Deflecting device for a safety belt

A guide device and safety belt technology, which is applied to the belt fixing device and other directions, can solve the problems of material cost and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

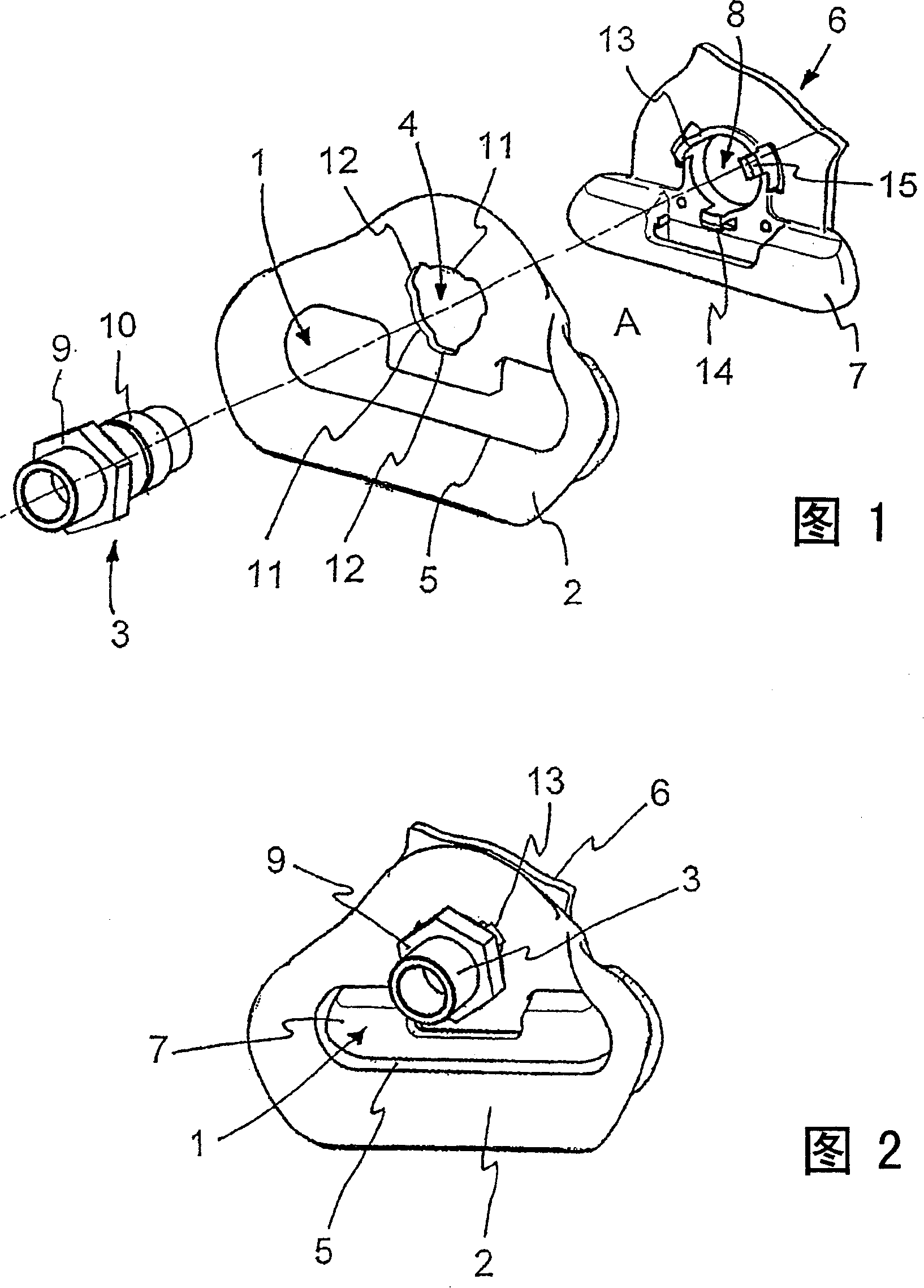

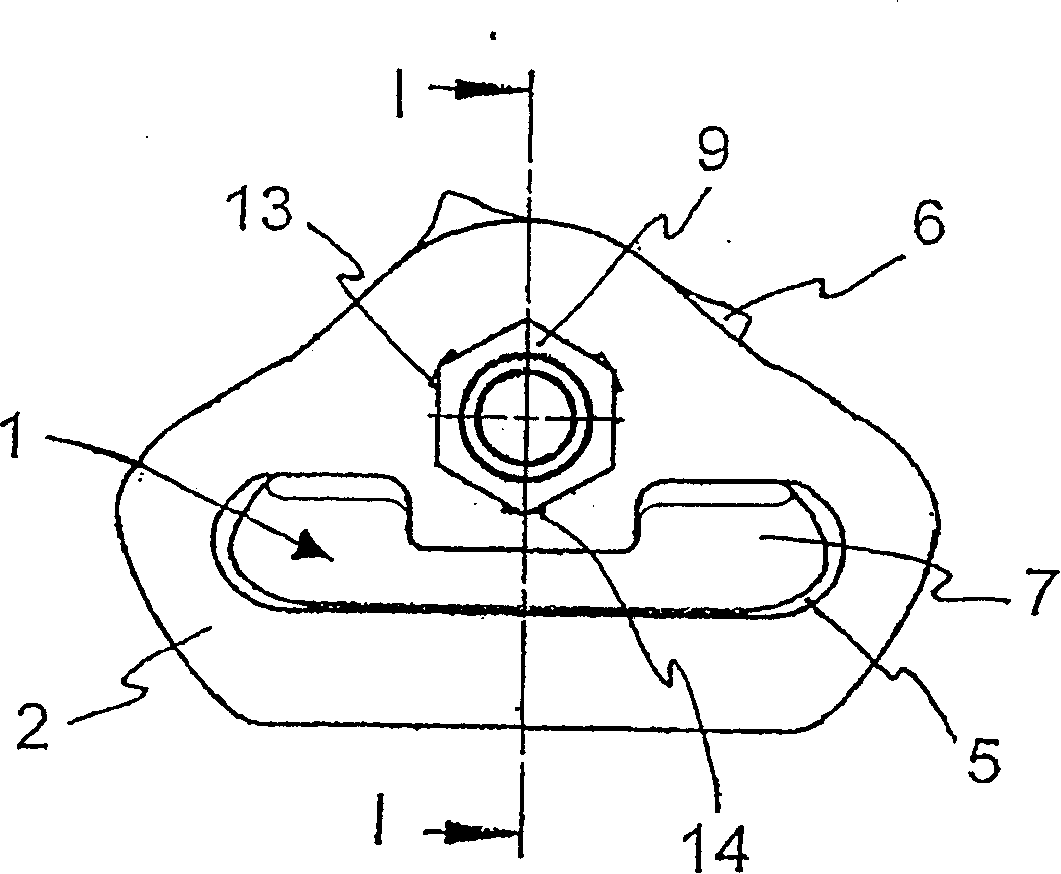

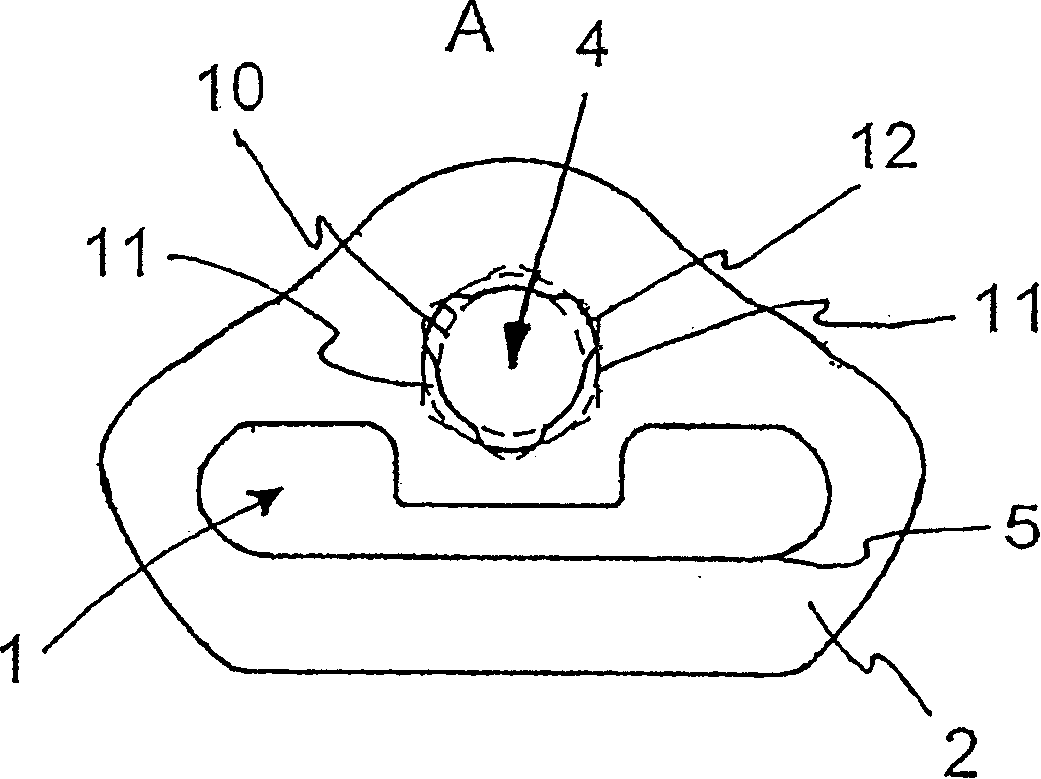

[0019] According to FIGS. 1 to 5 , the guide device for a seat belt not shown in detail first comprises a guide 2 provided with a guide gap 1 for the seat belt, which guide 2 passes through the guide 2 A fastening screw 3 with a fastening hole in the shape of a bore 4 is fastened to a receiving component not shown in detail of the vehicle body, for example to a vehicle pillar. The guide gap 1 itself has a rounded sliding surface 5 for the seat belt in order to ensure that the guide gap is not obstructed.

[0020] As in the prior art, the guide part 2 is preferably produced in one piece as an all-metal component by cold forming from sheet steel or by plastic injection-molded steel sheets.

[0021] In addition, a known adapter 6, which is preferably made of plastic by injection molding, is arranged between the guide part 2 and the receiving component, which adapter 6 has a displacement body 7 which likewise has a Hole 8 through which fixing screw 3 passes. The guide part 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com