Microwave switch for sealed space

A microwave switch and sealed technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of reduced reliability, inability to disconnect contacts, failure of the whole machine, etc., to eliminate the phenomenon of vacuum micro-discharge, eliminate vacuum Cold welding phenomenon, the effect of improving power carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

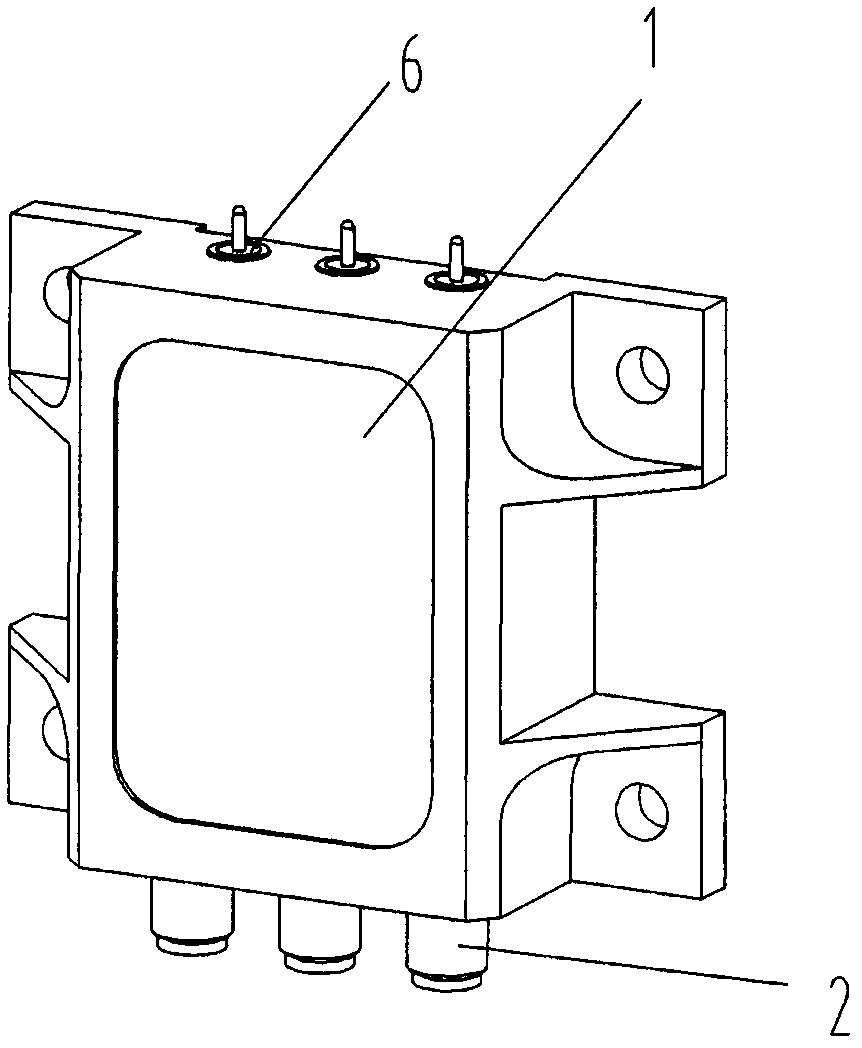

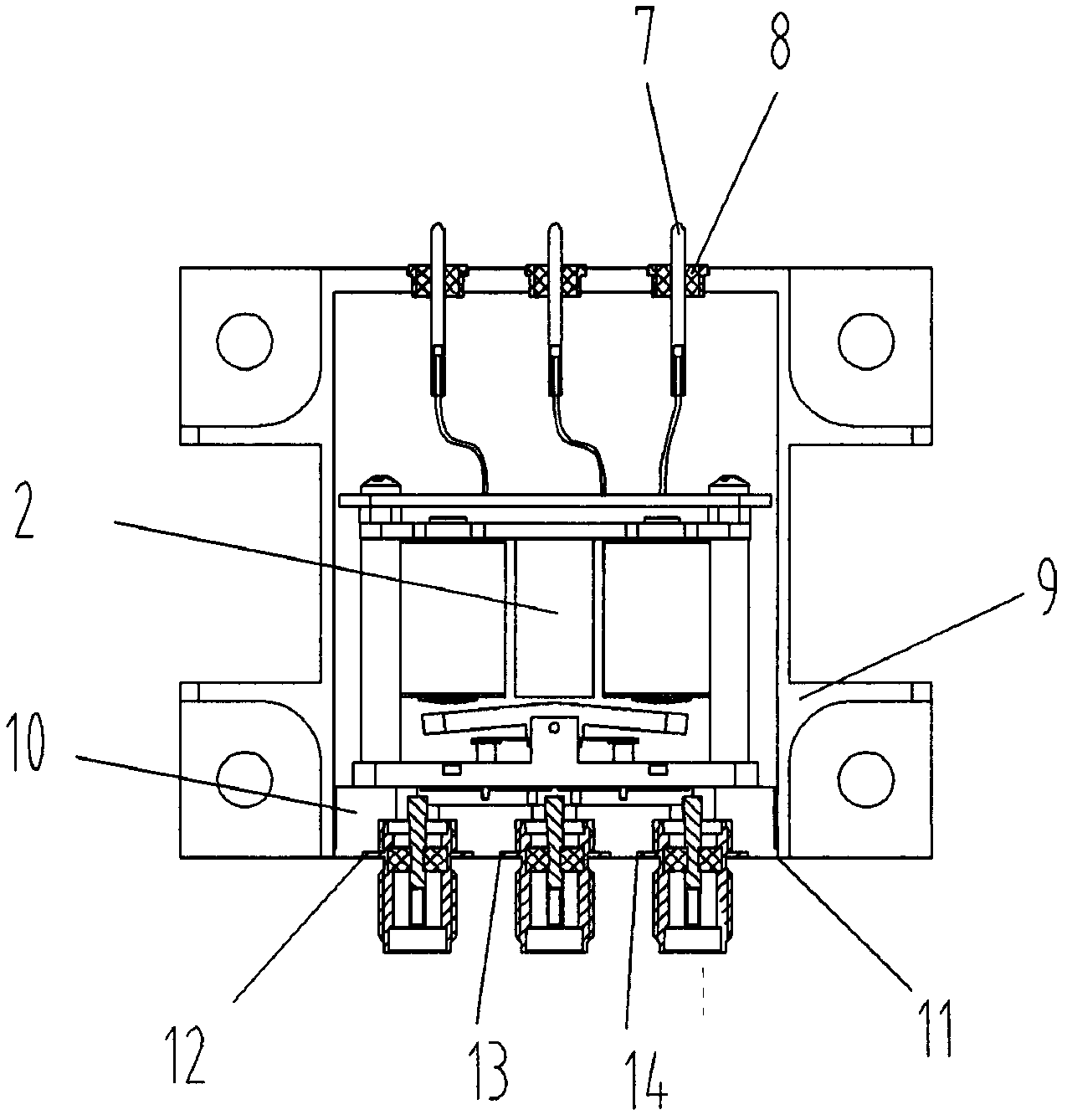

[0015] Such as figure 1 , 2 As shown in , 3, the microwave switch for sealed space of the present invention includes a microwave switch body 2 for sealed space, a sealed casing 1, and the sealed casing 1 includes a lead-out rod group 6 for insulating and sealing the internal control signal