Automatic machine for cutting and jointing cord fabric of radial plytyre

A technology of radial tires and splicing machines, applied in the cutting of tires and textile materials, textiles and papermaking, etc., can solve the problems of not being able to adapt to the production of radial tires, poor product quality precision, and poor automation, so as to save foreign exchange funds and production The effect of high efficiency and reduced error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

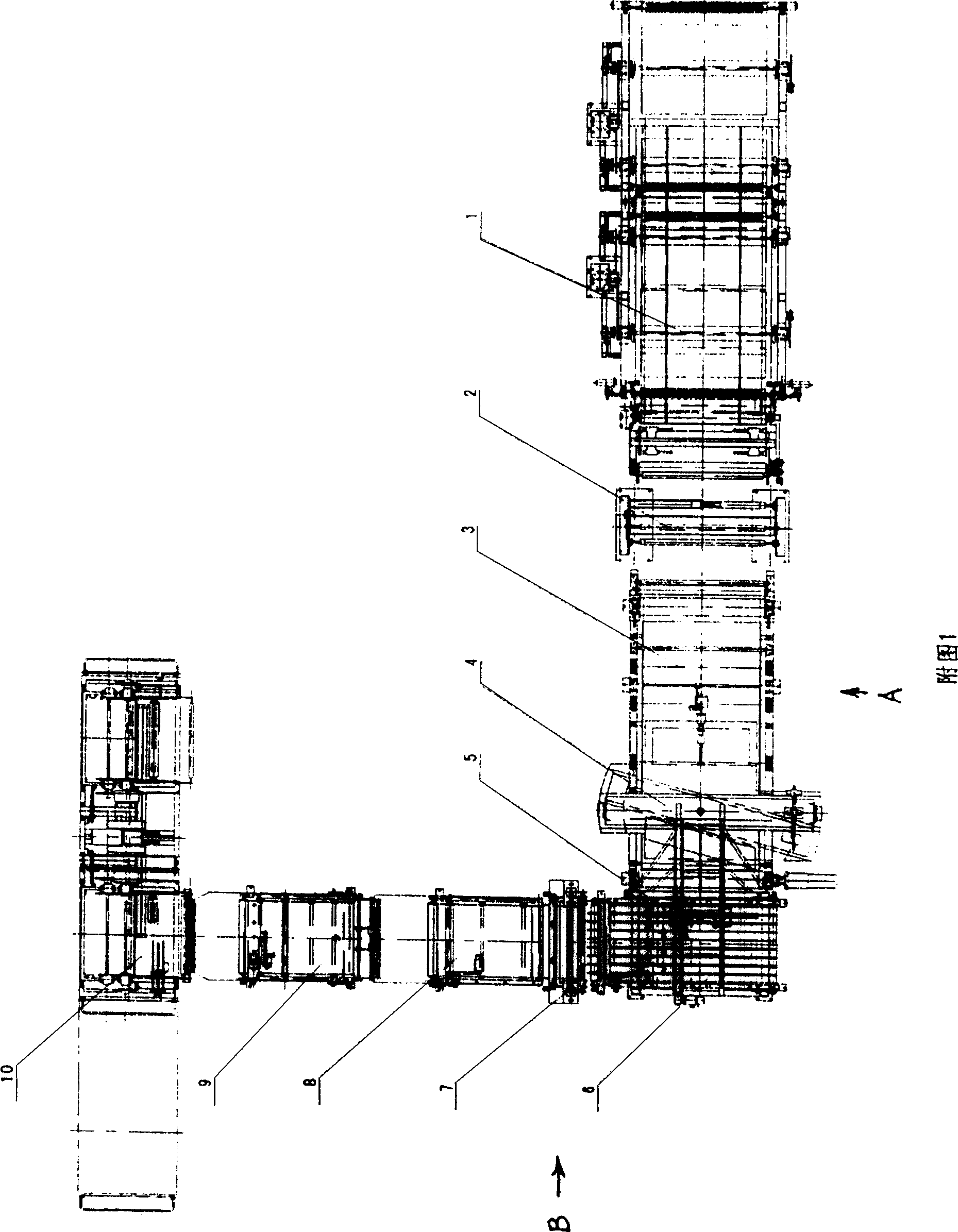

