Coaxial beverage keg connector comprising a ball joint

A connector, coaxial technology, used in adjustable connections, pipes/pipe joints/fittings, packaging, etc., can solve problems such as easy breakage, and achieve the effect of extending life, reducing stress concentration, and eliminating failure modes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

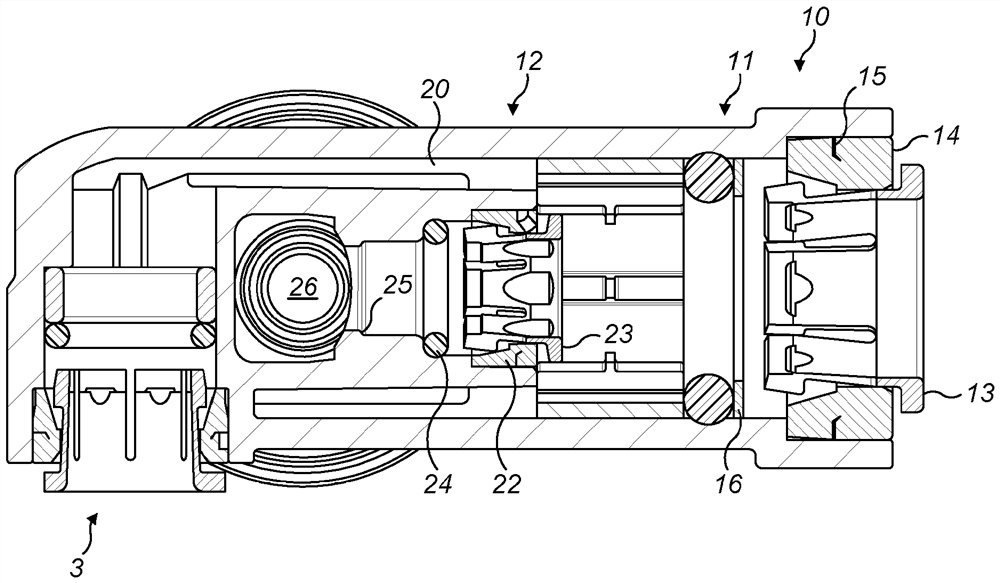

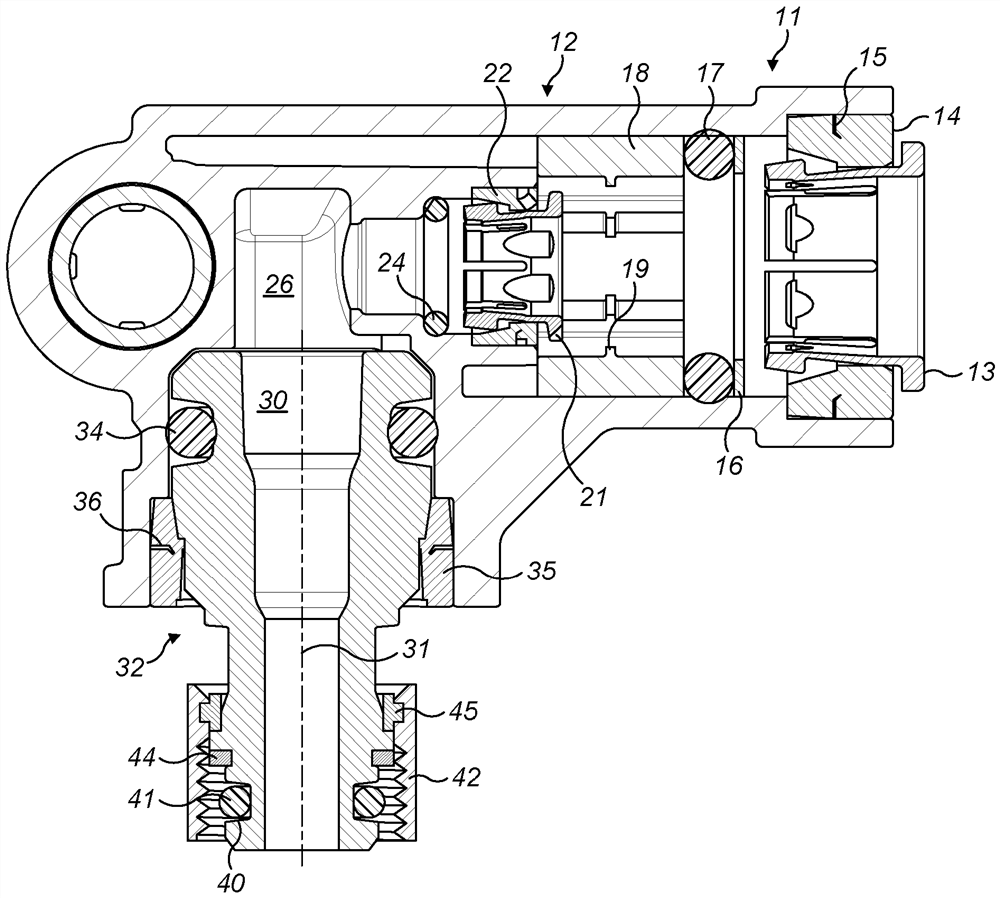

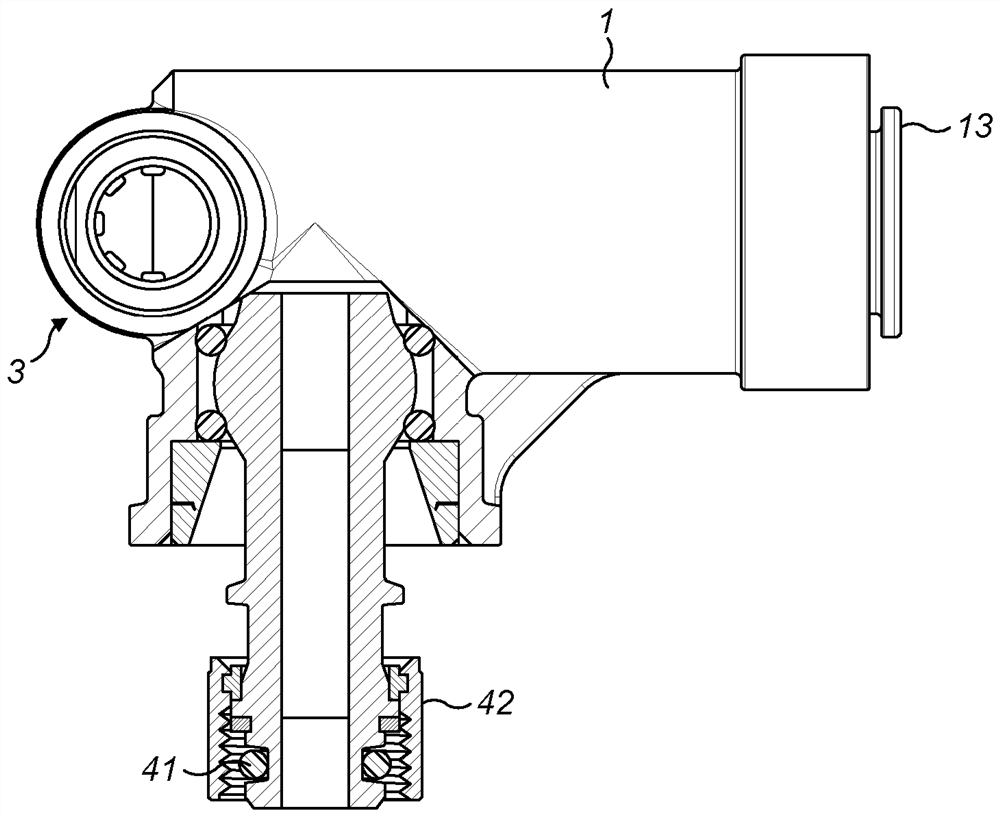

[0022] Figure 1 to Figure 5 The prior art example of ® has many components in common with the present invention. Therefore, the following description will first describe Figure 1 to Figure 5 of the regular connector, and will then refer to the Figure 6 to Figure 9 To describe the differences of the present invention.

[0023] Figure 1 to Figure 5 The connector consists of two main components, namely, the body 1 and the rod 2. The body 1 is provided with a first inlet port 3 which in use is connected to a cooling water supply. The first port 3 comprises a collet 4 to clamp a pipe for the water supply in a manner well known in the art. The collet 4 fits into a barrel 5 provided with teeth 6 for clamping inside the body. The connection is sealed by an O-ring 7 held in place by a spacer 8 .

[0024] On opposite ends of the body 1 is a coaxial outlet 10 comprising an outer outlet port 11 and an inner outlet port 12 . The outer outlet port 11 is formed from a number of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com