Engine braking method

A technology of engine braking and engine, which is applied in engine control, engine components, machine/engine, etc., can solve the problems of limited application, poor reliability and durability of hydraulically driven valve opening, complex structure and control, etc., and achieves wide application, Optimal braking performance, easy manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

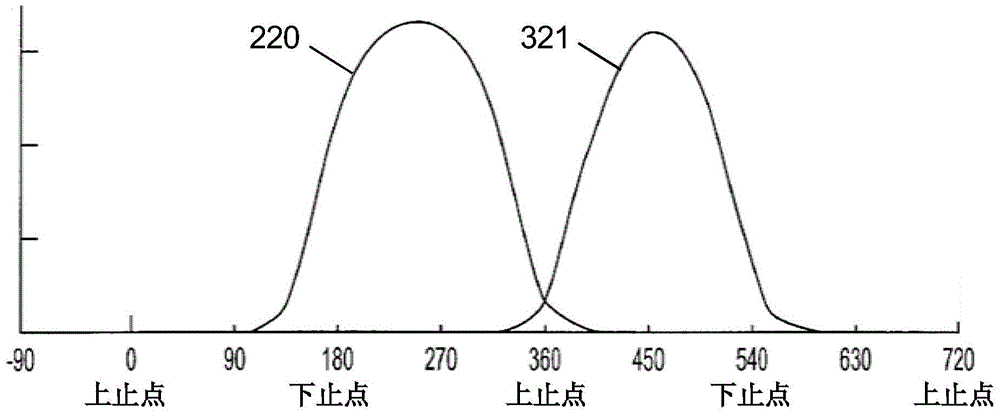

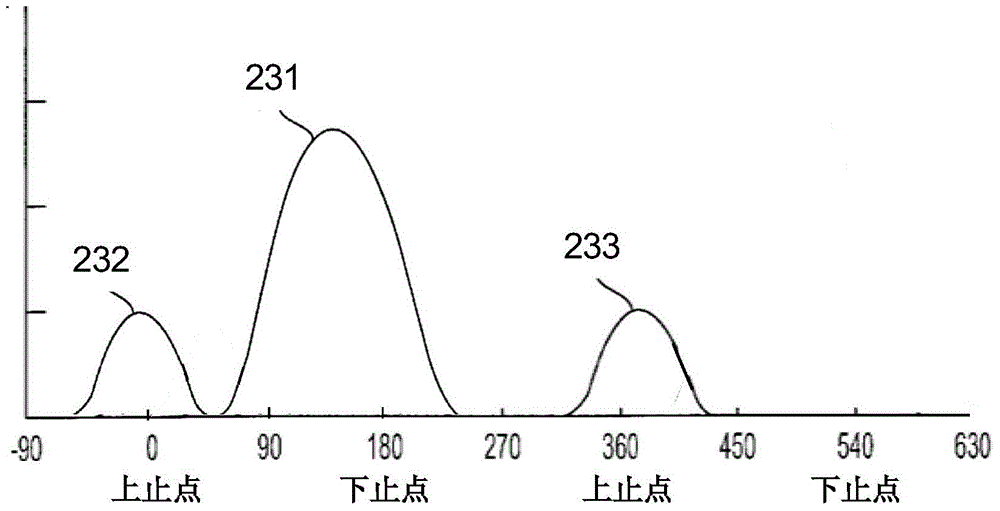

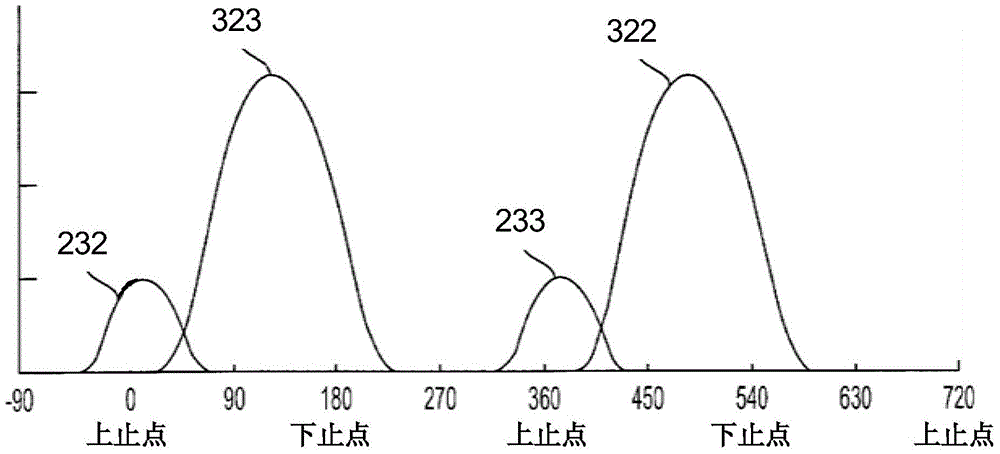

[0035] Figure 1 to Figure 6 Embodiment 1 is used to describe the engine braking method of the present invention. figure 1 It is a schematic diagram of the engine braking control of the present invention. Normal ignition operation of the engine 10 in accordance with figure 1 The solid arrow on the left in the center runs. At this time, the engine brake control mechanism 50 is closed (not powered), and the axial drive mechanism 100 of the cam roller biases the cam roller 235 at the first axial position, and the cam roller 235 is connected with the conventional ignition cam 230, and the conventional ignition cam The movement of 230 is transmitted to the valves, resulting in the normal firing operation of the engine 10 . Switch to figure 1 The dotted arrow on the right in the center runs. At this time, the brake control mechanism 50 of the engine is turned on (energized), and the axial drive mechanism 100 of the cam roller moves the cam roller 235 from the first axial positi...

Embodiment 2

[0042] In this embodiment, on the basis of the first embodiment above, the engine braking operation of the intake valve is added. Both the exhaust valve actuator and the intake valve actuator have the axial drive mechanism 100 of the cam roller, the structure, principle and operation process of which are the same as those described in Embodiment 1 above, and will not be repeated here.

[0043] This embodiment includes four cams: a conventional ignition exhaust cam 230, a braking exhaust cam 2302, a conventional ignition intake cam and a braking intake cam (one more than embodiment 1). use the intake cam). When the engine needs conventional ignition operation, the axial driving mechanism 100 of the cam roller biases the cam roller 235 at the first axial position, and the intake and exhaust cam rollers are connected or adjacent to the conventional ignition intake and exhaust cams, and the conventional The movement of the ignition intake and exhaust cams is transmitted to the va...

Embodiment 3

[0046] In this embodiment, on the basis of the above-mentioned embodiment 1 or embodiment 2, an operation of modifying the movement of the valve is added. The principle is to add a Lost Motion mechanism to a valve actuator, such as a rocker arm, and the Lost Motion mechanism is connected to at least one valve. Through the opening and closing of the motion loss mechanism, the movement of the valve connected with the motion loss mechanism is changed. In this way, on the basis of the valve movement obtained in the above-mentioned embodiment 1 or embodiment 2, a new valve movement is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com