Mobile surface scrubber solution recovery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

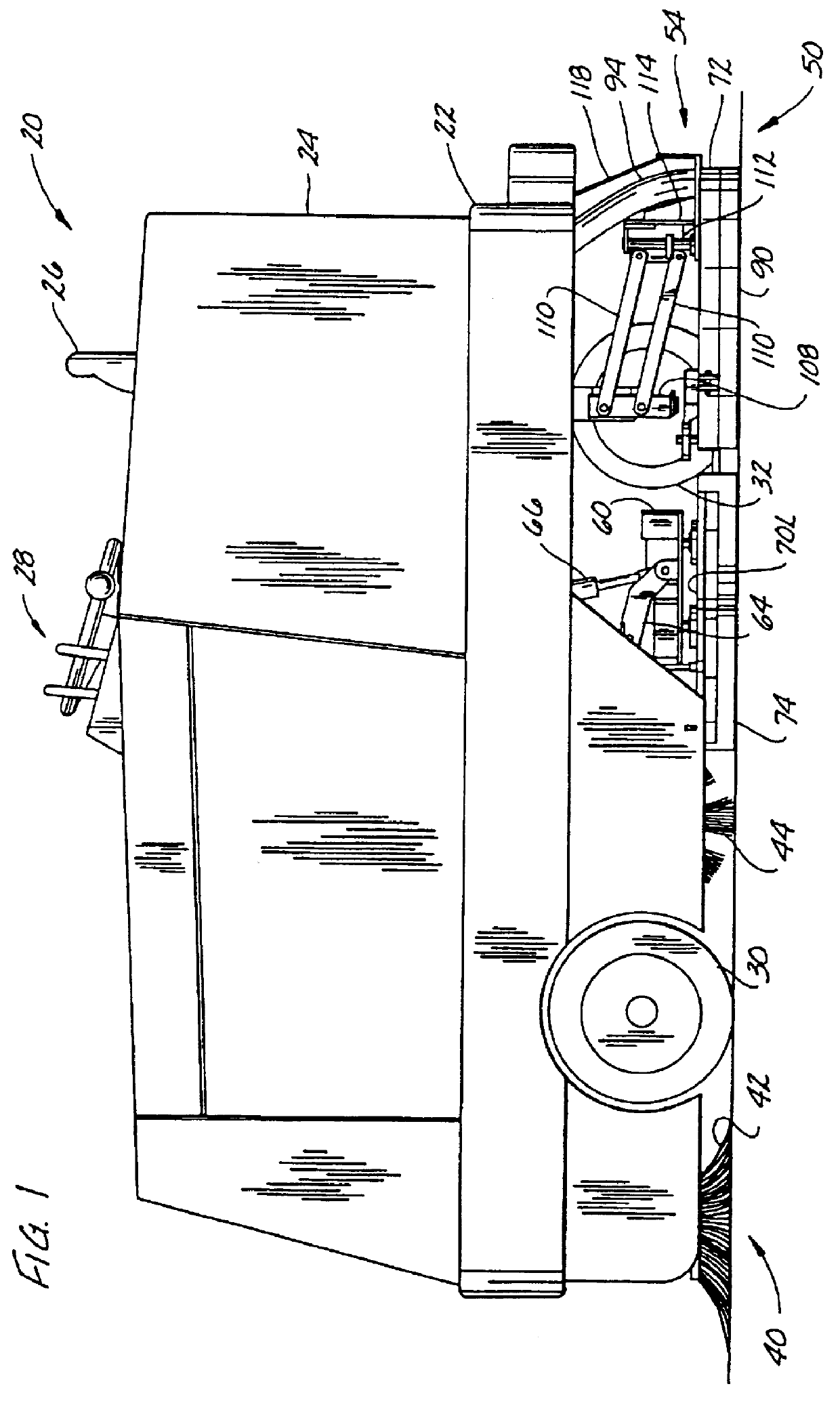

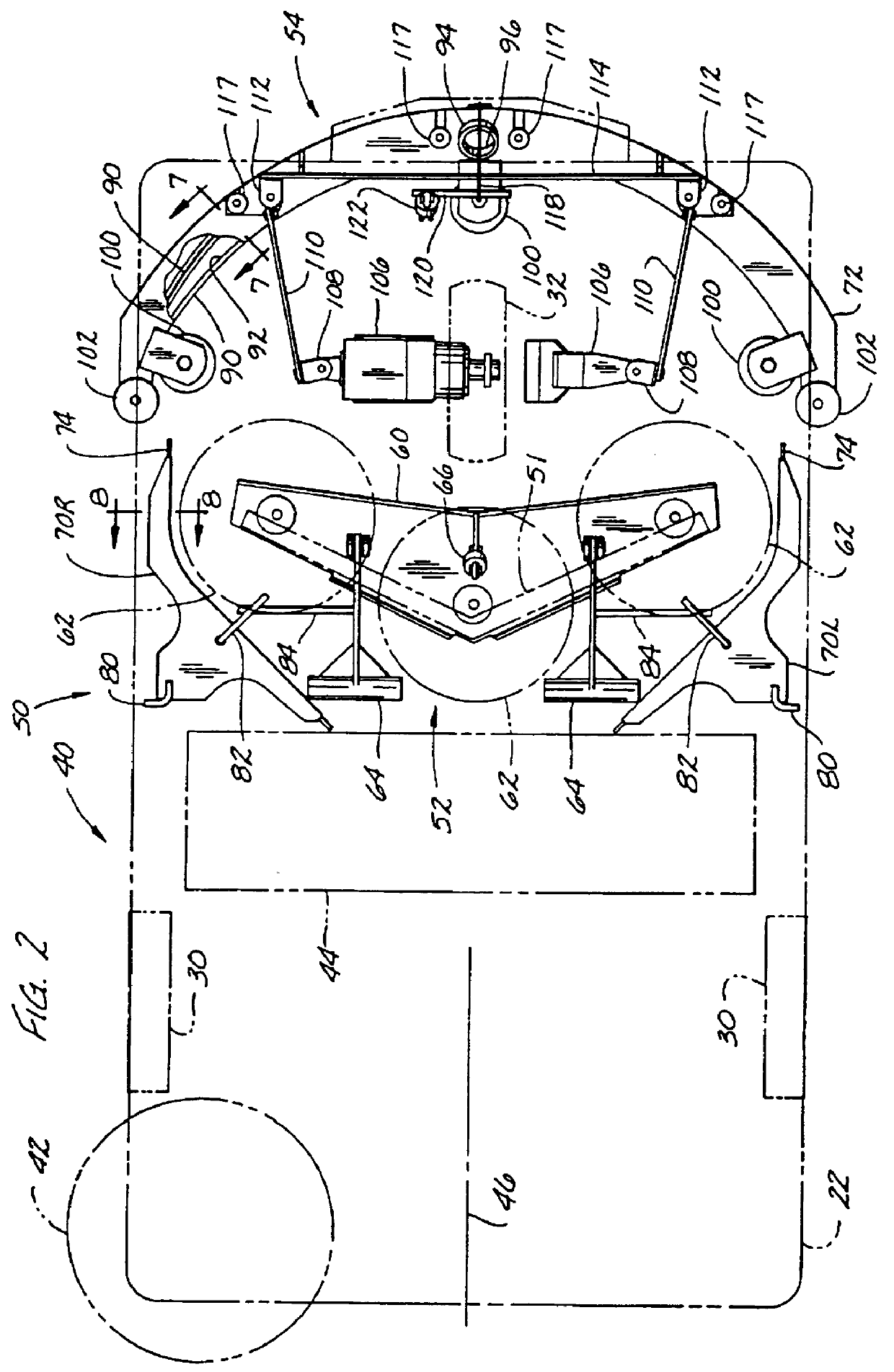

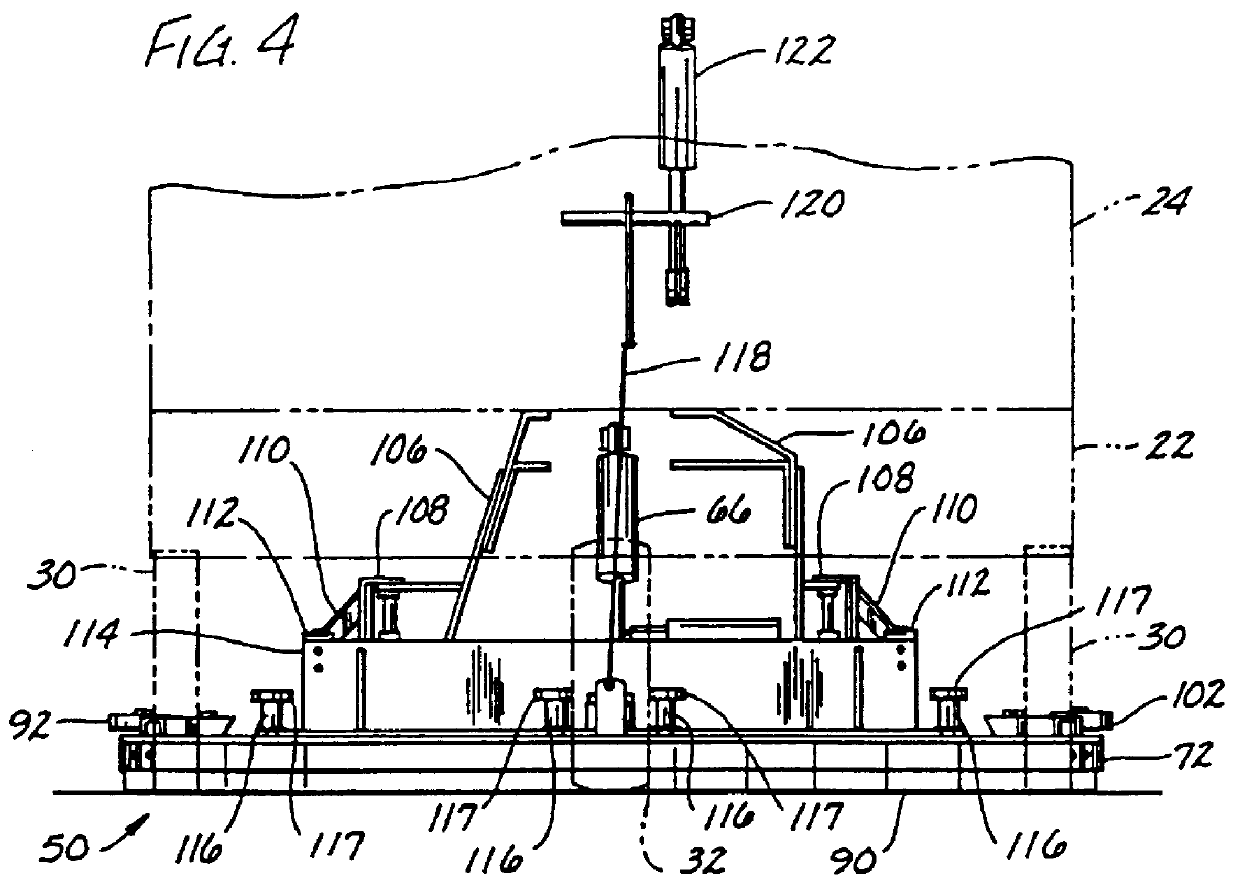

Referring now to the drawings and in particular to FIG. 1, a mobile surface scrubber indicated generally at 20 is of the type used to sweep and scrub a surface such as a warehouse or factory floor or a parking lot. The surface scrubber 20 has a frame 22 supporting a body 24 which houses the various sweeper and scrubber components. A seat 26 mounted on the body 24 permits an operator to ride on the scrubber 20. Hand operated controls, generally designated as 28, are positioned in front of the seat 24 so that the operator may access them when seated to control the scrubber 20 operation. Foot operated controls (not shown) are positioned on the floor in front of the seat 24. Two front wheels 30 and one rear wheel 32 are mounted on the frame 22. The rear wheel 32 is driven by an engine (not shown) such as a 2 liter, 45 hp. 4 cycle. Toyota gasoline powered engine, a 63 hp, gasoline or LP powered Ford engine, or a 46 hp, 4 cycle, Perkins diesel powered engine to propel the scrubber over th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com