Printer with pair of tape roll guide members having a recessed part for housing a pressing roller

a technology of pressing roller and guide member, which is applied in the field of printing machines, can solve the problems of unstable feeding of print-receiving tape, affecting printing, and slack in the print-receiving tape, and achieves the effect of wide adjustable space range and increased strength of guide members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

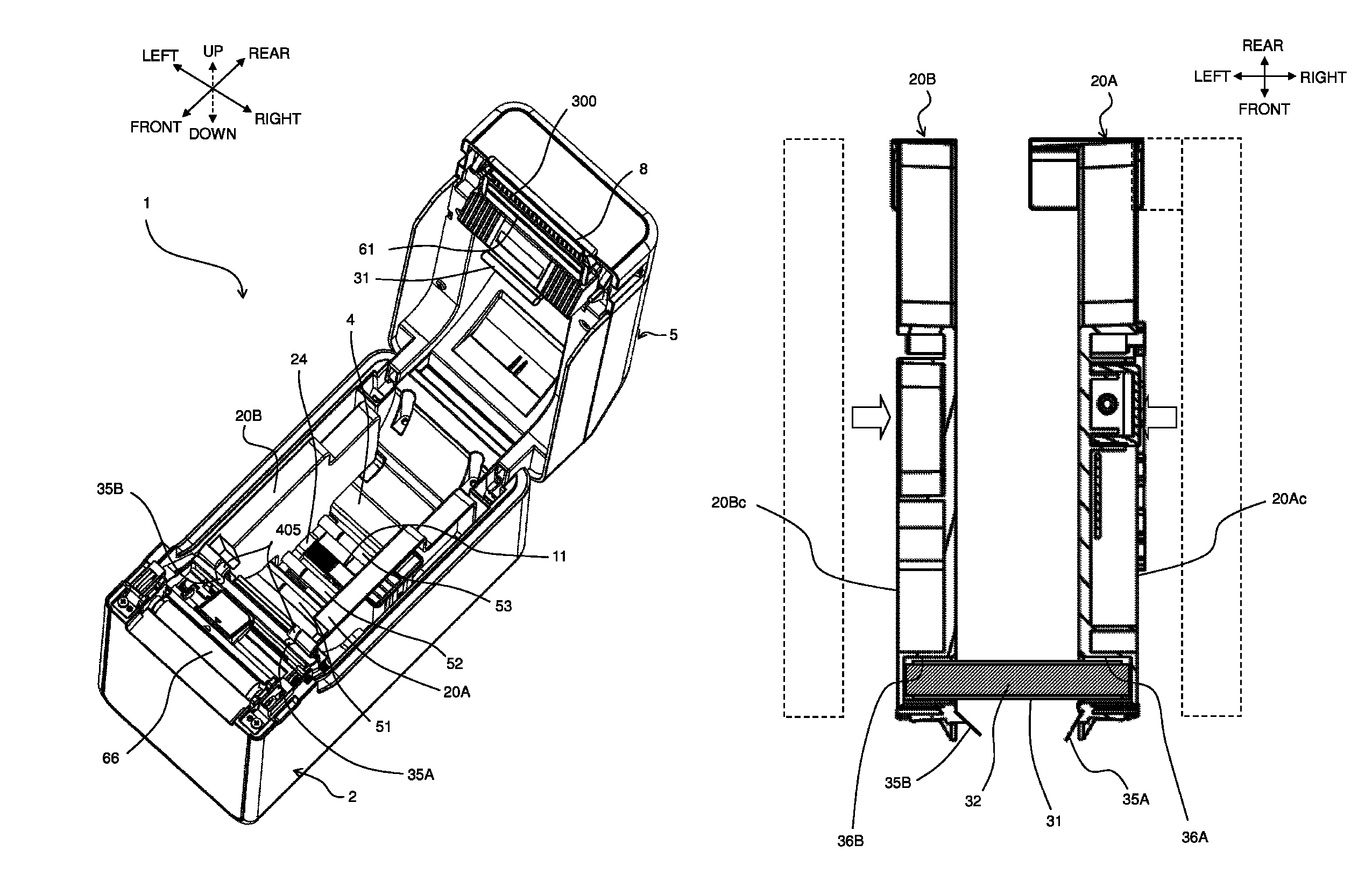

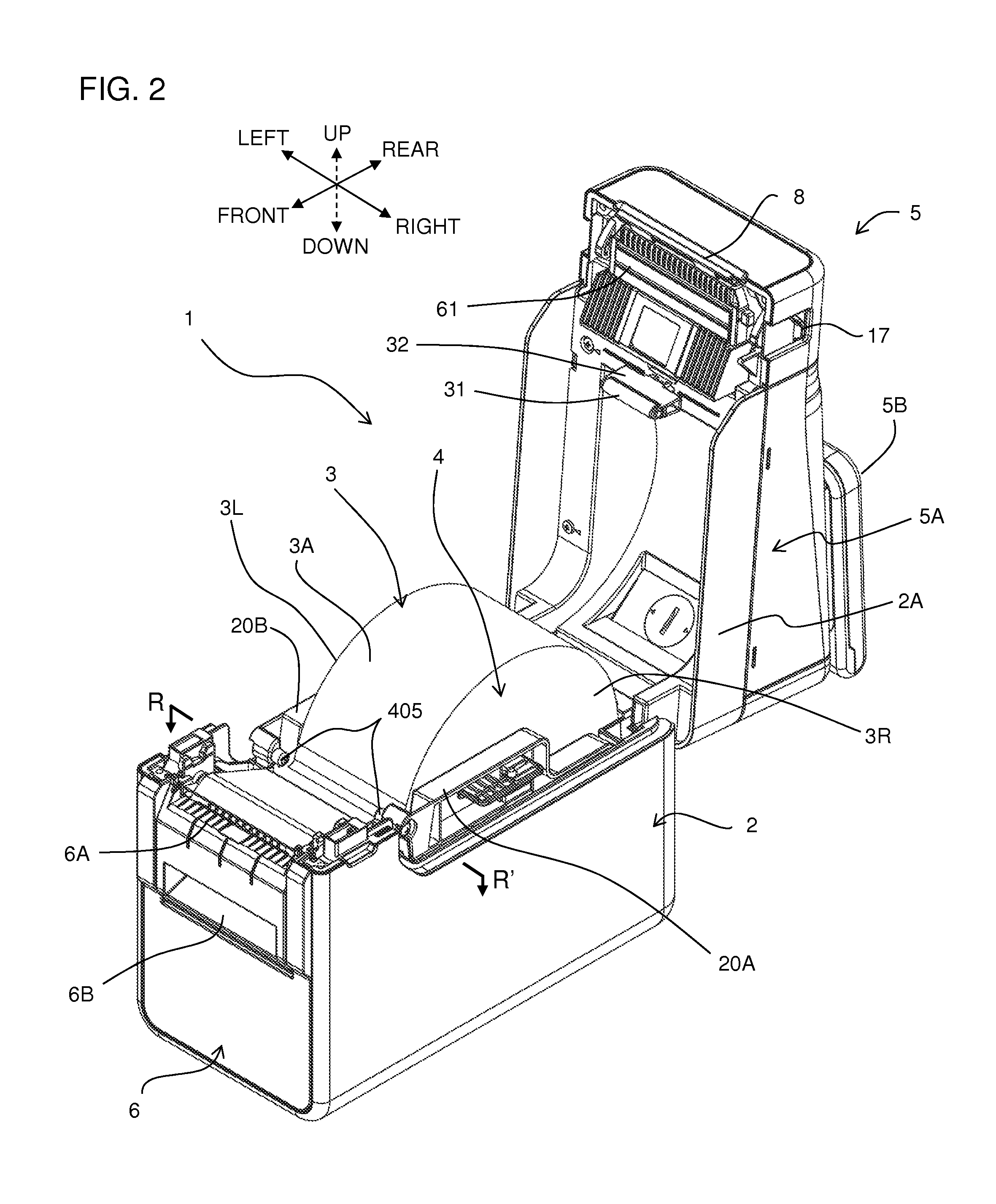

[0029]The following describes an embodiment of the present disclosure with reference to accompanying drawings.

