Steamer

a technology of steamer and steam chamber, which is applied in the field of steamer improvement, can solve the problems of affecting the appearance or setting of food, and achieve the effect of effectively preventing the build-up of steam and avoiding mixing the odors of different foods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

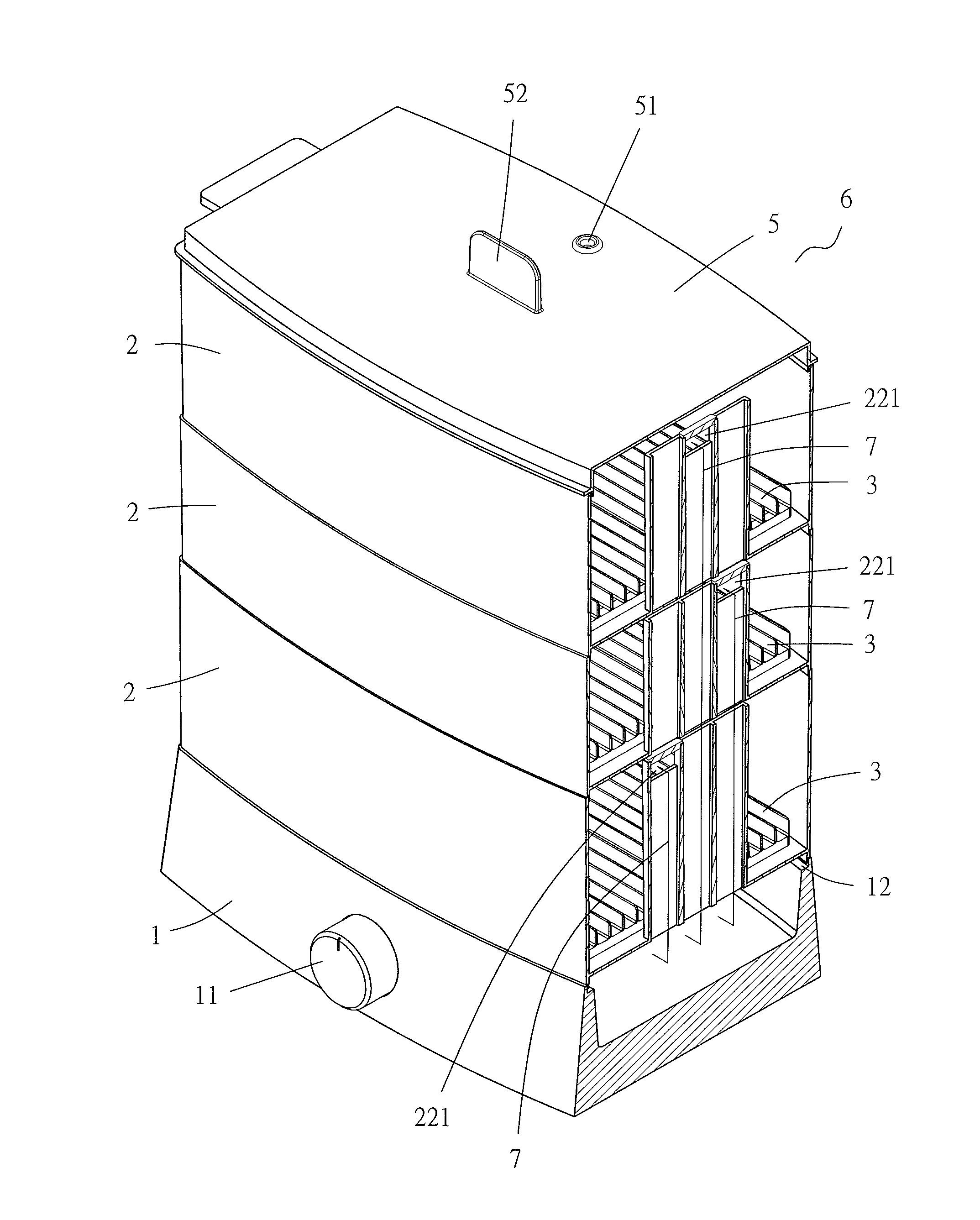

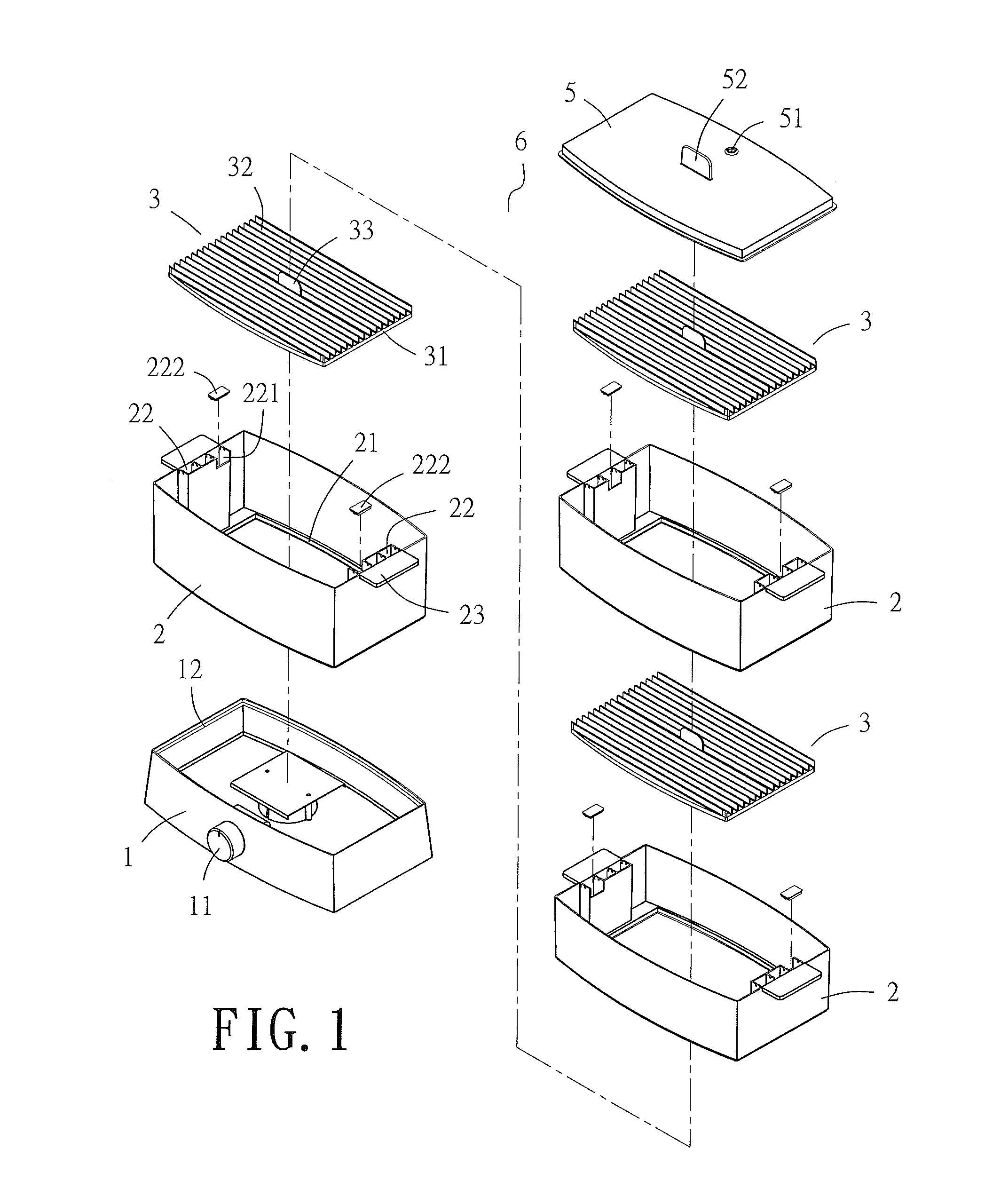

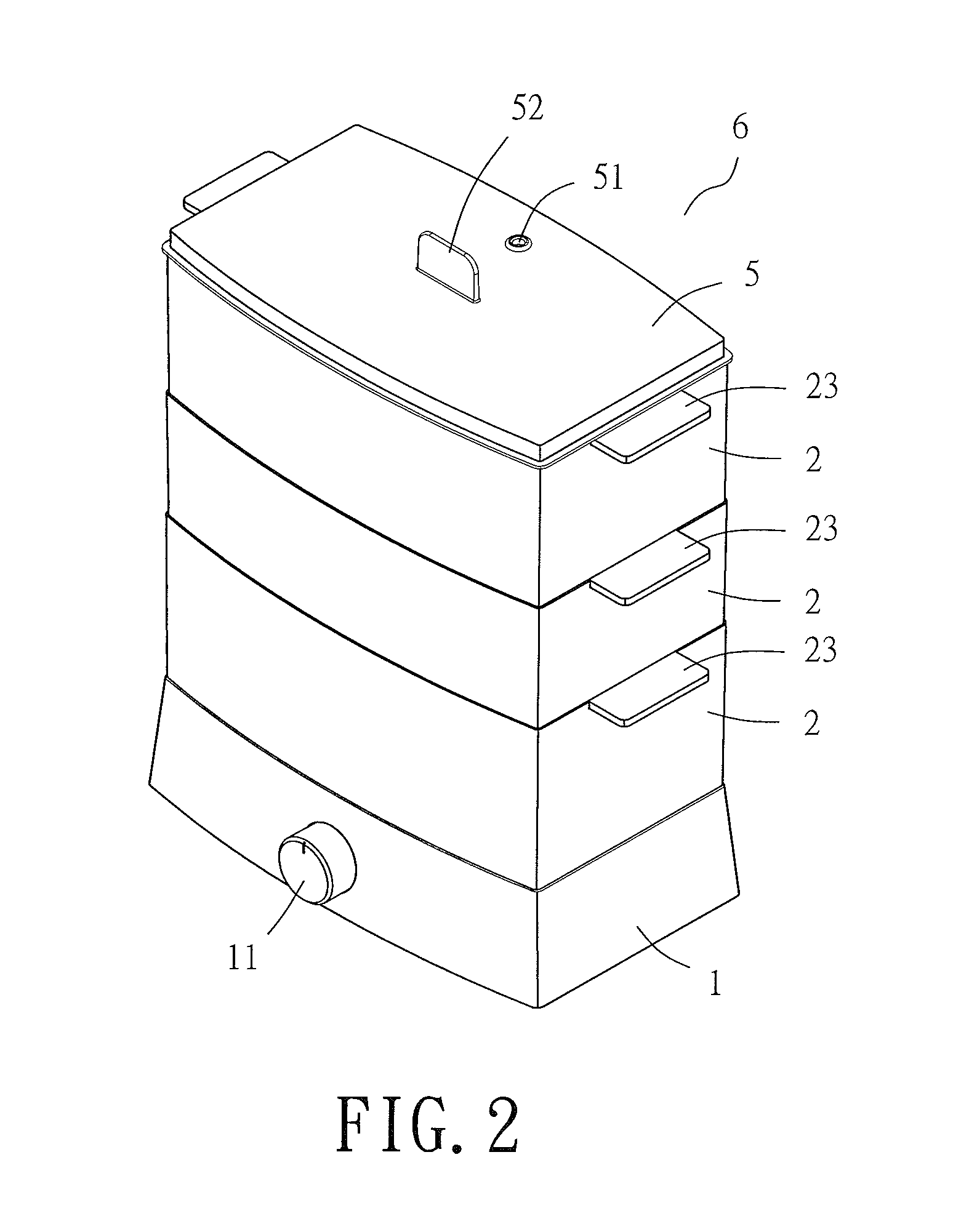

[0031]As shown in FIG. 1, an improved steamer 6 made in accordance with the present invention is shown, and includes a base 1 incorporated with a heating unit and a controlling switch, a plurality of pot units 2, a plurality of racks 3, and a lid 5.

[0032]The base 1, incorporated with a heating unit and a controlling switch, is provided with a timer 11 located at the front. The base 1 is provided with a recessed shoulder 12 on top thereof, such as shown in FIG. 3.

[0033]Each of the plurality of pot units 2 is configured in conformance to the shape of the base 1 and has a hollowed configuration. A bottom of each pot unit 2 is provided with a grooved shoulder 21, as shown in FIG. 3, and one or more than one steam ducts 22 are located on longitudinal sides of the pot unit 2. In the current embodiment, three steam ducts 22 are arranged. In those three steam ducts 22 of each pot unit 2, one of the steam ducts 22 is defined with an opening 221 on which a cover 222 is associated. According t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com