Method for fabricating silicon nitride ROM

A read-only memory, silicon nitride technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as the development of miniaturization of components, and achieve the effect of reducing losses and avoiding electrical problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

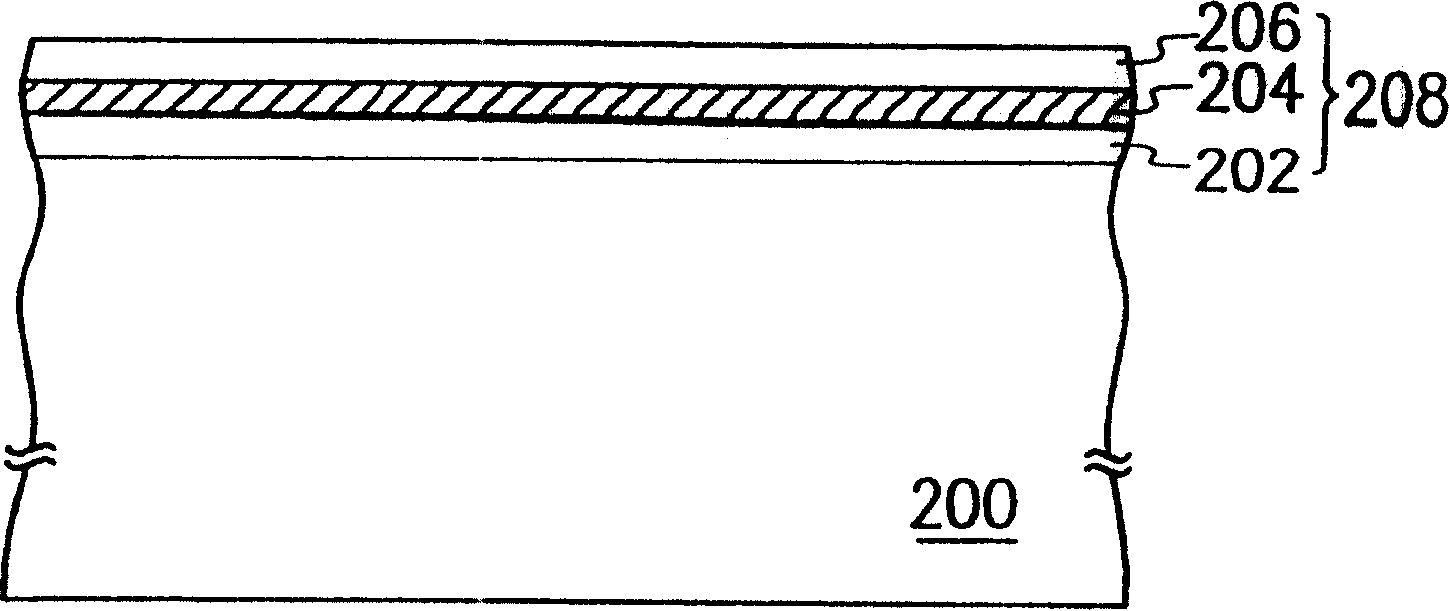

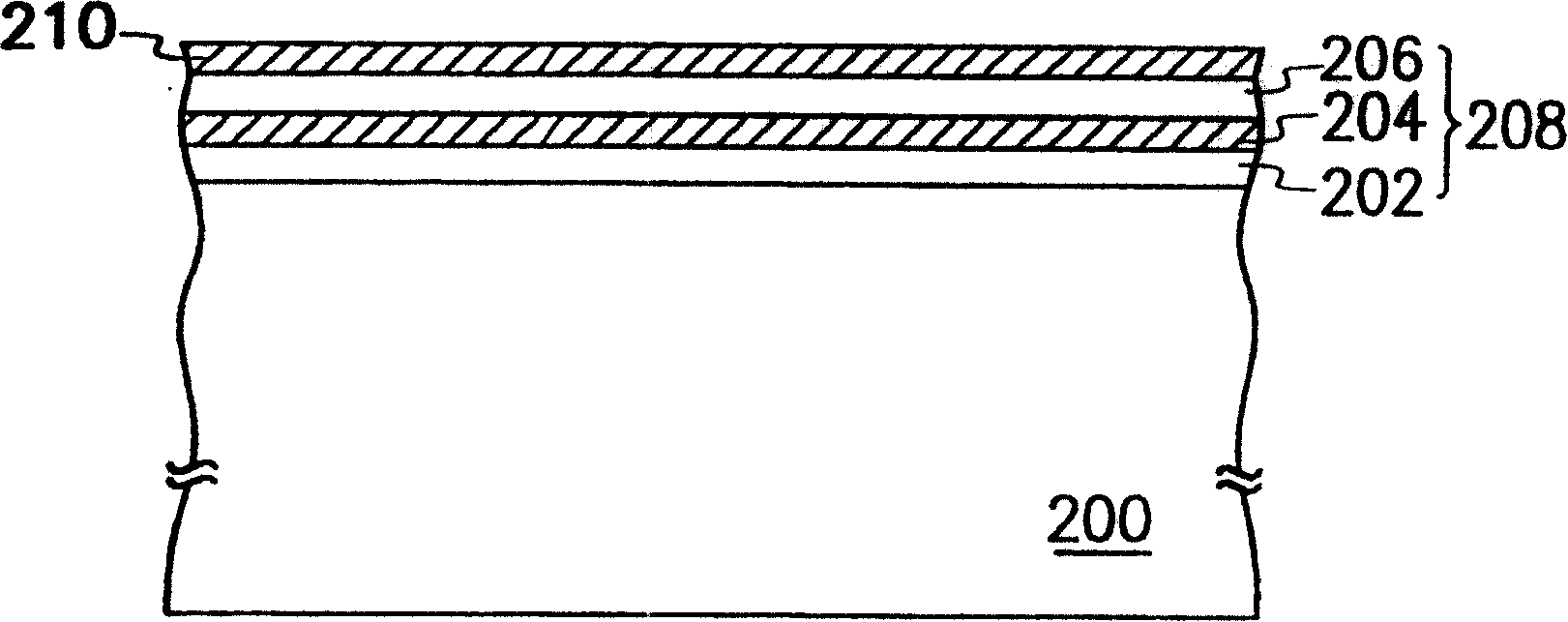

[0024] Figure 2A to Figure 2E It is a sectional view of the manufacturing process of a silicon nitride read only memory (nitride read only memory) according to a preferred embodiment of the present invention.

[0025] Please refer to Figure 2A , forming a silicon oxide / silicon nitride / silicon oxide (oxide-nitride-oxide, ONO for short) stacked layer 208 (stacked layer) on the substrate 200, and its stacked structure is formed by a layer of bottom oxide layer (bottom oxide layer) 202, a layer of silicon nitride layer 204 and a layer of top oxide layer (top oxide layer) 206, and the thickness of each layer is about 50-100 angstroms for the bottom oxide layer 202, silicon nitride layer Layer 204 is between 55-80 Angstroms and top oxide layer 206 is between 70-120 Angstroms.

[0026] Then, please refer to Figure 2B , forming a layer of protective layer (protective layer) 210 on the silicon oxide / silicon nitride / silicon oxide stack layer 208, wherein the selection ratio of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com