Liquid sealed connecting pipe

A closed technology for connecting pipes, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

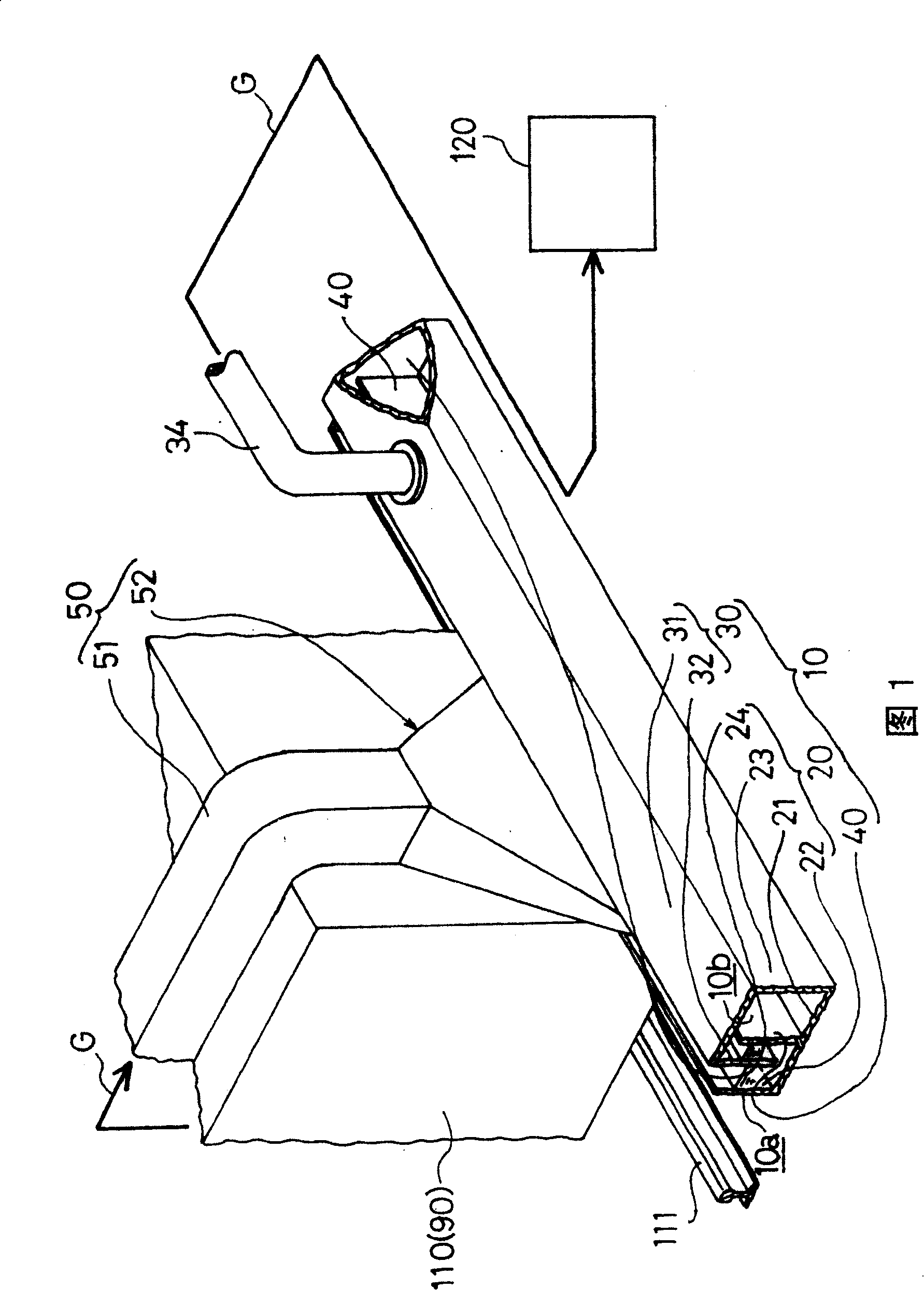

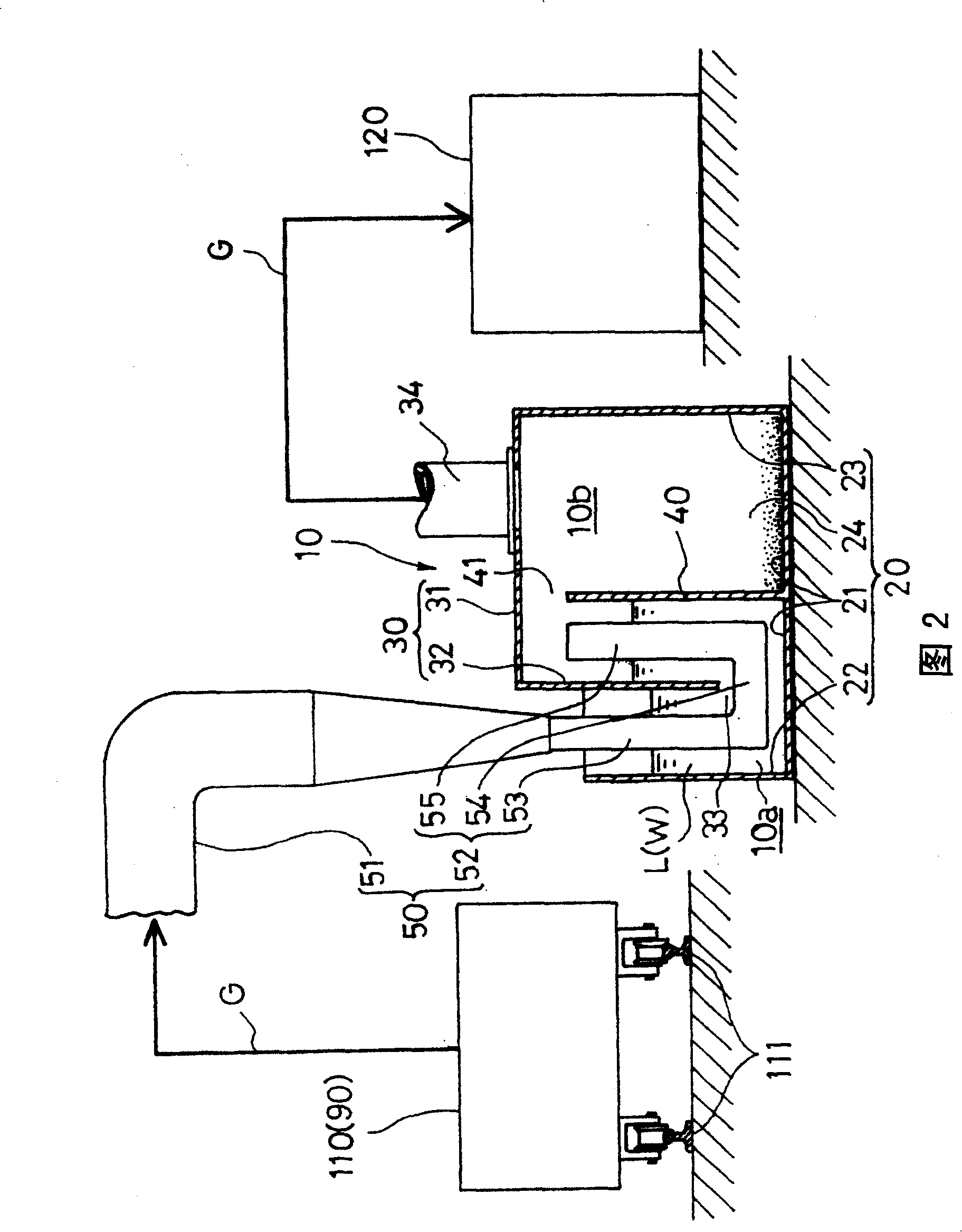

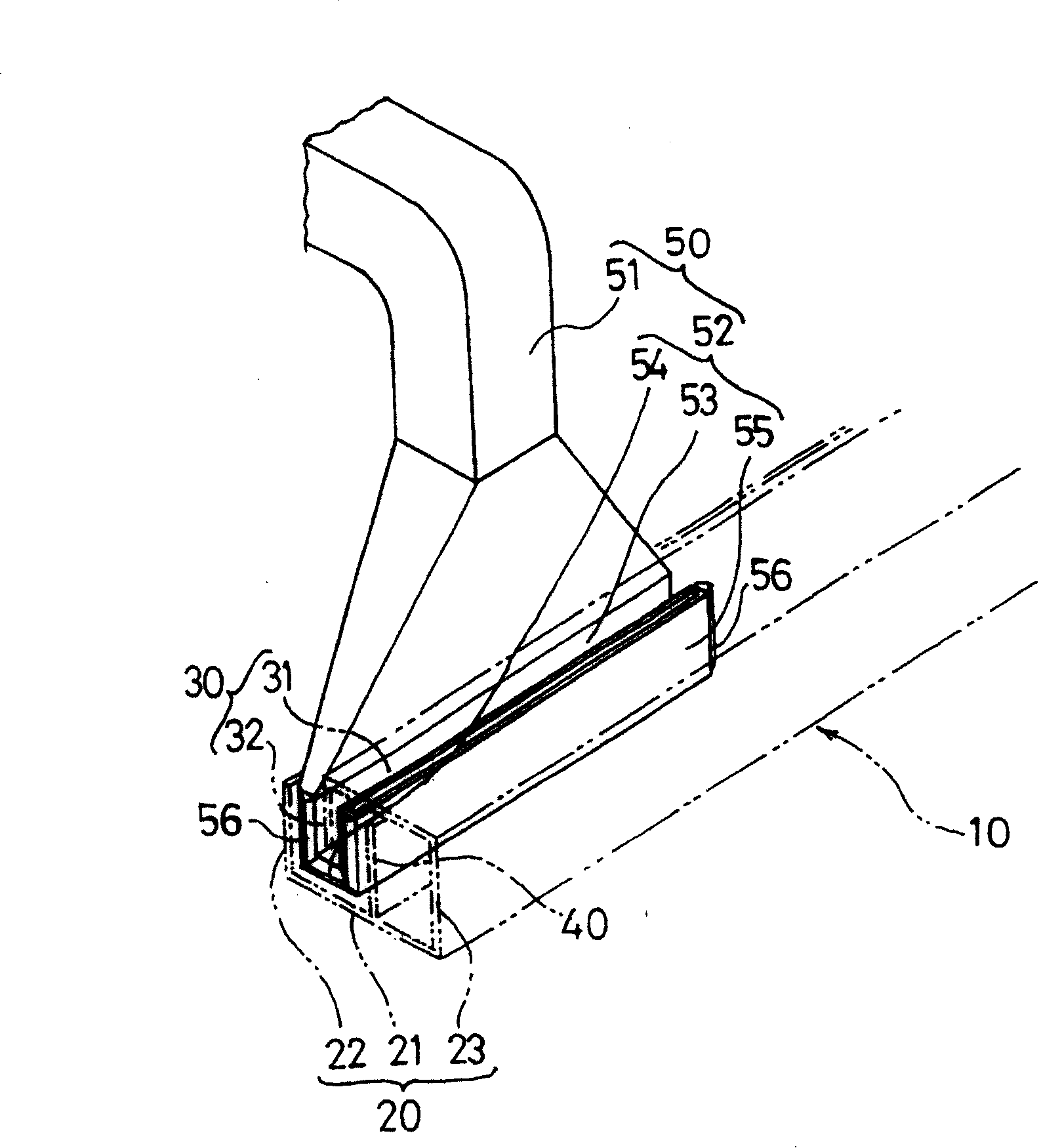

[0038] FIG. 1 is a partially cutaway perspective view showing Embodiment 1 of a liquid-enclosed connecting pipe 10 of the present invention, and FIG. 2 is a front sectional view thereof. As shown in these figures, the liquid-enclosed connection pipe 10 is to send the dust-containing gas G derived from the forward and reverse moving mobile machine 110 guided by the rail 111 into the dust-containing gas G installed on the ground. The processing facility for G, that is, the ground-side equipment 120 is installed between the mobile machine 110 and the ground-side equipment 120 , and can continuously feed the gas G containing dust even while the mobile machine 110 is moving.

[0039] The moving machine 110 has a generation source of the dust-containing gas G, and is provided with a delivery pipe 50 for leading the dust-containing gas G to the liquid-enclosed connection pipe 10 . The sending pipe 50 is composed of a sending pipe main body 51 and a U-shaped duct 52 formed on the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com