Checkerboard shear volume reduction system

A volumetric and slicing technology, applied in the field of radioactive materials, can solve the problems of work scheduling and overall consideration of loss, reactor shutdown, time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

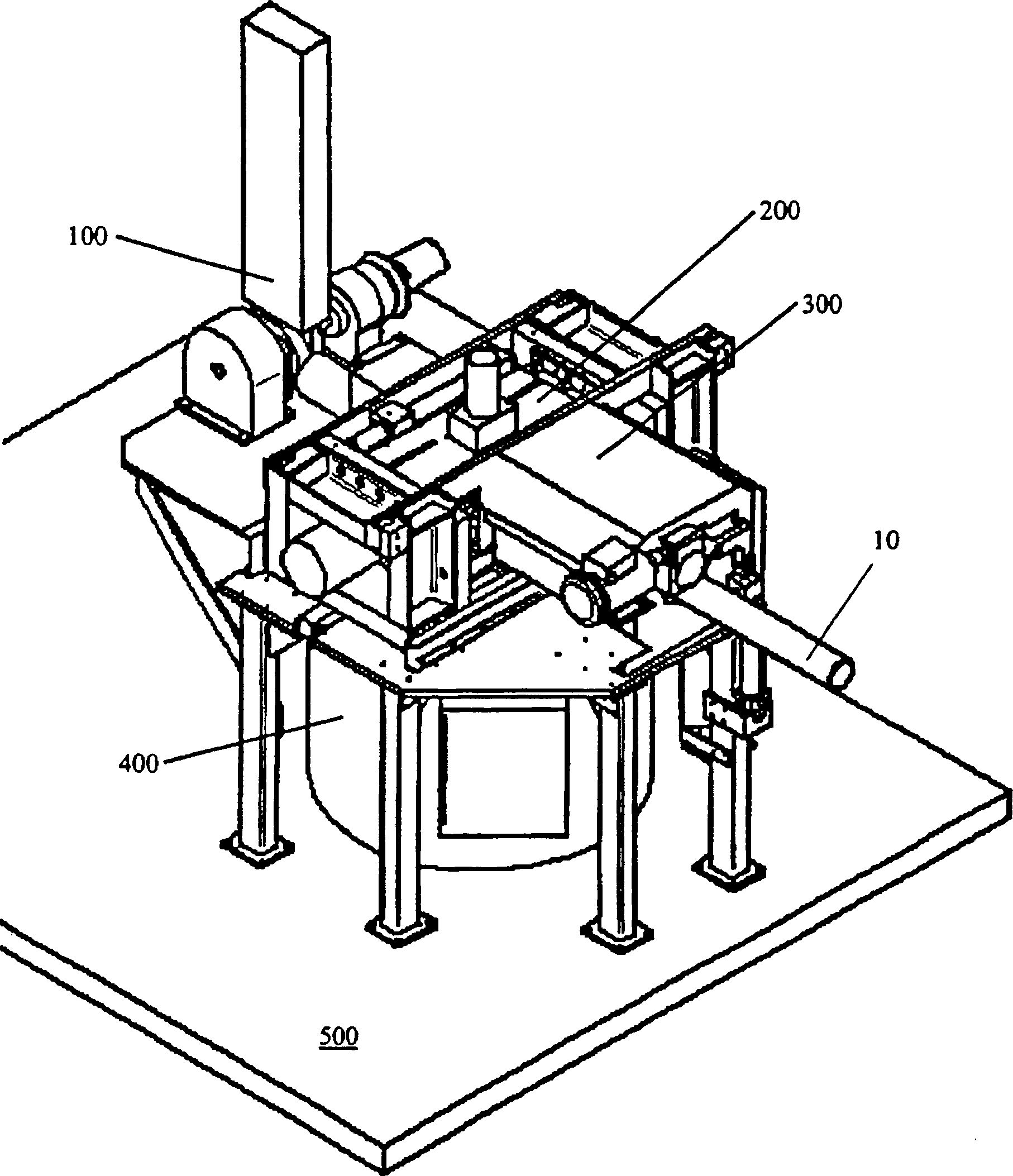

[0019] refer to figure 1 , shows a checkerboard shear volume reduction system in the present invention. The system includes a retracting unit 100 , a pressing assembly 200 , a delivery assembly 300 and a containment assembly 400 . The pressure tube volume reduction system is mounted on a work platform 500 that is movable horizontally and laterally to move between lattice sites and inward / outward to move towards and away from lattice sites (the lattice sheet) to move, and to be able to move vertically to move up and down relative to the grid area. exist figure 1 The cylindrical pressure tube 10 is shown in the position where the volume reduction takes place.

