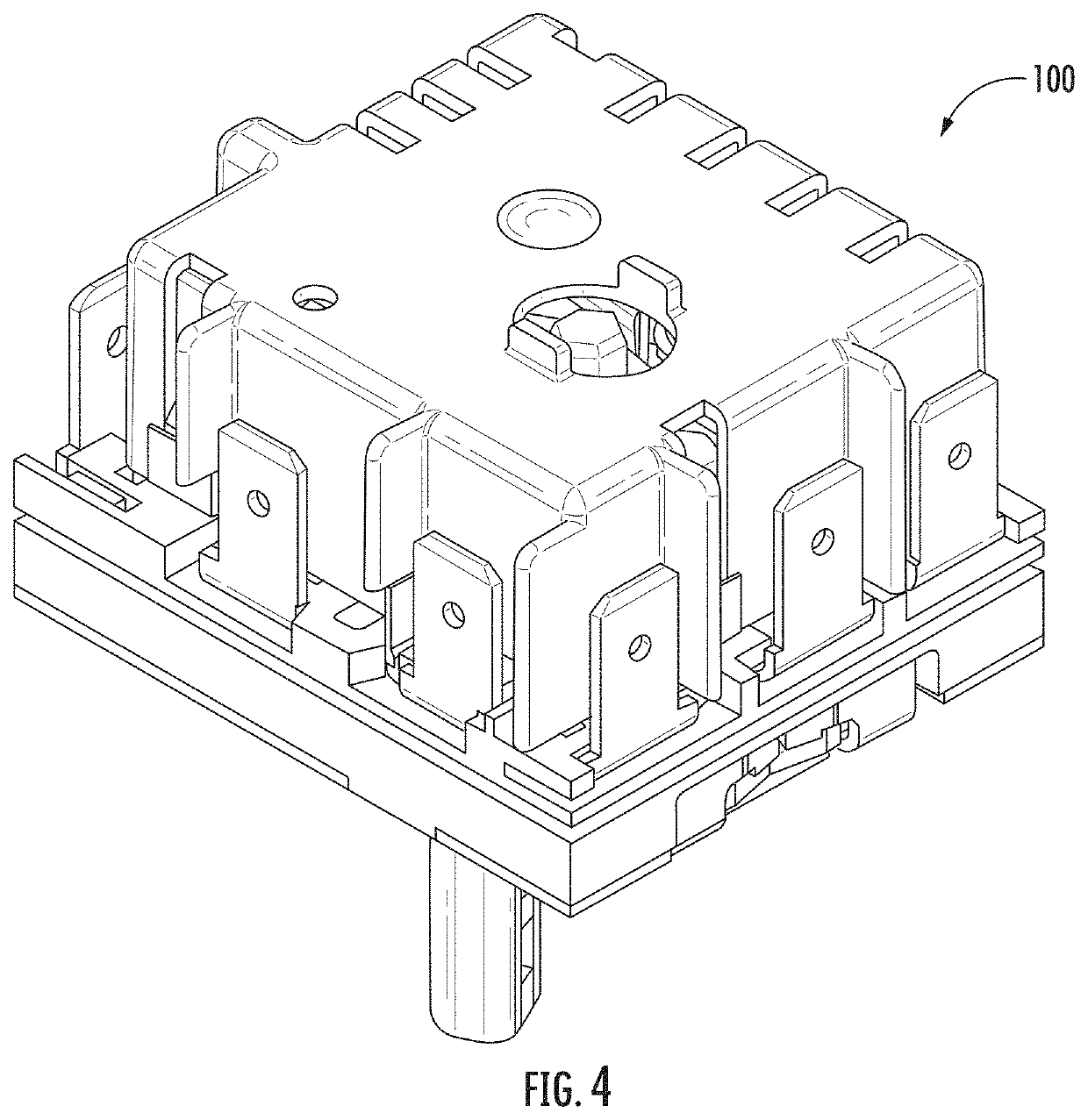

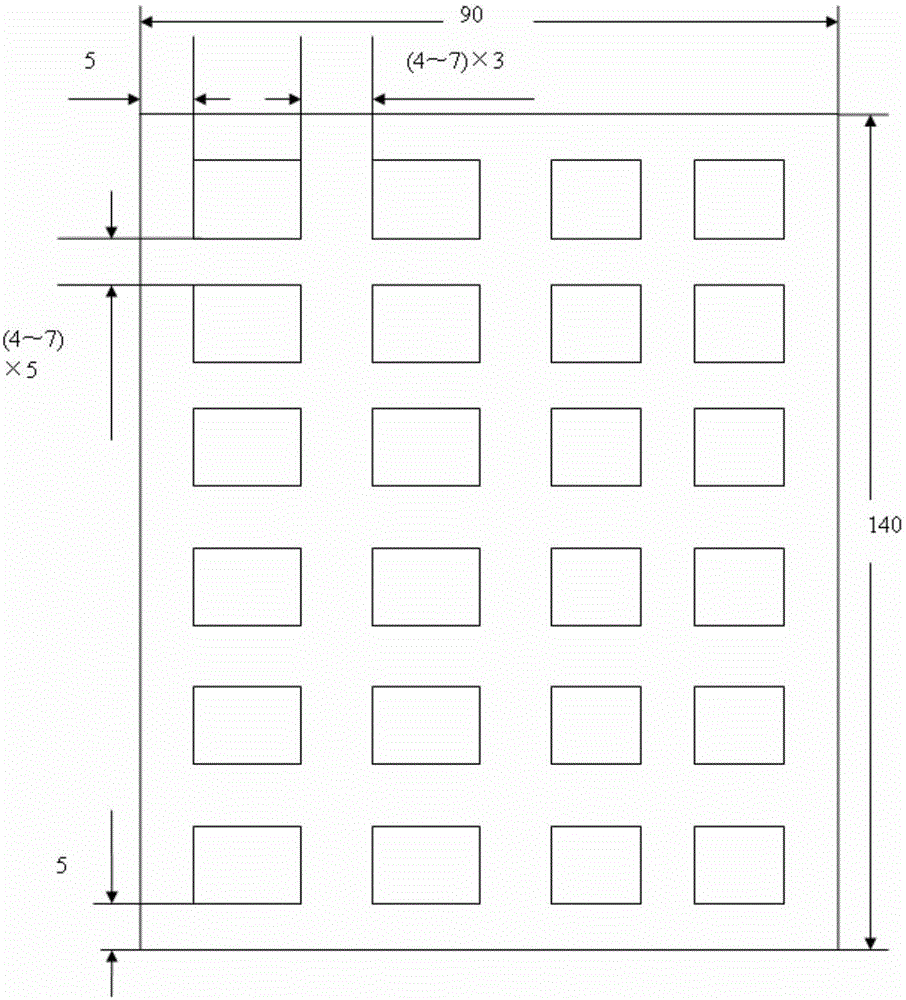

Increased push travel alternative for energy regulator

PendingUS20220148831A1Improved shaft wobbleReduce crackingThermal switch detailsEmergency protective devicesCamControl theory

An infinite switch includes a front cover, a back cover, and a base secured between the front cover and the back cover. A floating shaft extending through the front cover and the base. A cam fixed to the base and slidingly receiving an end of the floating shaft. The floating shaft is moveable in an axial direction extending parallel to a longitudinal axis of the floating shaft and the cam is fixed to prevent movement in the axial direction.

