Expanding apparatus for hydraulic pressure cold drawing machine

A cold drawing machine and hydraulic technology, applied in the direction of the mandrel, etc., can solve the problems of inability to expand the diameter, difficulty in making large-diameter seamless precision pipes, etc., and achieve the effect of large diameter expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

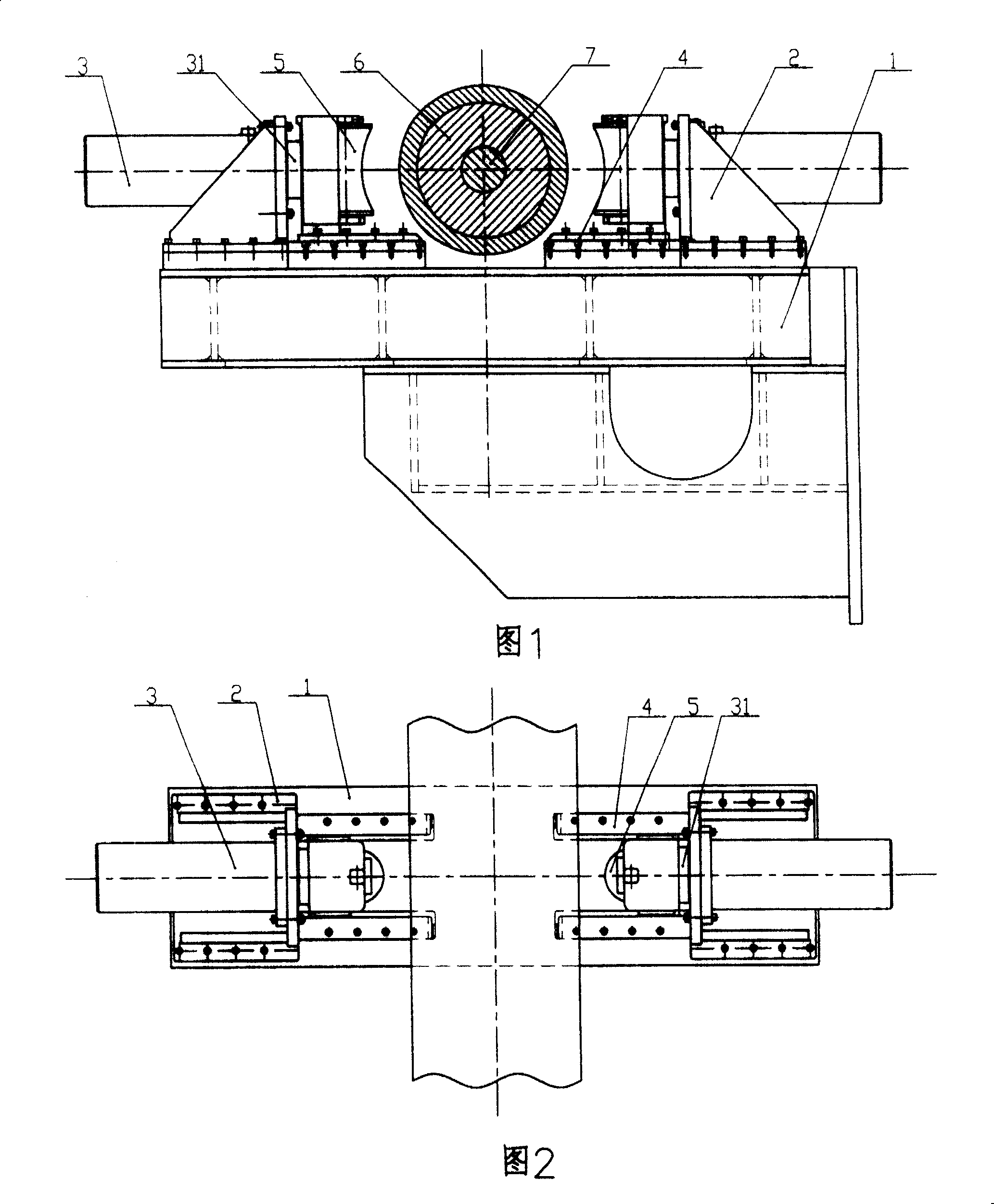

[0010] The expanding device of the hydraulic cold drawing machine of the present invention as shown in Fig. 1, Fig. 2 has a pipe holding mechanism, an inner mold 6 and a core rod 7, and the pipe holding mechanism is fixed on the bed of the cold drawing machine, and the pipe holding mechanism has One bracket 1, two bases 2, two tube holding cylinders 3, four slide plates 4 and two tube holding rollers 5, the base 2, tube holding cylinders 3, slide plates 4 and tube holding rollers 5 are respectively arranged on On both sides of the tube blank, the base 2 is respectively fixed on both ends of the bracket 1, the tube holding cylinder 3 is fixed on the base 2, the tube holding cylinder 3 has a push rod 31, the slide plate 4 is fixed on the front end of the push rod 31, and the tube holding roller 5 is concave drum shape, the diameter of the concave surface is consistent with the diameter of the expanded pipe, the tube holding roller 5 is connected to the slide 4 in rotation, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com