Shock/vibration dampening

a technology of vibration dampening and vibration, applied in the field of vibration dampening and settling, can solve the problem of increasing the flight distance of an arrow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

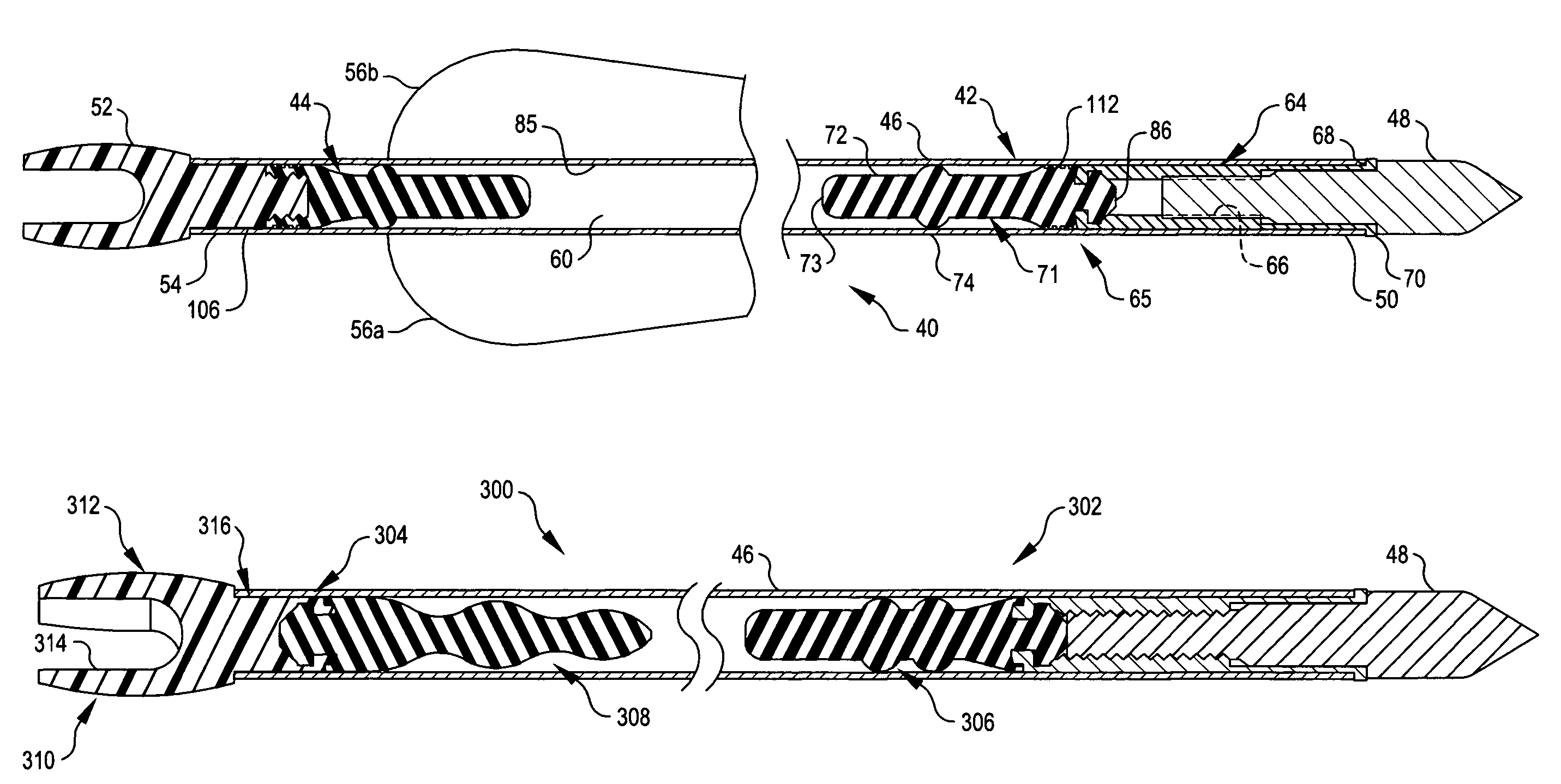

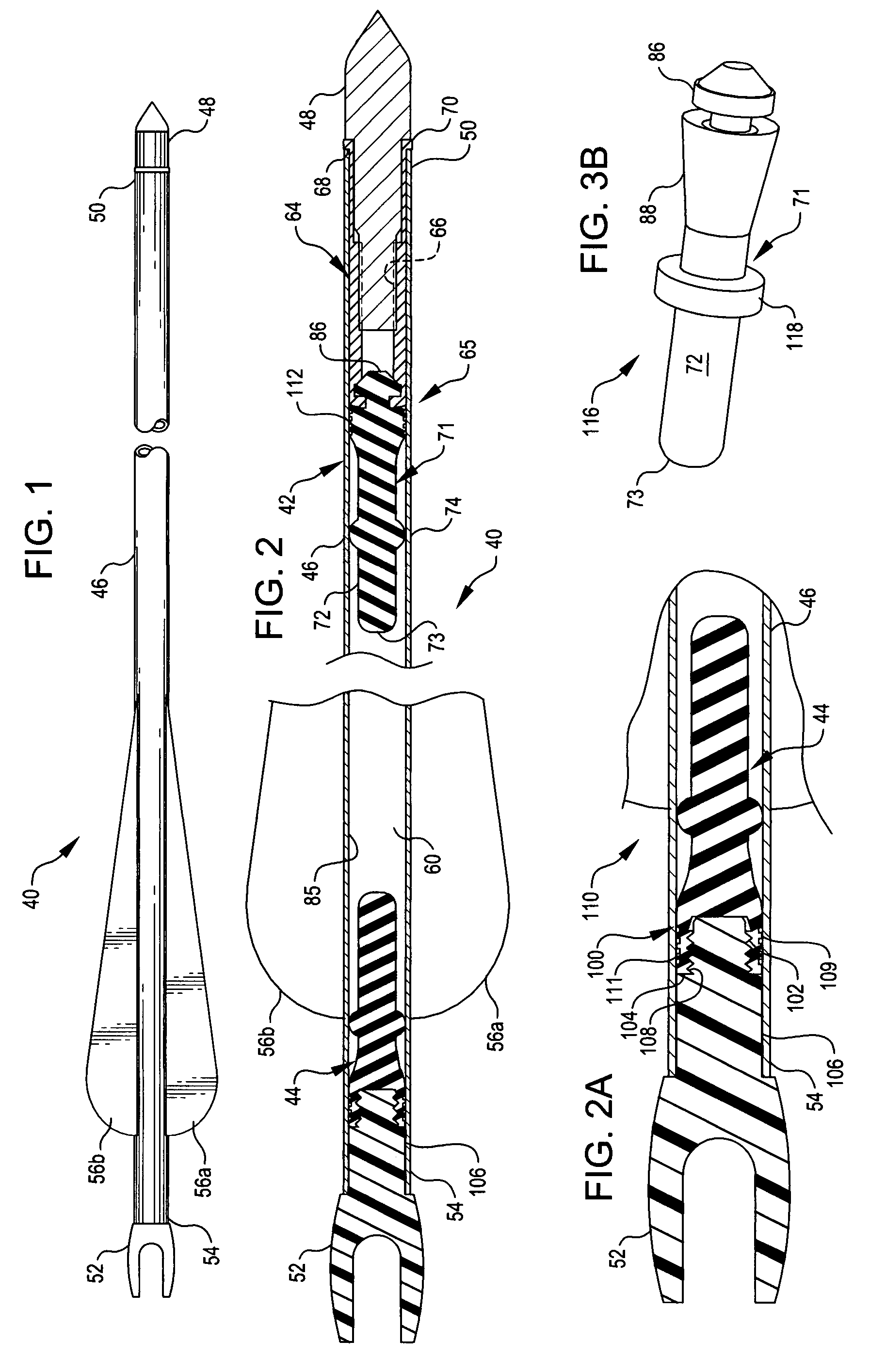

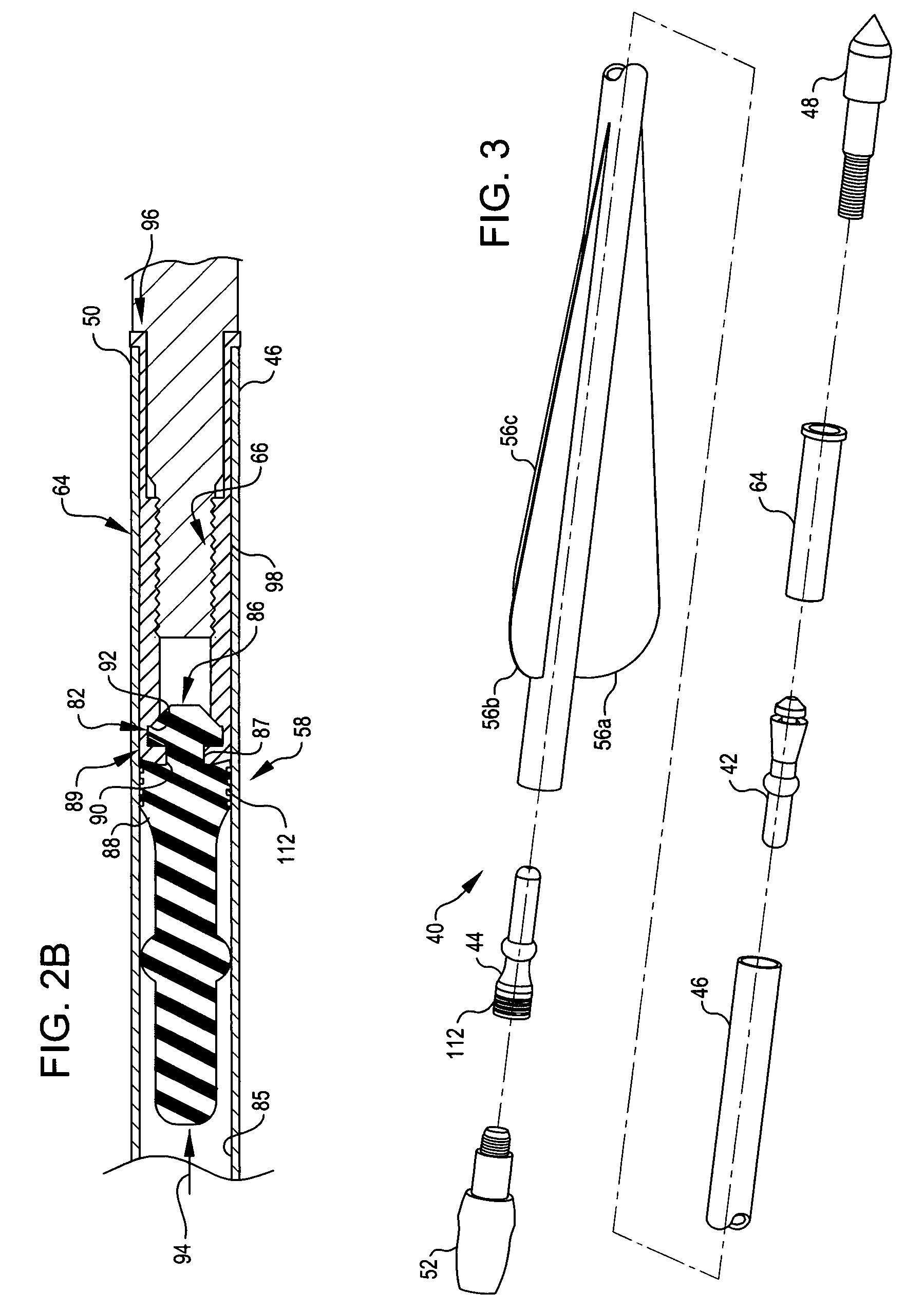

[0050]Referring now to the drawings, FIGS. 1, 2, 2A, 2B, 3, and 3A depict an arrow 40 equipped with: (1) a point end vibration dampener 42, and (2) a nock end vibration dampener 44. Both dampeners are constructed in accord with the principles of the present invention and installed in arrow 40 in accord with those principles.

[0051]Arrow 40 has a hollow shaft 46, an arrow point 48 at the rear end 50 of the shaft, and a nock 52 at the front end 54 of the shaft. Fletches 56a-c of conventional construction are mounted to arrow shaft 46 toward its front end 54.

[0052]Referring now to FIGS. 2, 2A, and 3, point end vibration dampener 42 is dimensioned for a high tolerance slip fit in arrow shaft 46 and is installed in the hollow interior 60 of the shaft toward the rear end 50 of the shaft. Nock end vibration dampener 44 is similarly dimensioned for a high tolerance slip fit in arrow shaft 46 and is installed in the interior 60 of the shaft adjacent the forward, front end 54 of the shaft.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| Settling time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com