Fuel cell stack

a fuel cell and stack technology, applied in the field of fuel cell stacks, can solve the problems of increasing the cost of fuel cells, and achieve the effect of preventing air retention and easy and reliably discharg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

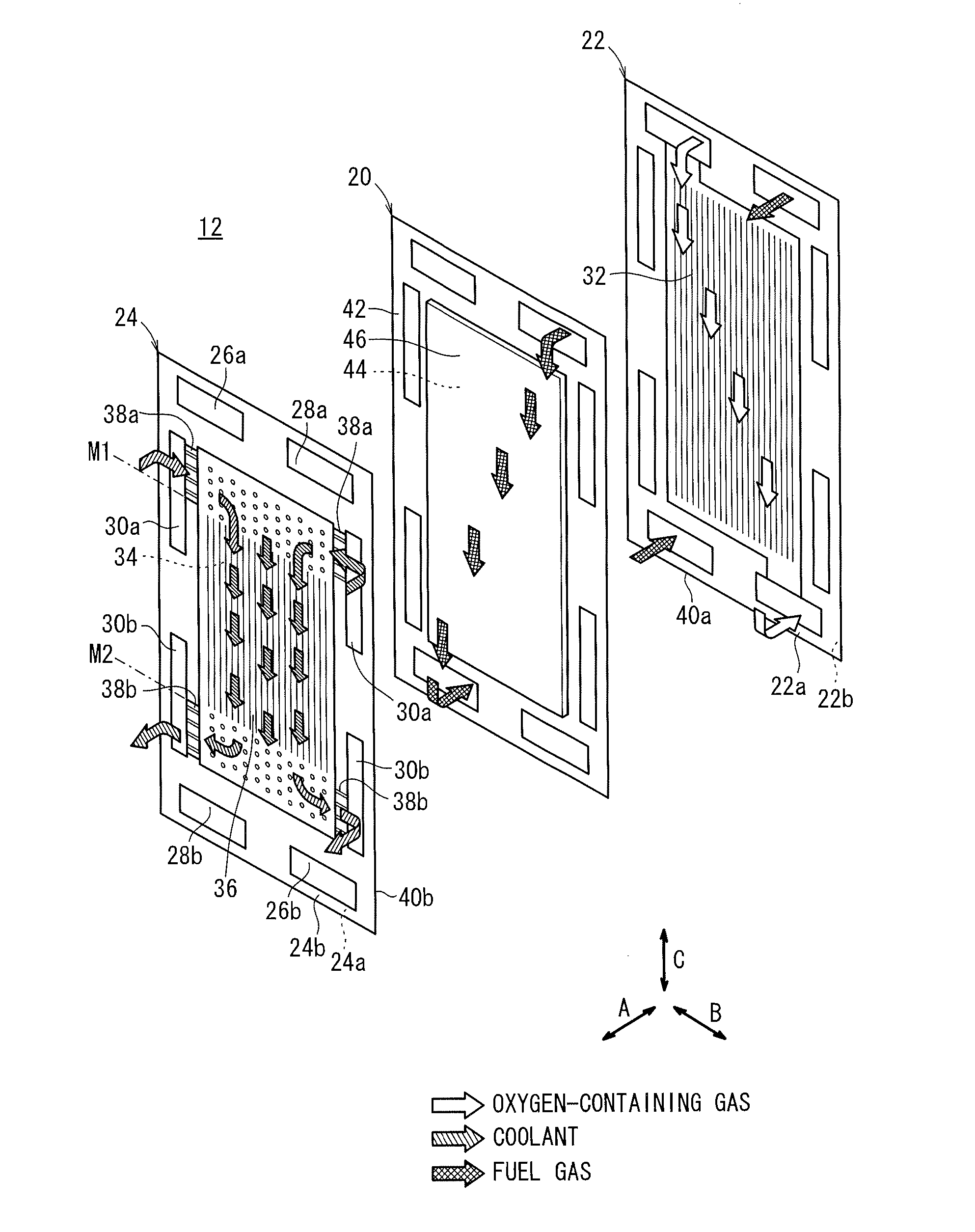

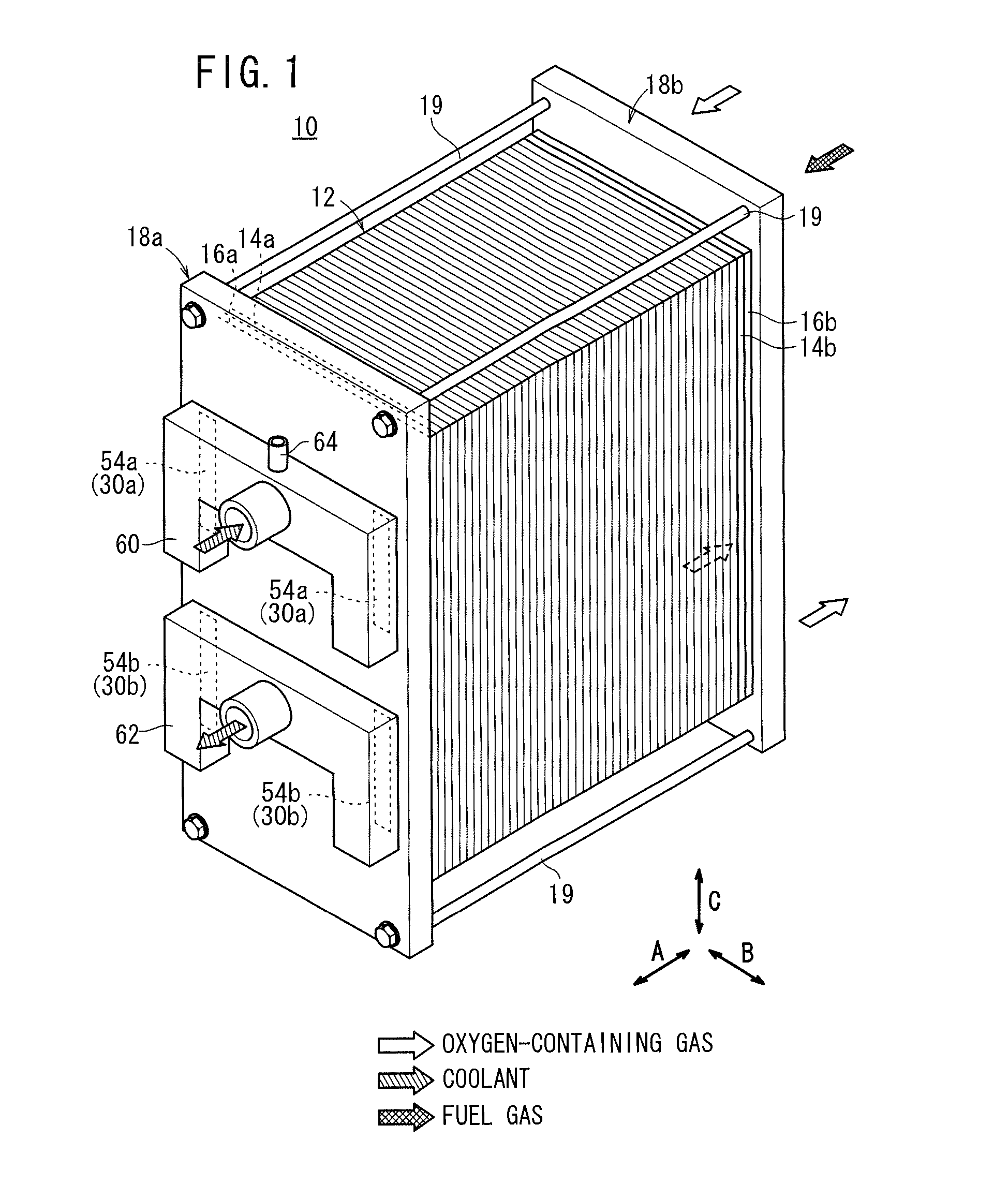

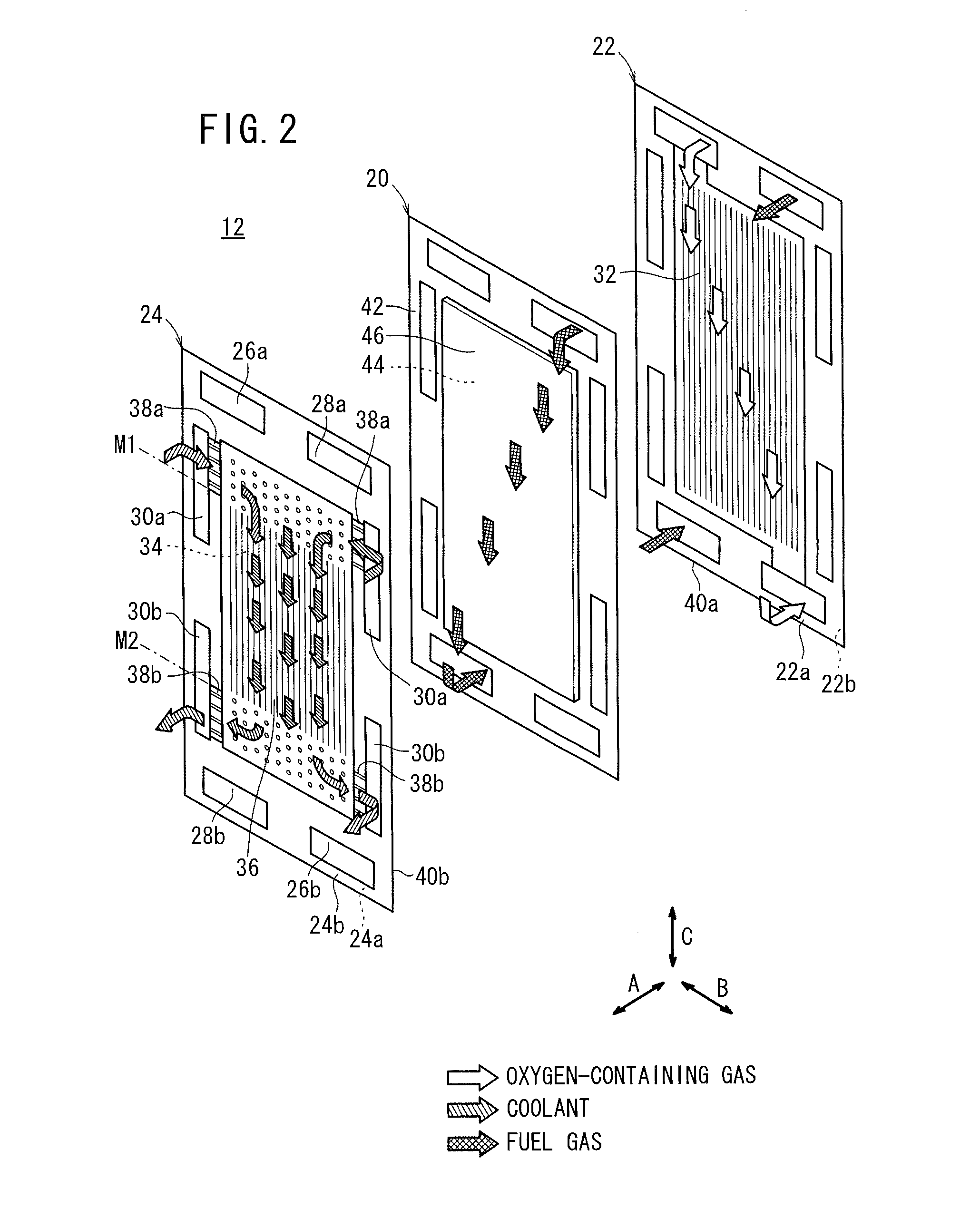

[0048]As shown in FIG. 1, a fuel cell stack 10 according to the present invention is constituted by fuel cells 12, a plurality of such fuel cells 12 being stacked mutually along a horizontal direction (in the direction of the arrow A).

[0049]On one end in the stacking direction of the fuel cells 12, a first terminal plate 14a, a first insulating plate 16a and a first end plate 18a are stacked thereon, whereas on the other end in the stacking direction, a second terminal plate 14b, a second insulating plate 16b and a second end plate 18b are stacked thereon.

