Loaded board test method

A technology for testing equipment and mounting boards, which is applied in the field of testing equipment for mounting boards, and can solve problems such as high manufacturing costs, instability, and insufficient structure for actual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

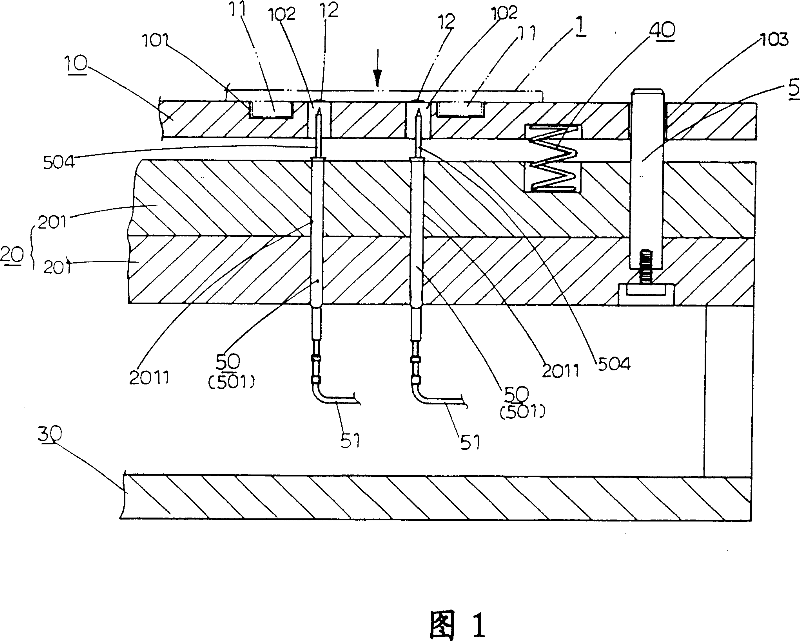

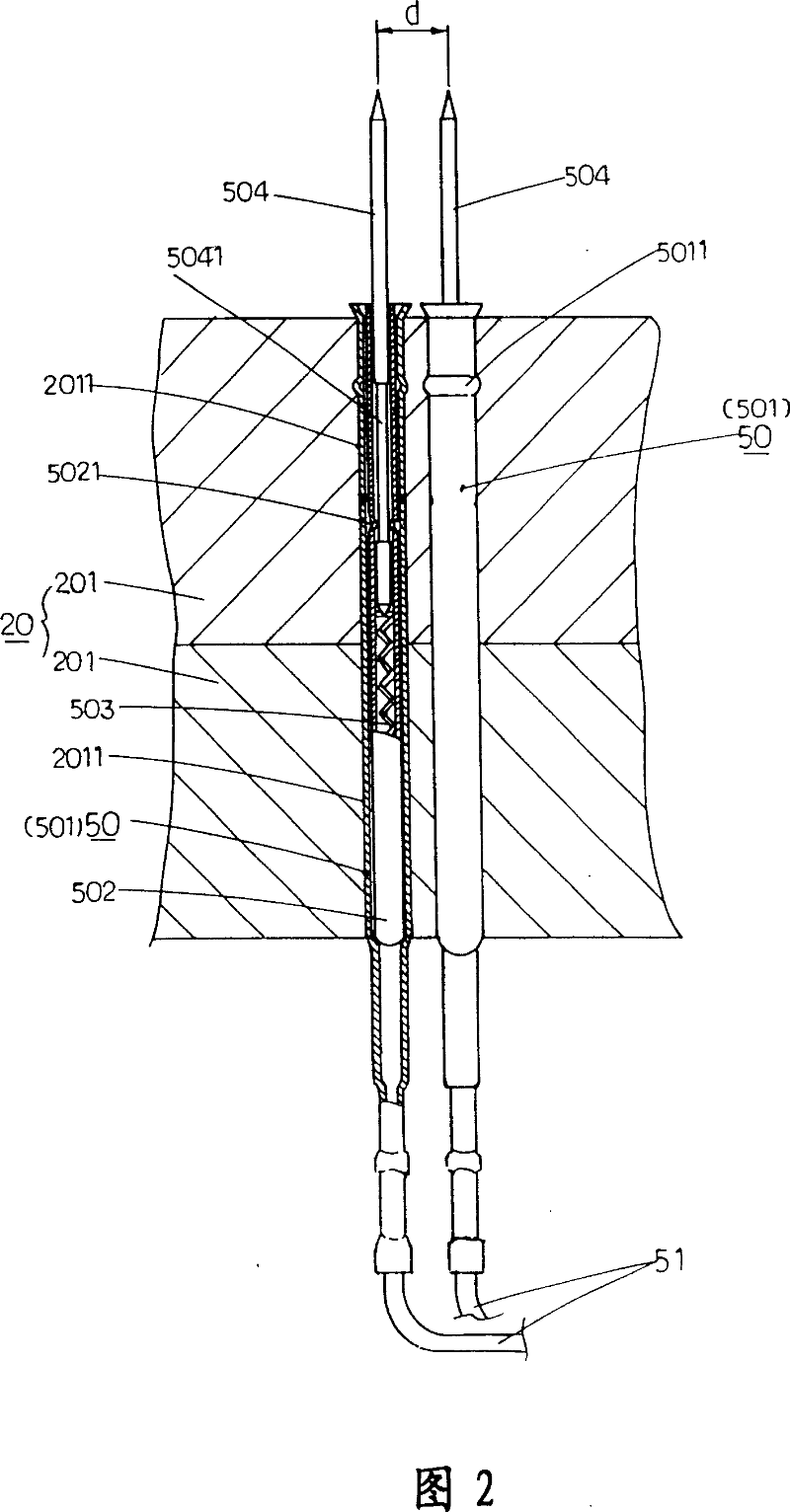

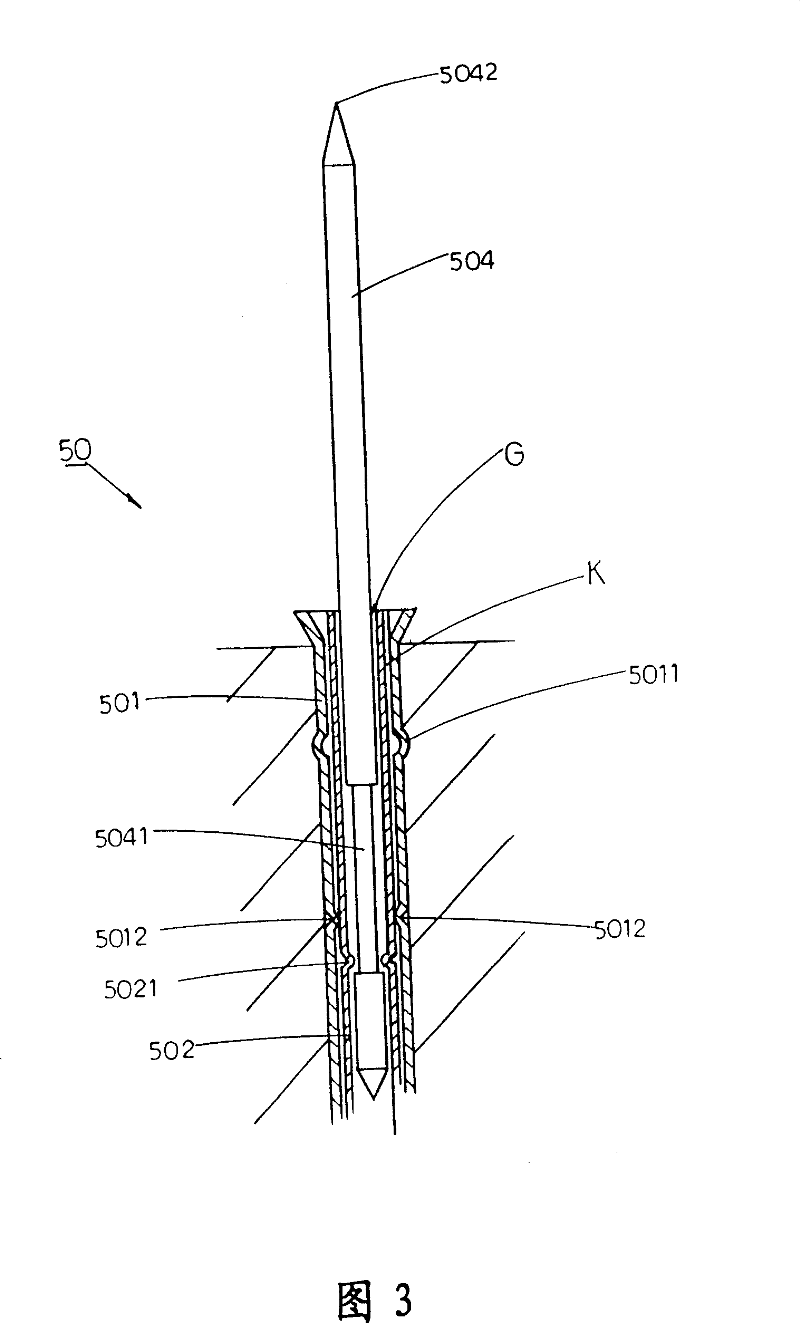

[0063] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, methods, steps, Features and their functions are described in detail below.

[0064] First of all, please refer to Fig. 4, which clearly shows that a test device for a mounting board of the present invention provides precise testing for a mounting board with tiny spacers after the electrical components have been installed. Disc 20, machine plate 30, dial 60, dial buffer element 61, linear probe 70, probe buffer element 80, protective plate 90 and linear bearing group 2 and other main components constitute. in;

[0065] The dial 60 includes a carrier board 601 for positioning the mounting board 1 to be tested, and a carrier board jack is respectively provided at the positions corresponding to the points 12 to be measured on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com