Quick clamp device of large nozzle of zinc pot

A technology of clamping device and large nozzle, which is applied in the field of quick clamping device of zinc pot large nozzle, can solve the problems of increasing the difficulty of bolt disassembly, difficult bolt disassembly, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

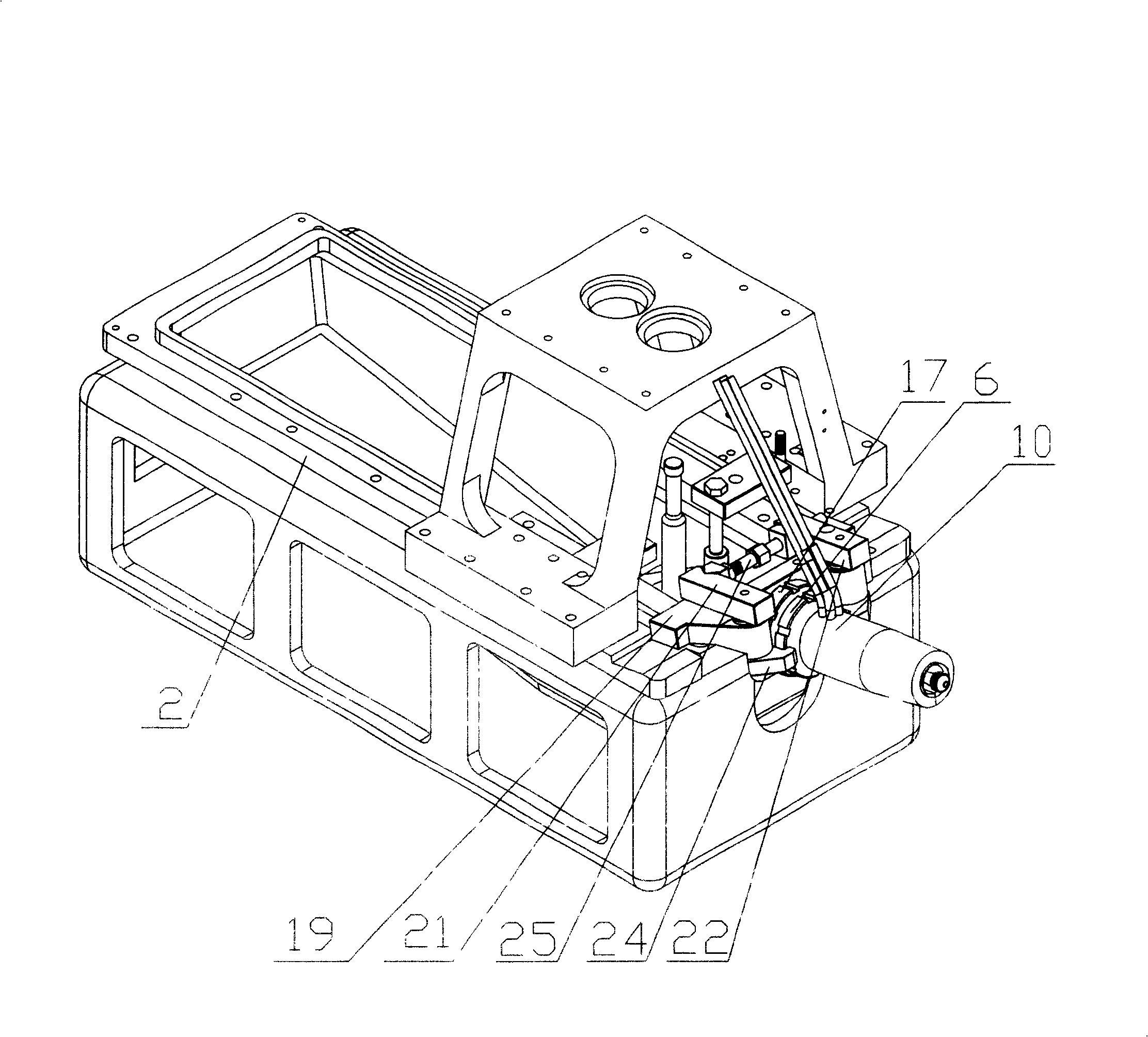

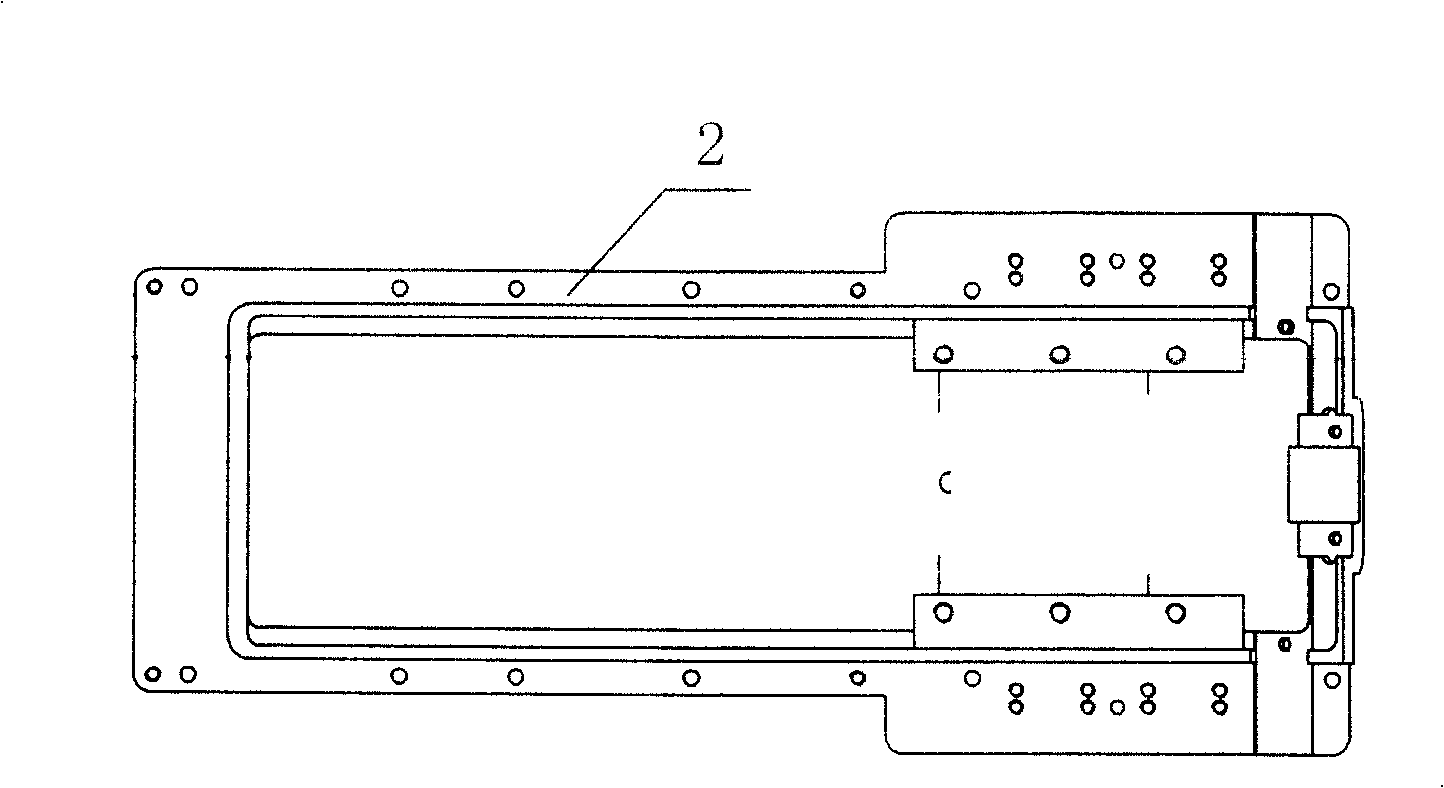

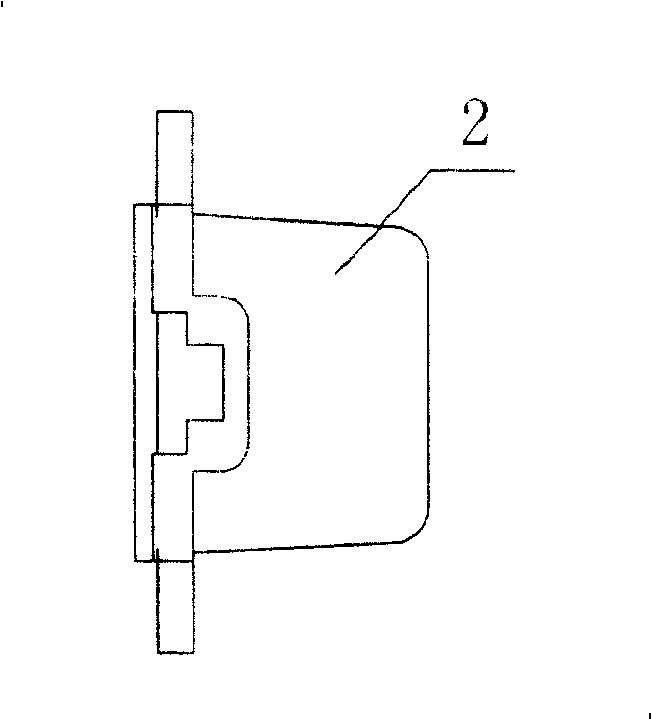

[0040] As shown in the drawings, the zinc pot large nozzle quick clamping device according to the present invention includes a pot body 2 and a large nozzle 10 installed at the front end of the pot body 2 . The front end of the pot body 2 is fixedly equipped with a large nozzle bushing 15 . Such as Figure 5 , Image 6 Shown, big nozzle sleeve pipe 15 is a tubular body, and its inner cavity is communicated with the zinc pot in the pot body 2, and the front end of big nozzle sleeve pipe 15 has external thread, and is connected with casing pressure plate 17 by thread. The front end opening of the large nozzle sleeve pipe 15 is a bell mouth with a small inside and a large outside, which can facilitate the insertion of the large nozzle 10 . The casing pressure plate 99 shown in Figure 7 and Figure 8 is fixedly installed on the front end of the pot body 2, pressed on the top of the large nozzle casing 15, and plays the role of fixing the large nozzle casing 15. The large nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com