Movable-tooth stepless speed transmission

A continuously variable transmission, movable tooth technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of restricting development and popularization, sudden change in speed, rigid impact, etc., and achieve flexible and convenient control and market prospects. Wide, weight-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

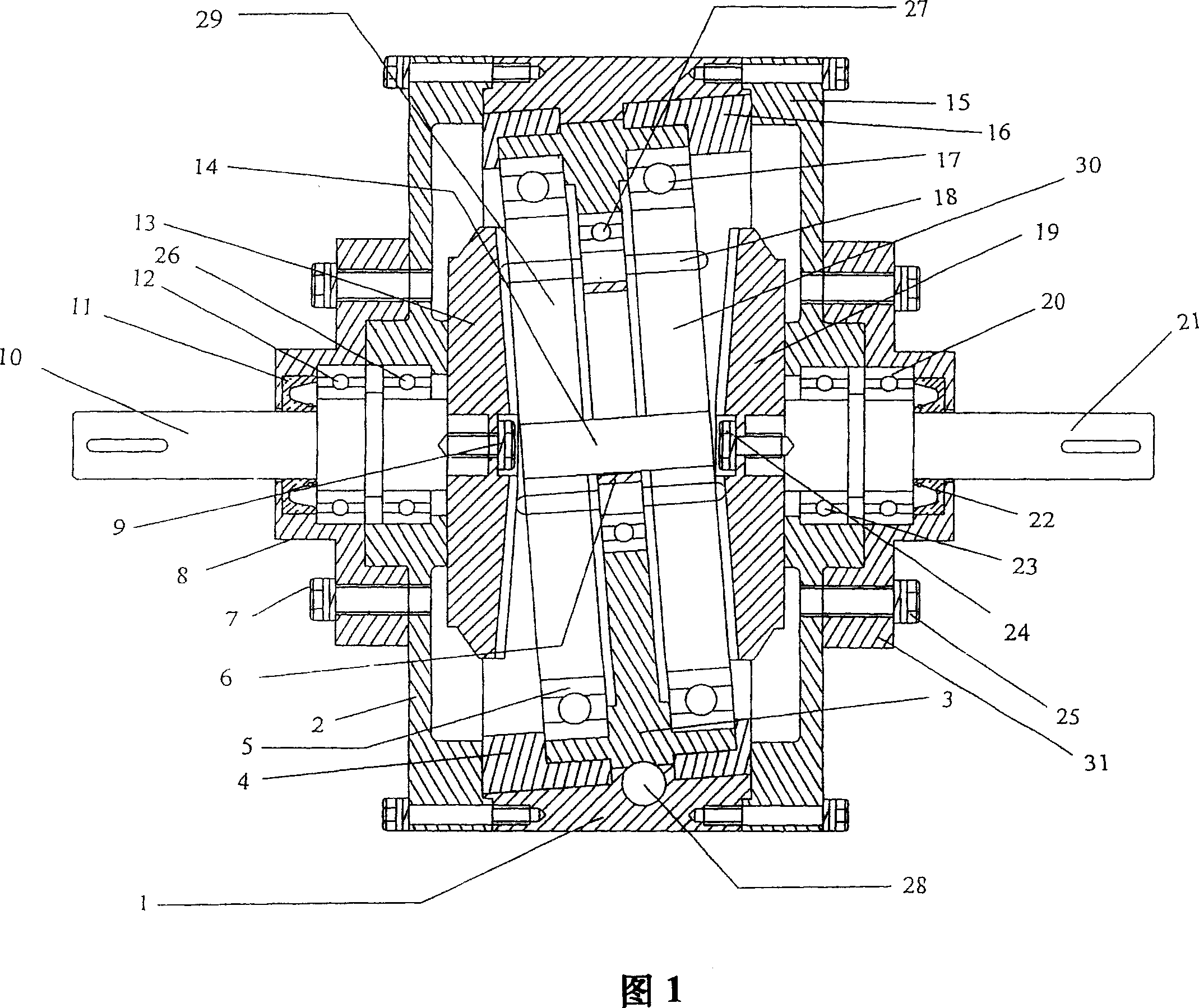

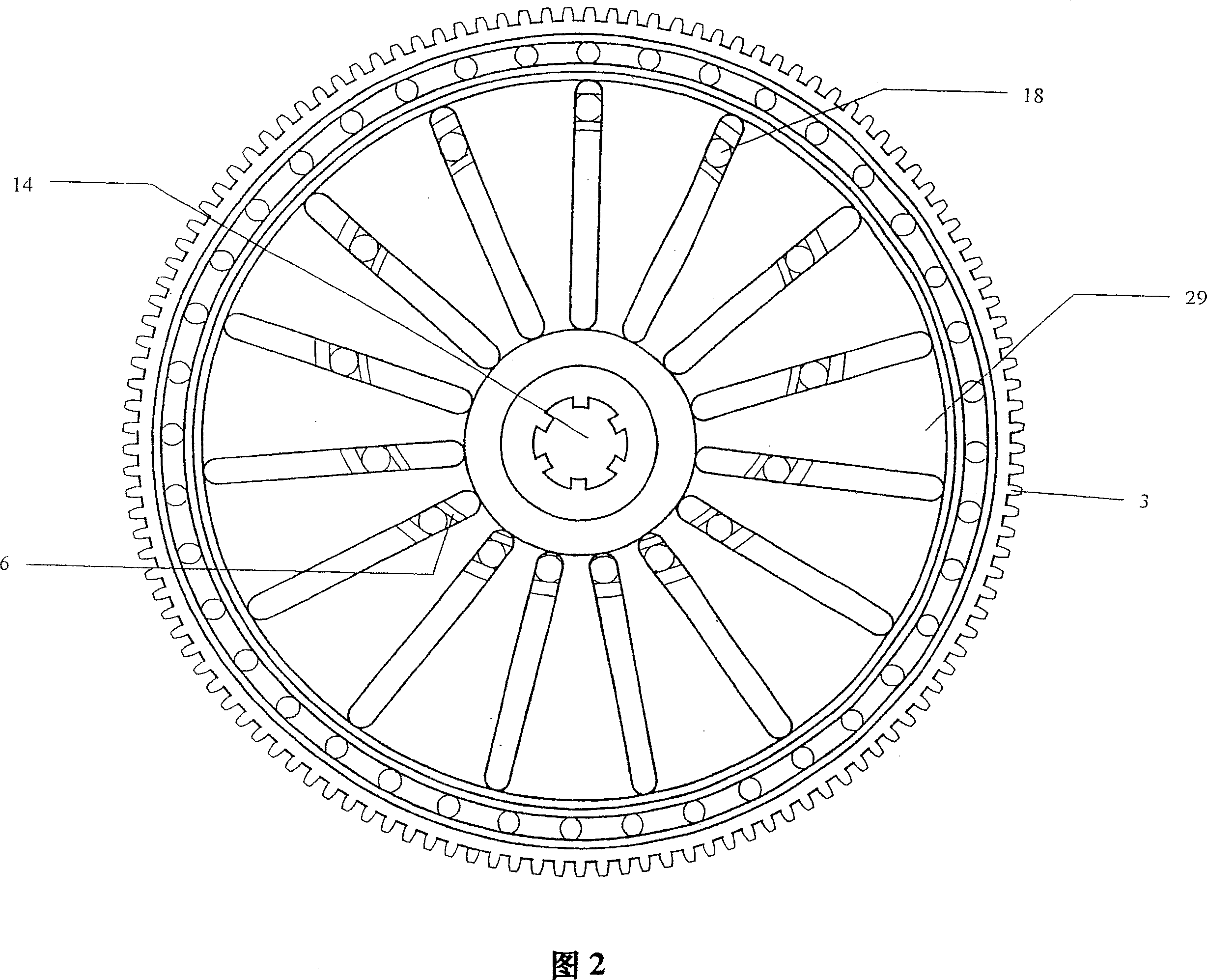

[0016] Fig. 1 is a principle diagram of a movable tooth continuously variable transmission of a preferred embodiment of the present invention. Please refer to Figure 1, where 1 is the shell; 2, 15 is the end cover; 3 is the eccentric worm gear; 4, 16 is the sliding bearing bracket; 5, 17 is the rolling bearing; 6 is the restraining ring; 7, 25 is the bolt; 8, 31 is a small end cover; 9,24 are high-strength bolts; 10,21 are input and output shafts; 11,22 are sealing rings; 12,20,23,26 are bearings; 13,19 are straight bevel gears; 14 18 is a movable tooth; 27 is a speed regulating bearing; 28 is a speed regulating worm; 29,30 are sheaves.

[0017] Wherein, in a preferred embodiment, the above-mentioned two sheaves 29 and 30 are, for example, identical in structure, the grooves are, for example, uniformly opened in the radial direction, and the connectors are, for example, spline shafts 14; the input and output cones are, for example, are straight bevel gears 13 and 19; movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com