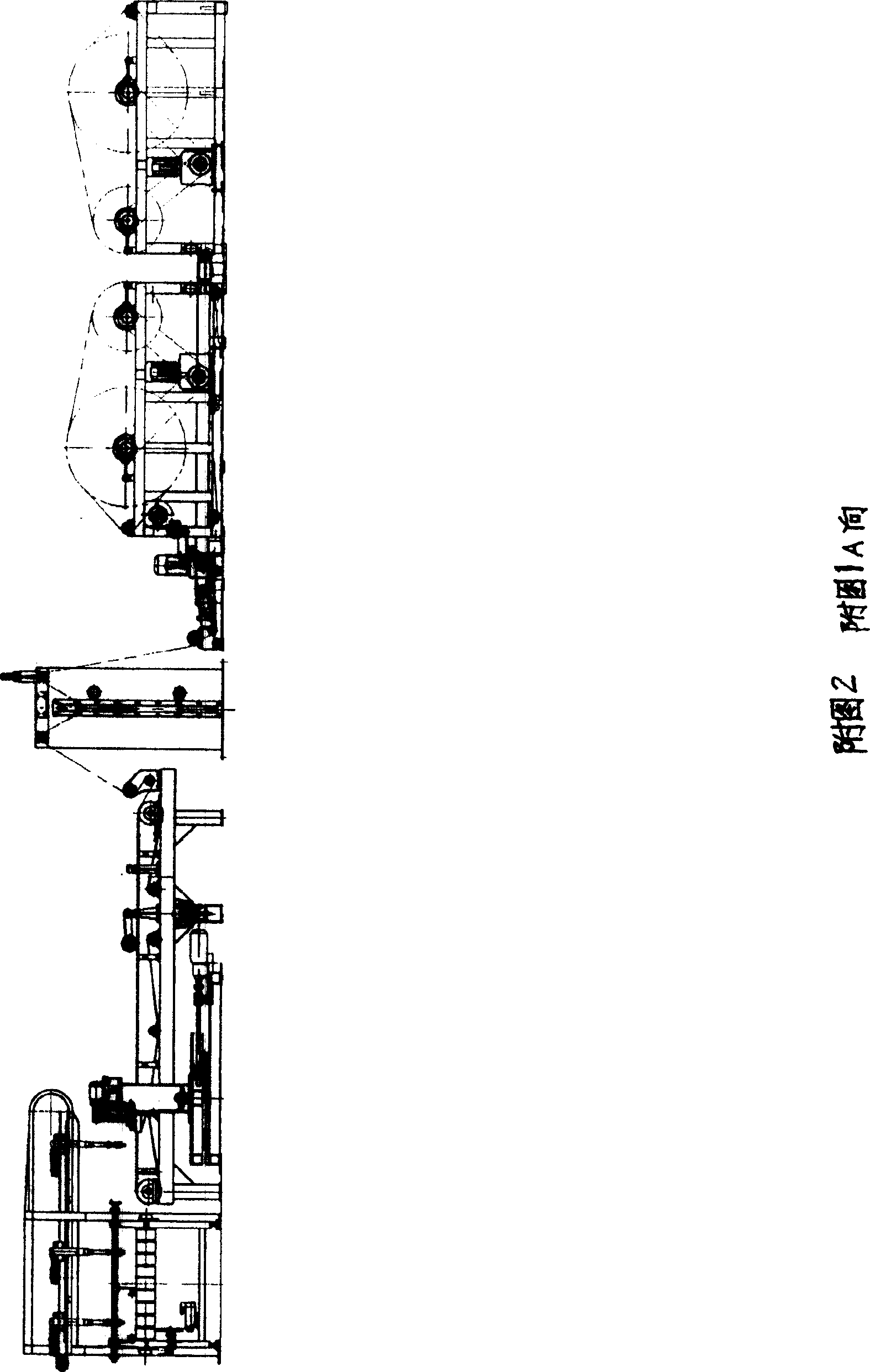

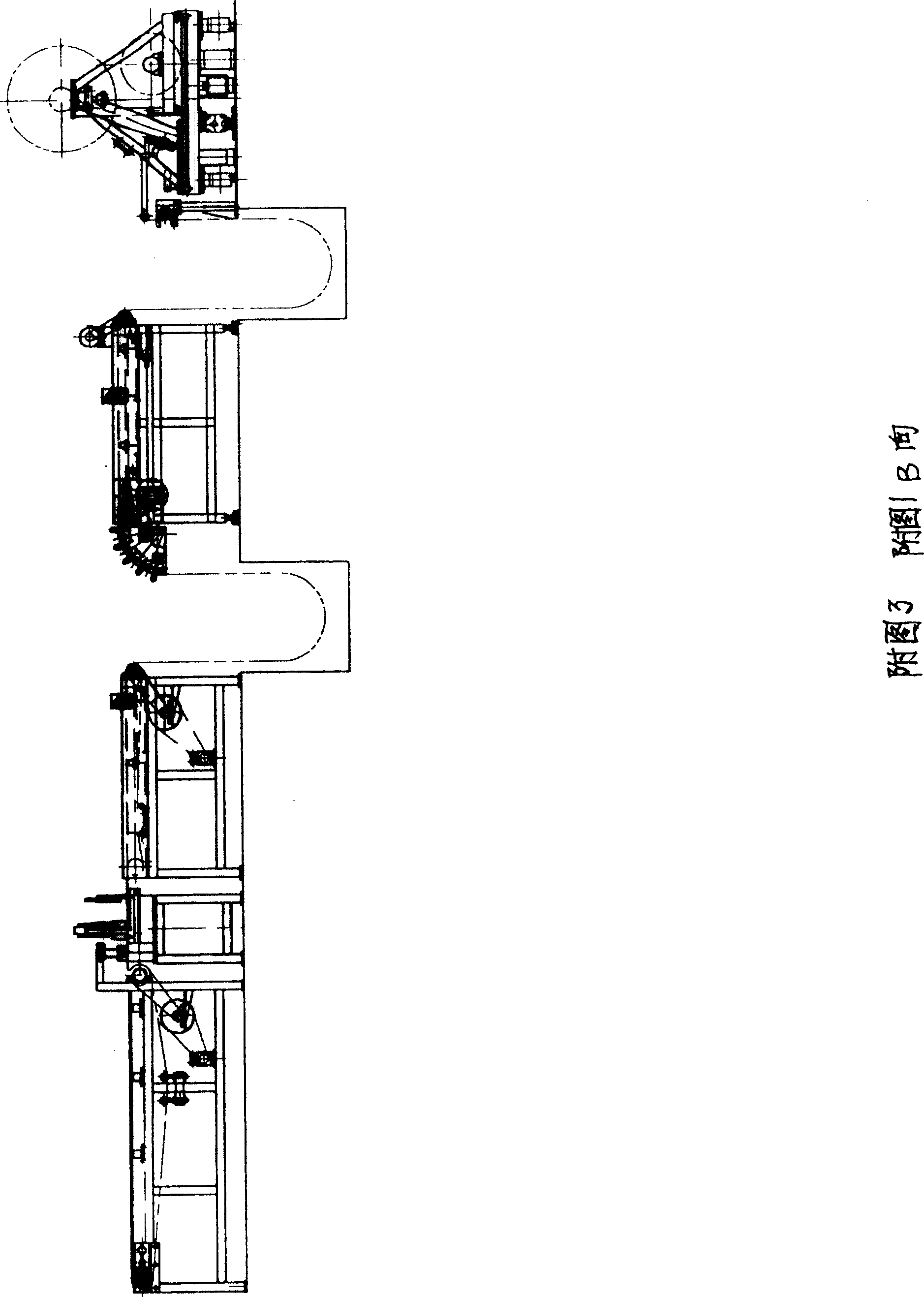

[0031]Embodiment: radial tire fiber cord automatic cutting and splicing machine (see accompanying drawings 1, 2, 3), is characterized in that it is made of double-station guide device 1, cloth storage device 2, conveyor belt A3, cutting device 4, automatic Fabric transfer device 5, conveyor belt B6, splicing device 7, conveyor belt C8, centering device 9 and double-station coiling device 10, wherein the above-mentioned double-station guiding device 1, cloth storage device 2, transportation The output planes of each device in the belt A3, conveyor belt B6, conveyor belt C8, centering device 9 and double-station coiling device 10 are sequentially connected to the input ends of the following devices; said cutting device 4, automatic distribution The device 5 and the splicing device 7 are not on the same plane as the above-mentioned devices. The cutting device 4 is installed above the middle section of the conveyor belt A3, the automatic fabric transfer device 5 is installed above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com