Expanding device for shape memory alloy pipe joint

A memory alloy and pipe joint technology, which is applied in the field of shape memory alloy pipe joint diameter expansion, can solve the problems of reduced service life, no overall deformation, and decreased stress corrosion resistance of pipe joints, and achieve radial expansion and uniformity. Avoid permanent residual deformation, and the effect of easy control of diameter expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

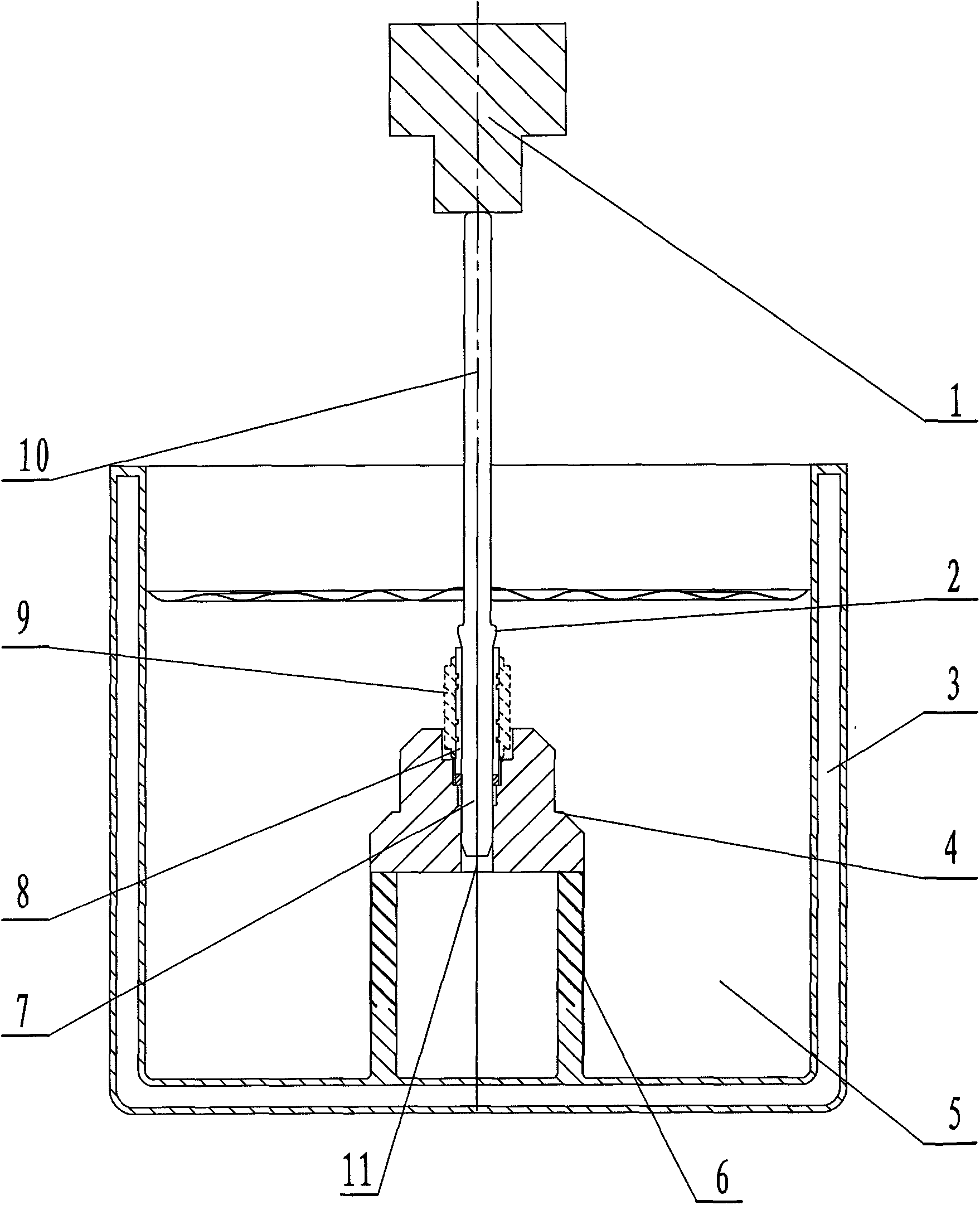

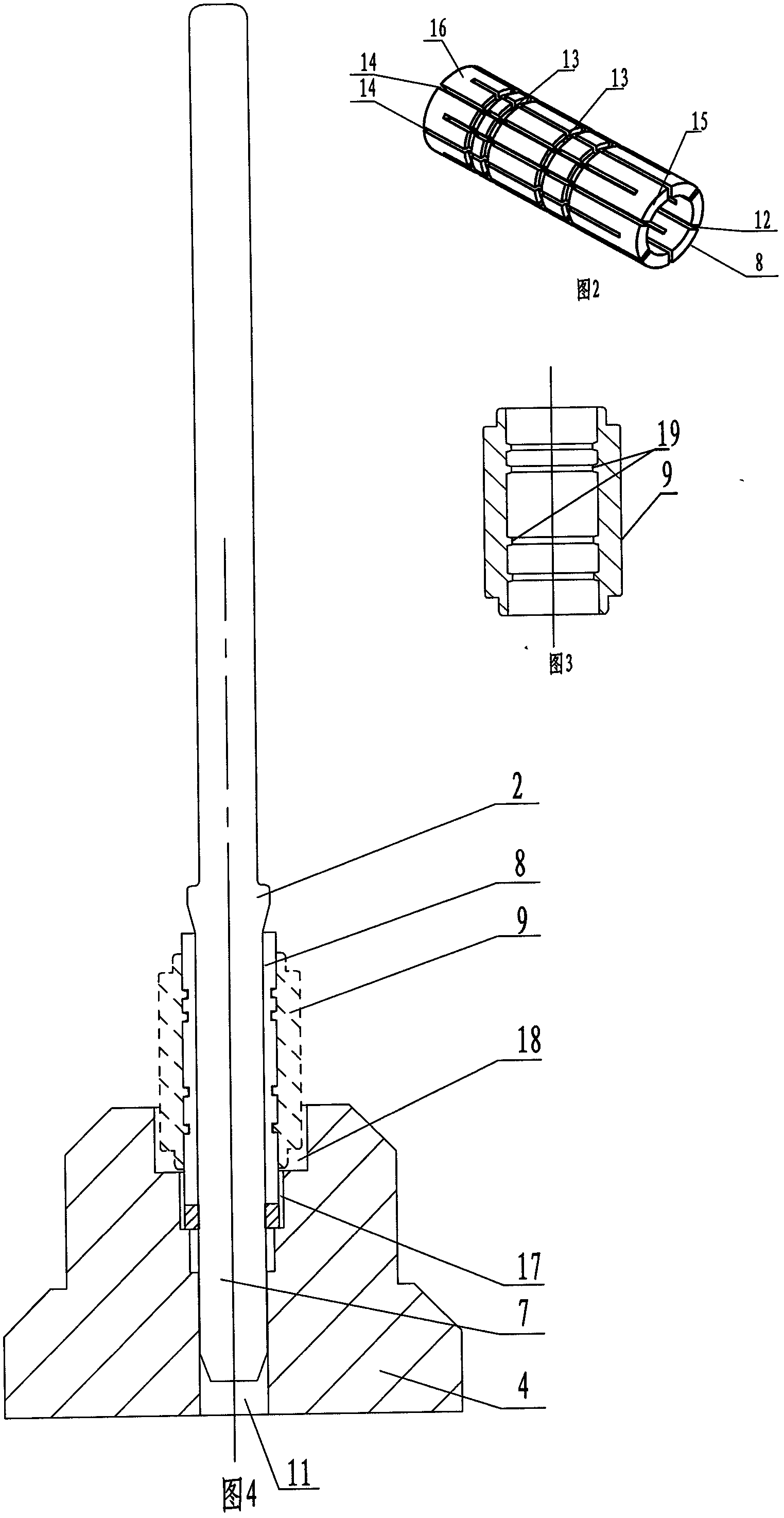

[0016] Such as figure 1 As shown, this embodiment includes an insulated bucket 3 equipped with liquid nitrogen 5, a guide base 4, a main reaming push rod 7 and a radial reaming sleeve 8, and the upper end of the reaming main push rod 7 passes through a transition connecting rod 10 Connect the output shaft 1 of the press, and the guide base 4 is fixed on the support seat (6) at the bottom of the heat preservation bucket 3, wherein:

[0017] Such as Figure 4 As shown, the guide base 4 is provided with a push rod guide hole 11, a second positioning hole 17 of the radial expansion sleeve 8 and a first positioning hole 18 of the shape memory alloy pipe joint 9, and the radial expansion Hole casing 8 is sleeved on the shaft body of said reaming main push rod 7, and the lower end of said reaming main push rod 7 is supported in said push rod guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com