Owner:ROBERTSHAW CONTROLS CO

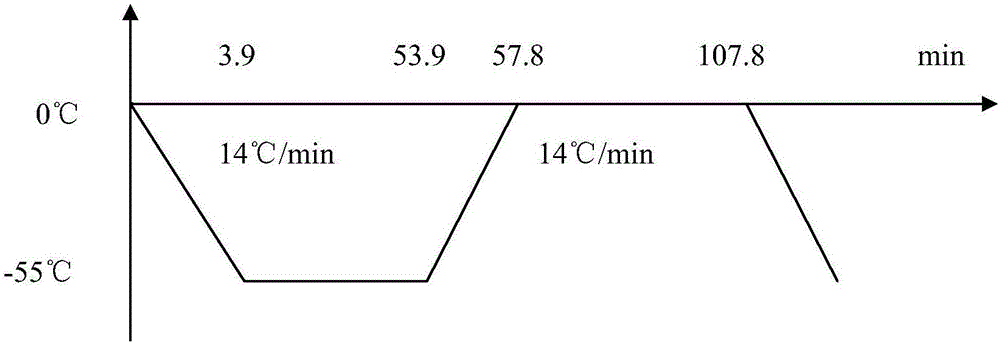

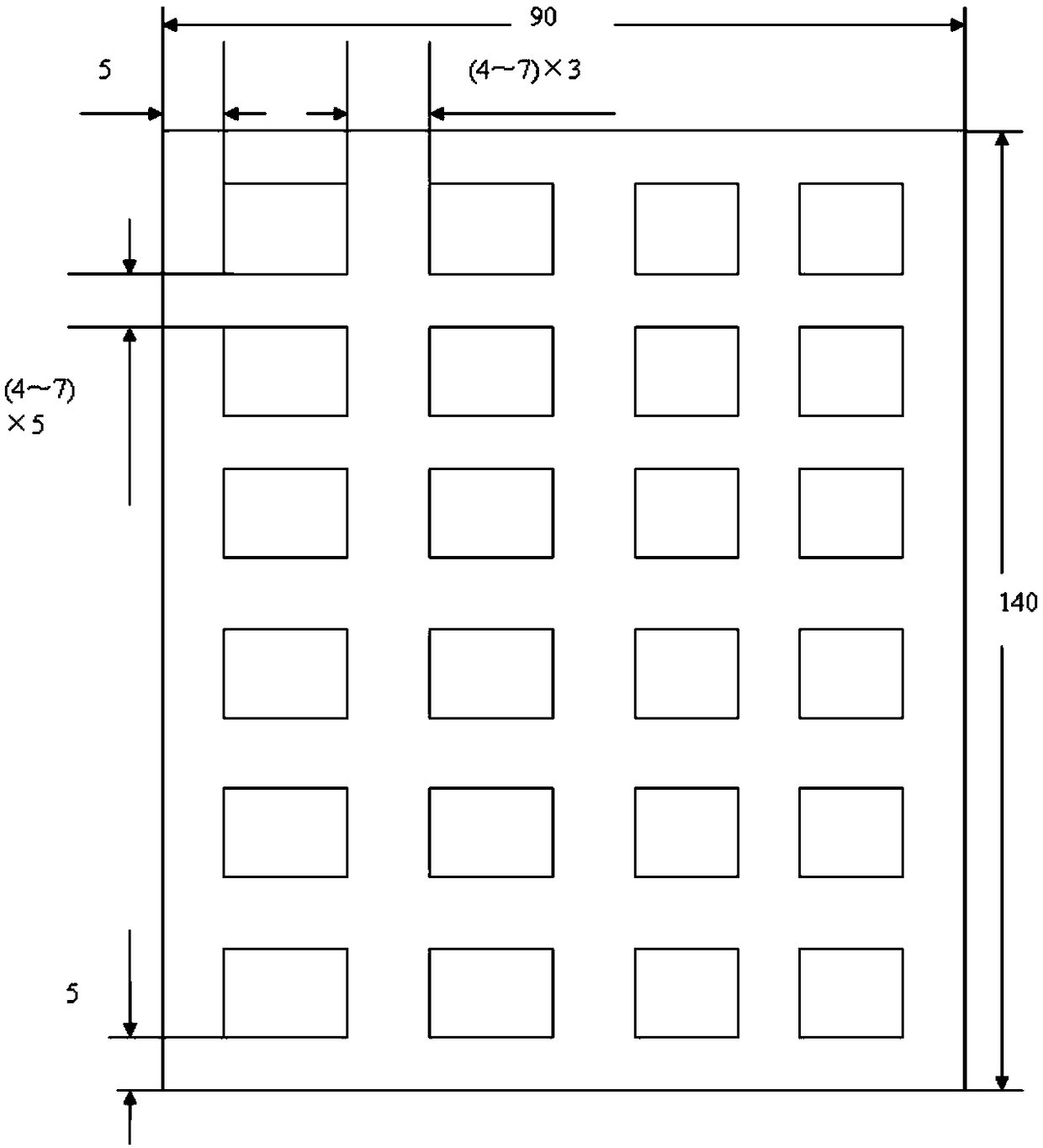

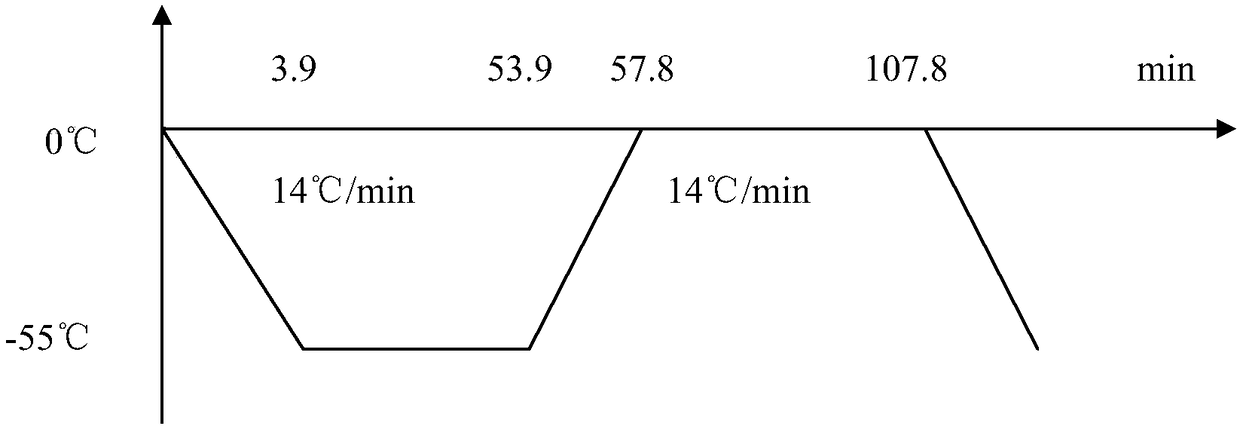

Method for clearing low-temperature failure of anti-skid brake control device

InactiveCN106347706AIncrease temperatureNo low temperature failureGround installationsResource consumptionEngineering

The invention provides a method for clearing a low-temperature failure of an anti-skid brake control device. According to the device, a large-power component is adjacent to a small-power component, heat is supplied to the small-power component under a low-temperature condition, every row of large-power components are opposite to a row of small-power components. After physical analysis on a failure, the reason of the low-temperature solder-point cracking is uncompacted solder packing, and a soldering technique is determined against the uncompacted solder packing to clear the solder-point cracking failure. Insulating paint for preventing condensation is coated to avoid short circuit or breakdown; micro-crack generated by plastic deformation can be controlled by adopting a method for increasing the bent radius of a pin, and the failure can be cleared. By adopting the device, the low-temperature resistance of an anti-skid brake control device can be improved under a condition of not changing the existing material of a shell or changing the quality grade of components, so that the aims of prolonging the service life of the anti-skid brake control device and reducing product waste and resource consumption can be achieved when the anti-skid brake control device works at 55 DEG C below zero and has a temperature of 45 DEG C below zero.

