Compositely packaged foil type manganin superhigh pressure sensor

A technology of ultra-high pressure and sensors, which is applied to the measurement of the properties and forces of piezoelectric resistance materials, etc., can solve the problems that embedded measurement cannot be used, the thickness of the sensor is thick, and the application range is limited, and it can achieve easy calibration and thickness Thinning, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

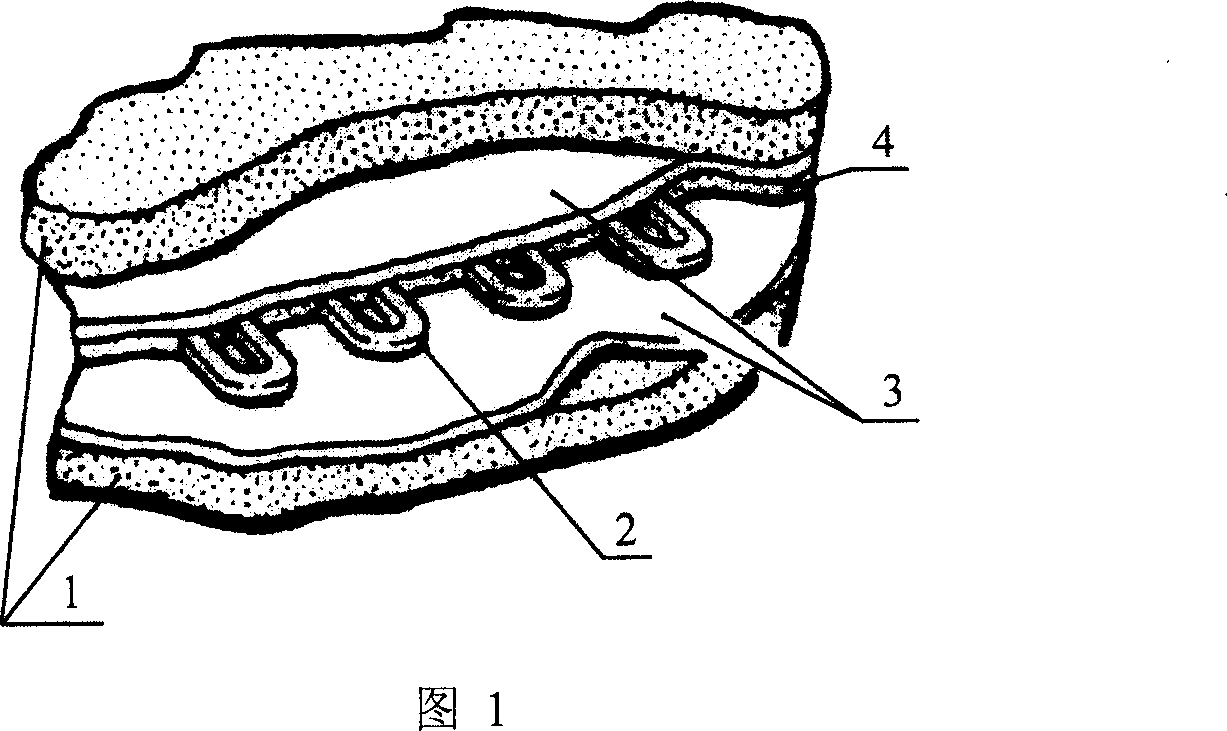

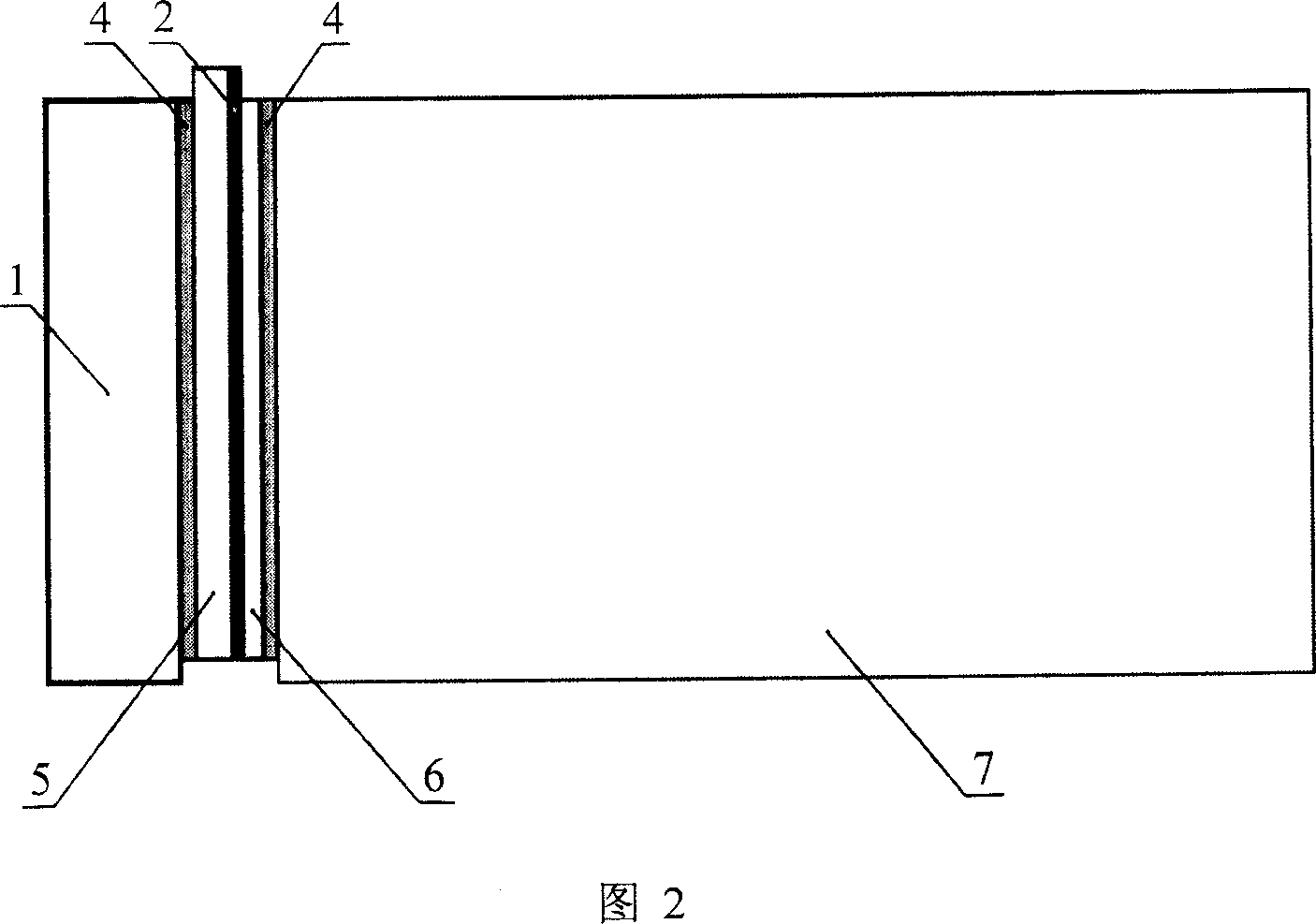

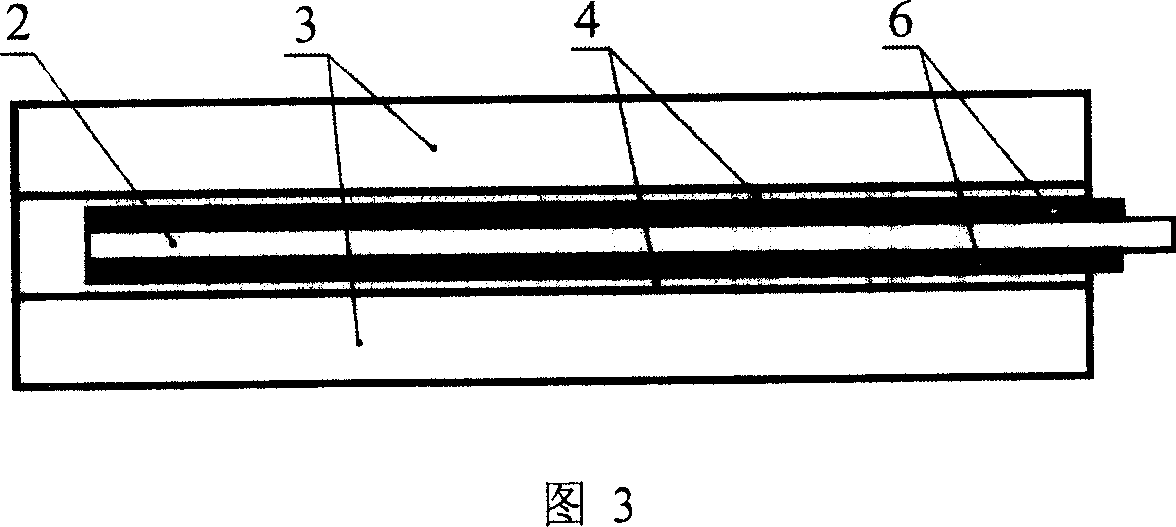

[0031] Manganese copper foil 8 with a thickness of 28 μm is selected, and it is firstly etched into an H-shaped pattern by photolithography. Then magnetron sputtering is used to deposit copper thin film 9 on the front and back sides of the lead position (shaded part in FIG. 4 ) of the manganin foil, with a film thickness of 2-5 μm. The manganese-copper foil and the lead constitute the pressure sensitive element 2 . Next, an aluminum oxide thin film 6 is deposited on the front and back sides of the pressure sensitive element 2 by electron beam evaporation, with a film thickness of 2-8 μm. Finally, sandwich the pressure-sensitive element coated with aluminum oxide film between two polytetrafluoroethylene films 3 and bond them together with a thin adhesive 4. The thickness of the polytetrafluoroethylene film is 250 μm.

[0032] The transient waveform diagram of the complete shock wave pressure recorded by the sensor in this specific embodiment is shown in FIG. 5 , the material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com