to the outside of the object. The sealing process is used to seal the microwave switch body 2 for the sealed space and the sealed casing 1, and the sealing line is 11.

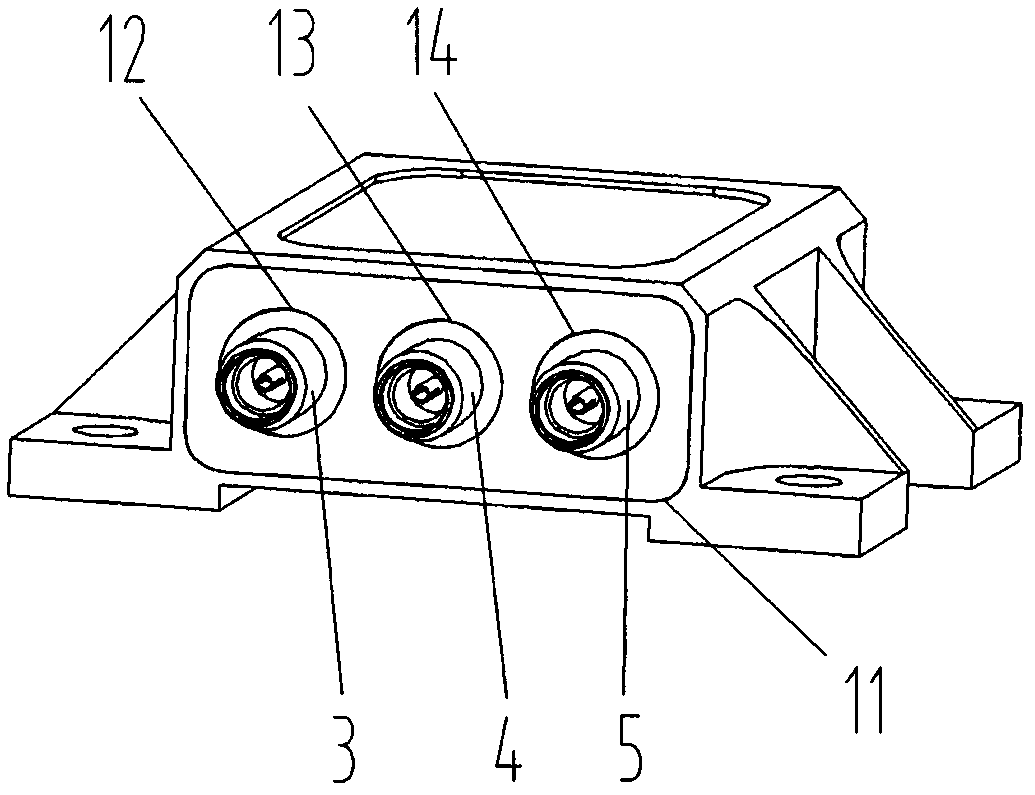

[0016] Such as figure 2 As shown, the radio frequency connectors 3, 4, 5 in the microwave switch body 2 for a sealed space are sealed with the guide base 10 by a sealing process to form sealing lines 12, 13, 14;

[0017] Such as image 3 As shown, the control signal lead-out end 7 is sintered with the insulating material 8 to form the lead-out rod set 6, and finally fixed on the casing 9 through a sealing process.

[0018] Such as image 3 , 4 As shown, the insulating material 15 is sintered to fix the inner conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com