Split-cycle engine with dwell piston motion

An engine, piston technology, applied in the field of split-cycle engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

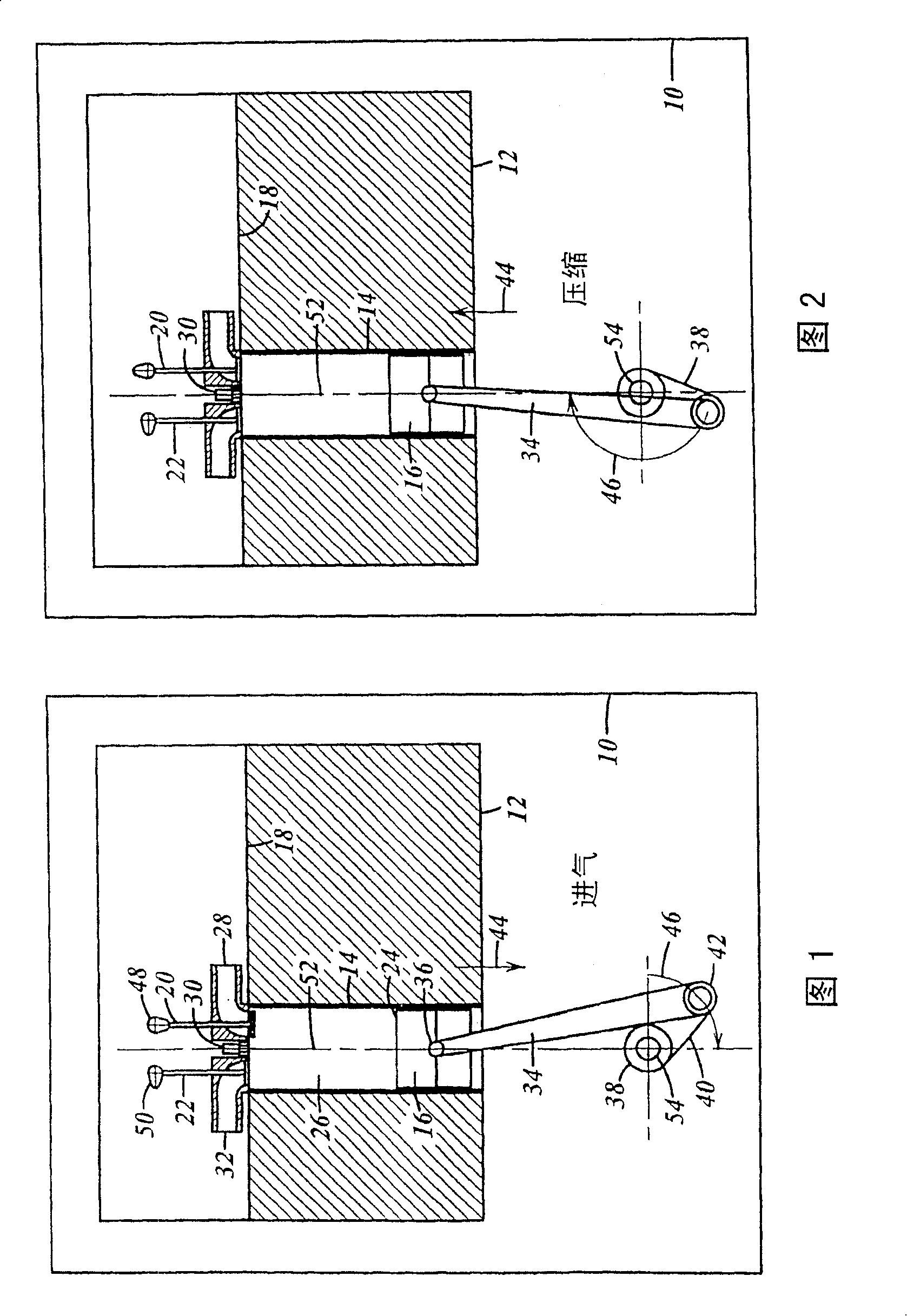

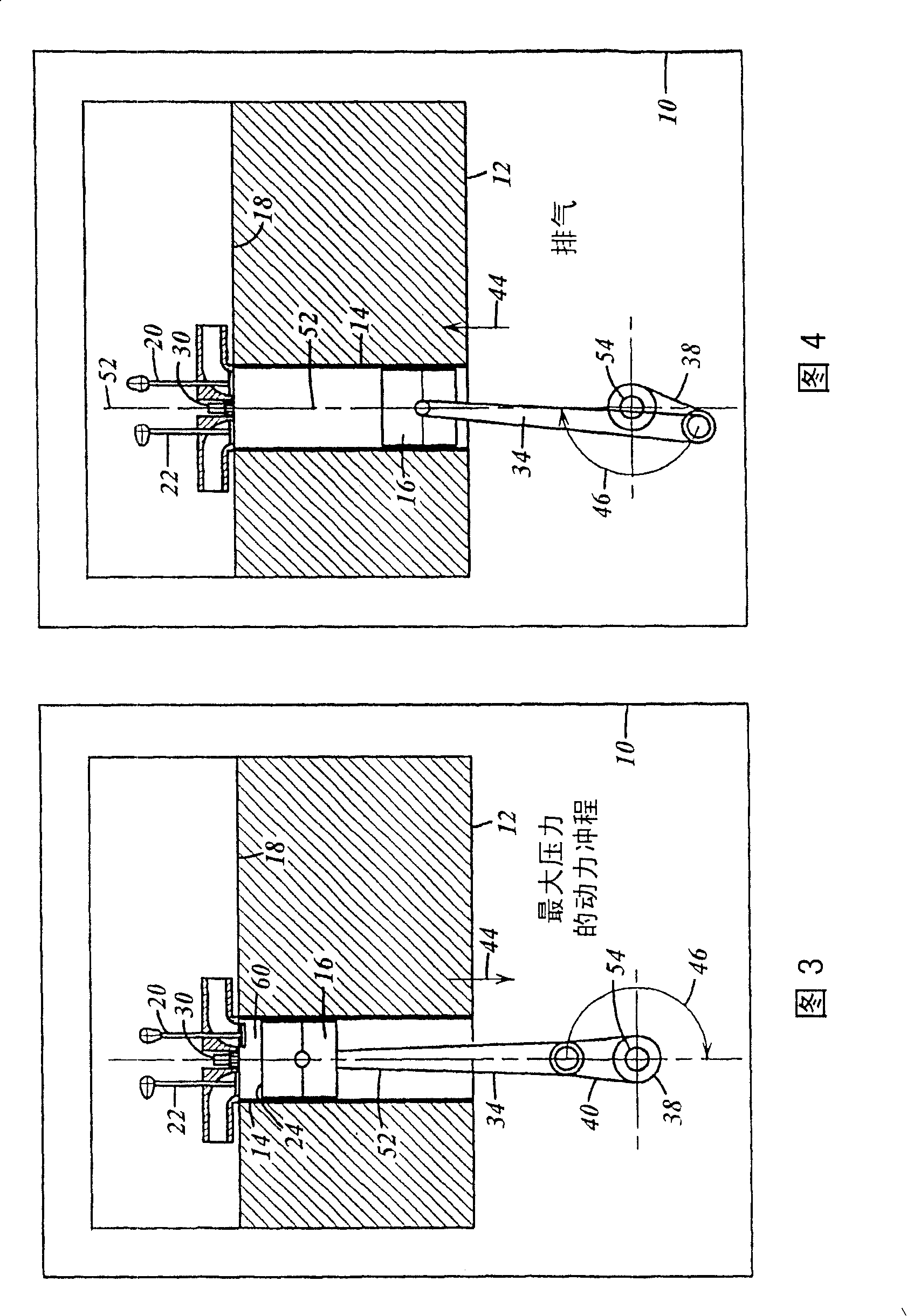

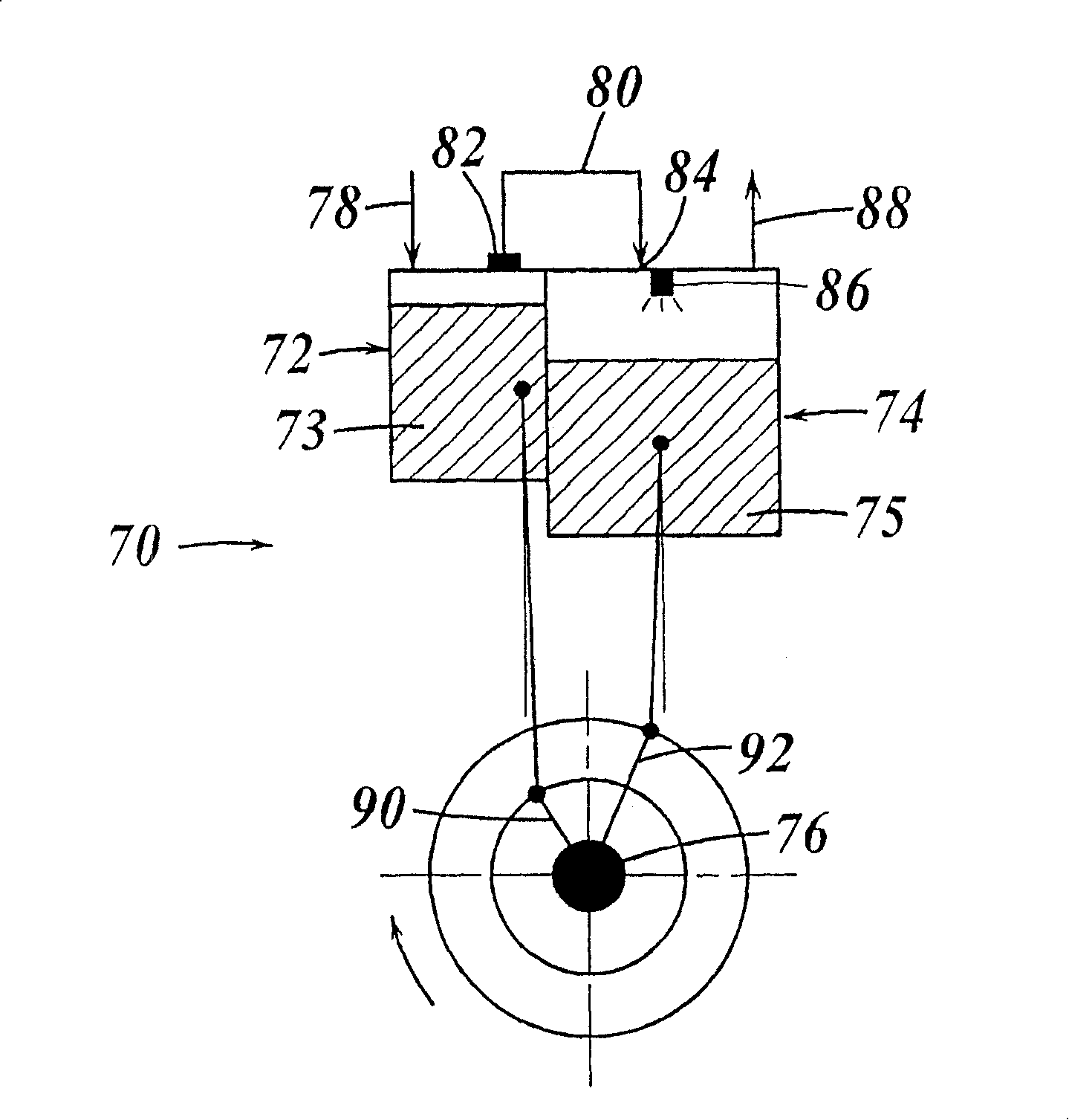

[0041] I. Overview

[0042] Scuderi Group Commissions Southwest Research Institute in San Antonio, Texas (SwRI ) to perform a paired computerized study. The first study involved constructing a computerized model representing various split-cycle engine embodiments compared to a computerized model of a conventional internal combustion engine with the same captured mass per cycle. The final report of the first study (SwRI presented on 24 June 2003 Project No. 03,05932, entitled "Evaluation of the Split-Cycle Four-Stroke Engine Concept"), is hereby incorporated by reference in its entirety. The first study led to US Patent Application No. 10 / 864748, filed June 9, 2004, by Branyon et al., entitled "Separated Cycle Four-Stroke Engine," the entire contents of which are incorporated herein by reference. The first study identified specific parameters (e.g., compression ratio, expansion ratio, diverter valve duration, phase angle, and overlap between diverter valve activity and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com