Self-countersinking screw with cutting receiving pockets

a self-countersinking screw and receiving pocket technology, which is applied in the direction of screws, threaded fasteners, fastening means, etc., can solve the problems of insufficient space, relatively difficult cutting edges, and insufficient upward diminishing volume of cutter recesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

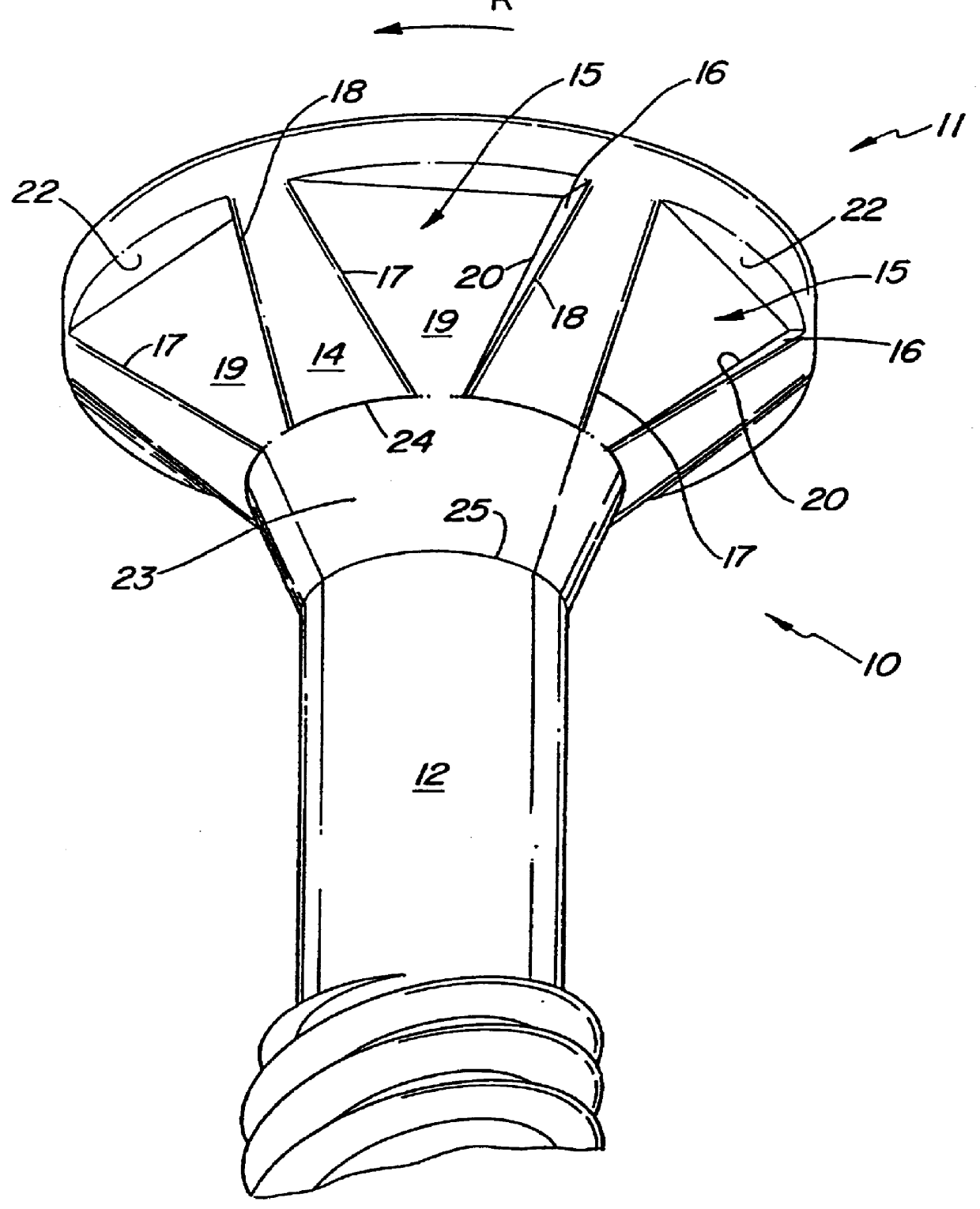

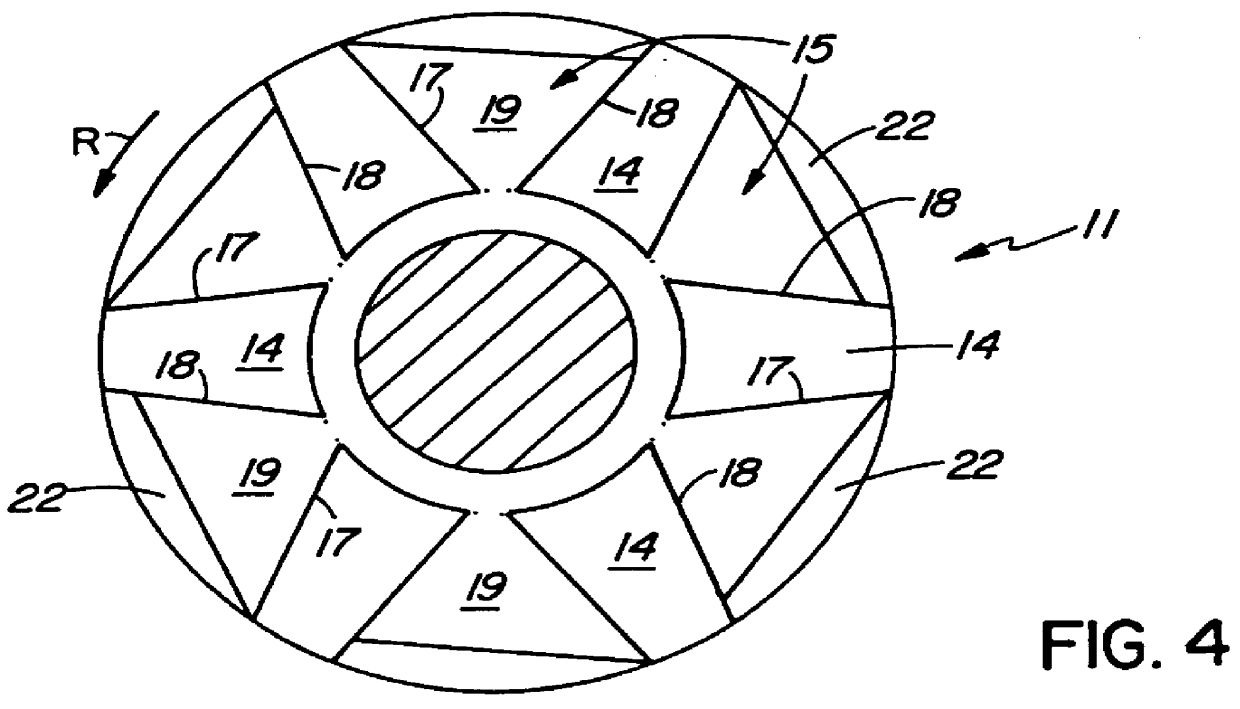

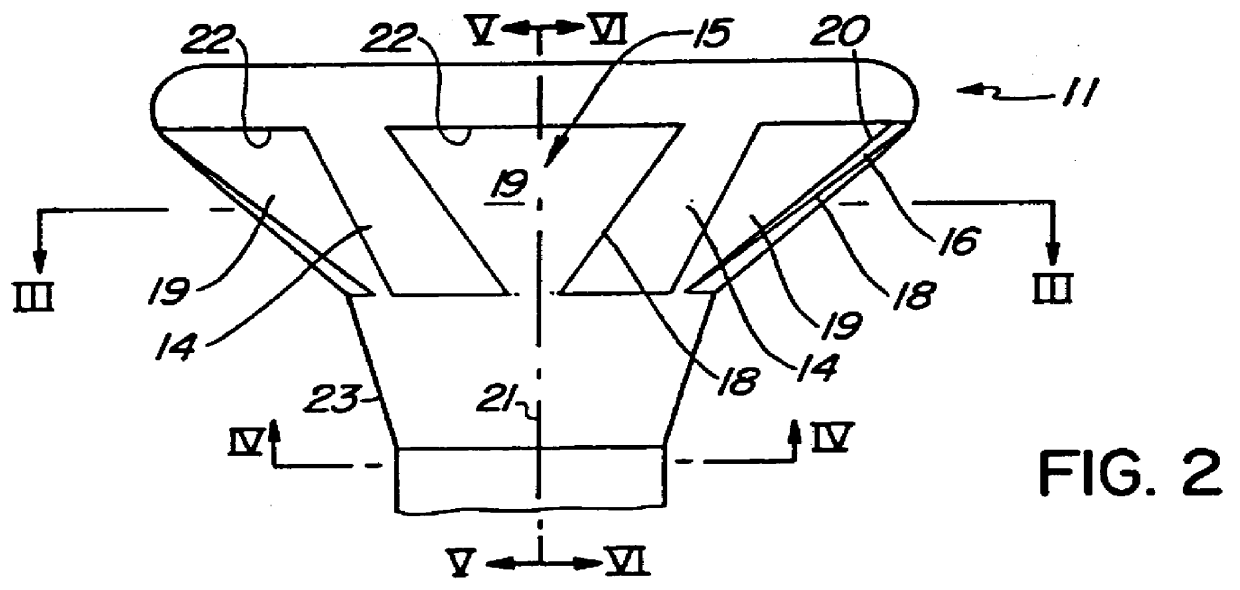

With reference to the drawings and in particular to FIGS. 1, 2 and 3 thereof, the self-countersinking screw 10 comprises a head 11 and a threaded stem portion 12. The head 11 has the general shape of an inverted-conical member and is formed; at the top, with screwdriver engaging means, in the embodiment shown, a hexagonal recess 13 adapted to receive the tip of a screwdriver (not shown). However, it should be noted that the screwdriver engaging means may be of any other suitable shape. The head exhibits an inversely frusto-conical underside 14 on which there are a plurality of generally triangular recesses 15.

The term "generally" triangular is used to indicate that the contour is not a true triangle as will be apparent from the description which follows. Each recess 15 comprises, from the standpoint of the direction of rotation R (FIGS. 1, 3, 4) driving the screw in a workpiece, a trailing wall 16 and a leading boundary 17. The trailing wall 16 forms a cutting edge 18 at the merger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com