Plate heat exchanger possessing exterior passageway and welded structure in new type sealing way

A plate heat exchanger, a new type of technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem that the reliable sealing effect of the corner hole sealing gasket cannot be effectively guaranteed, and the sealing gasket is aging or hardened. , It is difficult to solve the problems such as the real sealing state of the corner hole sealing gasket, so as to achieve the effect of improving the scope of use, reliability and anti-leakage level, lasting sealing effect and low sealing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

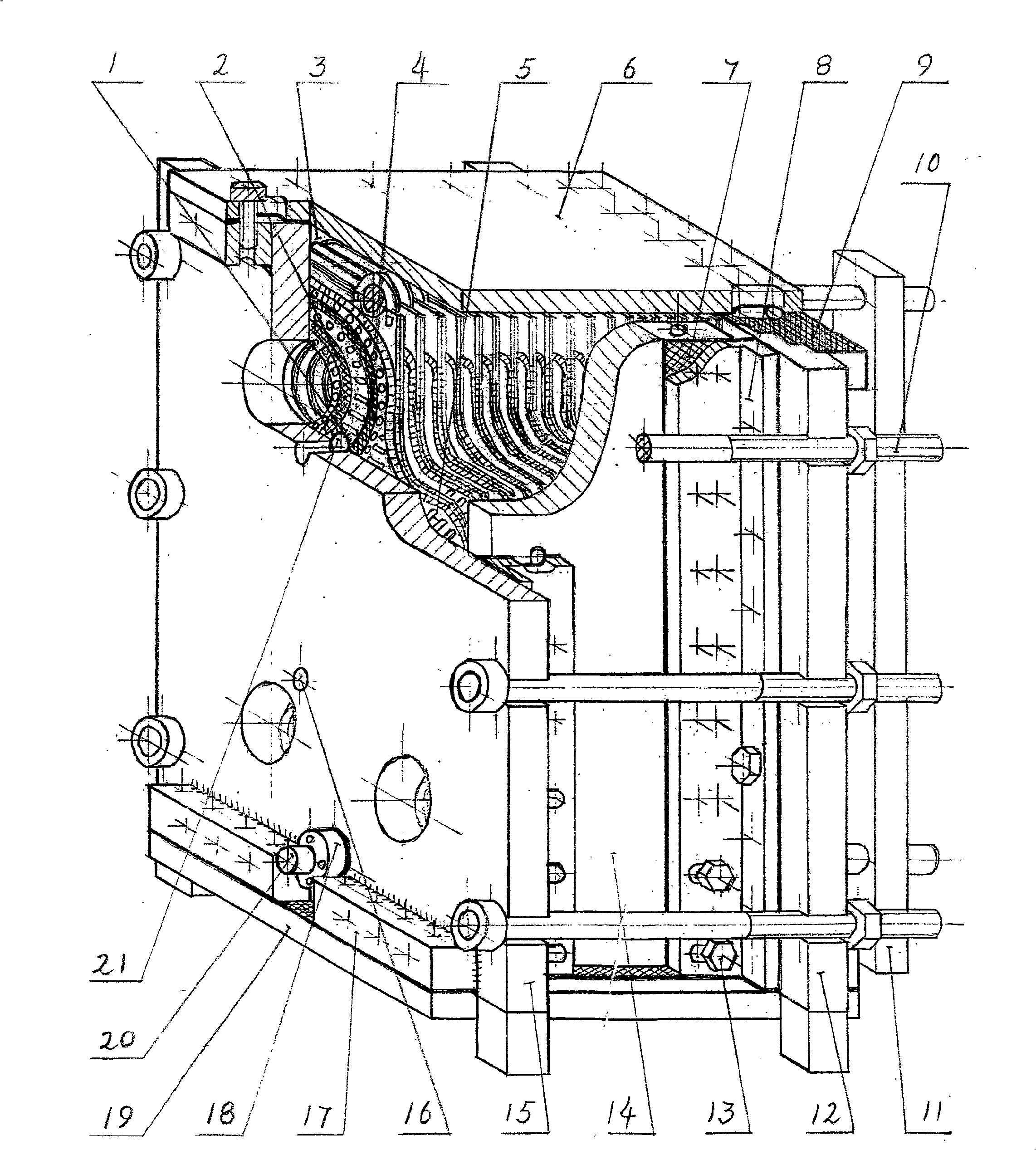

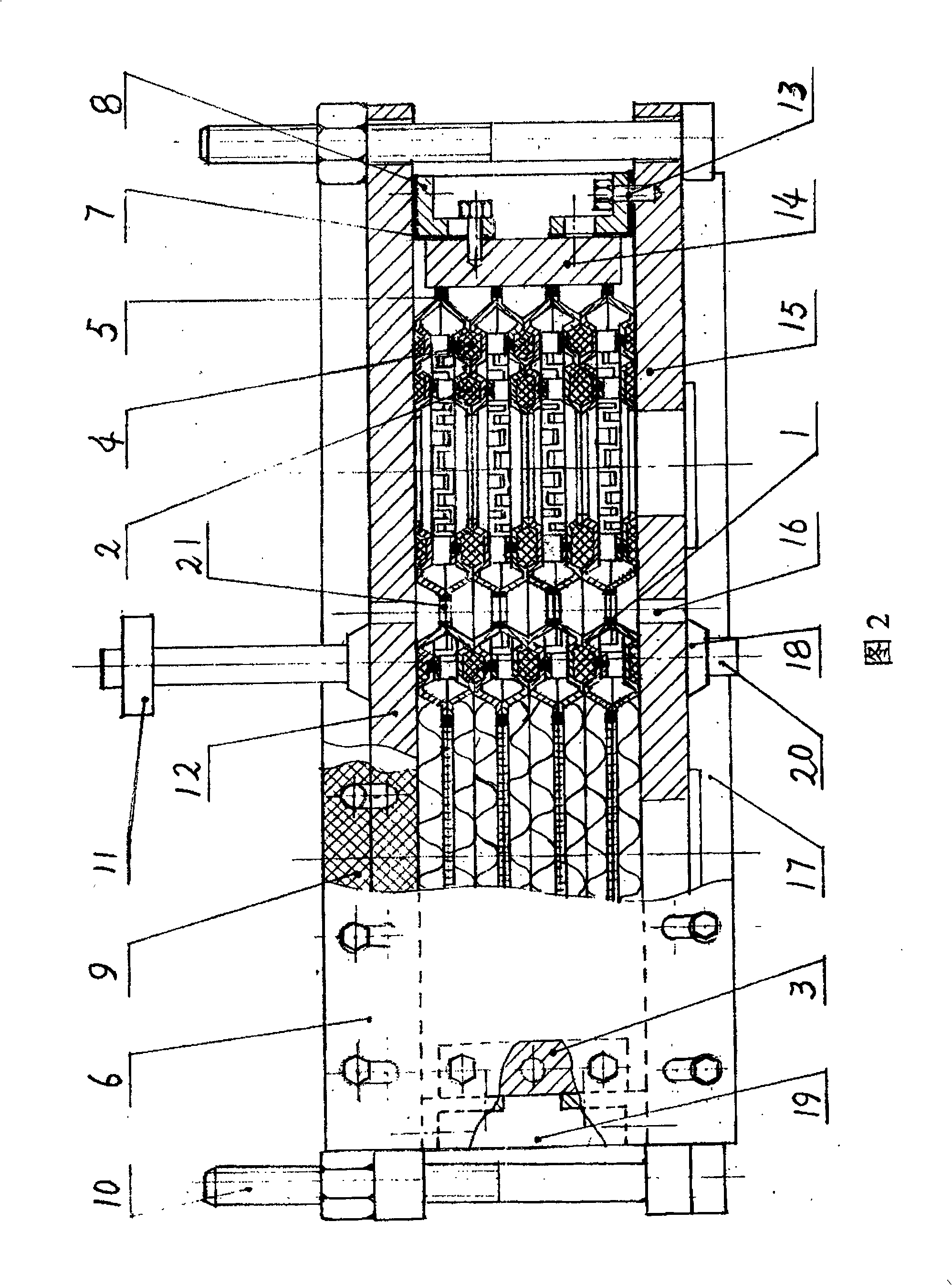

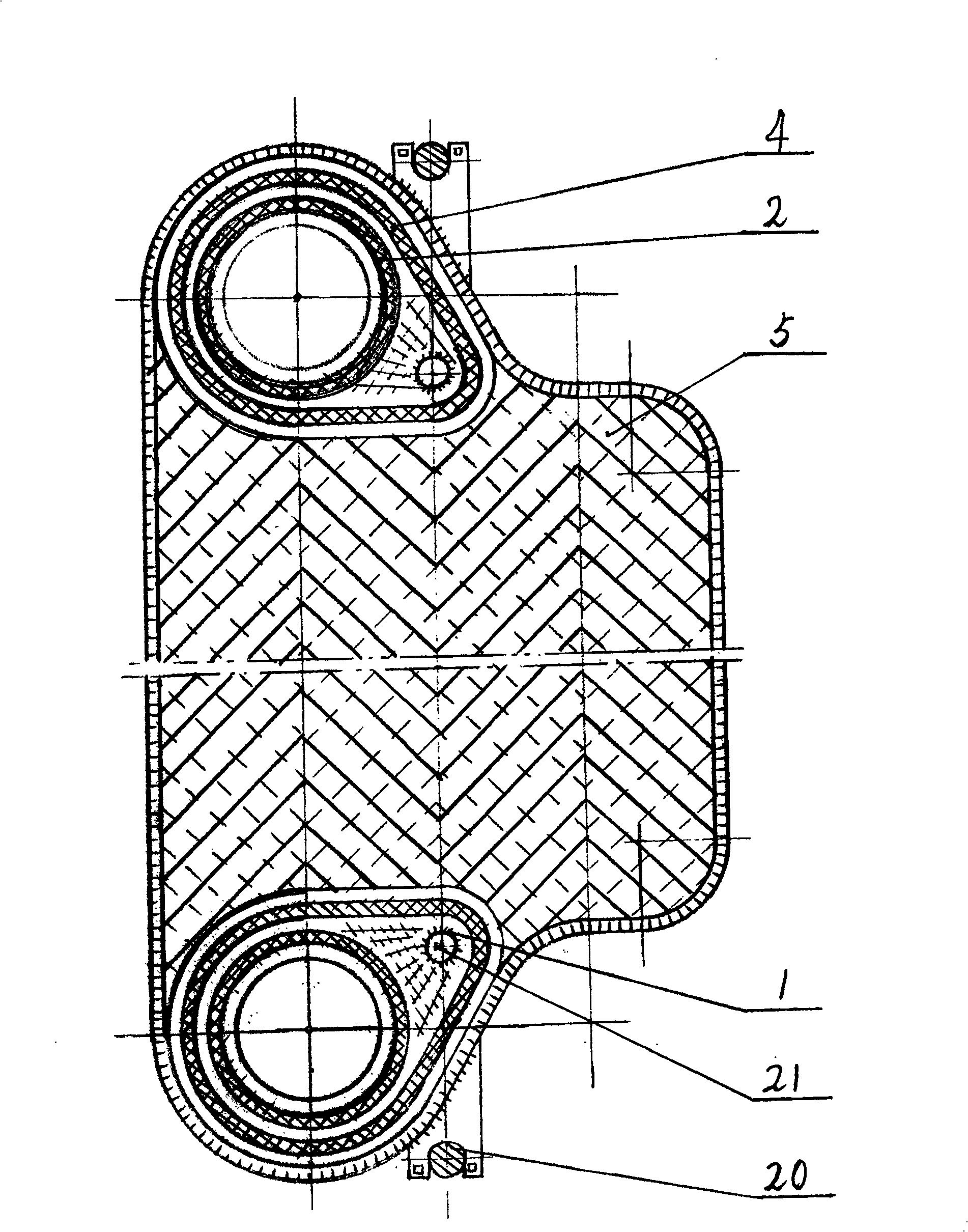

[0021] As shown in the figure: in the specific implementation process, two heat exchange fins with inner channel corner holes are completely welded together at the periphery to form a heat exchange fin box 5 welded and sealed around the periphery. There are grooves for placing the inner and outer sealing gaskets on the outer periphery of the corner holes of the inner passages that exist in groups on 5, and the inner sealing gaskets 2 and the outer sealing gaskets 4 are placed in these grooves. 1. There is an anti-leakage observation hole 21 in the middle of the outer sealing gasket 2 and 4. The heat exchange fins of each heat exchange fin box 5 are provided with holes for welding and sealing at the observation holes. The heat fins are completely welded together at the periphery, and at the same time, the observation holes on the two heat exchange fins are also welded together, so that a ring-shaped leak-proof observation hole sealing weld 1 is formed around the observation hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com