A Pulse Width Modulation Method Applicable to Vehicle Motor Controller

A pulse width modulation, motor controller technology, applied in the direction of AC motor control, general control strategy, motor, etc., can solve the problem that the temperature of the power switching device, the low output voltage/current sine, and the reduction of the switching frequency cannot be guaranteed. It can minimize the control delay, improve safety, and reduce harmonic losses and torque fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

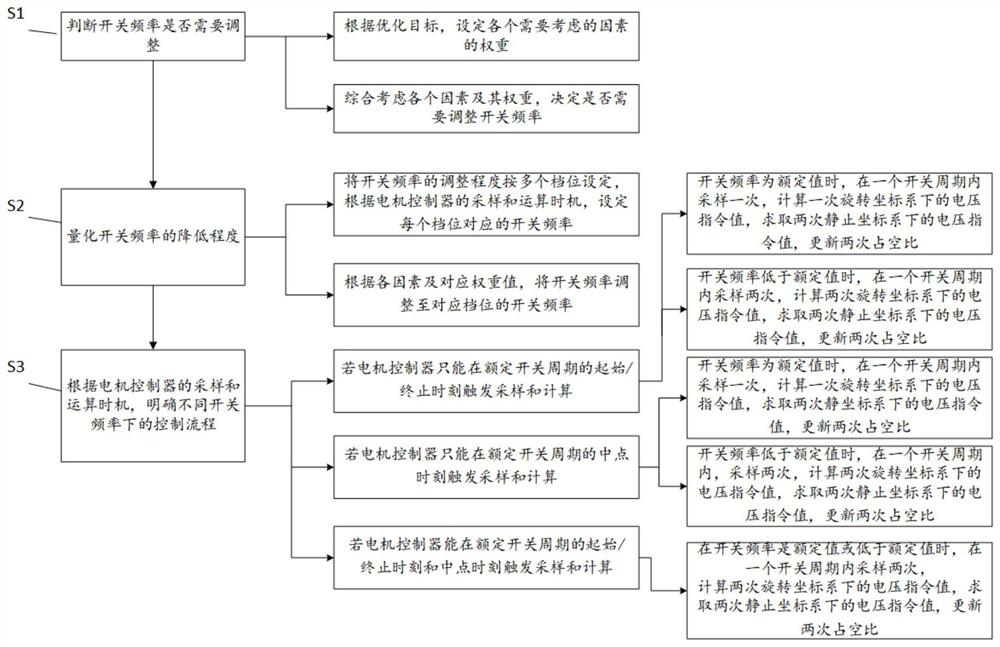

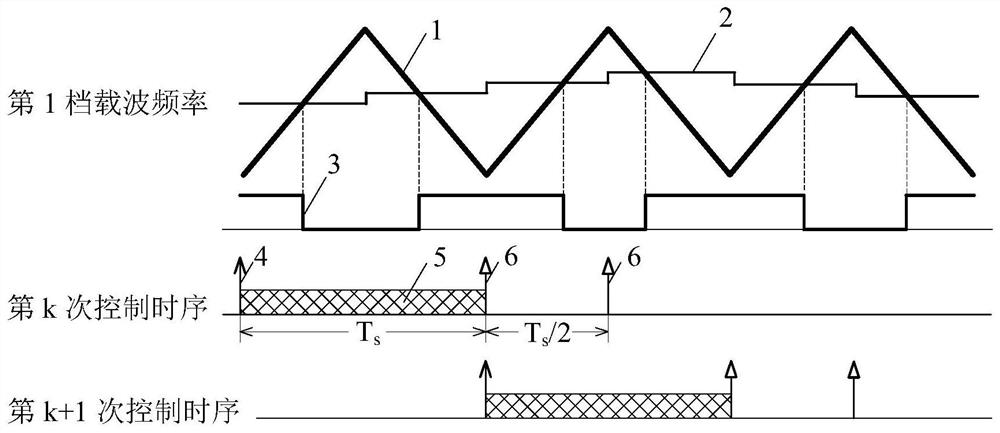

[0071] The following are when the switching frequency is the rated value, and only when sampling and calculation are triggered at the start / end of the rated switching (carrier) cycle, combined with figure 2 , the specific implementation steps of the pulse width modulation method provided by the present invention are described:

[0072] (1) At the moment shown in trigger sampling and operation 4, that is, at the beginning of the rated carrier cycle (the lowest point of the carrier), the instantaneous value of the three-phase output current of the motor controller is exactly equal to the average value in one switching cycle. At this point, the motor controller starts to collect the state quantities and command values of the motor controller and the motor.

[0073] (2) Further, within the time window shown in the sampling sum operation 5, the switching frequency is determined according to the variable information collected in step (1).

[0074] (3) After that, within the time w...

Embodiment 2

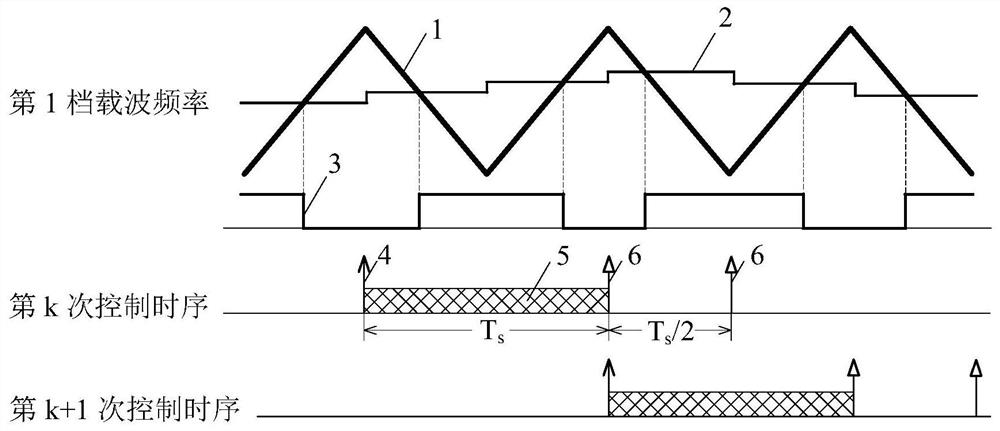

[0080] The following is when the switching frequency is the rated value, and the sampling and calculation can only be triggered at the midpoint of the rated switching (carrier) cycle, combined with image 3 , the specific implementation steps of the pulse width modulation method provided by the present invention are described:

[0081] Different from the above Embodiment 1, at the moment shown in trigger sampling and operation 4, that is, at the midpoint of the rated carrier cycle (the highest point of the carrier), the instantaneous value of the three-phase output current of the motor controller is exactly equal to one switching cycle. average of. At this point, the motor controller starts to collect the state quantities and command values of the motor controller and the motor. The rest of the execution flow sequence is delayed by half a carrier cycle. In one switching (carrier) cycle, sample once, calculate the voltage command value in the rotating coordinate system once...

Embodiment 3

[0084] The following is when the switching frequency is the rated value, and the sampling and calculation can be triggered at the start / stop time and midpoint of the rated switching (carrier) cycle, combined with Figure 4 , the specific implementation steps of the pulse width modulation method provided by the present invention are described:

[0085] Different from Embodiment 1 and Embodiment 2, the motor controller starts to collect the state quantities and command values of the motor controller and the motor at the start time and the midpoint time of the rated carrier cycle. After that, the motor controller should complete all the information collection and operation within half the carrier cycle, and update the duty cycle value at the next start time or midpoint time. In one switching (carrier) cycle, sample twice, calculate the voltage command value in the rotating coordinate system twice, obtain the voltage command value in the static coordinate system twice, and updat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com