A filling method of concrete in the joint area of partially combined prefabricated beams

A filling method and concrete technology, which are applied in the direction of load-bearing elongated structural components, buildings, building components, etc., can solve the problems of complicated construction and slurry leakage, and achieve the effect of convenient construction and prevention of falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

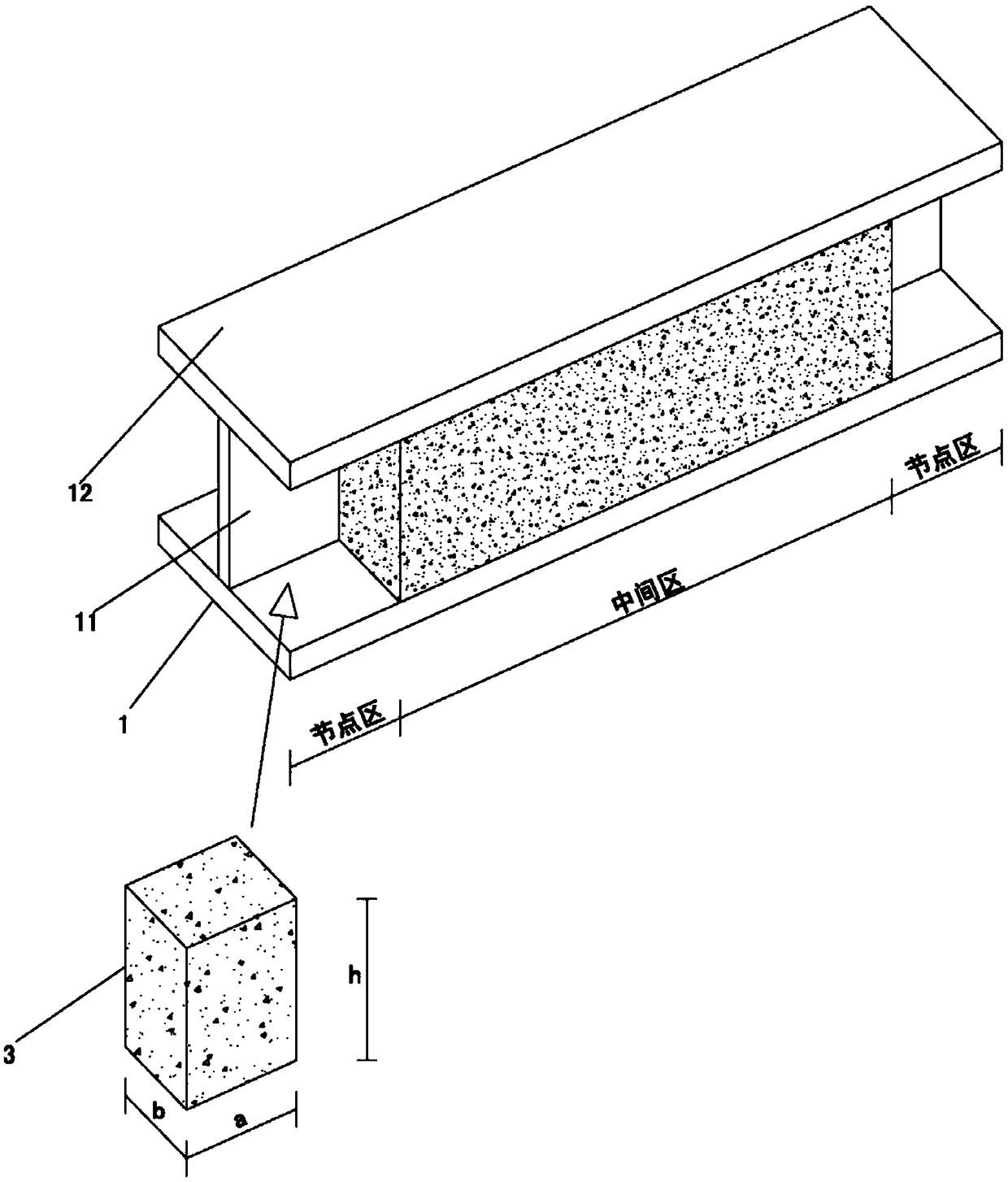

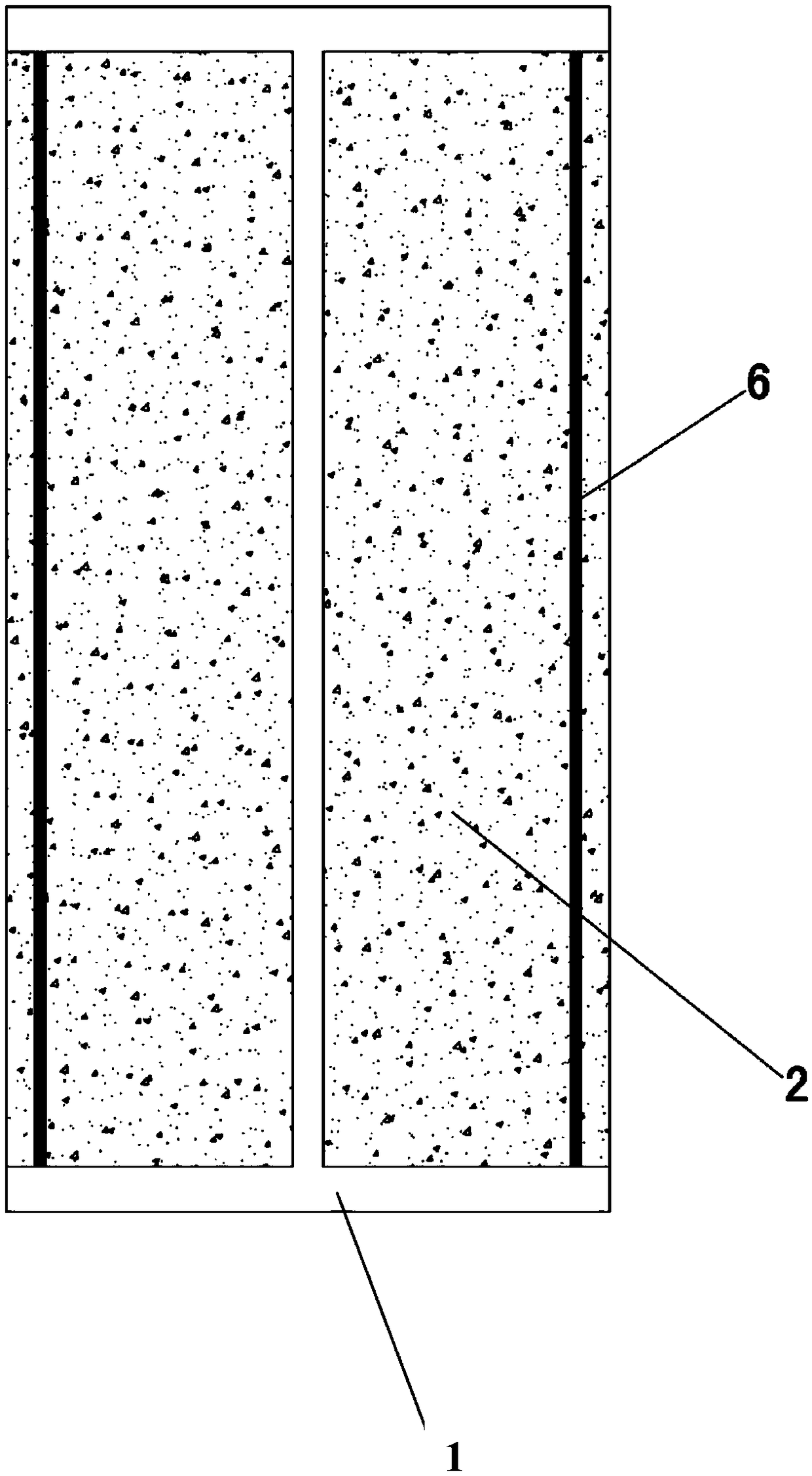