[0050]The first end plate 18a and the second end plate 18b, which are constructed with rectangular shapes, are integrally fastened and retained by a plurality of tie rods 19 extending in the direction indicated by A. The fuel cell stack 10 may be retained integrally by a box shaped casing (not shown), which includes the first end plate 18a and the second end plate 18b serving as respective end plates thereof.

[0051]As shown in FIG. ...

second embodiment

[0088]FIG. 5 is a perspective view with partial omission of a fuel cell stack 70 according to the present invention.

[0089]Structural elements of the second embodiment, which are the same as those of the fuel cell stack 10 according to the first embodiment, are designated by like reference characters and such features shall not be described in detail. Similarly, in the description of the third embodiment or later that follows, detailed explanations of such features are omitted.

[0090]The fuel cell stack 70 is equipped with a first insulating plate 72a and a second insulating plate 72b. In the first insulating plate 72a, a pair of grooves (coolant passage connecting portions) 78a, 78a, which communicate in a vertical direction between the coolant supply passages 30a and the coolant discharge passages 30b, are formed in a surface 76a thereof facing the fuel cell 12.

[0091]Similarly, in a surface 76b of the second insulating plate 72b facing the fuel cell 12, a pair of grooves (coolant pa...

third embodiment

[0093]FIG. 6 is a perspective view with partial omission of a fuel cell stack 90 according to the present invention.

[0094]The fuel cell stack 90 is equipped with at least one separator 92. The separator 92 is constructed substantially in the same manner as the first separator 22 or the second separator 24. For example, the second sealing member 40b provided in the second separator 24 is cut out to form grooves (coolant passage connecting portions) 94 that communicate vertically between the coolant supply passages 30a and the coolant discharge passages 30b. Consequently, with the third embodiment, the same effects as those of the first and second embodiments are attained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gravity | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

| pressure loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com