Cement clinker sintering technology and its equipment

A cement clinker and process technology, which is applied in the field of cement clinker firing process, can solve the problems of inability to realize fast burning and quenching of clinker, automatic control and large-scale operation of stable and continuous operation, low heat transfer efficiency of the system, and large impact. Achieve the effects of stable continuous operation, automatic control and large-scale, and improve heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

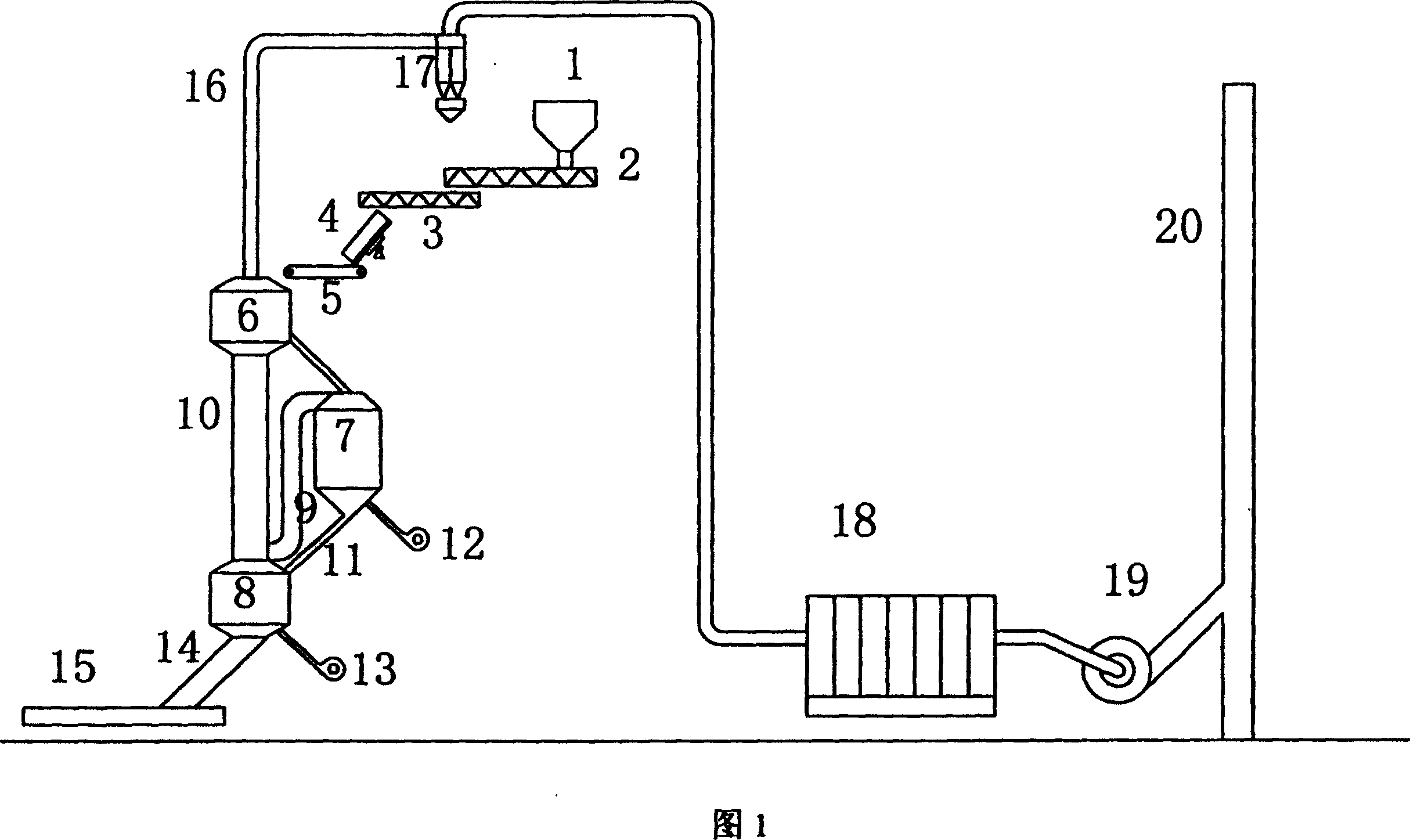

[0015] Referring to accompanying drawing 1, its structure is that the outlet of feeding device is connected with preheating drying chamber 6, and preheating drying chamber 6 is connected with induced draft fan 19 through induced air pipe 16; 10 is connected to the cooling chamber 8; the cooling chamber 8 is connected to the combustion chamber 7 through the sealing pipe 11; the combustion chamber 7 is connected to the hot gas mixing burner 10 through the hot air pipe 9.

[0016] The preheating drying chamber 6 is connected with the cyclone dust collector 17 through the induced air pipe 16;

[0017] The cooling chamber 8 is connected with the clinker conveyor 15 through the feeding pipe 14 .

[0018] The preheating and drying chamber 6, the combustion chamber 7, and the cooling chamber 8 are independent devices respectively.

[0019] The feeding device is composed of a raw material bin 1, a steady flow metering device 2, a material water stirring device 3, a ball forming plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com