Owner:XIAN AVIATION BRAKE TECH

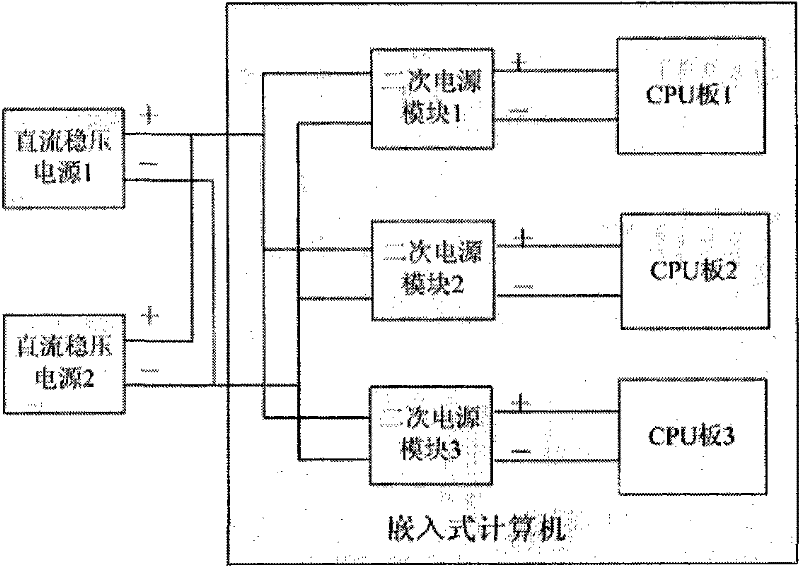

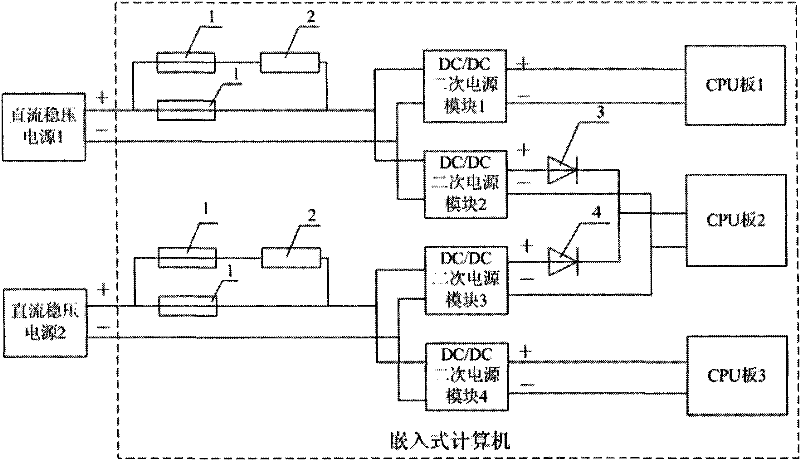

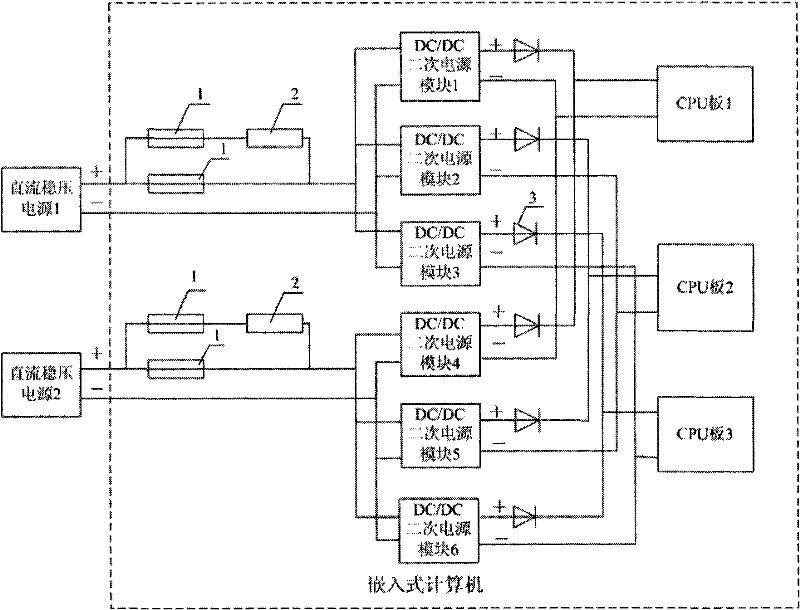

Reliable power supply circuit of triple redundancy embedded computer system

ActiveCN101777790BImprove power supply reliabilityEliminate failed failure modesEmergency protective circuit arrangementsEmergency power supply arrangementsHemt circuitsShort circuit protection

The invention relates to a reliable power supply circuit of a triple redundancy embedded computer system, in which a fuse is connected with an output end of a positive bus bar of each DC stabilized power source after being connected with a resistor in series and then connected with a fuse in parallel so as to carry out short circuit protection on the bus bar, each DC stabilized power source is divided into two paths after short circuit protection to supply power for two DC / DC secondary power source modules, two DC / DC secondary power source modules for which power is supplied by different DC stabilized power sources are selected, the output ends of the two selected DC / DC secondary power source modules are respectively connected with a diode in series and then are connected together in parallel to supply power for a CPU board, and the other two DC / DC secondary power source modules respectively supply power for another two CPU boards. The invention solves the problem of reliability of the power supply circuit of the triple redundancy embedded computer and eliminates the single point failure mode of system failure caused by open circuit or short circuit failure.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