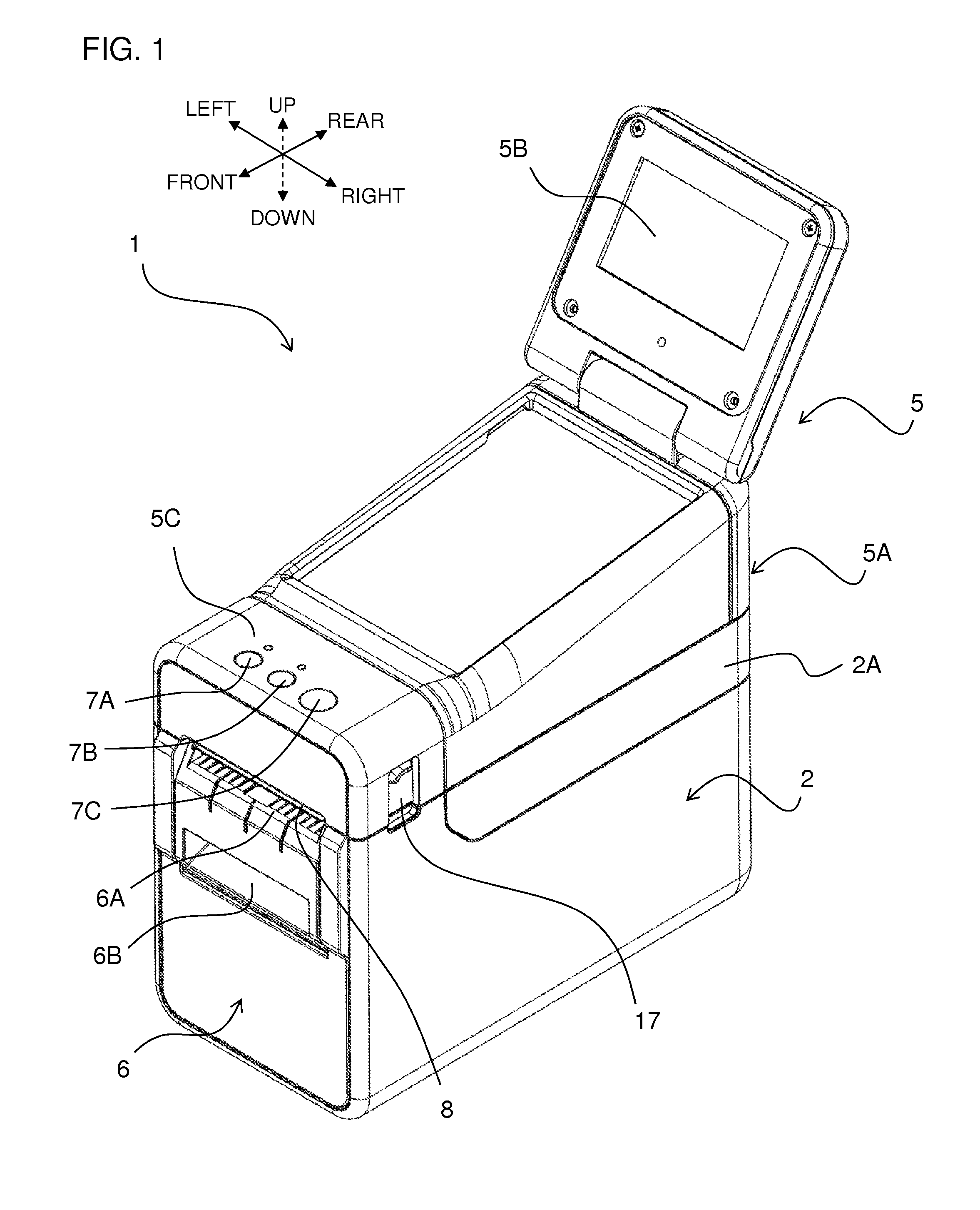

General Outer Appearance Configuration

[0030]First, the general outer appearance configuration of the label producing apparatus 1 of this embodiment will be described using FIG. 1. Note that the front-rear direction, left-right direction, and up-down direction in the descriptions below indicate the directions of the arrows suitably shown in each figure, such as FIG. 1.

[0031]In FIG. 1, the label producing apparatus 1 comprises a housing 2 comprising a front panel 6, and an upper cover unit 5. The housing 2 and the upper cover unit 5 are made of resin, for example. The upper cover unit 5 comprises a touch panel part 5A, a substantially rectangular-shaped liquid crystal panel part 5B, and an operation button part 5C.

[0032]The upper cover unit 5 is pivotably connected to the housing 2 at the rearward end part via a rotating shaft part 2a (refer to FIG. 4 described later), forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com