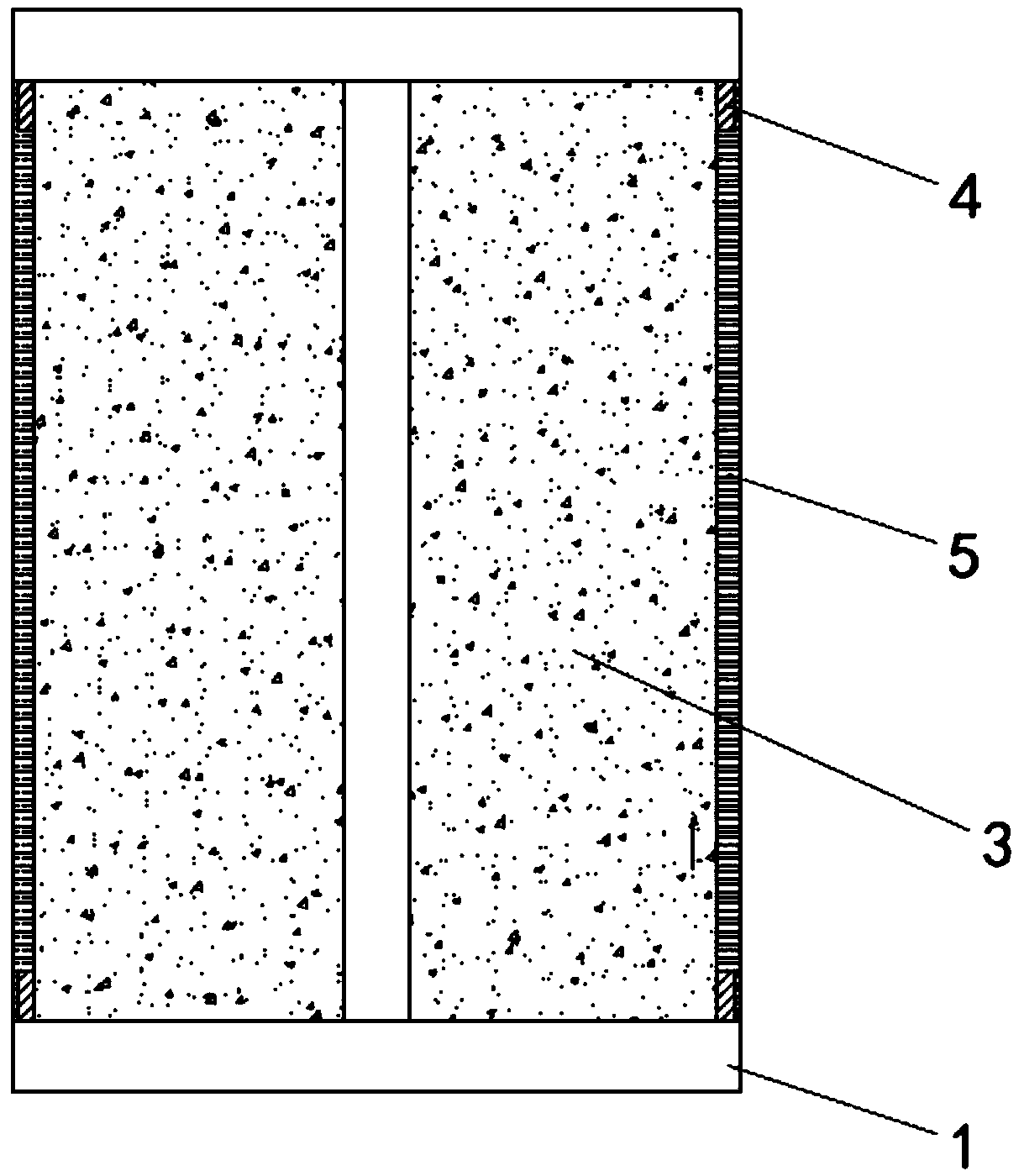

[0023] Please refer to the attached figure 1 to attach image 3 Shown, the present invention is a kind of filling method of concrete in the joint area of a partially combined prefabricated beam, which comprises the following process steps:

[0024] 1), prefabricated prefabricated beam 1, the prefabricated beam 1 is divided into a middle area and a joint area along its length direction, concrete 2 is poured in the middle area, the joint area is reserved, and no concrete is poured in advance. In this embodiment, the prefabricated beam 1 is specifically an H-shaped steel beam, which includes a web 11 and flanges 12 arranged on both sides of the web 11 ; the concrete 2 is located between the flanges 12 . The section of the beam in the middle area of the H-shaped steel beam 1 is provided with a tie rod 6 , that is, the tie rod 6 connects the upper and lower flanges 12 and is buried in the concrete 2 .

[0025] 2) Pre-preparing the concrete filling block 3 according to the siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com