Technique for manufacturing wearable pipe made from composite bimetal

A manufacturing process and wear-resistant pipe technology, which is applied in the field of bimetal composite wear-resistant pipe manufacturing technology, can solve the problems of high bonding strength of the composite interface and the inability to achieve large-area metallurgical bonding of the two layers of metal in the composite pipe, so as to avoid primary defects , to ensure the effect of long-distance mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

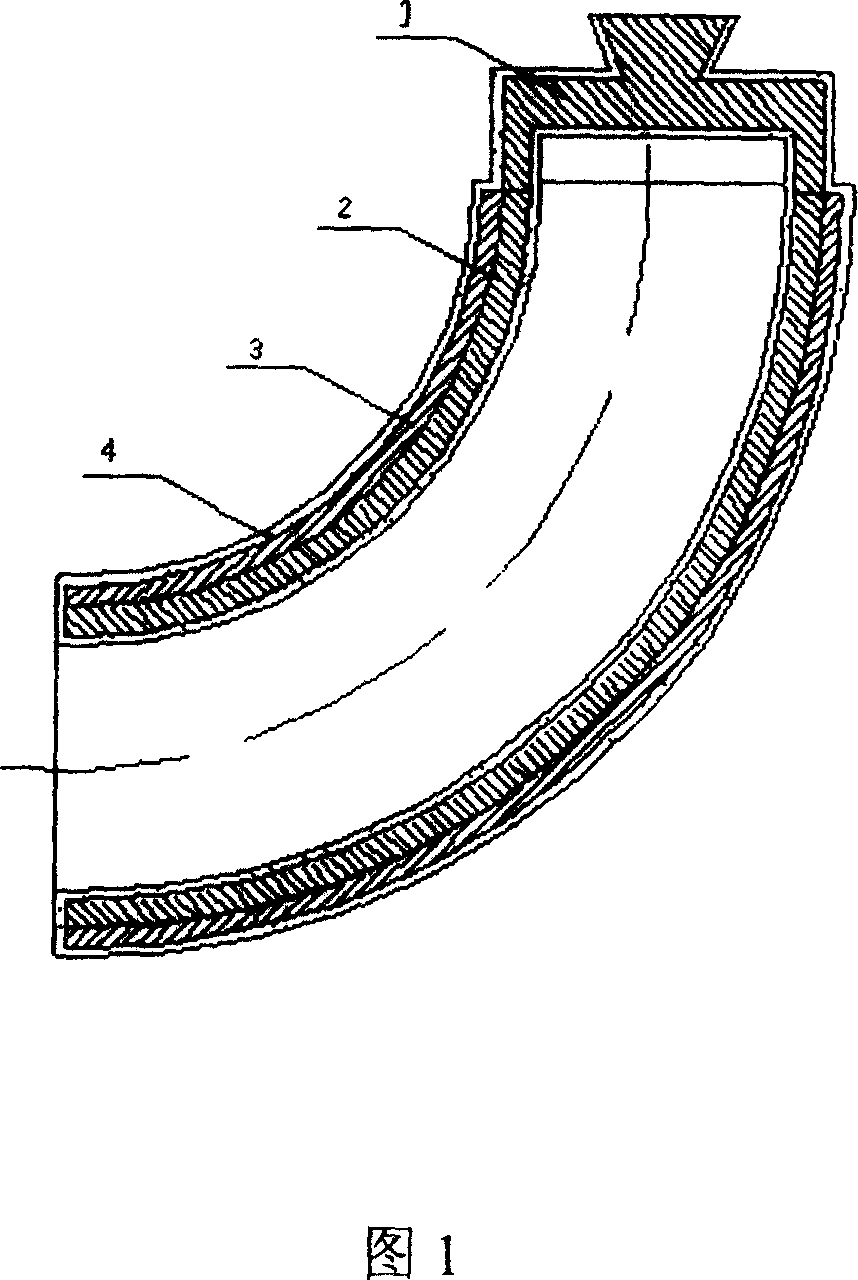

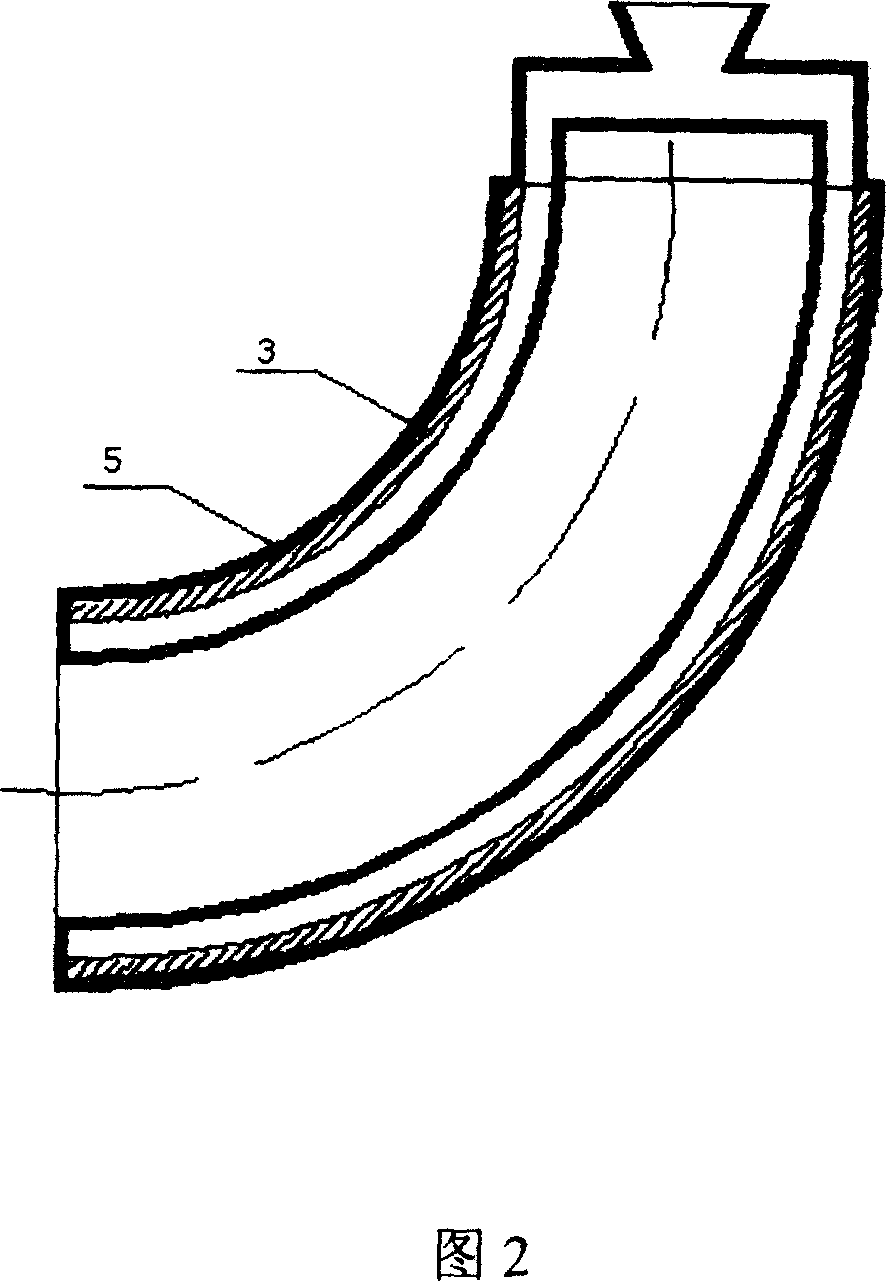

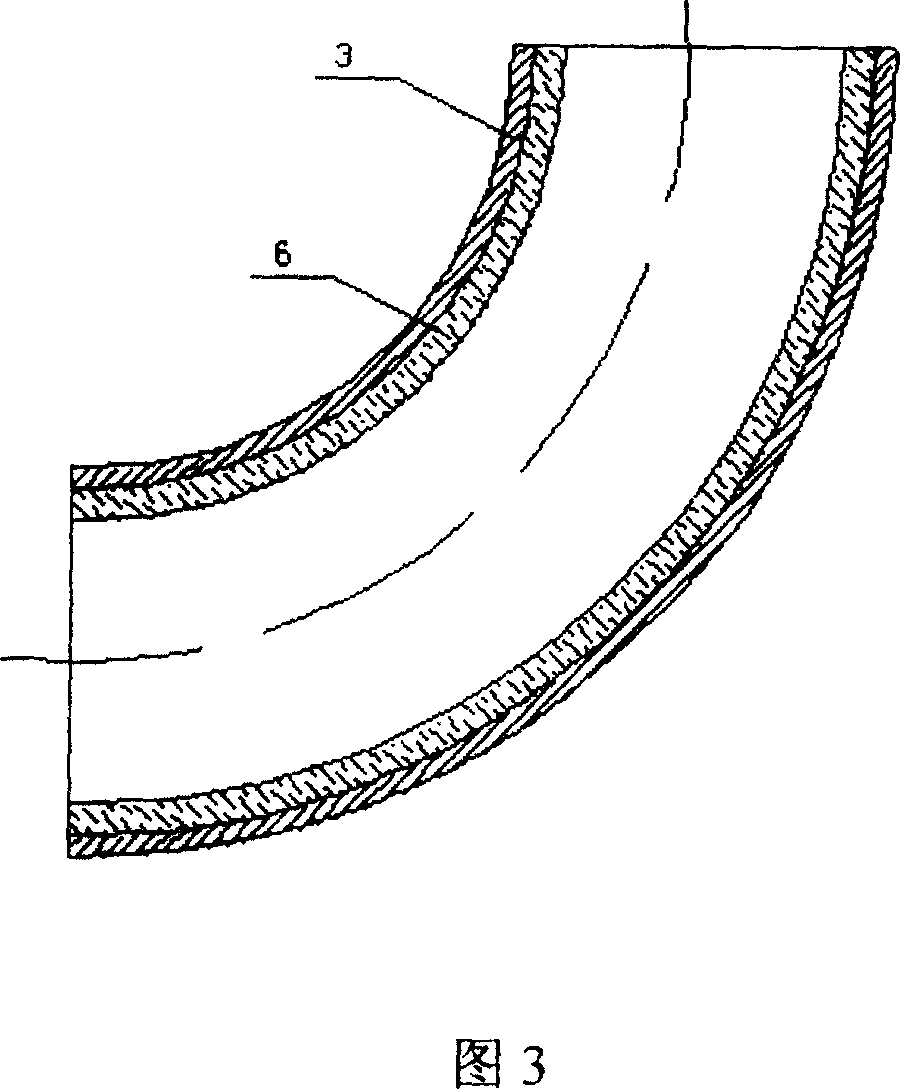

[0048] Embodiment 1: Manufacture bimetallic composite elbow, refer to process flow chart 5 and shown in Fig. 1, 2, 3.

[0049] Refer to process flow diagram 5. Manufacturing process of the present invention is carried out according to the following steps:

[0050] a. Use an A3 steel seamless straight pipe with an inner diameter of Φ133mm to make the outer casing 3 by heat-bending, with a radius of curvature of 600mm and a central angle of 90 degrees.

[0051] b. Cut the polystyrene foam block into the lost foam 2 in the shape of the inner liner with a heating wire. The outer diameter of the lost foam 2 is equal to the inner diameter of the outer sleeve 3, the thickness is 8mm, and the radius of curvature and the central angle are the same as the outer sleeve 3 are equal. Refer to Figure 1.

[0052] c. Cut the polystyrene foam block into the shape of the gating system with a heating wire, and fix it to the inner liner lost foam 2 by bonding it with white latex. Refer to Fig...

Embodiment 2

[0061] Embodiment 2: Manufacture bimetallic composite wear-resistant tee pipe, refer to process flow chart 5 and shown in Figures 1, 2 and 4.

[0062] Refer to process flow diagram 5. Manufacturing process of the present invention is carried out according to the following steps:

[0063] a. Weld the 16Mn steel seamless straight pipe with an inner diameter of Φ219mm to make the three-way outer casing 3 .

[0064] B. Cut the polystyrene foam block into the lost foam 2 of the liner pipe shape with the electric heating wire. The outer diameter of the lost foam 2 is equal to the inner diameter of the outer sleeve, and the thickness is 12mm. The length of each part is equal to the three-way outer sleeve. The method of filling is used to make the lost foam of the lining seamless at the tee joint.

[0065] c. Cut the polystyrene foam block into the shape of the gating system with a heating wire, and fix it to the inner liner lost foam 2 with white latex glue 1 .

[0066] d. Prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com