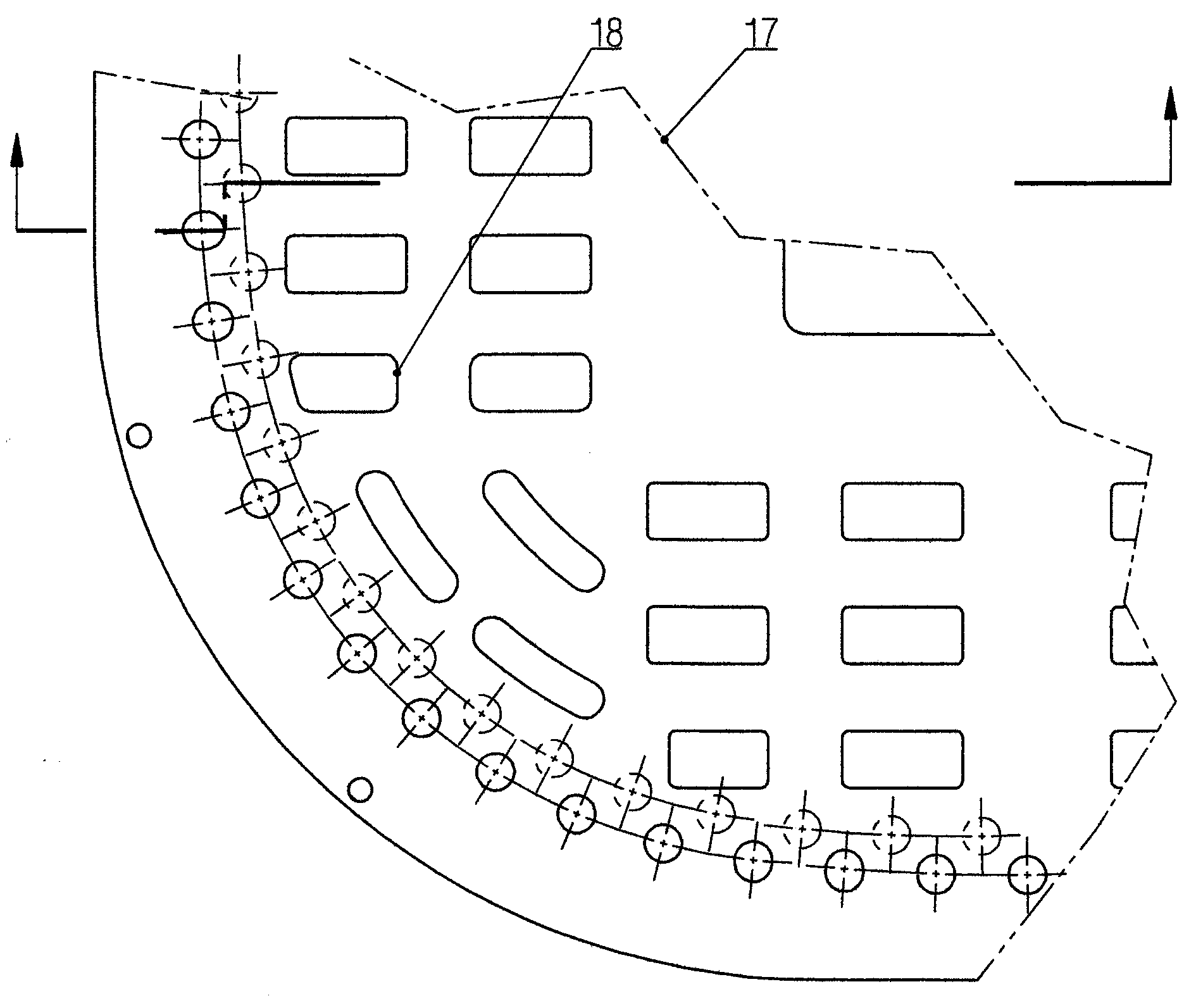

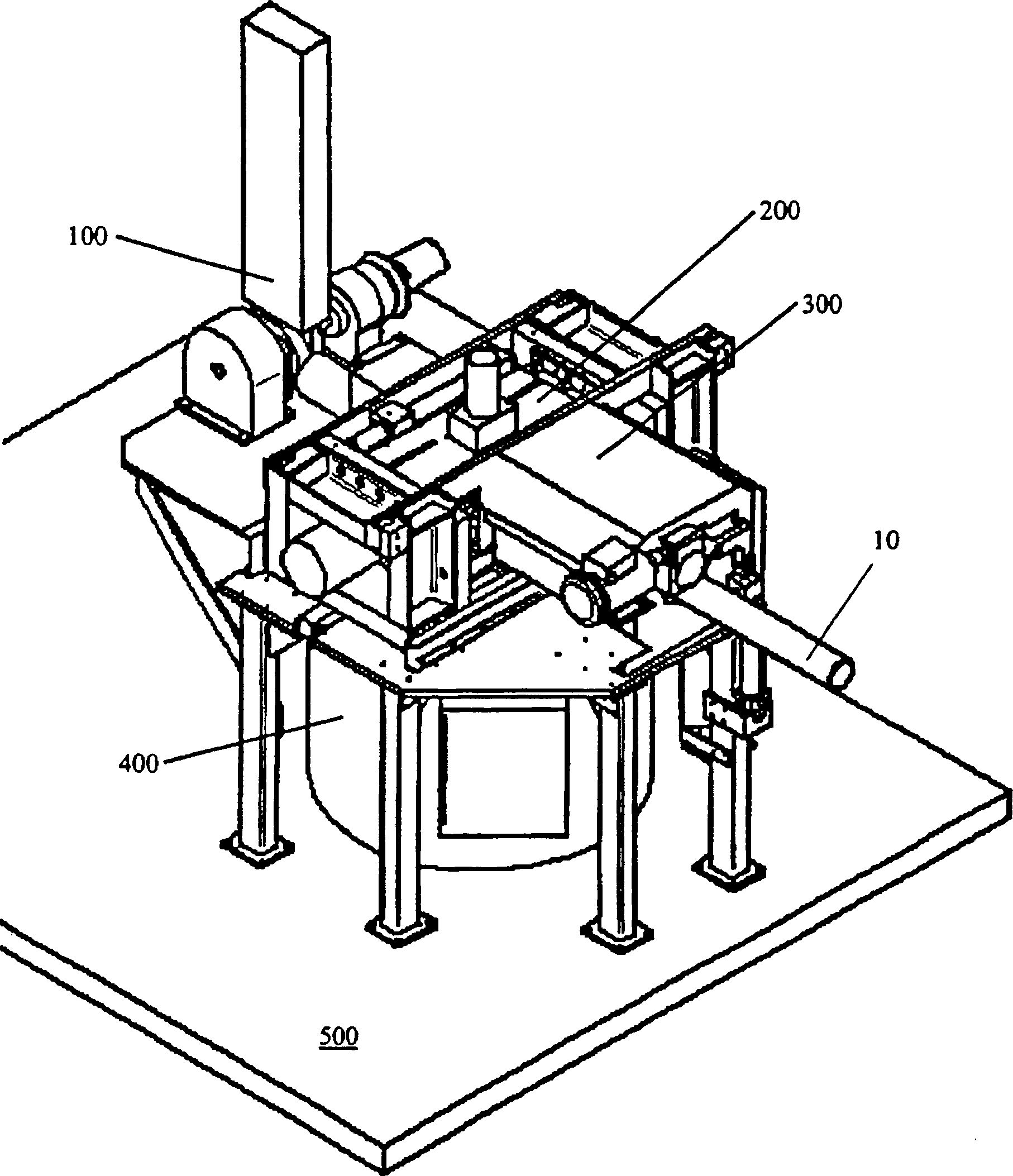

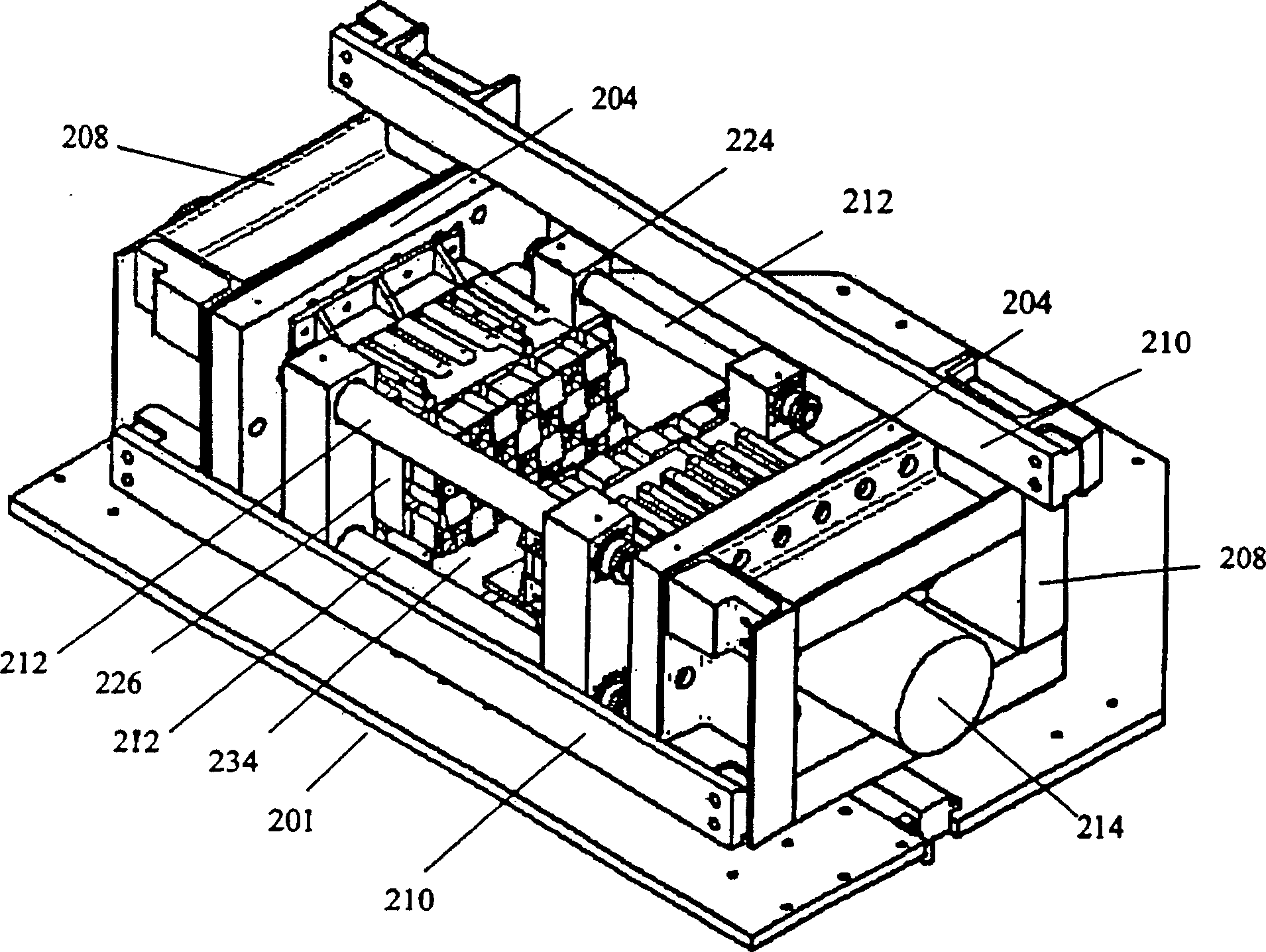

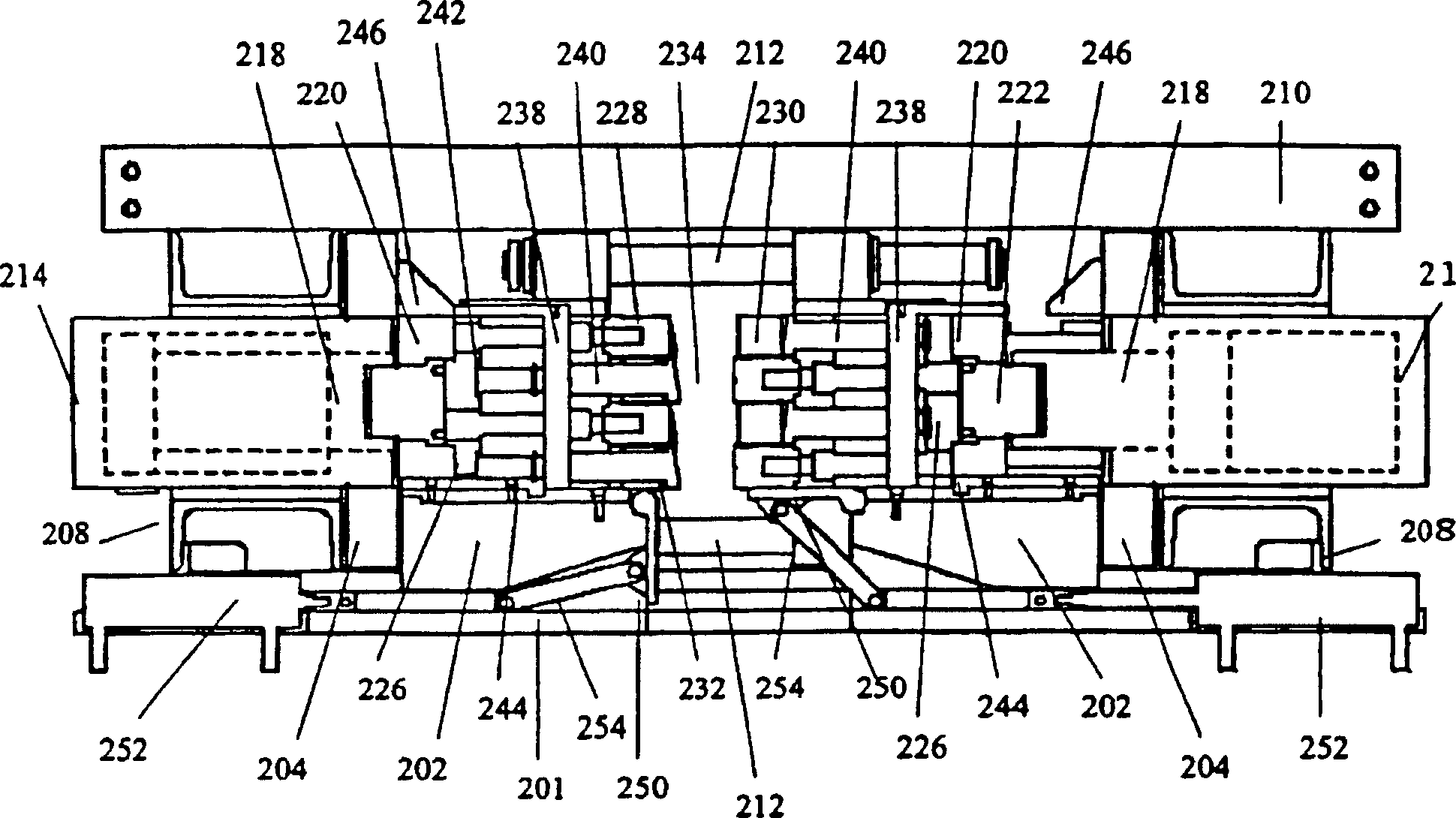

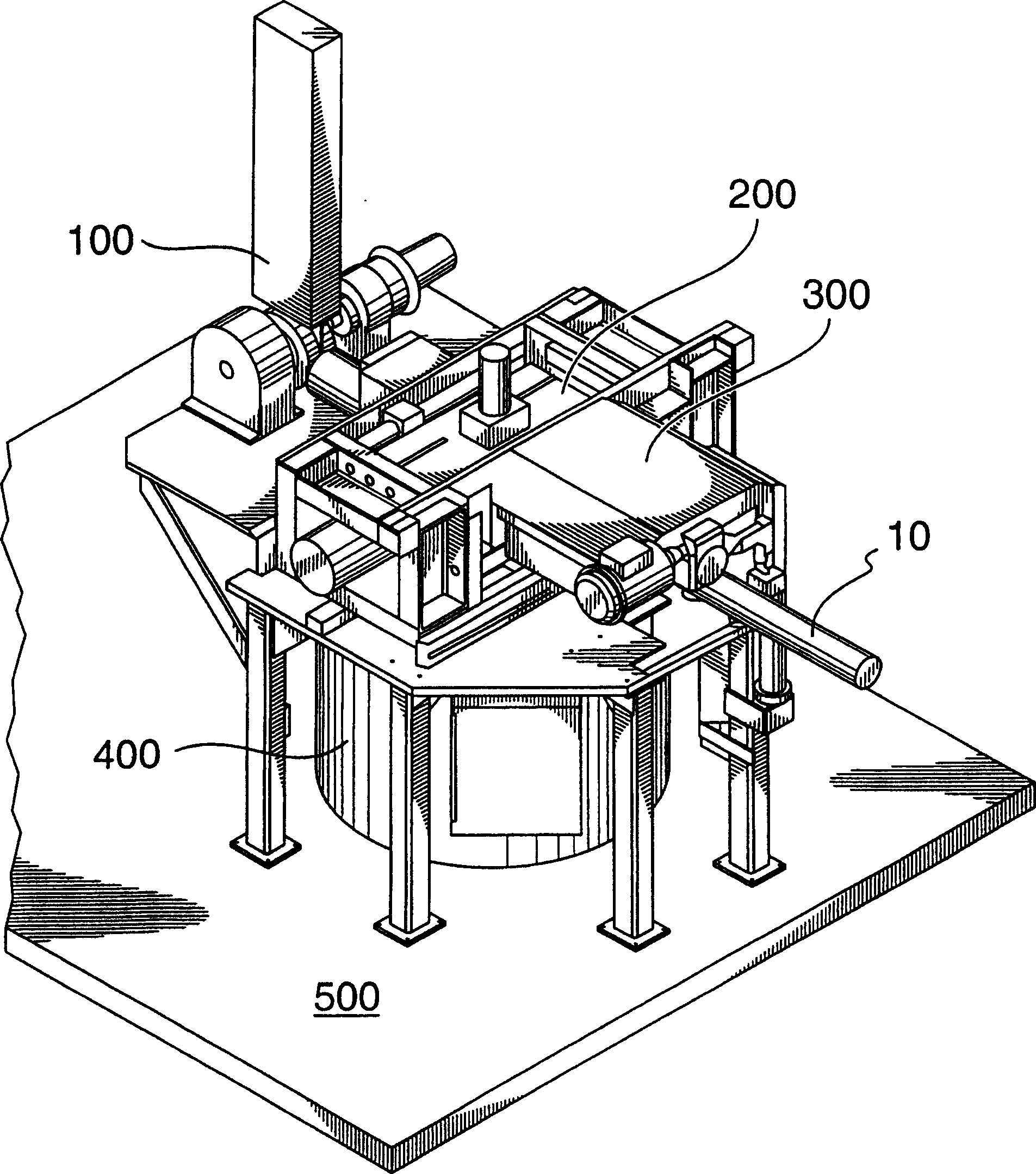

Checkerboard shear volume reduction system

InactiveCN1541394AEasy to handleAvoid complexityNuclear energy generationNuclear engineering problemsNuclear reactorEngineering

A method and apparatus for reducing the volume of a cylindrical tube for disposal by crushing flat and then shearing into small coupons. Shearing is accomplished by opposed dies having a checkerboard grid of cutting edges. The resulting coupons are preferably substantially square in shape. The invention is particularly useful for reducing the storage volume of irradiated radioactive pressure tubes from a nuclear reactor.