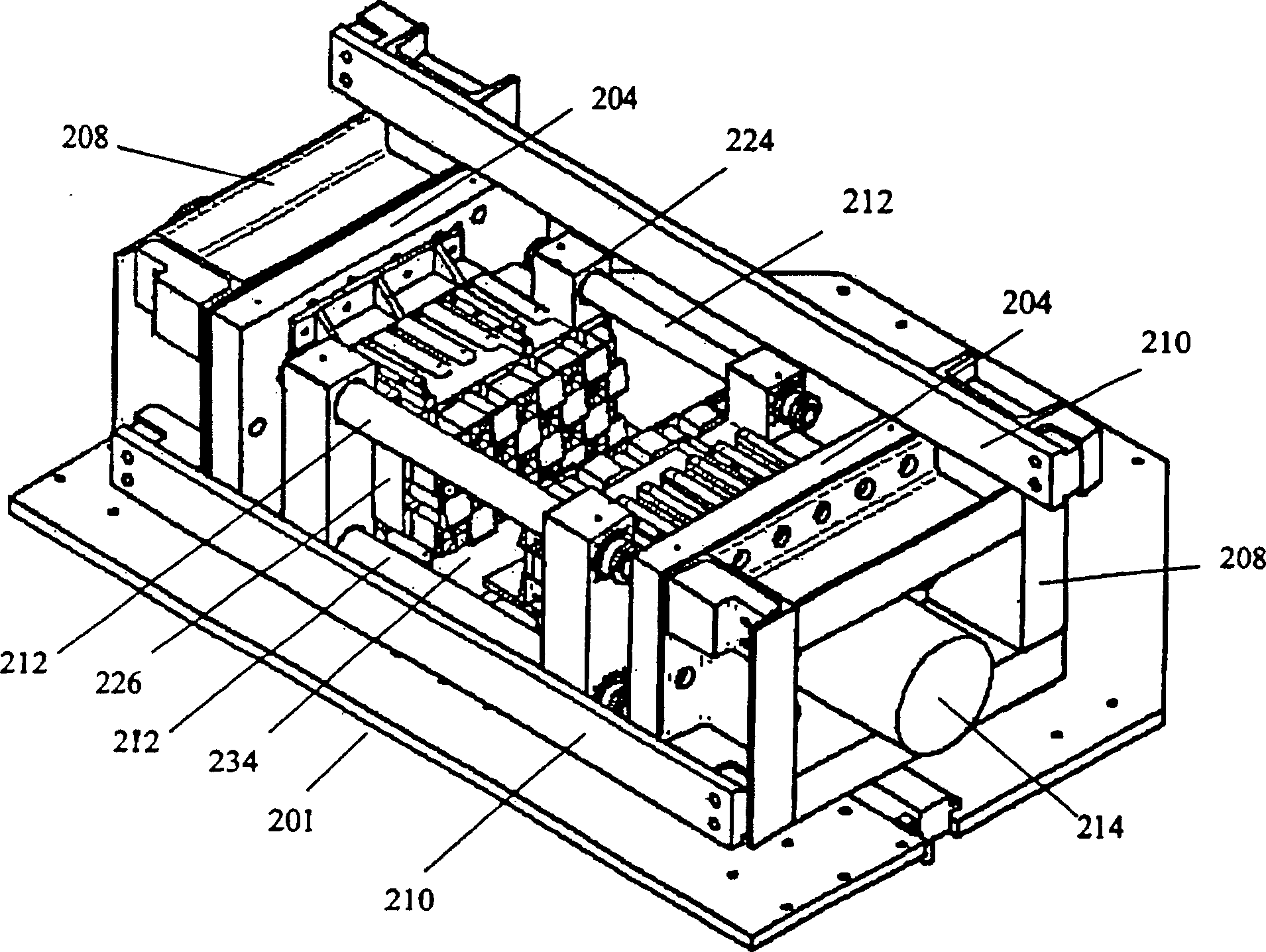

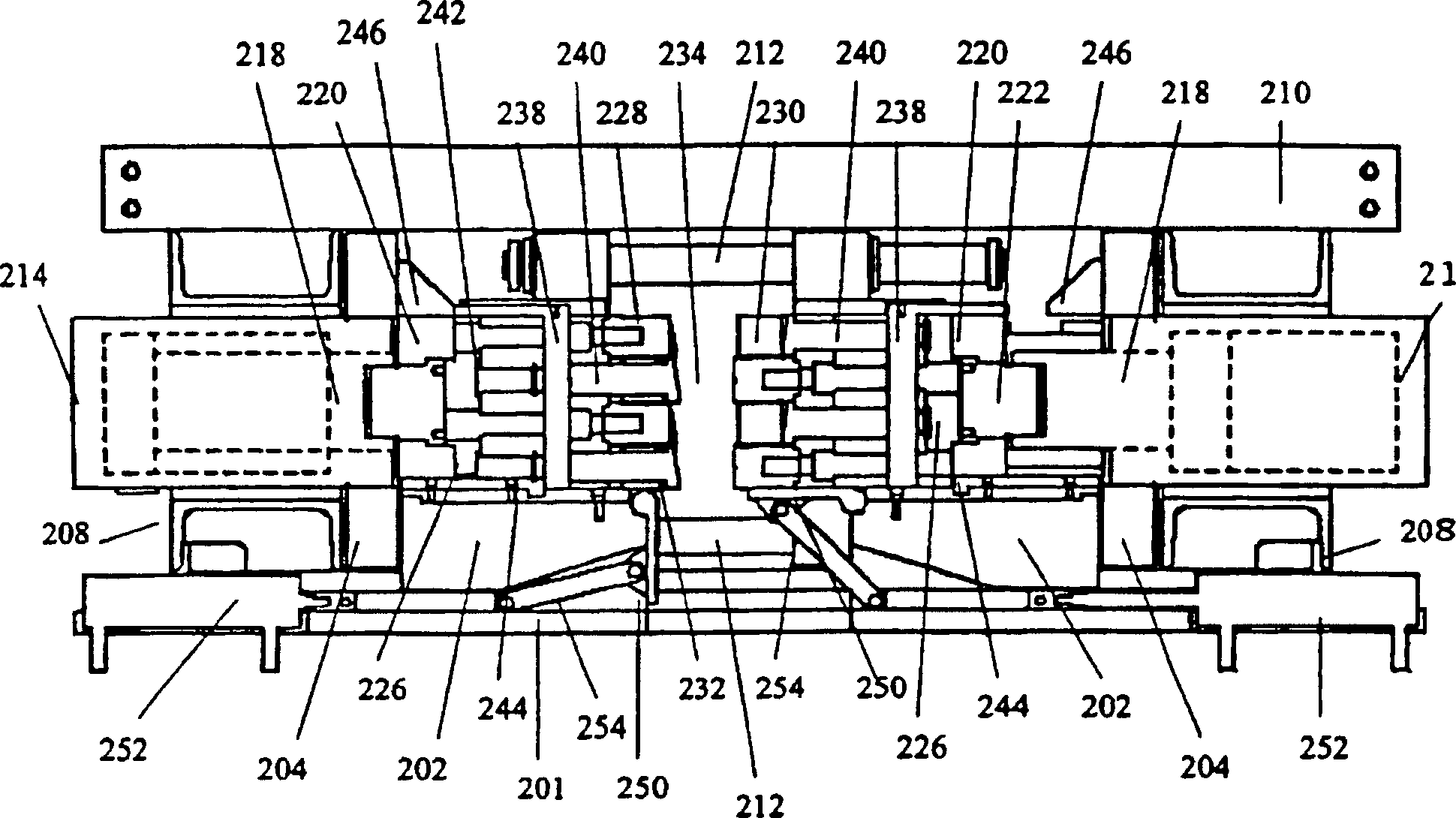

[0020] Refer below figure 2 and 3 , shows the pressing assembly 200 in more detail. The press assembly 200 includes a base 202 and an end plate 204 . The end plate 204 is relatively fixed by the box frame 208 , the bottom plate 201 and the parallel tie plates (stapes) 210 . Tie plates 210 are bolted at the four c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com