Owner:ATOMIC ENERGY OF CANADA LIMITED

The method to eliminate the low temperature failure of the anti-skid brake control device

InactiveCN106347706BIncrease temperatureNo low temperature failureGround installationsResource consumptionEngineering

The invention provides a method for clearing a low-temperature failure of an anti-skid brake control device. According to the device, a large-power component is adjacent to a small-power component, heat is supplied to the small-power component under a low-temperature condition, every row of large-power components are opposite to a row of small-power components. After physical analysis on a failure, the reason of the low-temperature solder-point cracking is uncompacted solder packing, and a soldering technique is determined against the uncompacted solder packing to clear the solder-point cracking failure. Insulating paint for preventing condensation is coated to avoid short circuit or breakdown; micro-crack generated by plastic deformation can be controlled by adopting a method for increasing the bent radius of a pin, and the failure can be cleared. By adopting the device, the low-temperature resistance of an anti-skid brake control device can be improved under a condition of not changing the existing material of a shell or changing the quality grade of components, so that the aims of prolonging the service life of the anti-skid brake control device and reducing product waste and resource consumption can be achieved when the anti-skid brake control device works at 55 DEG C below zero and has a temperature of 45 DEG C below zero.

Owner:XIAN AVIATION BRAKE TECH

Checkerboard shear volume reduction system and method

InactiveCN1265397CEasy to handleAvoid complexityNuclear energy generationNuclear engineering problemsNuclear reactorEngineering

A method and apparatus for reducing the volume of a cylindrical tube for disposal by crushing flat and then shearing into small coupons. Shearing is accomplished by opposed dies having a checkerboard grid of cutting edges. The resulting coupons are preferably substantially square in shape. The invention is particularly useful for reducing the storage volume of irradiated radioactive pressure tubes from a nuclear reactor.

Owner:ATOMIC ENERGY OF CANADA LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com